#ConcretePrinting

Text

#3DPrinting#ConcretePrinting#ConstructionTech#Innovation#FutureOfConstruction#SustainableBuilding#DesignFreedom#EfficientConstruction#GreenBuilding#BuildingTechnology#ConstructionIndustry#BuildingInnovation#ArchitecturalDesign#SmartConstruction#BuildingMaterials#EnvironmentalImpact#3DPrintedHomes#InfrastructureDevelopment#TechAdvancements#BuildingSolutions

1 note

·

View note

Text

#dconcreteprinting#d#dprinting#druck#hous#dcp#dprinted#pikus#architecture#cobod#concreteprinting#concrete#mensekorte#peri#heidelbergcement#innovation#digitalfabrication#dconcrete#architecturedesign#additivemanufacturing#dprint#dprintedfurniture#striatus#creality#dprintedbridge#construction#design#blockresearchgroup#zahahadidarchitects#arquitetura

0 notes

Photo

💥 Please be advised 💥 For more info, call us during office hours. . . . . . #covid19 #coronavirus #concreteprinting #concreteprinters #mudbots #youthinkweprint #utahgram #utahbusiness (at Midvale, Utah) https://www.instagram.com/p/B-Jp0f6jHCM/?igshid=1lz7gu7pmwr9f

#covid19#coronavirus#concreteprinting#concreteprinters#mudbots#youthinkweprint#utahgram#utahbusiness

2 notes

·

View notes

Photo

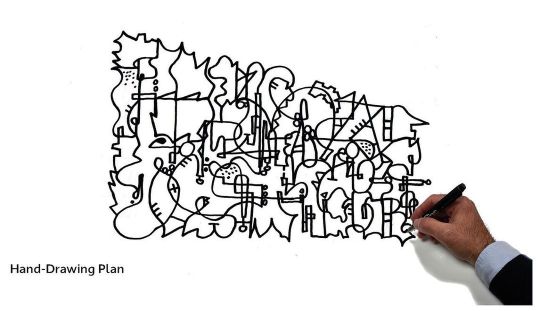

NATIONAL MUSEUM OF KOREAN LITERATURE The rational vs the irrational in architecture The comparison of a free-hand movement with controlled structural patterns highlights the contrast between 3D printed and traditional construction technology. Traditional concrete technology follows established methods, bound to the supply chain production rationalisation of manufacturing, which insisted upon technology based on the formwork dimension governed grid. 3D technology eliminates this notion of the grid-based rationalisation systems by using ‘singular’ material and its bottom-to-top layering method. No more factory-based rationalised supply chain systems. Post-rationalisation collides with a rationalisation of the meaningless combination of elements confined to a sequence forming a conglomerate of an organism, while the organism is a singular motion, technique, material and a free form. No more container stacked rectangles. Shape does not matter, if the rational resonates with the desired outcome. The expression of thoughts, unconstrained by technology leads to a liberation of thought itself. Just as ink made it possible to record and translate thought, not only in the form of words as symbols, but also in the generation of stories. A story can be anything, a narrative, a multi-layered, polyphonic, flowing whole—why should architecture be constrained by building blocks, unable to fully express itself, always relying on a heavy industrial supply chain? #architectsofinvention #nikolozjaparidze #architecture #design #architect #architecturelovers #museum #literature #archilovers #art #building #architects #handdrawing #3dprintedhouse #concreteprinter #parametricarchitecture #construction #rhino #sketch #grasshopper #seul #korea #concrete #hysis #nexon #archidaily #dezeen #designboom @designmuseum @tbilisidesigndays #archdaily #archello @divisare_ @archilovers @architizer @architecture_mag @archinectuk @designmorphine @designboom (at Seoul, Korea) https://www.instagram.com/p/CR1Iw4wMi0h/?utm_medium=tumblr

#architectsofinvention#nikolozjaparidze#architecture#design#architect#architecturelovers#museum#literature#archilovers#art#building#architects#handdrawing#3dprintedhouse#concreteprinter#parametricarchitecture#construction#rhino#sketch#grasshopper#seul#korea#concrete#hysis#nexon#archidaily#dezeen#designboom#archdaily#archello

2 notes

·

View notes

Text

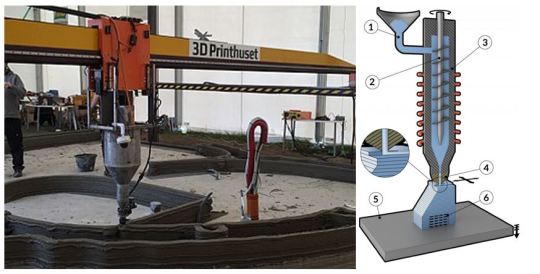

Components of a 3D concrete printer

In the image above a 3D concrete printer is shown and also a schematic view how the inside of a 3D printer looks like. In the following piece the different components are described, first of all there is a tube with the concrete mixtures, which has the purpose of supplying the printer with fresh material. The mixture has to be exactly right, otherwise the layers will not support each other or will not stick to each other (for more information on the mixture see my previous posts). Secondly there is a mixer inside the hopper which pushes the concrete to the nozzle, component number three is the hopper where a small amount of concrete is contained to ensure a consistent flow of concrete to the nozzle. The fourth component is the nozzle, which is set to a certain amount of concrete per minute. It is possible to adjust the nozzle when it is required to make smaller or larger layers. the fifth piece is the surface which the product is printed on. The sixth component is the product itself. In the first few hours the layers are not dry yet. After it has dried the structure get it’s intended strength.

0 notes

Photo

#repost • @3dprinted.architecture Austin-based construction technologies company @icon3dtech, is building an assemblage of 3D-printed homes for the homeless. The project design was undertaken by @loganarchitecture As part of Austin’s new Community First! Village, a 51-acre development that will provide affordable housing for those coming out of chronic homelessness, ICON has completed the welcome center for the site. It is 500 square feet in size and was 3D-printed over the course of several days, but only took 27 hours of labor to construct. In 2018, ICON constructed the first permitted 3D-printed home in the United States. Called the Chicon House, the 650-square-foot home was printed in under 24 hours, costing around $10,000. However, the firm believes future single-story homes, as large as 2,000 square feet, could be printed for thousands less. Funded by: @mobileloaves, @cielopropertygroup, @findyourden Interiors: @clairezinnecker Architecture: @loganarchitecture Finishings: @franklinalanatx Structural Engineering: @fortstructures Photos by: @reganmortonphotography #3dprinting #3dprints #3dprinters #3dprinted #3dprinter #3dprint #3dprintedarchitecture #roboticmanufacturing #architecture #architect #design #mimar #mimarlık #sustainability #additivemanufacture #organic #parametric #parametricarchitecture #construction #maker #civilengineering #parametricdesign #computation #house #housedesign #sustainability #village #concrete3dprinting #concreteprinting #austin https://www.instagram.com/p/CN7QeeflYe9/?igshid=tk8bnbsngah7

#repost#3dprinting#3dprints#3dprinters#3dprinted#3dprinter#3dprint#3dprintedarchitecture#roboticmanufacturing#architecture#architect#design#mimar#mimarlık#sustainability#additivemanufacture#organic#parametric#parametricarchitecture#construction#maker#civilengineering#parametricdesign#computation#house#housedesign#village#concrete3dprinting#concreteprinting#austin

0 notes

Text

Tweeted

Just Pinned to Robots, droids & drones.: ConcretePrinter https://t.co/IdHAkJVzS7 pic.twitter.com/PmYBrzNpmg

— Robots & Drones (@dronesrobots) November 28, 2018

0 notes

Text

Become a Regional Master Dealer

REGIONAL

MASTER DEALERS

Want to own your own company?

Want to earn over 100K a month?

Want more time with your family?

We thought so!

MudBots is looking for the best. If you have a background in construction, love new technology and especially love business in general, you’re in the right place.

MudBots has developed the first line of 3D Concrete Printers available to the world. Media everywhere is saying that the new technology will change the construction industry forever. Seldom do opportunities come alone with the huge market interest and untapped market. This is what business opportunist dreams of.

Quality of Life

Success is measured in many ways, but true success is measured by the peace a person feels when they know they are doing something they love, their efforts are rewarded with increased gain, and they have the time to enjoy both with the ones they love. There are countless ways to make a living, but if you don’t enjoy what you’re doing or you don’t have the time to enjoy anything else, it’s hard to be satisfied. MudBots Master Dealers enjoy all three. They earn a remarkable leaving, they have the freedom to work when they want and because of their success, they get to focus on the more important things in life – their Family.

JOB DESCRIPTION

The only way to manage a company that is growing as fast as MudBots is to have qualified individuals in every region of the country who can demonstrate products and serve their dealers. The Master Dealer program gives the company and its dealers the representation needed while offering a significant opportunity to those who embrace the call.

EXCLUSIVE REGION

As an RMD, you will be given an exclusive license to represent and profit off of ALL the MudBots sales in your state/region. It is generally a full state, but in larger markets, a state may be divided to provide for better reachability and service.

RESIDUAL INCOME

There are many ways to profit as an RMD but the “residual commission” is by far the most enticing. Sell it once and continue earning for years to come. As an RMD you will earn up to 30% on every printer sold. With printers ranging from 35k to 900k, it’s not hard to see how lucrative the venture can be. If RMDs sign up one new dealer every month who sells one printer a month within 12 months, depending on the profit sharing each RMD sets up with their dealers, earning after 12 months of work with 12 compliant dealers should be well over 100k a month. Why so much? Quite simply, we want to attract the best in the industry. An organization is only as good as its people. We want professionals, self-motivated individuals who are passionate about building their own business along ours.

Minimum Requirements

Training

Printers

Truck

Trailer

Demo Product

1 Dealer / Month

Attend a 3-day training in SLC

Purchase 2 demo printers

Must have a late model truck

Must have an enclosed branded trailer

Demo product to 2 dealers each week

Sign one dealer each month

ECONOMY

One of the best thing about concrete printers is the recession-proof nature of products. If the economy slows, the need for faster and more affordable construction methods increases. Those trying to complete with traditional construction methods will quickly discover they can’t even come close, resulting in even more demand for MudBots products. Prospects can get on board now or wait until they are losing contracts without one.

WORK OR FUN

The best thing about a career with MudBots is that it’s just plain fun. As more and more ways are discovered for utilizing 3D Concrete Printers, every day is an exciting adventure. It’s fun to make money doing what you love and this is definitely an exciting product that sells itself. Industry professional everywhere are in awe when they see products being printed without the need of straight lines and forms. This is a product that people will watch for hours in amazement. The longer they watch, the more they realize how valuable 3D Printing will be to their business.

GETTING STARTED

To get started, call and request an NDA and RMD application. Once accepted, you may attend the next RMD training where you will spend three full days of training and Q&A. You will learn about the industry, the opportunity, printer operation, specific mixes, lab testing, structure engineering, potential markets & marketing strategies. By the time you return home, you will be confident in your ability to promote and service the dealers in your area.

Become a Regional Master Dealer

with MudBots now.

GET A FRANCHISE

#Mubots#3dconcreteprinting#Concreteprinting#Concreteprinter#Concreteprinters#3dconcreteprinter#3dconcreteprinters#Concreteprinterforsale#Houseprinter#3dhouseprinter

0 notes

Photo

NATIONAL MUSEUM OF KOREAN LITERATURE The story is printed by us Just as ink revolutionised the written word, the printing press revolutionised book publication– 3D printing revolutionises architecture, how we build, with a view to innovation and sustainability. Cheaper, quicker, easier— sustainable. The importance of literary culture is promoted by bringing future technology and innovation – narrative and form combine, printed in an architectural gesture. Hand drawing manifestation In re-establishing the primacy of hand-drawing and its original possibilities in the making of buildings, the 3D printing approach is more sensual than it first seems. A return to the rudimentary skills of a drawing using the printing tool makes art of buildings. The manifestation of a hand-drawing, printed to form a building opens amazing possibilities in the expression of cultural and expansive gestures within the built environment. #architectsofinvention #nikolozjaparidze #architecture #design #architect #architecturelovers #museum #literature #archilovers #art #building #architects #render #architecturedesign #3dprintedhouse #concreteprinter #parametricarchitecture #construction #rhino #grasshopper #seul #korea #concrete #hysis #nexon #archidaily #dezeen #designboom @designmuseum @tbilisidesigndays #archdaily #archello @divisare_ @archilovers @architizer @architecture_mag @archinectuk @designmorphine @designboom (at Seoul, Korea) https://www.instagram.com/p/CQ2zNr7MS7N/?utm_medium=tumblr

#architectsofinvention#nikolozjaparidze#architecture#design#architect#architecturelovers#museum#literature#archilovers#art#building#architects#render#architecturedesign#3dprintedhouse#concreteprinter#parametricarchitecture#construction#rhino#grasshopper#seul#korea#concrete#hysis#nexon#archidaily#dezeen#designboom#archdaily#archello

2 notes

·

View notes

Photo

National Museum of Korean Literature The Architecture of the building is a collection of randomised shapes formed by vertical walls which meander through the building creating the building mass. The two lower floors are organised as back-of-house with regular flat slabs and columns, where the first floor is an arched space cut through the walls creating a large open space to encapsulate the main museum and community facilities. Transparent and translucent glass partitions segregate functional spaces where necessary. NMKL thus realises a space that symbolizes multi-dimensional enjoyment of Korean Literature. In order to achieve this kind of architecture, 3D Concrete Printing Technology is feasible to be utilised. In comparison with traditional concrete formwork building, 3D printed technology makes very complex shapes and structures possible with a significant reduction of cost, time and materials. This gives a unique quality as the singular materiality of concrete is maintained throughout the exterior and interior of the building. Ecologically sustainable mixing aggregates, such as clay, basalt, fibreglass, offer different colours and textures creating a most exciting architecture. #architectsofinvention #nikolozjaparidze #architecture #design #architect #architecturelovers #museum #literature #archilovers #art #building #architects #render #architecturedesign #3dprintedhouse #concreteprinter #parametricarchitecture #construction #designer #seul #korea #concrete #hysis #nexon #archidaily @dezeen @designboom @abitare_magazine @designmuseum @tbilisidesigndays @archdaily @archello @divisare_ @archilovers @architizer @architecture_mag @archinectuk @designmorphine @designwithinreach @designbunker (at Seoul, Korea) https://www.instagram.com/p/CQ04EzmMoRp/?utm_medium=tumblr

#architectsofinvention#nikolozjaparidze#architecture#design#architect#architecturelovers#museum#literature#archilovers#art#building#architects#render#architecturedesign#3dprintedhouse#concreteprinter#parametricarchitecture#construction#designer#seul#korea#concrete#hysis#nexon#archidaily

1 note

·

View note

Photo

NATIONAL MUSEUM OF KOREAN LITERATURE The rational vs the irrational in architecture The comparison of a free-hand movement with controlled structural patterns highlights the contrast between 3D printed and traditional construction technology. Traditional concrete technology follows established methods, bound to the supply chain production rationalisation of manufacturing, which insisted upon technology based on the formwork dimension governed grid. 3D technology eliminates this notion of the grid-based rationalisation systems by using ‘singular’ material and its bottom-to-top layering method. No more factory-based rationalised supply chain systems. Post-rationalisation collides with a rationalisation of the meaningless combination of elements confined to a sequence forming a conglomerate of an organism, while the organism is a singular motion, technique, material and a free form. No more container stacked rectangles. Shape does not matter, if the rational resonates with the desired outcome. The expression of thoughts, unconstrained by technology leads to a liberation of thought itself. Just as ink made it possible to record and translate thought, not only in the form of words as symbols, but also in the generation of stories. A story can be anything, a narrative, a multi-layered, polyphonic, flowing whole—why should architecture be constrained by building blocks, unable to fully express itself, always relying on a heavy industrial supply chain? #architectsofinvention #nikolozjaparidze #architecture #design #architect #interior #architecturelovers #museum #archilovers #art #building #architects #render #architecturedesign #3dprintedhouse #concreteprinter #parametricarchitecture #construction #rhino #grasshopper #seul #korea #concrete #hysis #nexon #archidaily #dezeen #designboom @designmuseum @tbilisidesigndays #archdaily #archello @divisare_ @archilovers @architizer @3dprintedarchitecture @archinectuk @designmorphine @designboom (at Seoul, Korea) https://www.instagram.com/p/CQ6TXamsZZP/?utm_medium=tumblr

#architectsofinvention#nikolozjaparidze#architecture#design#architect#interior#architecturelovers#museum#archilovers#art#building#architects#render#architecturedesign#3dprintedhouse#concreteprinter#parametricarchitecture#construction#rhino#grasshopper#seul#korea#concrete#hysis#nexon#archidaily#dezeen#designboom#archdaily#archello

0 notes

Video

Let's all do our part in preventing the spread of #coronavirus 👉🏻 DO THE FIVE! . . . The World Health of Organization (WHO) is advising people to follow these 5 simple steps to help prevent the further spread of COVID-19. . . . During these scary times, it is imperative to exercise DISCIPLINE. Keep safe everyone! ▶️ #mudbots #concreteprinting #3dconcreteprinting #concreteprinters #youthinkweprint #safehands #dothefive #covid19 #utahgram #utahbusiness (at MudBots 3D Concrete Printing - #1 Concrete Printer in the World) https://www.instagram.com/p/B-DvLD6jLgX/?igshid=1j01qv4ad92ii

#coronavirus#mudbots#concreteprinting#3dconcreteprinting#concreteprinters#youthinkweprint#safehands#dothefive#covid19#utahgram#utahbusiness#1

0 notes

Text

Is Concrete Printing A New Industry?

CONCRETE PRINTER OVERVIEW

Our company gets calls every week from people and companies

that are interested in knowing more about the new industry of

3D Concrete Printing. People are intrigued by the possibilities,

but the industry is so new. They have lots of questions and

the more questions that are answered, the newer ones they discover.

The truth is that concrete printing is going to revolutionize

construction in a way that we haven’t seen since the invention of the tractor.

Our parent company is a robotics manufacturer so we understand as well

as most the changes before us. Automation is coming and those

who embrace it will discover distinct advantages over their competition.

These are the pioneers that are on the forefront of technology

and their companies will lead the day moving forward.

The opportunities are endless

From printing fountains and statues to decorative fencing, monuments, and of course, homes and warehouses. This is a new industry, but it will evolve very quickly in numerous directions.

We recommend that before giving us a call, you take a moment and read some of the history and information below that you should find helpful.

Concrete 3D Printing - Is it a new industry?

As the world is slowly learning about a 3D Printed Castle, and similar videos are beginning to go viral, entrepreneurs all over the world are both fascinated and enamored with thoughts of potential possibilities. There is no doubt that this technology will change construction forever, but as thousands of curious prospects begin to come in, it’s becoming obvious that the cost to educate the public is going to be extensive. Everyone has so many questions, but no one is really talking.

At first glance, the idea of printing concrete seems easy. After all, everyone has seen a 3D printer or CNC router tables, so where is the real mystery? As hundreds are anxious to simulate what they’ve seen on YouTube, they do so with a very naive approach.

INTEGRATION OF CONCRETE 3D PRINTING TECHNOLOGY

The idea of moving concrete with a computer controller isn’t hard at all. Anyone with a CNC router table can rig up a funnel and some sprinkler pipe to simulate most of the videos we’re beginning to see. And 90% quickly discover that the real mystery is in controlling and finishing the mud. Most of the people we speak to are fascinated by the idea, but nearly everyone hates the layer by layer look of the finished product. Even still, the idea of plastering the finished product is a viable solution, but the preference would be the ability to finish as you go and eliminate even more expense in an unnecessary step.

So while many CNC companies are just getting around to pouring their first bucket of mud through a funnel connected to a CNC table, and discovering the challenges of working with a material that changes every minute, the real players are already working to engineer a way to provide a finish that doesn’t require a crew of plasterers to come behind and make the finished product look good.

The Real Challenge with this New Solution

So even if you have a thousand hours to waste on figuring out the formula for mixing the right mud that will support itself without turning into a flat mess or falling over when trying to cantilever the third and fourth pass, the next step requires a team of engineers to design a troweling feature that can follow the printed path and rotate with every turn. This is where others generally lose interest because it requires a competent group of software and mechanical engineers that understand the dynamics of 5-axis robotics as well as the structural characteristics of building with mortar.

The Germans lead the pack right now, but they aren’t interested in selling what they have built. Their business model is to provide service rather than sell their printing machine. Several Chinese companies are trying to cash in, but to date, they haven’t shown anything more than pushing some mortar out of a 2-axis CNC table. All they have accomplished is linear printing rather than 3D printing as evidenced by their videos. The group that started most of this with the 3D printed castle is ahead of most, but still have no solution for the undesirable finish that everyone’s concerned about.

Those that are a year or two into this know enough to recognize the challenge of managing a mechanical device that can rotate every corner and move in a manner that does not knock down the work that’s been done in an attempt to trowel as-you-go. It is the real task.

So now that we’ve shared a view of where this industry is at, let’s take a look at who we are.

#Mubots#3dconcreteprinting#Concreteprinting#Concreteprinter#Concreteprinters#3dconcreteprinter#3dconcreteprinters#Concreteprinterforsale#Houseprinter#3dhouseprinter#Cementprinter#3dcementprinter#Youthinkweprint#ConcreteprinterinUtah

0 notes

Text

Going Up

GOING UP

FROM HERE TO THERE

“This cutting edge technology will change everything we know about traditional methods of construction.”

3D Concrete Printing is the hottest new technology to come along in decades. The benefits allow for reduced production times by as much as 70% resulting in significant cost and time savings. This cutting-edge technology will change everything we know about traditional methods of construction. Those who recognize this will be able to capture the momentum and position their respective product offerings as the de-facto of the industry.

MudBots

MudBots is a 3D concrete printing company eager to partner with all industry players from batch plant equipment builders, bag mix suppliers, to additive and chemical companies. MudBots is a proven print platform and the perfect equipment to develop the cement, concrete, and epoxy mixes of the future. Just as the home office printer revolutionized the inkjet cartridge industry, we aim to revolutionize the specialty mud industry.

MudBots is the first in the industry to offer a 6’ x 6’ x 5’ Cartesian 3D Printer to aid in the development of specialty concrete mixes. We are excited to offer you a turn-key system consisting of: a work envelope optimized cartesian printer powered by high quality IP65 direct drive NEMA 34 hybrid stepper motors. These motors run in tightly controlled servo loop and is controlled by custom FPGAs and administered by LinuxCNC running on a real-time operating system. These elements combine to form a system with low jerk, high payload, and a repeatability of > 0.1” .

Simplify3D & LinuxCNC

Simplify3D

Simplify3D software is capable of generating complex tool paths using multiple extruding nozzles — all from a simple .STEP file! Simplify3D is a current industry leader in 3D printing software with full control over print parameters including print speed, slice height, width multiplication, infill generation and percentage, and multiple workpiece support. These features allow you optimize YOUR printer for YOUR mud mix to ensure that YOUR prints match YOUR models!

LinuxCNC

A robust and vetted mixing and concrete delivery platform fully integrated into LinuxCNC, allowing you to pump small aggregate and synthetic fibers right to the extrusion nozzle with on-the-fly control overflow rate and out-feed pressure.

THE INDUSTRY IS ABOUT TO TAKE

A GIANT LEAP FORWARD.

ARE YOU PREPARED?

See MudBots in action with 3D Printing of Concrete Structures demo videos.

WATCH NOW

#Mubots#3dconcreteprinting#Concreteprinting#Concreteprinter#Concreteprinters#3dconcreteprinter#3dconcreteprinters#Concreteprinterforsale#Houseprinter#3dhouseprinter#Cementprinter#3dcementprinter#Youthinkweprint#ConcreteprinterinUtah

0 notes

Photo

#Repost • @3dhomeconstruction Nestes vídeos estaremos mostrando em um compilado algumas etapas da primeira casa, entre elas como ficaram as instalações elétricas, hidro-sanitarias e peças de decoração. Hub Impressão 3d na Construção Civil: @inovahouse3d @domus3d.com.br #construcaocivil #construir #impressao3d #imprimir #empreendedorismo #empreender #inovar #inova #inovação #novidade #brasil #arquitetura #urbanismo #engenhariacivil #engenharia #avançar #invest #investimento #casas #popular #constructionlife #3dconcreteprinter #concreteprinter #startup #goodvibes #uae #mdr #mcmv #infraestrutura https://www.instagram.com/p/CFmp4q8FubA/?igshid=nkg1lz1wgvca

#repost#construcaocivil#construir#impressao3d#imprimir#empreendedorismo#empreender#inovar#inova#inovação#novidade#brasil#arquitetura#urbanismo#engenhariacivil#engenharia#avançar#invest#investimento#casas#popular#constructionlife#3dconcreteprinter#concreteprinter#startup#goodvibes#uae#mdr#mcmv#infraestrutura

0 notes

Video

#repost • @4constru A primeira casa impressa em 3D do Brasil foi projetada e executada pela equipe da @3dhomeconstruction, que hoje integra a 4constru. A casa foi construída no município de Macaíba, região metropolitana de Natal-RN, no primeiro semestre de 2020. A residência possui 66,81m² e foi impressa em 48 horas. Ela conta com dois quartos, sala de TV, cozinha, um banheiro, área de serviço e garagem e atende aos padrões de habitação de interesse social. Nós nos orgulhamos muito em saber que dêmos esse primeiro passo rumo ao futuro da tecnologia! Confira abaixo todas as fases da obra: Em primeiro lugar, foi realizada a limpeza do terreno da obra, a topografia do mesmo e execução da laje radier. Em seguida, a máquina de impressão 3D foi instalada e calibrada. Então, finalmente chegou a hora de iniciar a impressão das paredes! A obra ocorreu tanto durante o dia, quanto durante a noite, e camada por camada, a casa foi ganhando forma. Quando a impressão chegou na altura da janela, além das esquadrias de madeira, foram adicionados vergalhões de aço sobre as caixarias, criando as vergas a fim de distribuir as cargas e tensões existentes nos vãos das janelas e portas. E assim foi possível seguir a impressão das camadas superiores. E aí, já estava concluída toda a impressão da obra! Que alegria ver um projeto tão nobre ganhando forma! #printinghouse3d #3dconcrete #3dprinthouse #3dconcreteprinting #3dprinter #3dprinters #3dhouse #3dprintingconcrete #concreteprint #impressao3d #3dprinting #3dconcreto #engenharia #engenheirocivil #construcao #construction #construtech #construtechs #construtechventures #dubaifuture #dubaifuturefoundation #printhouse3d #construcaocivil #civilconstruction #domus3d #3dhome #3dhomeconstruction #4constru #latinagroup https://www.instagram.com/p/CP0K5HWpSHY/?utm_medium=tumblr

#repost#printinghouse3d#3dconcrete#3dprinthouse#3dconcreteprinting#3dprinter#3dprinters#3dhouse#3dprintingconcrete#concreteprint#impressao3d#3dprinting#3dconcreto#engenharia#engenheirocivil#construcao#construction#construtech#construtechs#construtechventures#dubaifuture#dubaifuturefoundation#printhouse3d#construcaocivil#civilconstruction#domus3d#3dhome#3dhomeconstruction#4constru#latinagroup

0 notes