#Aluminium Wall Cladding

Text

Aluminium Cladding- Claddco

Elevate your building’s design with Claddco’s premium aluminium cladding solutions. Our aluminium cladding is perfect for enhancing the aesthetics and performance of residential, commercial, and industrial properties. Known for its durability, lightweight properties, and modern appeal, aluminium cladding from Claddco provides superior weather resistance and low maintenance. Trust our expert team to deliver bespoke solutions tailored to your specific needs, ensuring a seamless installation and lasting results. Choose Claddco for the best aluminium cladding options that combine style, functionality, and longevity.

0 notes

Text

HPL Cladding stands for High-Pressure Laminates cladding which is used to add another layer of material on the surface of your house and office’s wall. Here Aspect Décor has one of the best wood exterior HPL cladding in Noida. You can take some valuable time to explore it and its services.

#HPL cladding in Noida#exterior wood cladding#aluminium composite panel cladding#aluminium cladding#aluminium wall cladding

0 notes

Text

Exploring the Versatility of ACP Sheets: Exterior Cladding vs. Interior Cladding

Aluminum Composite Panel (ACP) sheets have become a popular and versatile option in modern architecture and interior design for improving a building’s appearance and usefulness. Both interior and exterior cladding use ACP sheets, each with a specific function determined by the particular requirements of the surrounding environment.

Understanding ACP Sheets: A Brief Overview

Aluminium Composite…

View On WordPress

#ACP panels#ACP sheet#acpsheet#Aluminium composite panels#aluminium panel#cladding material#Eurobond#Eurobond ACP#Eurobond ACP panels#exterior cladding#interior cladding#wall cladding

1 note

·

View note

Text

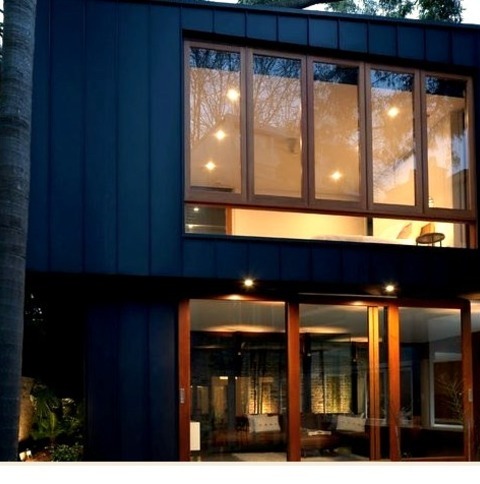

Metal - Contemporary Exterior

Inspiration for a small, modern, metal-sided, two-story house with a metal roof.

#glazed walls#black aluminium cladding#cedar windows#glass sliding doors#contemporary terrace#polished concrete

0 notes

Photo

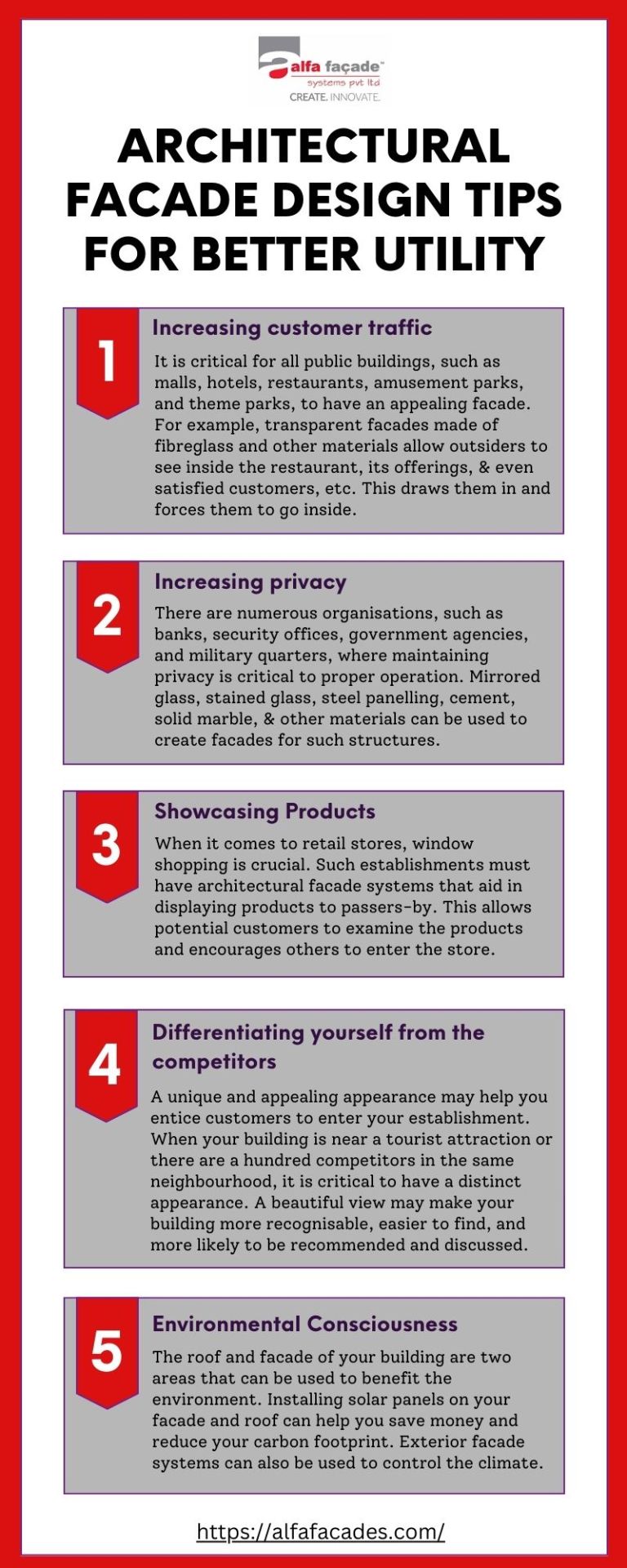

A facade is the exterior of a building that gives it its identity. Building design considers structural stability, space utilisation, and energy consumption. Furthermore, design is an important part of the process because it serves several important functions while also giving a structure an aesthetic appeal that adds to its personality. As a result, the design of the facade must be done optimally in order to achieve an incredible structure. Here are a few things to keep in mind when designing an architectural facade for your building:

#alfa facade#Alfa facade infographic#facades#building#facade design#facade glazing company#structural glazing services#acp cladding services#facade system & glazing services#aluminium composite panel cladding services#structural glass glazing services#Curtain Wall Glazing Services#upvc sliding doors & windows#upvc sliding windows#aluminium sliding windows#Aluminium louvers#architectural facade#tips#5 tips

1 note

·

View note

Photo

Bofia Restaurant by Azaz Architects

1 note

·

View note

Text

Kollhoff towers over The Hague

Continuation of The Hague presentation. From what I managed to grab while running. It is not without reason that he presents these shots. Firstly, the charm of autumn. Secondly. These are very famous buildings.

Kollhoff towers over The Hague. Ministry of Interior and Ministry of Justice Administration Building.

The Ministry of Internal Affairs is built of red brick, and the Ministry of Justice is covered with light granite. The towers are also called “JuBi-Gebouw”, Ju for Justitie and Bi for Binnenlandse.

The green skyscraper on the right is called “De Kroon” and was designed by Rapp + Rapp architects. At 131 m, it is slightly smaller than Kollhoff's two towers and was completed in 2011.

Two skyscrapers by Hans Kollhoff, a German architect and professor, were completed in 2012. A German architectural studio won the competition for new ministries in The Hague. Kollhoff is a representative of postmodern architecture and new classicism, as well as a hero of New Urbanism.

A pair of towers rises from the volume opening onto the promenade called Turfmarkt with the cour d'honneur cum garden. The ministry towers, with 36 floors and a height of 150 meters, stand out from the urban background with pilaster facades made of brick (for the Ministry of Interior) and granite (for the Ministry of Justice). The grey-green granite cladding of the base is made of four-centimeter-thick sandblasted slabs. These slabs are attached to the load-bearing wall with conventional stainless-steel anchors, with thermal insulation in between. In the corners of the ground floor, thicker L-shaped slabs supported by steel consoles were used.

This effectively emphasizes the expression of stability, which is also the intention of the hammered plinth. The rather flat facade of the first two floors with wide openings faces the street and connects to the ground with a curved profile, ending with a delicate course of strings. Shop windows are framed with brass-colored aluminium profiles. The second through fourth floor facades are topped by a tall main cornice that highlights the building's granite base and the shared ministries' functions. Here, the same casement windows that lie between the piers in the towers above serve as separate openings. Double windows allow natural, manually regulated ventilation throughout the building. The prefabricated facades of the towers are connected by pilasters which, covered with the same polished green granite as the base, break the upper edge of the wall and end in a crown. The connections between the elements disappear behind the overlapping panels, becoming invisible when viewed from the front.

The steeply sloping atrium, cut into the volume, has a main glazed front that overlooks the garden with revolving doors and brass-colored aluminium profiles. The garden is surrounded by a granite bench protruding from the building's plinth. This bench supports a fence made of decorative square posts and curved rectangular steel profiles coated in light anthracite. The tips are lacquered in gold.

Photo credits: @marcinwojcik

#Turfmarkt#den haag#Hague#Kollhoff#Hanz Kollhoff#JuBi Gebouw#towers#architecture#buildings#cityscape#city#city landscape#mobile#trip#fall#mobile photography

2 notes

·

View notes

Text

Best HPL Sheets Manufacturer in India

What is HPL Sheets?

HPL Sheets – High Pressure Laminates : For a very long time, traditional wood – with its pristine looks has been used in various ways to suffice for our dwelling needs. Our buildings always used the beauty and usefulness of wood. However, in-spite of its advantages, wood had some serious shortcomings. First, it was not in abundant supply. Second, it had a life limited to a couple of years and its maintenance was not easy.

Also, it is here that ReynoArch brought forward AHPL, which is an Aluminum based High Pressure Laminate (HPL Sheets). It is more durable and elegant in looks as compared to wood. It is also highly weather resistant. AHPL has overcome the shortcomings of wood as it is manufactured using aluminium coil with double layered Lumiflon coating that is resistant to dust.

To top it all ReynoArch HPL sheets comes in a variety of colors, textures and sizes. ReynoArch also offers customized colors and sizes. All this at a very competitive price coupled with an unmatched quality. AHPL has redefined the concept of high-end facade and exterior. ReynoArch offers professional service as it has a robust marketing network in India and abroad. Whether it is Villas, housing societies, corporate buildings or resorts, AHPL is a perfect foil in place of wood.

FEATURES

Weather Resistant

Anti fading

90 Degree bendable

Chemically resistant

Scratch-resistant

Versatile and easy to manage

Management Simplicity

Floor Wear Tolerance

Soft heat resistance

Looks powerful, rigid, and beautiful

Color Transition Tolerance of Artificial Light

Cigarette Burn Tolerance

Why should you choose REYNOARCH HPL SHEETS?

ReynoArch Best HPL Sheets are noted for their colorful designs and real wooden feel, so it comes as no surprise that they make the surroundings lively and beautiful to look at. It is a vibrant and trendy graphic that will immediately raise the spirits. Our HPL sheets can reside in your home for a longer period of time without losing their color and beauty effectiveness.

It is clean of minor or larger bruises or marks created by the children or injuries due to its lumiflon coating. You must be aware of the health effects of HPL sheets because they are used nearly everywhere. Finally HPL sheets are fully risk-free because they do not contain any toxic substances, are hygienic, and safe for your child and family.

HPL Sheets Related FAQ

What is HPL Sheet? Where is HPL Sheets used?

HPL cladding, or high-pressure laminate cladding for short, is primarily used for exterior and interior surfacing in commercial and residential properties. Multiple layers of kraft paper saturated with thermosetting mastics with incomparable bonding strength are heated to create this cladding.

Is HPL a water-resistant material?

Yes, ReynoArch HPL is water-resistant making it a perfect application for home exteriors.

What is HPL wall cladding, and how does it work?

HPL sheets are used for wall cladding in both exterior and interior architectural architecture because of their rigidity and resilience. It is the finest modern-day building material for cladding because it can withstand extreme weather, and its extended life span is exceptional for use. High-Pressure Laminate is a lightweight metal that is easy to install, so custodians widely use it.

Source URL:- https://reynoarch8.wordpress.com/2023/02/28/hpl-sheets-manufacturer-in-india/

#HPL Sheets#HPL Sheet#Best HPL Sheets Manufacturer in India#HPL Sheets Manufacturer in India#HPL Sheets Manufacturer Near Me#architecture#interiordecor#interiors#HPL sheet price#High Pressure Laminates#High Pressure Laminates Sheet

2 notes

·

View notes

Text

What are the Advantages of using Aluminium Composite Panels?

Benefits Of ACP:

The Aluminium Core Panels can be used for multiple purposes such as the construction of houses, rooftop coverings, claddings, etc. They offer many advantages to the customers over other types of building materials, and hence, they are utilized in almost all construction purposes in urban and metropolitan cities.

The various benefits of ACP sheets have been mentioned as follows –

Cost-efficient

Long-Lasting Life

Fire Redundant

Low Maintenance Cost

Available in a wide variety of textures

Easy To Install

Weather Resistance

Enhances the looks

Let’s look at each of the benefits in detail:-

Cost-efficient – They are very economical and cheap as compared to other alternatives such as steel plates, insulated coverings, etc. They are available at a low bargain when bought from local wholesalers and sheet distributors of the region. They also have very less maintenance costs, which allows the customers to use them for many years without spending any additional costs.

Long-Lasting Life – An average ACP panel lasts for more than 10 years after the purchase, which means that they are a long-term investment for the buyers. They protect the house from sunlight, rain, and termites for many years at a stretch, without facing any kind of damage/loss of quality.

Fire Redundant – These cheap alternatives to an insulated covering are fire-redundant and fully fire-proof, which allows the customers to take care of the safety of their houses. They also protect the interior fittings of the building from any incident of fires, gas smoking, etc.

Low Maintenance Cost – These ACP sheet panels have very low maintenance costs as well as very less chances of being attacked by external factors such as termites, water, sunlight, etc. The costs of maintenance are so low that a customer can almost spend nothing on maintaining these panels for the next 5-10 years after purchasing them from the markets.

Available in a wide variety of textures – The sellers make these sheets in a large variety of textures and colors for the benefit of the potential buyers in the markets. They are also available in a large number of shapes and sizes so that one can choose the perfect panels as per the requirements of their own house. They are available in over 100+ color variants and 80+ texture variants in the markets.

Easy To Install – These sheets are easily installed by the way of fitting and shaping in your houses. You only need to spend minimal amounts on the services used for installing these panels in your homes. The sellers usually provide free fitting services to the customers or charge very less to install these protective aluminum coverings at their residences.

Weather Resistance – They are weather-resistant and climate-resistant, which means that one can easily install them in places where rain and sunlight cause extensive damage to your houses. These panels also have termite-resistant qualities which protect the furniture and electrical appliances installed in your house. They are also having temperature-resistant qualities which makes them ideal for any kind of weather conditions in the future.

Enhances the looks– The ACP panels usually improve the overall appearance of your house, but with the right shapes and colors you can renovate your entire house with the help of these aluminum covers. The right color selection and textures can bring out the best patterns on the walls of your residences. These panels are also available in a large variety of sizes, which can be crucial while designing the looks of your homes with these coverings.

you can try pratapbond acp pane

3 notes

·

View notes

Text

Aluminium Cladding Suppliers in Melbourne

Claddco is a trusted supplier of aluminium cladding in Melbourne, offering a comprehensive range of high-quality products to meet diverse architectural and construction needs. Specializing in aluminium composite panels (ACP), Claddco provides durable and versatile cladding solutions suitable for both residential and commercial projects.

1 note

·

View note

Text

Types Of Prominent Textures Used In ACP Sheet Design For Walls

We���ll focus on the texture of the ACP sheet design for walls out of these 7 components. Adding a statement look to a blank wall in a house or workplace is the art of interior design. Given that there are so many different panel options, it is the ideal moment to redesign the wall in a modern and stylish manner.

Types Of Textures For ACP Sheet Design For Walls

Let us see some texture ideas when it comes to ACP sheet design.

1. Wooden

2. Metallic

3. Sand

4. Stone

Discover Great Services Of ACP Sheet Design For Walls In Delhi With Aspect Decor

Aspect Decor believes, that a house ought to be both durable and attractive.

Read This Blog For More Info: Types Of Prominent Textures Used In ACP Sheet Design For Walls

0 notes

Text

Exploring the Versatility of ACP Sheets: Exterior Cladding vs. Interior Cladding

Aluminum Composite Panel (ACP) sheets have become a popular and versatile option in modern architecture and interior design for improving a building's appearance and usefulness. Both interior and exterior cladding use ACP sheets, each with a specific function determined by the particular requirements of the surrounding environment.

Understanding ACP Sheets: A Brief Overview

Aluminium Composite Panels are composed of two aluminum sheets bonded to a core material, often made of polyethylene or fire-resistant materials. This construction gives ACP sheets a perfect balance of strength, flexibility, and lightweight properties. The combination of aluminum's durability and the design possibilities offered by the composite structure has made ACP sheets a go-to material for architects and designers.

Exterior Cladding: Weathering the Elements

Design and Aesthetics: ACP sheets used for exterior cladding are chosen for their ability to withstand the harsh outdoor elements. The design options are vast, ranging from bold and contemporary to classic and textured finishes. The external appearance of a building is often the first impression, and ACP sheets contribute significantly to the visual appeal.

Weather Resistance: One of the primary considerations for exterior cladding is the ability to withstand weather conditions. ACP sheets designed for exteriors feature coatings that provide UV resistance, preventing color fading and maintaining the vibrancy of the facade despite prolonged exposure to sunlight. Additionally, they are engineered to resist rain, temperature variations, and other environmental challenges.

Durability and Strength: Exterior ACP sheets are crafted to be thicker and possess higher strength to endure wind loads and external forces. The core material is chosen for its ability to provide structural support and insulation against outdoor conditions.

Interior Cladding: Aesthetic Flourish and Functional Elegance

Design and aesthetics: ACP sheets for interior cladding offer an extensive range of colors, finishes, and textures, providing designers with a canvas to express creativity. The emphasis here is on creating visually appealing spaces that complement the interior aesthetics of a building.

Functionality: While still offering durability, interior ACP sheets prioritize factors such as scratch resistance, ease of cleaning, and sometimes decorative finishes. The core material may be tailored to meet requirements such as fire resistance and sound insulation, contributing to a safe and comfortable indoor environment.

Versatility: ACP sheets for interior applications are known for their adaptability. They can be used to create feature walls, partitions, and even furniture, adding a modern touch to interiors. The lightweight nature of ACP sheets allows for easy installation and customization, making them an ideal choice for interior designers.

Conclusion: Choosing the Right ACP for the Right Purpose

In conclusion, the choice between ACP sheets for exterior and interior cladding depends on the specific needs of the project. Exterior cladding demands resilience against the elements, emphasizing weather resistance and durability, while interior cladding allows for a broader spectrum of design options with a focus on functionality and aesthetic appeal.

The versatility of ACP sheets ensures that architects and designers have a reliable material that caters to both the structural and design aspects of a building, allowing for the creation of harmonious and visually stunning spaces, whether it be the exterior facade that stands against the elements or the interior surfaces that define the character of the indoor environment.

#exterior cladding#interior cladding#acpsheet#aluminium panel#eurobond acp#cladding material#wall cladding

1 note

·

View note

Text

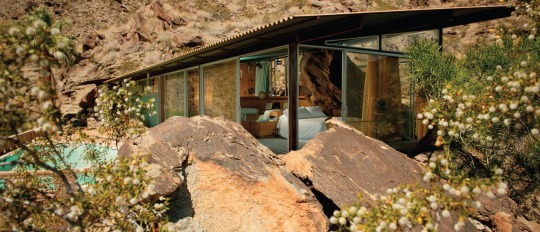

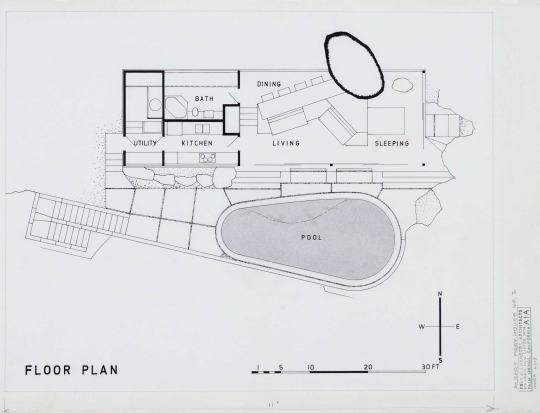

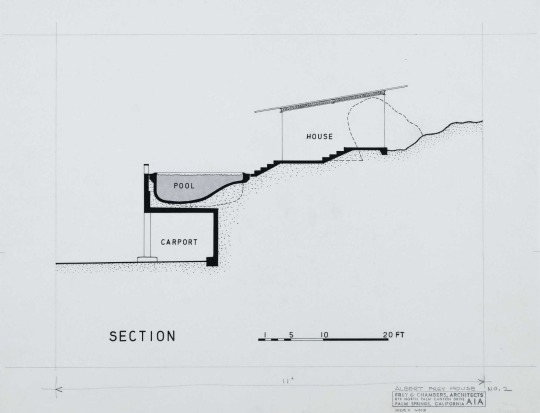

Frey Residence II | Albert Frey

Palm Springs, CA | United States | 1963

Albert Frey’s own homes offered opportunies for experimentation. He built his first in 1940 on an open 0.8- hectare (2-acre) site on the valley floor at Paseo El Mirador. Originally little more than a sculpted cabin clad in aluminium, Frey later added a swimming pool and then remodelled extensively in 1953, adding a secondary circular bedroom pod. When he sold up in the early Sixties, the new owner demolished Frey House I. Frey, meanwhile, travelled upwards. He picked a hillside site 67 metres (220 ft) above Palm Springs, on the slopes of Tahquitz Canyon. From here, the city occupies the valley floor, with banks of glass framing the vista from within the house. The design process began with a careful study of the terrain and the sun’s movement, and an appreciation of this dramatic view. Again, the scale of the single-storey house is modest. A ribbed-metal roof shelters the glass-walled belvedere where the rock pushes through into the interior, forming a dramatic ‚bookend‘ or backstop to Frey’s dining table. This sits in a fluid, multifunctional living space with the bedroom to one side; service spaces and a galley kitchen are tucked away to the rear. An elliptical pool, also enjoying the open views, is the one luxury.

Images: © Bethany Nauert

Words: © thegreatdaydreamer

#architecture#modern architecture#palm springs#desert#modern home#midcenturyhome#midcenturymodernhome#albert frey#interior#interior design#decor#house design#design#luxuryhomes#swimmin pool

4 notes

·

View notes

Text

Aluminium Honeycomb Panels: Lightweight Giants of Modern Engineering

Aluminium honeycomb panels are a marvel of engineering, combining lightweight construction with remarkable strength and durability. These panels consist of a core made of hexagonal aluminium honeycomb cells sandwiched between two thin layers of aluminium sheets. While they might seem simple in design, their applications and benefits are vast and varied.

Unmatched Strength-to-Weight Ratio

One of the most striking features of aluminium honeycomb panels is their exceptional strength-to-weight ratio. The honeycomb structure provides incredible strength while keeping the overall weight of the panel relatively low. This makes them ideal for applications where weight reduction is crucial without sacrificing structural integrity.

Applications in Aerospace

In the aerospace industry, where every ounce matters, aluminium honeycomb panels are widely used in aircraft construction. They are utilized in aircraft interiors for wall panels, flooring, ceiling panels, and other structural components. Their lightweight nature helps reduce fuel consumption while maintaining the structural integrity necessary for flight safety.

Architectural Marvels

Beyond aerospace, aluminium honeycomb panels have found their way into architectural designs, revolutionizing the construction industry. Their versatility allows architects and designers to create innovative structures that are both visually stunning and structurally sound. From exterior cladding to interior partitions, these panels offer endless possibilities for modern architecture.

Energy Efficiency and Sustainability

Aluminium honeycomb panels also contribute to energy efficiency and sustainability in construction. Their lightweight nature reduces the load on buildings, resulting in lower energy consumption for heating, cooling, and transportation during construction. Additionally, aluminium is highly recyclable, making these panels an eco-friendly choice for green building projects.

Versatility in Transportation

In addition to aerospace applications, aluminium honeycomb panels are utilized in various transportation sectors, including automotive and marine industries. In automobiles, they are used for interior components, such as door panels, floors, and trunk liners, contributing to improved fuel efficiency. In marine applications, they offer lightweight solutions for boat hulls, decks, and bulkheads, enhancing performance and fuel economy.

Fire Resistance and Safety

Safety is paramount in any application, and aluminium honeycomb panels excel in this regard as well. Their inherent fire-resistant properties make them suitable for use in environments where fire safety is a concern, such as building interiors and transportation vehicles. Additionally, their high strength ensures structural integrity even under extreme conditions, providing peace of mind to architects, engineers, and occupants alike.

Cost-Effective Solutions

Despite their advanced engineering and superior performance, aluminium honeycomb panels offer cost-effective solutions for various industries. Their long lifespan, low maintenance requirements, and energy-efficient properties translate to significant cost savings over the lifetime of a project. Moreover, their lightweight nature reduces transportation and installation costs, further enhancing their cost-effectiveness.

Conclusion

Aluminium honeycomb panels represent the pinnacle of modern engineering, offering a perfect blend of strength, durability, versatility, and sustainability. From aerospace to architecture, transportation to construction, these panels have transformed industries and opened doors to endless possibilities. As technology advances and new innovations emerge, aluminium honeycomb panels are sure to remain at the forefront of modern design and engineering, shaping the world we live in for generations to come.

Stay informed about the latest advancements in rail technology by following our updates on Tumblr and visiting MetaCor Rail Applications.

0 notes

Text

REASONS FOR FACADE RESTORATION & MAINTENANCE

Facade restoration and cleaning remove dirt, grime, and other pollutants from a building's surface and restores it to its former glory. The term facade refers to the building's outward appearance, and it is usually the surface with the entrance door.

One might think that the value of facade cleaning is limited to the building's aesthetic appeal, but it is more than that. By including proactive facade restoration in your building maintenance programme, you can preserve these benefits while lowering the cost of repairs over the long term. Continue reading to learn more about our four top reasons for considering facade restoration and maintenance.

Restorative cleaning can boost the aesthetic value of a building

Restorative cleaning is a refined technique that goes beyond simply cleaning dirt and debris from building surfaces. Building facade restorations of historic buildings, in particular, may help boost your community's economy through 'heritage tourism'. Some preventative measures for facade maintenance include metal restoration, professional glass restoration, and stone facade restoration.

Facade damage builds up incrementally overtime

Building facade restoration may be too easy to overlook because building damages accumulate over time. Slight damages may go unnoticed at first, but they add up over time. The longer you ignore it, the more damaging it can become to the facade surface (and, potentially, for the reputation of the business).

It is more environmentally friendly than replacement

According to a British study, new construction and replacement can result in up to 50 tonnes of CO2 emissions per property. With restoration, however, CO2 emission is limited to 15 tonnes. While these figures vary widely, they paint a clear picture of the environmental impact of choosing restoration over replacement. Choosing to do facade restorations over tearing down parts of your building and giving these parts a well-deserved second chance is a more environmentally conscious choice.

It may help you fulfill your business goals

Vintage buildings are inherently beautiful, especially when properly maintained. They are magnificently crafted and unique to their era. Whether you want to sell or attract tenants, your historic property may just be one facelift away from fulfilling your business goals.

Keep detailed records of all inspection findings along with the results of prior maintenance and repair activity.

Do you have questions about facade restoration for your facility? Contact Alfa Facade Systems

#alfa facade#Alfa facade blog#facades#facade design#upvc sliding doors & windows#upvc sliding windows#facade glazing company#structural glazing services#acp cladding services#facade system & glazing services#structural glass glazing services#maintainence#facade restoration#restoration#curtain wall glazing services#Glass and steel railing services#skylights manufacturers in india#aluminium doors and windows manufacturers

0 notes

Text

Rivet Applications in Modern Construction

Strength and Versatility in Building

Rivets have been a cornerstone in construction for centuries, providing robust and reliable fastening solutions for various structures. In modern construction, rivet technology has evolved significantly, offering advanced solutions that cater to the industry's dynamic needs. This blog post explores the diverse applications of rivets in contemporary construction, highlighting their benefits and specific use cases.

Structural Steel Construction

One of the primary applications of rivets in modern construction is in the assembly of structural steel frameworks. Rivets provide strong and permanent joints that are essential for the integrity of large structures such as skyscrapers, bridges, and industrial buildings. Unlike bolts and screws, rivets do not loosen over time, making them ideal for joints subjected to constant stress and heavy loads.

Example: Rivets are extensively used in the construction of high-rise buildings. They ensure that the steel beams and columns are securely fastened, providing the necessary stability and strength to support the entire structure.

Facade and Cladding Systems

Modern buildings often feature complex facade designs that require reliable fastening solutions. Rivets are commonly used to attach cladding panels to the building's framework. Their ability to provide a clean and aesthetically pleasing finish makes them a preferred choice for architects and builders.

Example: The installation of metal cladding on commercial buildings is carried out using aluminium and steel rivets, which makes it look smooth and makes it durable and resistant to different weather conditions.

HVAC and Ductwork Installation

In HVAC (Heating, Ventilation, and Air Conditioning) systems, rivets are used to affix and form ductwork. Their quick-to-do and strong stability make them perfect for connecting and supporting rods and shafts to walls and ceilings.

Example: Sometimes, blind rivets are the best choice especially in HVAC applications where access to the backside of the joint is limited. They make it easier to fix without causing any leaks. This method works effectively for joining these steel ducts.

Roofing and Gutter Systems

Attaching metal sheets for the roofing, channel strips and, assemble

gutter systems, are the main applications for rivets. The security and

resistance to climatic conditions of the rivets make the above materials

permanent for decades. Example: It's no wonder that they would choose stainless steel rivets in the aforementioned situation, as they provide the best performance in terms of moisture and salt resistance.

Window and Door Frames

Rivets are a common fastening method for installing windows and doors due to the reason they could keep security and protection of the structures along with windows frames and other parts of the building. They are simply used to linking frames during the installation process and also for fastening beading panels which forming a firm junction for the windows and doors.

Example: Rivets belong to the category of fasteners, mostly used in

situations of splintering of windows sis doors in modern commercial

buildings and organizations which are used for unwanted entry.

Innovative Architectural Designs

Nowadays we see different designs of architecture which have put custom fastening solutions at the forefront of the designer's attention. For the bond, the goods constructed from the mentioned material such as titanium or high-strength aluminium, as the primary element, are being displayed.

Since they are so important, they can serve projects beyond the mainstream, such as those with complex geometric facades or those who possess highly minimalist yet extremely durable structures.

Example: In the construction of contemporary art museums

and innovative commercial spaces, rivets provide the flexibility and strength needed to bring complex architectural visions to life.

Conclusion

Rivets are currently recognized to be an essential or essential component in the building sector and are popularly known for their toughness, long life span, and their attraction specifically to customers. No matter what the use, such as industrial steel constructions, exterior facades, cladding to HVCC systems, or futuristic design, rivets should be thought of as a crucial link between the integrity and life of the new structure and as such deserve due attention from professional builders in using them. As building techniques get better and materials change, rivets are still going to be useful by providing access to better fastening methods that will always correspond to the needs of the industry.

1 note

·

View note