#silicone rubber factory

Text

#machine#sigma mixer#sigma blade mixer#z blade mixer#double arm mixer#equipment#chemical#industrial#laboratory#lab#video#silicone rubber#factory

0 notes

Text

Services - Hot Water Bottle Factory

CHUANGU has been committed to the development, design, and production of hot water bottles. At present, it has a complete production capacity of rubber, PVC, and silicone hot water bottle inner tanks. Quick proofing and customization capabilities for hot water bottle cover such as plush covers, knitted covers, toy covers, etc.

#pvc hot water bottle#water bottle manufacture#rubber hot water bottle#silicone hot water bottle#water bottle#bottle manufacture#water bottle manufacturer#hot water bottle factory

0 notes

Text

RE8 Characters quirks and habits

Alcina:

Had a habit of checking her reflection and making sure everything was still in the perfect place whenever she found something reflective.

Sometimes it only took her a split second to deem herself fine and sometimes it took longer.

It annoyed her if she couldn't find a mirror or something soon after she dealt with a maid or hunter.

So you took to carrying around a custom made compact for her.

The first time you presented it to her, she blushed just a little embarrassed. She worried you thought her vain but you honestly didn't mind.

Now she accepted this little habit that you started for her, occasionally asking for the compact when she feels she needs to check.

She thinks it's thoughtful of you to pay attention to this little detail of her. And is never short on thanking you for it.

Donna:

Had a habit of picking at the skin around her nails when she was nervous.

Sometimes she would pick so much she would pick a sore open.

To help her combat this you made sure to carry a small thing of lotion so that the moisturized skin would be harder to pick at.

Then you started carrying small little fidget items around, offering her different ones until she settled on which one was perfect.

She wore two different ring fidgets that you had gotten her. One had a section that she could spin and the other turned into a a puzzle of seven rings when removed from a finger.

Donna loved these and was sure to show you her thanks everyday.

Heisenberg:

The man had a habit of chewing on things when bored or stressed.

Sometimes it was his nails, sometimes it was his hair, sometimes it was the end of a pen. Really nothing was off the list when came to his chewing.

You thought and researched things that could help, but your search wasn't conclusive. So you aimed for at least finding something that would be better for him to chew on.

You're answer to that question came from the Duke. You had asked to find something that perhaps would be suitable for Heisenberg and he nodded and said he'd look for something.

That something ended up being a dog tag looking necklace that was made out of some type of rubber called silicone.

You paid him and took it with you back to the factory.

At first Heisenberg just looked at it and dismissed it. But at your insistence he plopped one end into his mouth and started chewing on it.

Turns out he loved it, it was just the right texture and helped tremendously with him not chewing on other things.

You got multiple different chews from the Duke after that. Different shapes and colors that ended up being spread around the factory.

The only time he didn't use one was when he was at a meeting or showing up somewhere as a Lord.

You though would end up carrying one in your pocket for after the meeting for him.

Miranda:

She was very concerned with keeping her imagine as an unobtainable goddess so she meticulously groomed herself.

That included preening her own feathers to make sure nothing was out of place.

Of course this took a while and made her grumble, especially when it came to the feathers out of her reach and pin feathers.

You were watching her one day, struggling to reach certain places when you got up and went over to her. With her watching you began to help preen her feathers. She never said anything and went back to preening the feathers she could reach.

After that she let you continue help her with her wings.

The pin feathers came off easier after a shower, so being the efficient woman she is Miranda took you in with her. Of course there were other benefits to that as well.

Sometimes she would just plop down on the bed and fling her wing over to you. You didn't mind, fixing her feathers it made you feel happy to help her in any way possible.

#alcina dimitrescu#resident evil village#lady dimitrescu#tall vampire lady#mother miranda#donna beneviento#re8 mother miranda#karl heisenberg#re8 heisenberg#re8 donna#lady beneviento#metal daddy#geeky writes

183 notes

·

View notes

Text

What is your favorite seal? Comment below!

Part of this blog's goal is to educate people about the different kinds of seals, so if you aren't sure read on and pick a favorite!

Water based Latex

Popular for residential use because of the ease of application and ability to adhere to most substrates. These can be painted on and are suitable for situations where gaps / voids are very small and movement is minimal. Latex is can be prone to shrinkage and can pull away from the substrate creating gaps, allowing water to penetrate. You will often find water based latex seals in freshwater such as Lake Ladoga or Baikal.

Acrylic

These are UV stable making them suitable for exterior applications, and are not prone to shrinkage. Acrylics can be difficult to apply and cannot accommodate significant movement. Contrary to popular belief, acrylic seals don't actually eat crabs!

Butyl

Adheres well to a broad variety of substrates but can be hard to apply due to their stringier consistency. They have poor resistance to abrasion and struggle to accommodate movements that introduce shearing forces. They are not suitable for demanding building applications. You can find them across all of the islands of Hawaii, but don't get close because they're endangered!

Polysulfide

Excellent flexibility even at low temperatures with little shrinkage or UV degradation, and can be used for underwater applications. Polysulfides are more expensive than similar sealants and have a tendency to have higher levels of volatile organic compounds (VOCs). Though, a life expectancy of 10 to 20 years does compensate for the price somewhat. When most people think of seals, these arctic animals with their fuzzy white babies are in the top three!

Silicone

Has excellent thermal resistance, good dynamic movement capability and good adhesion. They can be easily vandalised and tend to collect dirt. For certain substrates (such as stone), staining may also be an issue, in some cases making the use of primers a necessity.

As weather proofing and air sealing applications silicones can be used structurally e.g. for bonding glass or metal to frames. Silicones are generally the most expensive but quality silicones have very good durability performance. These seals are often seen along the shores of La Jolla beach.

Polyisobutylenes

Have similar properties to natural rubber but with improved durability, good resistance to chemical attack, and have very low permeability. These are commonly used as the primary seal for insulating glazing units (IGU) as they are capable of resisting the transmission of vapour and gases. The products are normally factory applied, rather than site applied. You can find Polyisobutylene seals all over the world, and they are the origin of Selkies!

Polyurethane

Adhere well to the majority of different surfaces with little substrate preparation, and are generally the go-to choice for contractors. They have excellent resilience to abrasion and shear forces as well as having strong adhesion and movement capability. When male seals of this type reach maturity they gain a scent similar to gasoline! In fact, Ponsuke is a polyurethane seal!

No singular seal is universally superior or inferior to another. Some are simply better at certain applications than others are due to their innate physical and chemical properties. But we all have our favorites!

113 notes

·

View notes

Note

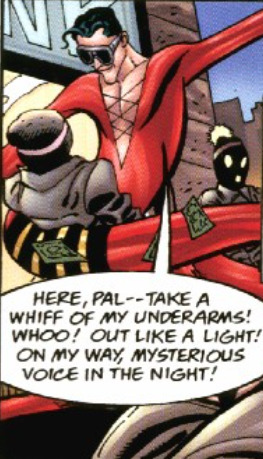

does he constantly smell like factory fresh rubber

Well according to JLA versus predator...

Stinky man, stinky smelly man XD.

No but for real I imagine he smells very synthetic most of the time, like food safe silicone smell. Wouldn't you just love a plastic man scented candle XD. But fresh rubber sounds nicer than whatever the hell was going on in the image above.

Thank plas 🤣

~( ꈍᴗꈍ)

5 notes

·

View notes

Text

Our factory specializes in the production of high-quality silicone hoses, offering customized logo options. We provide a diverse range, including 1-inch rubber water hose pipes, U-shape rubber radiator hoses, and the latest steel wire silicone hump hoses. Our hump silicone hoses boast high temperature resistance and can be tailored to meet specific requirements. With a commitment to delivering excellent services, we take pride in offering top-notch products to cater to your needs.

customized size silicone hose

#silicone hoses#customized#Silicone hose manufacturers#Best Silicone hose manufacturers#automobile accessory#Car Accessories#spare parts#Silicone Radiator Hoses

3 notes

·

View notes

Text

5 Things I learned about Online Labor

1. Exploitation in Silicon Valley

Silicon Valley is known as the tech capital of the world. It is the most technically diverse and productive place in the world always innovating new technologies. Since 1957 Silicon valley has been viewed as having an informal place of work that sacrifices the appearance of hierarchy for an atmosphere of family. The informality of this environment discourages the formation of unions.

2. Hidden Exploitation around the world

There are levels to the exploitation within silicon valley. Another group that is exploited, but often overlooked is those who are considered unskilled workers. These are people who participate in factory jobs that manufacture the products for companies like Apple and Microsoft. These people are unfortunately forced to work in poor conditions, are underpaid and underappreciated. An example of this would bet the Chinese manufacturing company Foxconn where workers were forced to live in dormitories within the factories with multiple people to a room. In 2010 eighteen assembly workers committed suicide as a result of the working conditions.

3. Slavery in the Modern Tech Industry

A material that is very valuable to many companies within Silicon Valley, is cobalt. Coltan is a product that is put into many different electronic devices and products, such as phones and electric vehicles. 80% of the world’s coltan is found in Congo which has the largest cobalt mine in the world. Congo has a history of being exploited. From 1885 to 1908 Congo, known then as Belgian Congo, around 15 million people were killed in the production of rubber. The coltan nine uses cheap labour and exploits children in the cultivation of coltan. These children are kept in slave like condition, being paid barely anything and often risking their lives. (Trusolino, 2023)

4. How you are being exploited.

As consumers of digital media, we are not only consuming content, but creating it. We are employees that keep the social media platforms of our choice alive. Though this is still morally questionable we still have the added benefit of enjoying the content we produce. This is not always the case. Lisa Nakamura in her articled titled The Unwanted Labour of Social Media where she discussed the unpaid and unappreciated labour of people of colour, specifically woman of colour online. These people take the roles of moderators on different platforms, policing misogyny, homophobia, and racism. Even though what they do is important they are often met with vitriol. These people should not have to take on these roles and if they do, should be compensated. (Nakamura, 2015)

5. The rise of Neoliberalism

Neoliberalism was a concept firmly rooted in North American politics and government in the 1970’s. The theory liberates the individual to be able to freely use their entrepreneurial skills within the institutional framework. The results of this concept are the free market, free trade, and the privatization of property. The problem with this concept is that the government is absolved of a portion of its responsibility to the people, dropping useful programs that help facilitate peoples growth. It only benefits the people who have the ability to obtain entrepreneurial skills and discourages employees from unionizing.

Related sources:

Nakamura, L. (2015). The Unwanted Labour of Social Media: Women of Colour Call Out Culture As Venture Community Management. New Formations, 86(86), 106–112. https://doi.org/10.3898/NEWF.86.06.2015

Trusolino , M. (2023). Lecture 5: Political Economy of Social Media: The Consumer and Free Labour [Power Point Slides].

2 notes

·

View notes

Text

Silicone hose manufacturer, supplier in China

Hebei Orient Rubber & Plastic Co.,Ltd. concentrates on these products: silicone elbow hoses from 45 degree to 180 degree, Reducer Hose, 45 and 180 degree, vacuum hose , Silicone braided hose,straight hose, Silicone T Hose,hump hose , silicone heater hose, silicone meter hose.etc.We offer bespoke silicone hose solutions.Learn more about the benefit of our internationally trusted silicone hoses and browse our wide selection of high-quality silicone hoses today!

2 notes

·

View notes

Text

INSULATORS

Discover different types of insulators at YONGGUANG, one of the leading insulators manufacturers, featuring porcelain electrical insulators, composite insulators, glass electrical insulators, disk-type insulators, composite pin insulators, shackle-type insulators, and stay-type insulators. Our diverse power line insulators cater to varied applications, ensuring optimal performance and reliability in power transmission systems.

Different Types of Power Line Insulators

Porcelain Electrical Insulator

Composite Insulator

Pin Insulator

Shackle Insulator

Stay Insulator

Advantages of Power Line Insulators from YONGGUANG

Electrical Safety

Transmission line insulators prevent the flow of electricity, reducing the risk of electrical shocks and ensuring the safe operation of electrical devices and systems. By blocking the path of electrical current, electrical insulators including disk insulator contribute significantly to protecting both people and equipment.

Mechanical Support

Insulators for sale like porcelain shackle insulator and stay insulator provide structural support for overhead wires and cables. They are designed to withstand mechanical stresses, such as wind, ice, and the weight of the conductors. This ensures the stability and longevity of power transmission infrastructure.

Corrosion Resistance

Many electrical insulator materials, such as ceramics and certain polymers, are resistant to corrosion. This is particularly advantageous in outdoor or harsh environments where exposure to moisture and other corrosive elements could compromise the performance and lifespan of electrical systems.

Types of Insulators in Substation

Porcelain Insulators

Suspension Insulators: The porcelain insulator is used to support overhead conductors in the air. These power line insulators consist of a series of porcelain discs connected in series by a metal link. Suspension insulators for sale are commonly used in high-voltage transmission lines.

Post Insulators: Designed to support bus bars or other equipment on a structure, post substation insulators have a single insulating unit and are mounted vertically on supporting structures.

Composite Insulators

Polymer or Silicone Rubber Insulators: Made from composite materials like fiberglass reinforced with epoxy or silicone rubber housing, the composite insulator for sale is lightweight and resistant to pollution. They are often used in polluted environments.

Glass Insulators

Disc Insulators: Glass electrical insulators used in substation are similar in design to the porcelain suspension insulator and is used in high-voltage transmission lines.

0 notes

Text

Liquid rubber covered double-ended double g-point vibrator rechargeable silicone soft female masturbation vibrator factory direct supply

View On WordPress

0 notes

Text

Shout out to my mechanic who saved me $400 by not buying the factory volkswagen tube and just using rubber piping that he silicon glued to the air intake system.

I think I'm like a top gear challenge for him whenever I bring in my sorry used car, and moths flying out of my wallet. He just laughs and goes yeah we'll figure it out with after market parts.

0 notes

Text

Mark Singer: The Pioneering Visionary Behind The Gorilla Glue Company

Glues, Adhesives, and Sealants are substances used to hold and attach surfaces. They can be used for Craft, DIY, Repairs, Construction, and other industrial purposes and needs. Whatever you need to fix, build, stick, create, bond, and seal – these sticky glues, adhesives, and sealants are the solution. These gummy and goey stuff are made of Silicones, Silane-Modified Polymers, Polyurethanes, Methacrylates, Cyanoacrylates, Epoxies, Butyl Rubber, or Elastomers.

Incredibly stronger glues, adhesives, and sealants are used mostly in the manufacturing innovation and industrial sectors as they can be very harmful during simple craft and repair work. Having the substance of higher strength fall on any bare bodily part can prove to be detrimental and needs to be addressed immediately. The versatility of these tacky and viscous substances is more sustainable in the amount of materials used to just get the job done. Different types and kinds of materials can be bonded and sealed by glues, adhesives, and sealants without the use of extra materials for additional support. Many companies, brands labels, and organizations make their patented sticky composite and market them, which would rake in huge profits if their quality is good and gets the job done as advertised.

Therefore in this article, we will be talking about one such company founded by Mark Singer in the manufacturing industry. An American woodworker found a type of glue that was Danish manufactured, being used in Indonesia. After asking the manufacturer for the glue to modify its composition a little, Mark bought and acquired the Northern American rights for the same. He went back to his country and built The Gorilla Glue Company in 1994, whose mission is – “to make products that deliver impressive results”.

About Mark Singer – Founder of The Gorilla Glue Company:

The pioneering and trailblazing visionary who founded The Gorilla Glue Company is Mark Singer. A woodworker who has been working with wood and its related tools and types of equipment is all too familiar with how the adhesive technology of glues, adhesives, and sealants work. Woodworking, designing, and making furniture was a tedious activity for Mark. He says – “Practice, patience, proper tools, good lighting, reading glasses, and technique are all really helpful.”

Between the late 1989s and early 1990s, Mark Singer traveled from America to Bandung, Indonesia to visit a furniture factory there. He found that the workers used a type of glue unknown to Mark, on Teak furniture. The glue was made in Germany, specifically Danish manufactured. Seeing how the market was rising and how in-demand the glue was with customers, Mark went back to his country with sample bottles of the same.

“Strong enough for the toughest jobs on planet Earth” – Tagline of The Gorilla Glue Company.

On arriving back home, he tested the glue on the furniture at his workshop. He found that this glue worked on not only Teak wood but also on metals, ceramics, plastics, stones, and much more. He immediately envisioned a product that is of high quality and a brand that people would love and find to be incredibly helpful. Therefore, he approached the Danish manufacturer of the glue and asked to modify its composition a little. After this, he bought and acquired the Northern American rights for the same and brought it to America. Here, Mark started his brand building and chose the brand logo, name, and products in 1994 and launched the business that same year.

About The Gorilla Glue Company:

The Gorilla Glue Company was founded by Mark Singer, in the year 1994. It is a manufacturing company that makes waterproof glues, adhesives, and sealants for a variety of purposes in a factory established in Cincinnati, Ohio, USA. Currently, the business is family-operated by the Ragland Family. Mark Singer sold The Gorilla Glue Company to the family in the year 1999 – after which the business growth took to the skies. Mark continued to focus on his woodworking and furniture-making career thereafter.

The company manages the patented brands of – Gorilla Glue, Gorilla Tape, O’Keeffe’s, and Lutz Tool. Later after the expansion of the company due to its immediate surge in high demand and prices, Gorilla Super Glue Impact-Tough Formula, Gorilla Construction Adhesive, Gorilla Wood Glue, and Gorilla Epoxy were the other brands created and included in the manufacturing line among many other premium products.

Vision Statement – “We believe in high-quality products and choose to only put the Gorilla logo on products that meet rigorous development standards.”

Building brands that people would love and manufacturing products that they would find to be incredibly helpful, the company believes that they do this for the people they care about – “The Gorilla Way”. The Gorilla Glue Company is an all-purpose adhesive substance used for many purposes, such as – Craftwork, DIY and Builders, Repairs and Construction, and Moving and Storage purposes.

The company is headed towards sustainability efforts with the vision to have future generations still using the brand’s products. A success story, this company is a proud member of the How2Recycle Program – a smarter labeling system that recycles for Americans and Canadians, operates in local areas, has store drop-off facilities, and compostable initiatives as well. Recognized as one of the top places to work for 13 continuous years, The Gorilla Glue Company is all set gearing up for future ventures and expanding its market with more innovative and creative, sticky products.

Visit More : https://thebusinessmagnate.com/mark-singer-the-pioneering-visionary-behind-the-gorilla-glue-company/

0 notes

Text

Best Rubber Hoses of Varieties at Affordable Price

Engineering departments can now get facilitated with a range of rubber hoses product consisting of premium quality at affordable price. The reputed company has for its consumers a wide range of rubber hoses used for various purposes. Rubber hoses these days are utilized to maximum capacity in the manufacturing area for reasons such as –

· Raw material abundance in the nature

· Flexibility in terms of utility of these products

Commonly used Rubber hoses in manufacturing sector

· Viton rubber hoses

· Silicon rubber hoses

· EPDM rubber hoses

· Neoprene rubber hoses

· Natural rubber hoses

Brief analysis of variety rubber hoses

Rubber sand Blasting Hoses

These hoses are basically used for high velocity works related to sands, racing, and cleaning stone glass and in other use of emery dust shots. Sometimes they are also used for bringing in the finished casting. These rubber hoses are basically smooth and containing a uniform lining with suitable rubber compound. Thickness cover is of suitable rubber compounds

Rubber Pneumatic Tool Hoses

When it comes to any kind of general construction works, roads, buildings, service stations etc, nothing can replace the utility of this kind of rubber hose. They are also extensively used in industries and tunneling too. This type of hoses has mainly double synthetic reinforcement. To make it further secure proofed, the rubber covers are totally free from any kind of blisters and prosperity.

Rubber Rock Drill Hoses

They qualify among the first preference in the area of drilling related work. Mostly found in open cast mines/quarries likewise iron ore, granite, quartz, lime stone etc. They basically have smooth resistant rubber inner linings with thick abrasions resistant rubber covers to handle thick bursting pressure

Rubber Cement Grouting Hoses

At construction sites, this rubber hoses are a great support for grouting of cements. These hoses are broad and non-porous free allowing air blisters and ensuring high amount of weather resistance cover.

Rubber Petrol & Diesel hoses

This hoses are used for dispensing petrol and diesel fuels. Hence one gets to see such rubber hoses in the petrol service stations. They are basically high grade textiles with two reinforcements that of copper wire and that of wire braids.

Rubber Air Hoses

Another commonly used rubber hose for general construction works, in factories, say in garages and steel mills and in many other places are rubber air hoses. They mainly have a very smooth inner lining that has reinforced synthetic yarn and thick rubber cover to mount the pressure exerted on this hose while on use.

Rubber Welding Hoses

These hoses are used for oxy acetylene welding and are highly suitable for usage in industries, steel mills, garages repair and others; the call for this hose comes loud. They have a smooth inner lining with reinforced synthetic yarn along with uniform non-porous cover. They can easily resist high bursting pressures.

Hence, if you require any such rubber hose immediate giving maximum tenacity along with budget friendly price; select a reliable company Sonu Hose that gives comfort with quality.

Contact us:

Call Now: +91-9311288288

G-mail: [email protected]

Visit our website: https://sonuhose.com

0 notes

Text

Upgrade Your Seals: A Guide to FEP Encapsulated O-Rings and Their Applications

In harsh environments where reliable sealing is needed, FEP encapsulated o rings are found to be widely used by engineers and designers for their excellent performances. These innovative rings have combined the strengths of FEP (fluorinated ethylene propylene) like chemical resistance with those of an elastomeric core such as its ability to create a sealable bond at the interface between two surfaces which are inherently not compatible in nature. Sealmax, a reputable company that offers high-performance sealing solutions, explores a guide to FEP Encapsulated O rings and applications in this blog post.

FEP (Fluorinated Ethylene Propylene): This is a thermoplastic material that possesses properties similar to those of PTFE.

Elastomeric Core: The major part of the O ring, usually made from flexible materials like FPM (fluorocarbon rubber) or VMQ (silicone), allowing for elasticity in order to achieve superior sealing.

Seamless FEP Coating: A super-thin protective layer enveloping the elastomeric core that makes it impermeable to corrosive agents and very high temperatures.

By means of this unique design, FEP encapsulated o rings outperform standard elastomeric O rings on difficult applications.

Applications of FEP Encapsulated O Rings: Thriving in Demanding Environments:

Chemical Processing & Petrochemical Industries:

Exceptional Chemical Resistance: The FEP layer gives a robust shield against hard chemicals, acids, solvents and fuels that are usual in processing factories and refineries. This guarantees consistent functioning and reduces chances of leakages thus protecting people as well as machines.

Food & Beverage Processing:

Food Safety & Contamination Prevention: These food safety compliant FEP encapsulated O rings are biocompatible and have great chemical resistance. They prevent food contamination hence maintaining product purity. Moreover, their smooth surface eases cleaning while minimizing bacterial buildup.

Pharmaceutical Production:

Cleanroom Compatibility & Sterilization: The cleanroom compatible FEP encapsulated o-rings can resist sterilization processes, which makes them suitable for sealing pharmaceutical production equipment. That way the manufacturing process is safe and pure.

Oil & Gas Industry:

High-Temperature Performance & Fluid Resistance: They suit oil refineries and drilling operations due to their ability to withstand high temperatures (up to 200°C depending on core material) as well as being resistant to oil and fuels. For instance, they minimize leaks because they have enhanced sealing performance, which is important for environmental protection as well as safety concerns.

Medical Devices:

Biocompatibility & Sterilization: Biocompatible nature and their ability to withstand sterilization are some of the reasons why specific FEP encapsulated O-rings are used. This makes them ideal for medical devices such as syringes, pumps among other equipment that require aseptic conditions.

Apart from these core applications, FEP encapsulated o-rings can be found in various other industries:

Aerospace Applications: Their broad temperature range, chemical resistance, and ability to handle various fluids make them suitable for demanding aerospace applications, ensuring safe and reliable operation in harsh environments.

Water & Wastewater Treatment: Due to the excellent chemical resistance and wide temperature range enabling them to work well in areas with harsh chemicals and fluctuating temperatures.

Considerations for Optimal Use

But factor in some things for better performance as FEP encapsulated O rings have several advantages:

Cost: When compared to standard O rings, the layer of FEP may mean that these cost a little bit more at first. Nevertheless, their long life and reduced maintenance usually offset this expenditure.

Abrasion Resistance: While it provides good chemical resistance, FEP may not be the best solution in highly abrasive environments. In such cases, you should consider alternative o-ring materials with better abrasion resistance.

Flexibility: They may have slightly less flexibility than elastomers because of the FEP coating.

The Takeaway: A Smart Investment for Demanding Applications

It is a giant step in sealing technology for FEP encapsulated O rings. Their superlative chemical resistance, wider temperature range and improved performance make them an invaluable asset to various industries. Understanding their properties, benefits and considerations will enable you to make an intelligent choice on which o-ring is perfect for your specific application.

Choosing the Right FEP Encapsulated O-Ring

FPE encapsulated o-ring selection involves many determinants:

Chemical Compatibility: It is therefore important to ensure that both the core material and the FEP layer can resist the specific chemicals encountered in your application. Look up the compatibility details from either datasheet or ask a sealing solutions expert.

Temperature Range: Determine a temperature rating suitable for an o-ring that matches your system’s operating conditions. Remember to take into account the lowest and highest temperatures at which your o-ring will work.

Pressure Requirements: Select a size and pressure rating of an o-ring, which would ensure ideal sealing characteristics. Reflect on pressure applied to an o-ring when it is used.

Fluid Compatibility: Take into account the nature of fluids such as oil, water among others whose contact with the rubber must not compromise both FEP layer and core material compatibility.

Sealmax: Your Trusted Partner for FEP Encapsulated O-Rings

At Sealmax, we know how important O-rings are in keeping things running smoothly. We have a wide selection of FEP encapsulated O-rings in different sizes, core materials and FEP thicknesses to suit your unique requirements. Our technical staff can guide you in selecting the best O-ring for your application so as to give optimum results and lasting service.

Contact Sealmax today about your encapsulated FEP O-Ring needs and see what it means to deal with a dependable supplier of sealing solutions.

Additional Considerations

Additional considerations on FEP-encapsulated O rings are outlined above as follows:

Replacement Compatibility: In most instances, FEP encapsulated o-rings can be substituted directly for standard rubber o-rings without altering the groove dimensions. However, ensure compatibility with your existing o-ring groove for maximum fit.

Reduced Elasticity: These rings may be slightly less elastic as a result of the FEP coating compared to other elastomeric materials. This translates to reduced ability to stretch and perhaps higher permanent deformation. If high levels of flexibility are crucial in your application, alternative materials for o-rings might work best.

These factors need to be deeply reflected upon and consult an expert in sealing solutions to make sure that FEP encapsulated O rings prove helpful in your operation by enhancing equipment performance and reducing downtime.

Conclusion: FEP Encapsulated O-Rings - A Smart Investment for Demanding Applications

FEP encapsulated O rings is an outstanding sealing technology step forward, which has presented a strong case for extreme operating conditions. They are also highly valued in many sectors because they have better performance characteristics such as superior chemical resistance to a wide range of temperatures. The information on attributes, benefits and considerations of using FEP encapsulated O-rings will enable you pick the best one prescribed for any given application.

If you need expert help or some good quality FEP encapsulated o-rings just talk to Sealmax now. We are committed to giving you the right sort of seals so that your equipment works perfectly and lasts long enough.

Resource: https://what-are-the-uses-of-ptfe-gasket.blogspot.com/2024/03/upgrade-your-seals-guide-to-fep.html

0 notes

Text

We are #professional #customization and #oem soft #PVC #rubber #silicone products #factory . We can offer #drawing , #design , #moldmaking , #sampling , and production #services . These products are commonly used in the soft PVC,rubber, silicone, garment #accessories , footwear, phone , #promotionalgifts items and so on. Such as: #pvclabel , pvc #keychain , pvc #patch , pvc #fridgemagnets , pvc #wristband , pvc #pendrive , pvc #cup #coaster , pvc bar #mat , pvc watch #strap , pvc #slippers , pvc #sole , pvc #zipperpuller , pvc #promoton items; silicone label, silicone #badge , silicone #mobile case, silicone #usb #case , silicone wristband, silicone zipper puller, etc.

Advantage(place order from us):

1.Factory direct supply,cheaper price

2.OEM Support, ODM available

3.3-5 Days fast supply

4.Sample test available

5.different colors and length can customized

6.Box logo can do as requested

For more details, please contact Debby:

[email protected]

#Soft pvc#3D#soft pvc cup coaster#customized#OEM#Custom Soft PVC fridge magnets#rubber zipper puller#pvc zipper puller#pvc patch Heat-Transfer#pvc label heat transfer#soft pvc keychain double side#soft pvc usb case#soft 3d pvc pen drive#OEM soft 3d pvc usb flash drive#double side keychain#soft pvc double side keychain#double side pvc keychain#pvc figure#3D pvc keychain#silicone tag#silicone badge#silicone label#rubber keychain#pvc Morale Patch#Pvc Velcro Patch#velcro pvcpatch#soft keyring#pvc key chain#soft pvc keychain

1 note

·

View note