Text

How to Make Your Rubber Hose Business Profitable

Are you looking to maximize profits in your rubber hose business? As a leading manufacturer and supplier of rubber hoses, we understand the importance of running a profitable business in this competitive industry. In this article, we will share expert tips and strategies on how to make your rubber hose business more profitable.

Understanding Your Target Market

One of the key steps to making your rubber hose business profitable is understanding your target market. Who are your customers? What are their needs and preferences? By conducting market research and identifying your target audience, you can tailor your products and services to meet their specific requirements, thus increasing customer satisfaction and loyalty.

Offering High-Quality Products

In the rubber hose industry, quality is paramount. Customers expect durable, reliable, and high-performance products that meet their needs. By investing in high-quality materials and manufacturing processes, you can produce superior rubber hoses that outperform the competition. Remember, satisfied customers are likely to become repeat customers and recommend your products to others.

Streamlining Operations and Cutting Costs

To maximize profits in your rubber hose business, it's essential to streamline operations and cut unnecessary costs. Look for ways to improve efficiency in production, distribution, and inventory management. Consider outsourcing non-core functions to reduce overhead expenses. By optimizing your processes and reducing wastage, you can enhance profitability without compromising on quality.

Implementing Effective Marketing Strategies

Effective marketing is crucial for attracting new customers and retaining existing ones. Invest in online and offline marketing channels to promote your rubber hose products. Develop a strong brand identity and communicate the unique benefits of your products to differentiate yourself from competitors. Utilize social media, email marketing, and targeted advertising to reach your target audience and drive sales.

Building Strong Relationships with Suppliers and Distributors

A successful rubber hose business relies on strong relationships with suppliers and distributors. Negotiate favorable terms and pricing with reliable suppliers to secure a steady supply of high-quality raw materials. Work closely with distributors to expand your market reach and ensure timely delivery of products to customers. By fostering mutually beneficial partnerships, you can strengthen your supply chain and enhance profitability.

Conclusion

In conclusion, running a profitable rubber hose business requires a combination of strategic planning, quality products, efficient operations, effective marketing, and strong partnerships. By implementing the tips and strategies outlined in this article, you can increase revenue, reduce costs, and achieve long-term success in the competitive rubber hose industry. Remember, success does not happen overnight – it takes dedication, hard work, and a commitment to delivering value to your customers. Make your rubber hose business profitable today by following these expert recommendations.

Contact Us

Call Now: +91-9311288288

G-mail: [email protected]

Visit our website: https://sonuhose.com

#hydraulic pump#hydraulic hoses#hydraulic cylinder#hydraulic gear pump#rubber hoses manufacturer#rubber hose

0 notes

Text

Best Rubber Hoses of Varieties at Affordable Price

Engineering departments can now get facilitated with a range of rubber hoses product consisting of premium quality at affordable price. The reputed company has for its consumers a wide range of rubber hoses used for various purposes. Rubber hoses these days are utilized to maximum capacity in the manufacturing area for reasons such as –

· Raw material abundance in the nature

· Flexibility in terms of utility of these products

Commonly used Rubber hoses in manufacturing sector

· Viton rubber hoses

· Silicon rubber hoses

· EPDM rubber hoses

· Neoprene rubber hoses

· Natural rubber hoses

Brief analysis of variety rubber hoses

Rubber sand Blasting Hoses

These hoses are basically used for high velocity works related to sands, racing, and cleaning stone glass and in other use of emery dust shots. Sometimes they are also used for bringing in the finished casting. These rubber hoses are basically smooth and containing a uniform lining with suitable rubber compound. Thickness cover is of suitable rubber compounds

Rubber Pneumatic Tool Hoses

When it comes to any kind of general construction works, roads, buildings, service stations etc, nothing can replace the utility of this kind of rubber hose. They are also extensively used in industries and tunneling too. This type of hoses has mainly double synthetic reinforcement. To make it further secure proofed, the rubber covers are totally free from any kind of blisters and prosperity.

Rubber Rock Drill Hoses

They qualify among the first preference in the area of drilling related work. Mostly found in open cast mines/quarries likewise iron ore, granite, quartz, lime stone etc. They basically have smooth resistant rubber inner linings with thick abrasions resistant rubber covers to handle thick bursting pressure

Rubber Cement Grouting Hoses

At construction sites, this rubber hoses are a great support for grouting of cements. These hoses are broad and non-porous free allowing air blisters and ensuring high amount of weather resistance cover.

Rubber Petrol & Diesel hoses

This hoses are used for dispensing petrol and diesel fuels. Hence one gets to see such rubber hoses in the petrol service stations. They are basically high grade textiles with two reinforcements that of copper wire and that of wire braids.

Rubber Air Hoses

Another commonly used rubber hose for general construction works, in factories, say in garages and steel mills and in many other places are rubber air hoses. They mainly have a very smooth inner lining that has reinforced synthetic yarn and thick rubber cover to mount the pressure exerted on this hose while on use.

Rubber Welding Hoses

These hoses are used for oxy acetylene welding and are highly suitable for usage in industries, steel mills, garages repair and others; the call for this hose comes loud. They have a smooth inner lining with reinforced synthetic yarn along with uniform non-porous cover. They can easily resist high bursting pressures.

Hence, if you require any such rubber hose immediate giving maximum tenacity along with budget friendly price; select a reliable company Sonu Hose that gives comfort with quality.

Contact us:

Call Now: +91-9311288288

G-mail: [email protected]

Visit our website: https://sonuhose.com

0 notes

Text

Applications and Working process of Control Valve

A valve is a device that regulates the fluid flow as well as the pressure within a system or process. Unlike on-off valves, a control valve is used to regulate the fluid flow by stopping and starting the fluid flow as per the direction is given by the controller.

Control Valve

Control valves consist of three main parts: the valve, the actuator, and the controller. Various components of the Actuator include rain cap, eye bolt, diaphragm, spring, actuator stem, diaphragm case, scale plate, stem connector, and yoke.

The components of body part include packing flange, packing follower, yoke claim nut, gland packing, valve stem, bonnet, stud bolt and nut, gasket, guide ring, guide bushing, valve plug, seat ring, valve body, trim set, and positioner.

Though the primary purpose of a control valve is to regulate the fluid flow, there are two main forms of action i.e. the sliding stem and the rotary action. The most common type of control valves in the sliding stem include globe valve, angle body valve, and angle seat piston valve while the rotary action includes a butterfly valve and ball valve.

Why Control Valves are Used?

Control valves are used for various purposes in the industrial, engineering, manufacturing, and scientific communities. The primary purpose of a control valve is to regulate the rate of the fluid flow by varying the size of the flow passage. Control valves are most commonly used for consequential control of process quantities including pressure, temperature, and the liquid level.

How do Control Valves work?

With the help of opening and closing internal passages, control valves regulate the fluid flow. Control valves form a control loop which is then used by a controller to send signals. Control valves respond to these signals and adjust the internal openings accordingly.

Control valves use the actuator to move the valve stem. Usually, it is either air (pneumatically) or electrically driven. The pressure between the inlet and outlet decides the rate of flow through the valve.

In order to reduce the fluid flow, the valve is closed, which results in more back-pressure and increases the difference between the inlet and outlet pressures.

Control valves help in controlling the fluid flow and are used in various industries including pipeline, oil & gas, food & beverage, the biopharma industry, and marine industry.

Sonu Hose is the top Control Valve suppliers and they are also the leading control valve suppliers in India. All their products are tested for resilient durability to provide the best industrial valve to their customers.

Contact Us

Call now: +91-9311288288

G-mail: [email protected]

Visit our Site: https://sonuhose.com

0 notes

Text

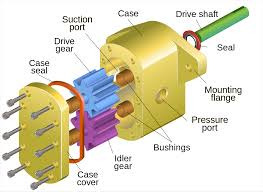

What is Gear Pump and it's Uses?

There are various types of pumps available in the market. Basically, they are categorised into two main groups.

(i) Centrifugal Pumps

(ii) Positive Displacement Pumps. Internal gear pump is a type of PDP (Positive Displacement Pump).

Knowing the uses of Gear Pumps:

The basic functionality of a gear pump is to use the meshing of gears to pump fluid by displacement. A gear pump is the most common type of pump which is used for hydraulic fluid power applications. It is also used widely in chemical installations to pump high viscosity fluids (which is the main functionality of a PDP).

Gear pumps are further categorised into two main variations:

• External gear pump — which use two external spur gears

• Internal gear pumps — which use an external and an internal spur gears

Gear pumps are able to pump a constant amount of fluid in each revolution. Some are even designed to function as either a motor or a basic pump.

A short brief on internal Gear Pump

Internal gear pump is exceptionally versatile. This kind of pump is often used on thin liquids like solvents and fuel oil, however it is also good for thick liquids such as asphalt, chocolate, and adhesives. In addition to its wide viscosity range, the pump has a wide temperature handling capability. This is possible due to the single point of end clearance (the distance between the ends of the rotor gear teeth and the head of the pump). The clearance can be adjusted to accommodate high temperature and maximise efficiency for handling high viscosity liquids.

The internal gear pump is self-priming, non-pulsing and can even run dry for short periods. They are also bi-rotational, which means that the same pump can be used for both loading and unloading vessels. Because internal gear pumps have only two moving parts, they are reliable, simple to operate, and easy to maintain.

How they work?

• Liquid enters through the suction port between the rotor (large exterior gear) and idler (small interior gear) teeth.

• The crescent shape divides the liquid and acts as a seal between the suction and discharge ports.

• Intermeshing gears of the idler and rotor form locked pockets that assure volume control.

• Rotor and idler teeth mesh completely to form a seal equidistant from the discharge and suction ports.

If your business is based on terminal unloading, marine, chemical, petrochemical, food and general industries you can surely choose gear pumps as they work the best in these fields. Contact Us today.

#hydraulic hoses#hydraulic pump#hydraulic cylinder#hydraulic gear pump#gear pump#gear pump manufacturer

0 notes

Text

Uses, Application & Components of Hydraulic Equipment

What is Hydraulic Equipment?

Hydraulic equipment uses pressurized fluid to power machinery and tools. These machines are widespread across industries due to their ability to generate high forces and precise control. Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. Here’s a breakdown of hydraulic equipment and its uses:

How Does it Works:

A hydraulic system relies on a pump to propel hydraulic fluid through hoses and tubes.

This fluid gets pressurized based on resistance in the system.

The fluid is controlled by valves which direct the flow and pressure.

Finally, the pressurized fluid reaches actuators (like cylinders or motors) which convert the hydraulic energy into mechanical work. This allows for movement and force exertion in various machinery.

Applications of Hydraulic Equipment:

Hydraulic equipment is used in a vast range of applications, including:

Construction machinery: Backhoes, excavators, bulldozers, and cranes all use hydraulics to power their actuators for digging, lifting, and maneuvering.

Manufacturing: Hydraulic presses are used for metal forming, shearing, and assembly line operation.

Agriculture: Tractors and other farm equipment utilize hydraulics to operate implements and attachments.

Transportation: Forklifts, dump trucks, and some airplanes use hydraulics for lifting, tilting, and braking.

Other applications: Hydraulic tools like wrenches, jacks, and cutters are used in various industries for repair and maintenance tasks.

Overall, Hydraulic Equipment provides a powerful and versatile way to generate controlled force and motion in many machinery and tool applications.

5 Major Application Of Hydraulic Equipment:

If you wonder whether you could use a hydraulic cylinder in your business on not, you are on the right page. The following are five major applications of hydraulic cylinders.

1. Food Industry:

If your business falls in the food industry, you might need a hydraulic pump to power your equipment. You need the cylinder to power forklifts to transport raw materials and end products from one place to another.

Some conveyor systems source power from hydraulic cylinders to process, package, and position food products. However, you need to use a powerful hydraulic cylinder, and thus you should work closely with a professional to help you choose the right one.

Hydraulic motors provide consistent torque for critical equipment in the food and beverage preparation processing procedures, such as shaping, cutting, separating, ingredients transfer, mixing, and dicing.

2. Construction Projects

A construction site is usually full of different tools and equipment that use hydraulic systems. For instance, a hydraulic cylinder is used to power forklifts, bulldozers, and loaders to lift and push loads.

Excavators also use hydraulic cylinders to control the movement of the bucket and boom. This equipment uses hydraulic fluid and motors to move the cylinder accordingly. Therefore, if your construction company offers excavation services, you need equipment with a powerful and reliable hydraulic cylinder.

Besides, hydraulic cylinders and pumps are used in brick molding machines and concrete pumps that transfer liquid concrete to a specific site. Other construction tools and equipment that utilize hydraulic cylinders include trenchers, scissors, compactors, augers, and concrete busters.

3. Metal Fabrication

Hydraulic presses that contain hydraulic cylinders are useful in the metal fabrication industry. The cylinders exert force on metal to cut, bend, drill, or assemble pieces. Examples of hydraulic-powered machines in metalworking are grinders, lathes, honing machines, planers, gears, and broaches.

Since metal fabrication involves creating complex structures, you need robust hydraulic cylinders to facilitate the processes.

4. Agricultural Processes

In the agriculture sector, machines powered by hydraulic cylinders are used extensively. Examples are tractors, loaders, spraying equipment, skid steers, baler, and heavy machines for planting, weeding, and harvesting.

You need these hydraulic-powered machines for agricultural applications whether you plant crops or rear livestock. Hydraulic cylinders are also used in attachments of some equipment such as wood splitters.

5. Waste Management Industry

Professionals in the waste management sector use different hydraulic powered equipment and systems such as lifters, loaders, and dumpers. Hydraulic cylinders provide adequate torque to control these machines. For example, they can pull down a garbage truck and transport it to the appropriate site.

Trash compactors also use hydraulic cylinders and motors to compress waste in the truck to create space for more. This way, you can remove a lot of waste at a go, reducing the need to take several trips and thus save fuel.

Hydraulic cylinders are also used in street sweepers to rotate the brushes. They are also installed in sweepers that use water to provide high-pressure mists to clean roads.

Moreover, food packaging equipment uses hydraulic cylinders to achieve precision and keep food fresh. You can also use advanced hydraulic systems if your business deals with packaging heavy multiple products in a single package. These uses show that the food industry significantly depends on hydraulic cylinders.

Hydraulic cylinders provide mechanical force used to power equipment for several applications. Our company sells and services all types of hydraulic cylinders. Contact us today for your hydraulic needs.

0 notes

Text

FOUR THINGS YOU NEED TO TELL YOUR HYDRAULIC EQUIPMENT SUPPLIER

For beginners, getting your head around hydraulics can be confusing. Hydraulics have a vast range of applications in our daily life; industries that use hydraulics include construction, automobile, mining and defense. Hydraulics is an area of civil engineering that deals with fluids and various applications related to it.

Below, we’ve put together four things you need to tell your hydraulic equipment supplier.

WHAT IS HYDRAULICS?

A hydraulic system uses compressed fluid to transfer force applied at one point to another point. A hydraulic machine gains controlled motion through the use of a transmitted fluid. There are various components that make up a basic hydraulic system: reservoir, pump, valves, fluid, motor, hose, filter and cylinder.

FOUR THINGS TO TELL YOUR HYDRAULIC EQUIPMENT SUPPLIER

When sourcing a piece of hydraulic equipment, it’s important to tell your supplier a few things about the environment the machine will be operating in.

MINIMUM & MAXIMUM AMBIENT TEMPERATURE

In order to determine the correct hydraulic fluid type, viscosity grade and viscosity index, you’ll need to tell your supplier the minimum and maximum ambient temperature. This also helps to determine whether tank heating is required at minimum ambient temperature, or whether a cooling capacity is required at maximum ambient temperature.

HUMIDITY CONDITIONS

If the machine is operating in an environment where humidity levels are high (for example, marine or tropical environments), a moisture absorbing tank breather may be required. Polymeric filters may also be required to limit water content.

DUST LEVELS

Environments with high dirt and dust levels may require contamination exclusion and control. From a sealed and pressurised reservoir, or a vented reservoir with a bladder (creating a barrier between the air in the tank and the oil), to a cylinder-rod wiper seal arrangement, there are plenty of ways to control airborne contamination.

SPECIAL CONDITIONS

You should also inform your supplier of any special conditions. For example, if the location is hazardous, there is a high pollution spill risk or presence of ignition source (fire risk).

At Sonu Hose Hydraulics, we’re experts in the design, manufacture and installation of quality hydraulic systems. Based in Hampshire, we’re proud to be one of the leading hydraulics manufacturers across Portsmouth, Southampton and Fareham. For more information, visit our website

CONTACT US:

Call Now: +91 9311288288

Website: https://sonuhose.com

G-mail: [email protected]

1 note

·

View note