#materialSciences

Text

International Research Excellence Best Paper Awards

Website link-https://bestpaperawards.com/

8 notes

·

View notes

Photo

Vapour separator.. . @bhakti_may_enterprises I.pictures —————————————————————————————— You want to see more interesting videos and pictures about engineering like this? —————————————————————————————— Check out 🔜 @bhakti_may_enterprises Admin @mj_mahya_ ———————————————————DM 👉for Engineering @engineering_evolution FOR 👉 Nature @mj_nature_home For 👉 Quote @lovemjmahya ——————————— Follow @bhakti_may_enterprises and you will see a new post about your passion. We are looking forward to see you! —————————————————————————————— All rights and credits reserved to the respective owner(s). If you are the copyright owner of this video/ picture and would not like to have this content featured on this channel, direct message us to have us remove it. —————————————————————————————— #mjmahya #worldofengineering #machining #gear #metal #metalwork #automotiveengineering #aerospace #aerospaceengineering #mechanicalengineering #materialscience #metallurgy #fabrication #manufacturing #engineering_memes #engineeringlovers #engineeringlife #engineeringblog #mjsalenservice #engineer #engineering #engineeringbasics #engineeringmemes #engineeringstudents #technologynews (at Pune, Maharashtra) https://www.instagram.com/p/CfXvhByvveM/?igshid=NGJjMDIxMWI=

#mjmahya#worldofengineering#machining#gear#metal#metalwork#automotiveengineering#aerospace#aerospaceengineering#mechanicalengineering#materialscience#metallurgy#fabrication#manufacturing#engineering_memes#engineeringlovers#engineeringlife#engineeringblog#mjsalenservice#engineer#engineering#engineeringbasics#engineeringmemes#engineeringstudents#technologynews

3 notes

·

View notes

Text

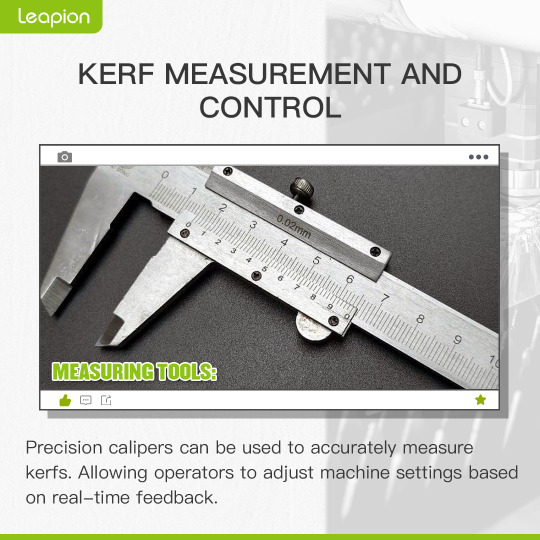

Measuring Tools:

Precision calipers can be used to accurately measure kerfs. Allowing operators to adjust machine settings based on real-time feedback.

#Measuring Tools:#LaserCutting#Manufacturing#KerfWidth#PrecisionEngineering#CuttingEdge#MaterialScience#LaserTechnology#EfficiencyMatters#TechExplained#LeapionTech

0 notes

Text

Abrasion Resistant Coatings Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Abrasion Resistant Coatings market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Abrasion Resistant Coatings market showcased a significant presence, boasting a valuation of US$ 8.2 billion. This underscores the substantial demand for Abrasion Resistant Coatings technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abrasion-resistant-coatings-market/

Projected Growth: Projections suggest that the Abrasion Resistant Coatings market will continue its upward trajectory, with a projected value of US$ 11.57 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 7.4 %, reflecting a steady and robust growth rate for the Abrasion Resistant Coatings market over the coming years.

Technology Adoption:

In the abrasion-resistant coatings market, technology adoption plays a pivotal role in enhancing product performance and expanding application possibilities. As industries demand coatings with superior durability and wear resistance, manufacturers are leveraging advanced materials science and nanotechnology to develop innovative solutions. These technologies enable the creation of coatings with enhanced hardness, flexibility, and adhesion properties, catering to diverse industrial requirements.

Application Diversity:

The abrasion-resistant coatings market exhibits remarkable application diversity across various sectors such as automotive, aerospace, marine, construction, and industrial machinery. Coatings are applied to substrates ranging from metals and plastics to composites, providing protection against abrasion, corrosion, and chemical exposure. Additionally, advancements in coating formulations have facilitated their use in specialized applications like high-temperature environments, heavy machinery components, and critical infrastructure, further expanding the market's reach.

Consumer Preferences:

Consumer preferences in the abrasion-resistant coatings market are influenced by several factors, including performance, cost-effectiveness, and environmental sustainability. End-users prioritize coatings that offer long-term durability, low maintenance requirements, and compatibility with different substrates. Additionally, there's a growing demand for eco-friendly coatings that minimize environmental impact without compromising performance. Manufacturers are responding by developing water-based formulations, reducing volatile organic compound (VOC) emissions, and incorporating renewable materials into their products to align with consumer preferences and regulatory standards.

Technological Advancements:

Technological advancements drive continuous innovation in the abrasion-resistant coatings market, leading to the development of next-generation materials and application techniques. Nanostructured coatings, such as graphene and ceramic nanoparticles, enhance hardness and scratch resistance, improving overall durability. Furthermore, advancements in application methods, such as spray coating, electroplating, and powder coating, enable precise and uniform deposition of coatings on complex geometries and large surfaces, maximizing efficiency and performance.

Market Competition:

The abrasion-resistant coatings market is characterized by intense competition among key players and a multitude of regional and niche manufacturers. Market players vie for market share by differentiating their products through technological innovation, product performance, and value-added services. Strategic partnerships, mergers, and acquisitions are common strategies employed to expand market presence, enhance product portfolios, and leverage synergies. Additionally, price competitiveness and supply chain efficiency play significant roles in determining market dynamics and company success.

Environmental Considerations:

Environmental considerations are increasingly shaping the abrasion-resistant coatings market, driven by regulatory pressures, sustainability goals, and growing awareness of environmental issues. Manufacturers are adopting eco-friendly formulations and manufacturing processes to minimize carbon footprint and reduce waste generation. Moreover, recyclability and end-of-life considerations are gaining importance, prompting the development of coatings that can be easily removed, recycled, or disposed of without adverse environmental impact. Sustainable sourcing of raw materials and the use of renewable resources further contribute to the industry's efforts towards environmental responsibility and stewardship.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

AkzoNobel N.V.

PPG Industries, Inc.

Sherwin-Williams Company

Hempel A/S

Jotun A/S

RPM International Inc.

Axalta Coating Systems Ltd.

Tnemec Company, Inc.

BASF SE

Sika AG

The Dow Chemical Company

Wacker Chemie AG

Saint-Gobain S.A.

Evonik Industries AG

3M Company

The research report provides a comprehensive analysis of the Abrasion Resistant Coatings market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abrasion-resistant-coatings-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

#CoatingTechnology#IndustrialCoatings#InfrastructureDevelopment#GlobalMarketTrends#MaterialScience#AdvancedManufacturing

0 notes

Text

Find more about Ansh Koyal Industries' amazing glass fiber properties! 🌟 Our products redefine innovation in every application, from strength to versatility. 💪🔬

Contact us:

🌐:https://anshkoyalindustries.in

📞:+91-9582791612

📍 : Factory No. 1953, Basement, DSIDC Industrial Area, Delhi, 110040

.

.

.

.

.

#AnshKoyalIndustries#GlassFiber#Innovation#Strength#Versatility#AdvancedMaterials#Engineering#Manufacturing#Quality#Durability#Performance#IndustryLeaders#FiberTechnology#MaterialScience#InnovativeDesign#ConstructionMaterials#CompositeMaterials#FutureTech#Sustainability#IndustrialSolutions#EngineeringExcellence#TechInnovation#ProductDevelopment#HighPerformance#DurableDesign#Efficiency#PrecisionEngineering#Reliability#AnshKoyal

1 note

·

View note

Text

Metal Stamping Market: Industry Insights, Growth Drivers, and Competitive Landscape Analysis

The global metal stamping market size is expected to reach USD 316.72 billion by 2030, registering a CAGR of 4.2% over the forecast period, according to a new report by Grand View Research, Inc. The increasing production of automobiles is anticipated to drive the demand for metal stamping as it is used in the manufacturing of car body panels, transmission components, and interior and exterior structural components. Automobile consumers are shifting their focus towards lightweight vehicles on account of rising concerns about environmental pollution. According to LMC Automotive, U.S. light vehicles sales reached around 14.5 million in 2020 and are expected to reach nearly 15.8 million by 2022. The growing demand for lightweight vehicles is encouraging auto component manufacturers to increase their production capacities and engage in new product developments.

Metal Stamping Market Report Highlights

Based on process, the blanking segment is anticipated to progress at a significant CAGR over the forecast period, owing to the increasing demand from the automotive industry on account of its precise and superior stamping ability.

The bending segment accounted for a revenue share of over 16.0% in 2022. Products manufactured using this process ensure stability and durability, thus it is mostly used in auto components.

Based on application, consumer electronics is projected to be the fastest-growing segment over the forecast period. The growth is attributed to the increasing utilization of lightweight metal components to improve the durability of electronics.

Industrial machinery held the second-largest revenue share of the global market in 2023. The segment growth is attributable to the rising demand for machinery and automation to improve output efficiency.

Asia Pacific held the largest revenue share of more than 36.0% in 2023 owing to increasing demand for cars and consumer electronics in the region

For More Details or Sample Copy please visit link @: Metal Stamping Market Report

This, in turn, is anticipated to augment market growth over the coming years. Major automobile manufacturers that have in-house component manufacturing facilities are expanding their production capacities to meet the growing demand for automobiles. Moreover, the telecommunications industry is also projected to witness lucrative demand for stamped products owing to the growing investments in 5G technology. For instance, in November 2020, FAIST Precision Suzhou announced its investment in the installation of a new die casting machine, called the FRECH GDK3200T, which will be used to run 5G projects for mass production. In the Asia Pacific, increasing demand for consumer electronics, such as mobile phones, computers, laptops, and headphones, is likely to boost the demand for metal stamping as it is used in manufacturing metal frames, such as metal headbands, which are used in headphones.

Change in consumer preferences towards enhanced audio experience along with a rapidly growing music industry, and advancement in VR technology are the major factors that are expected to drive the demand for headphones. This, in turn, is likely to propel market growth over the coming years. The market is highly competitive with the presence of local as well as global players including Alcoa Corp., Lindy Manufacturing Co., Tool & Manufacturing Company, and D&H Industries. These companies are focusing on long-term agreements, capacity expansions, and mergers and acquisitions to meet the growing product demand from potential customers. For instance, in October 2021, Shiloh Industries completed the acquisition of two stamping plants fromBenteler for the automotive business. These plants are equipped with modern precision laser cutting and hot-formed steel stamping products for the production of chassis components.

#MetalStamping#Manufacturing#MetalsIndustry#IndustrialProduction#Automotive#Aerospace#Engineering#MarketAnalysis#SupplyChain#MaterialScience#TechnologyTrends#GlobalMarket#Innovation#Sustainability#CompetitionAnalysis

0 notes

Text

Unlocking the Potential of UNS S32750 Super Duplex 2507 Sheets: A Comprehensive Guide

In the realm of modern engineering, where precision and durability are paramount, materials play a crucial role in determining the success of a project. Among the plethora of options available, one material stands out for its exceptional properties – UNS S32750 Super Duplex 2507 Sheets. Renowned for their resilience, corrosion resistance, and versatility, these sheets have become indispensable across various industries, from oil and gas to chemical processing and beyond.

Understanding UNS S32750 Super Duplex 2507 Sheets

UNS S32750, also known as Super Duplex 2507, is a super duplex stainless steel that offers a unique combination of properties. It derives its name from the dual-phase microstructure consisting of austenite and ferrite, which contributes to its exceptional strength and corrosion resistance. This grade of stainless steel contains elevated levels of chromium, molybdenum, and nitrogen, further enhancing its performance in challenging environments.

The Advantages of Grade S32750 Sheets

Corrosion Resistance: One of the most notable advantages of UNS S32750 sheets is their outstanding resistance to corrosion. They demonstrate excellent resistance to chloride-induced stress corrosion cracking, making them ideal for use in marine environments, offshore oil rigs, and chemical processing plants.

High Strength: With a higher tensile and yield strength compared to conventional austenitic stainless steels, Super Duplex 2507 sheets offer superior structural integrity, making them suitable for demanding applications where strength is critical.

Versatility: Whether it's in the form of sheets, plates, or coils, UNS S32750 stainless steel offers versatility in fabrication, allowing for the creation of custom components tailored to specific project requirements.

Applications Across Industries

UNS S32750 Super Duplex 2507 sheets find widespread applications across diverse industries:

Oil and Gas: From subsea pipelines to offshore platforms, these sheets are integral to the construction of equipment subjected to harsh operating conditions.

Chemical Processing: Super Duplex 2507 sheets excel in environments containing corrosive chemicals, providing long-term reliability for equipment such as reactors, heat exchangers, and storage tanks.

Desalination: With the growing demand for fresh water, the corrosion resistance of UNS S32750 sheets makes them a preferred choice for desalination plants, where seawater is converted into potable water.

Calico Metal: Your Trusted Partner in Stainless Steel Solutions

At Calico Metal, we understand the significance of sourcing high-quality materials for your projects. As a leading supplier of stainless steel products, including UNS S32750 Super Duplex 2507 sheets, we are committed to delivering excellence in both product quality and customer service.

With a focus on reliability, integrity, and innovation, Calico Metal has earned a reputation for being a trusted partner across industries. Our extensive inventory, coupled with stringent quality control measures, ensures that you receive premium-grade materials that meet your exact specifications.

Conclusion

In the realm of engineering excellence, the choice of materials can make all the difference. UNS S32750 Super Duplex 2507 sheets stand as a testament to the remarkable capabilities of stainless steel in meeting the most demanding requirements of modern industry. With their exceptional properties and versatile applications, these sheets continue to redefine the standards of performance and reliability.

When it comes to sourcing premium-grade stainless steel products, look no further than Calico Metal. With our unwavering commitment to quality and customer satisfaction, we are your trusted partner in unlocking the potential of stainless steel for your next project.

#UNS32750#SuperDuplex2507#StainlessSteelSheets#GradeS32750#CorrosionResistance#EngineeringMaterials#OilandGasIndustry#ChemicalProcessing#Desalination#CalicoMetal#MaterialScience#Fabrication#IndustrialApplications#EngineeringExcellence#QualityControl

0 notes

Text

0 notes

Text

High-quality Nickel Strips, meeting ASTM B161/B725 standards, are essential in various industries for their corrosion resistance and mechanical properties. Manufactured by Technolloy Inc., these Nickel 201 Strips find applications in pumps, valves, and control equipment for oil and gas extraction. With versatile features, they're valued for maintaining product purity in synthetic fibers and food processing. Explore their use in chemical and electronics industries due to their resistance to acids and alkalis. #NickelStrips #TechnolloyInc #IndustrialMaterials

Specifications for Nickel 201 and Nickel 200:

Nickel 201:

Ni%: Minimum 99

Mn%: Maximum 0.35

Fe%: Maximum 0.4

Si%: Maximum 0.35

Cu%: Maximum 0.25

C%: Maximum 0.02

S%: Maximum 0.01

Nickel 200:

Ni%: Minimum 99.2

Mn%: Maximum 0.35

Fe%: Maximum 0.4

Si%: Maximum 0.35

Cu%: Maximum 0.25

C%: Maximum 0.15

S%: Maximum 0.01

These specifications highlight the composition of each alloy, showcasing the minimum and maximum percentages of various elements. These details are crucial for ensuring the desired properties and performance of Nickel 201 and Nickel 200 in different applications.

For more Information

Visit website: https://www.technolloy.com/nickel-strips-manufacturer-exporter.html

Email: [email protected]

Contact: (022) 49617682

#NickelStrips#Nickel201#Nickel200#AlloySpecifications#MaterialScience#IndustrialMaterials#Manufacturing#Metallurgy#TechnolloyInc#ASTMStandards#CorrosionResistance#MechanicalProperties#NickelAlloys#EngineeringMaterials#QualityControl#MetalSpecifications

0 notes

Text

Continuum Theories in Solid Earth Physics, Elsevier Science Ltd (1 February 1986)

DM for Order sarasbooksonline.com

Contact : +91-9958491228

#reading#readinglist#Physics#MaterialScience#Science#Technology#bookshelfies#worldwide#exclusive#sarasbooksonline

0 notes

Text

International Research Excellence Best Paper Awards

Website - https://bestpaperawards.com/

Nomination Link - https://x-i.me/bpanom12

2 notes

·

View notes

Text

Comparing Calcium Carbonate to Other Fillers in Talc Powder Production

Arawali Supply Chain Solutions breaks down the superiority of calcium carbonate in talc powder production. Delve into the comparison and make an informed choice for your industry.

#CalciumCarbonate#TalcPowderProduction#ArawaliSupplyChain#FillersComparison#IndustryInsights#MaterialScience#ManufacturingSolutions

0 notes

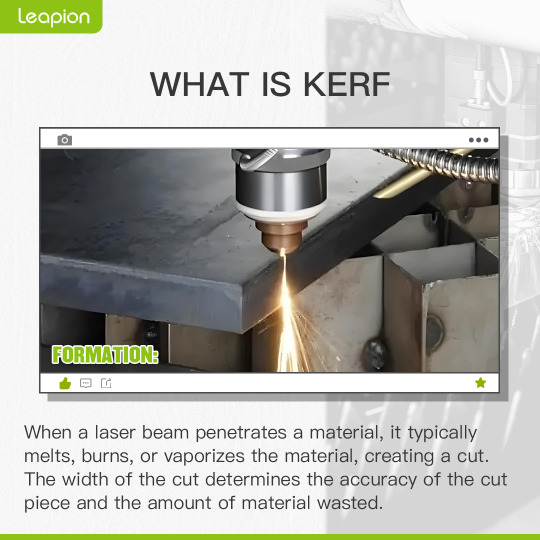

Text

What is Kerf? Let's Break it Down! 🔍 The kerf is the width of material removed by the laser beam during the cutting process. Essentially, it's the cutting width and can vary depending on the operating parameters. When a laser beam penetrates a material, it typically melts, burns, or vaporizes it, creating a cut. The width of this cut determines the accuracy of the cut piece and the amount of material wasted. Understanding kerf is crucial for precision and efficiency in your projects! Got questions? Drop them in the comments! 💬👇 🌐 Learn more: www.leapion.com 📧 Contact us: [email protected]

#LaserCutting#Manufacturing#KerfWidth#PrecisionEngineering#CuttingEdge#MaterialScience#LaserTechnology#EfficiencyMatters#TechExplained#LeapionTech

0 notes

Text

The report "Industrial Wax Market by Type (Fossil-based wax, Synthetic wax, Bio-Based wax), Application(Candles, Packaging, Coatings & Polishes, Hot-melt Adhesives, Tires & Rubber, Cosmetics & Personal Care, Food), and Region - Global Forecast to 2025", The Industrial wax market was USD 7.3 billion in 2020 and is projected to reach USD 8.9 billion by 2025, at a CAGR of 4.0 % from 2020. The growing market for various application industry such as cosmetics and personal care, tire and rubber and candles is expected to drive the demand for industrial wax market. The demand for bio-based wax in food, packaging, cosmetics & personal care, and other applications is growing in developed region such as North America and Europe due to environmental regulations. Moreover, growing population, the GDP growth, increase in per captia and disposable income in countries such as china, India and other Asian countries is boosting the market for industrial wax.

https://www.marketsandmarkets.com/PressReleases/industrial-wax.asp

#IndustrialWax#WaxMarket#Manufacturing#IndustrialApplications#MarketTrends#MaterialScience#IndustrialChemicals#WaxProducts#Sustainability

0 notes

Text

𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐂𝐥𝐚𝐬𝐬𝐢𝐟𝐢𝐜𝐚𝐭𝐢𝐨𝐧: Materials are categorized into various classes, including metals, ceramics, polymers, composites, and semiconductors. Each class has unique properties and is suited for specific applications.

𝐏𝐫𝐨𝐩𝐞𝐫𝐭𝐢𝐞𝐬 𝐨𝐟 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬: Materials scientists study the physical, mechanical, electrical, thermal, and chemical properties of materials.

Visit @ https://symbiosisonlinepublishing.com/materialsscience-engineering/

#engineering#nanotechnology#nanotech#materialscience#materials#materialsengineering#materialsresearch#metalmaterials#newenergymaterials#polymers#Ceramicmaterials#MicroelectronicMaterials#bioengineeringmaterials#bioengineering#biomedicalmaterials#compositematerials#functionalmaterials#materialsprocessingtechnology#sciencejournal#journals#journal#publication#publishing#symbiosisonlinepublishing#pubmed#peerreview#openaccess#openaccessjournal

0 notes

Text

Metal Forging Market: Industry Size, Growth Trends, and Key Players Strategies

The global metal forging market size is expected to reach USD 145.44 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 7.7% during the forecast period. Rising awareness about climate change and increasing investment in renewables, especially in wind and hydro, by governments is expected to boost the consumption of forged components. Thus, this investment is expected to propel the product demand during the forecast period. For instance, in October 2021, the U.S government unveiled plans to build up to 7 major offshore wind farms. The government is targeting to produce 30 gigawatts of wind power by 2030.

Metal Forging Market Report Highlights

The aluminum raw materials segment is anticipated to register the fastest CAGR during the forecast period due to the high demand for lightweight materials from industries, such as aerospace, power generation, and automotive

The aerospace application segment is expected to grow at a steady CAGR during the forecast period due to the high demand for air travel owing to changes in social behavior, which, in turn, is boosting aircraft production

North America is expected to register a CAGR of 4.7%, in terms of volume, from2022 to 2030. Increasing investment in the construction & infrastructure industry and demand for renewables is driving the regional market

The agriculture application segment is expected to register a significant CAGR, in terms of revenue, during the forecast period

Steady demand for farm equipment in countries, such as India and Brazil, is likely to support market growth in the coming years

For More Details or Sample Copy please visit link @: Metal Forging Market Report

Similarly, in April 2022, the government of the country announced that it is planning to develop a 40 GW offshore wind project by 2050 that is expected to spread over 50 wind farms.Metal forging is the process, in which metals are shaped and formed using compressive force. These forces are applied using pressing, hammering, and rolling. Increasing demand for the product in various industries, such as power, construction, agriculture, marine, and aerospace, is anticipated to augment the market growth.Based on raw material, carbon steel accounted for the largest revenue share in 2021 and it is expected to maintain its dominance throughout the forecast period.

The growth is attributed to the properties of the material as the product often has a tight grain structure, which makes it mechanically strong to withstand friction. Also, carbon steel is cheaper than its counterparts.Construction is anticipated to expand at a steady CAGR, in terms of revenue, during the forecast period. The growth is attributed to increasing government investment in the construction sector to untangle the negative impact created by the COVID-19 pandemic.In November 2021, the Italian government came up with a new recovery and resilience plan to foster economic growth by 1.5 to 2.5% by 2026. The government is expected to invest in the construction of public buildings, renewable energy, and waste & water management.

In 2021, Asia Pacific was the largest regional market, in terms of revenue as well as volume. China and India were the largest consumers of metal forgings in 2021 in the APAC region. The rising demand for forged products from various application industries, such as construction, automotive, and energy, has pushed product consumption in the region.The global metal market is highly competitive. The rising demand for forged products has forced key manufacturers to opt for merger & acquisition strategies. For instance, in June 2021, Bharat Forge, a leading forging company in India announced that they have acquired Sanghvi Forging & Engineering Ltd.

#MetalForging#Manufacturing#MetalsIndustry#IndustrialProduction#Automotive#Aerospace#Engineering#MarketAnalysis#SupplyChain#MaterialScience#TechnologyTrends#Sustainability#CompetitionAnalysis

0 notes