#manufactoring

Note

i literally can't stop rotating hunger au worldbuilding and lore in my head. forgive me if you've ever touched on this in an ask before, but... re: the existential horror of being a parasite that has the sense of self of the host it ate. if one of grian's friends ever did get taken and used as a watcher larva host. how do you think he would feel about the watcher that came out the other side? would he want to see them as still the same person as his friend, or...?

Ive been staring at this ask since i got it with like. I need you to picture the most comically heartbroken expression right now okay. like this is me reading that and thinking about it in great and terrible detail:

Gods he would be devastated if this ever happened. He knows what thats like. He knows just how much it hurts-- and that its not a hurt that can be quantified, because its just that intense, that scalding, that encompassing of an experience to go through. I think, genuinely, Grian would be so utterly horrified and grief-stricken for whichever friend went through the Watcherification process that it would trump every other potential feeling on the list

But i think, ultimately, he would still view them as his friend, and treat them in the same way. There's a little bit of hypocrisy in Grian's character that i enjoy engaging with while writing him, and a good part of that in hunger au is centered around how he's firmly designated himself as the monster, and everybody else is the victim, and theres no room for nuance because he sucks and theyre the only people who are valid. When in reality, yes he hurt them, yes he did terrible and invasive things, but he did them out of pure survival rather than maliciousness, and that does make a subtle difference. And... hes not the only one who has fucked up, either!! The entire point of hunger au is how everyone has fumbled the bag in various ways and now they're all trying to clean it up together. Its just, yknow, Grian is so wrapped up in his own pain that he cant see those grey areas yet

And the thing is, if one of his friends got Watchered™, so to speak, and was standing in front of him, i think he would treat them with SO much compassion. Theyve been through possibly the worst thing anyone can experience and come out the other side-- at his core, Grian is i think a character who wants to do good, and do good by other people, and in this hypothetical that would translate into a lot of kindness he doesnt usually afford for himself. Honestly i think he'd spend the time trying to show them the ropes, get them set up in a better position than he found himself in, and provide his own fumbling emotional support as best he could, just out of sheer solidarity. Like, he gets it. He's been there. He may as well help out.

And i think he wouldnt even realize how hypocritical he's being until someone else pointed it out to him, about how he treats this friend with so much care but is simultaneously cruel to himself. I dont think he'd know how to handle that-- he's sort of dug himself a rut in the road with the way he thinks about and treats himself, and the cognitive dissonance would be really uncomfortable for him. Ultimately a good thing!!! Growth is often very uncomfortable. But imo Grian has a tendency to run from things like feelings of discomfort, so i think it'd take him a while to reconcile his previous ways of thinking with whats being presented in front of him essentially in the form of a mirror.

So uh. tl;dr: he'd be a little hypocrite about it and would feel a lot more compassionately inclined towards the friend than he does himself, and would try to help them out as best he could. Thank you for the incredible question that has given me the opportunity to rotate this worm at even higher speeds than usual inside my brainpan DKNFEKNDSKDJKDKD

#shouting speaks#asks#hunger au#compliments#theres also like. the factor that a lot of grian's self-hate stems from the games#he was always a bit unstable about his self-perception after he became a Watcher#but he wasnt as actively loathing himself until after the life games started#like he took GREAT pains to ''eat ethically'' and try to manufactor joy more than fear#which is why he starved. its harder to wrangle those emotions out of people than it is to shove them in a box; scare them; & eat the buffet#idk i have so many feelings about him as a character. oh hunger!grian my blorbo of blorbos. we're really in it now#txt

65 notes

·

View notes

Text

Did some fucking masterful salesmanship towards the end of my shift that netted the company a big ten-ish quid. All in a day's work.

#basically someone came in looking for a zip for a cropped corset top that her daughter bought#which she had worn once and the zip it came with immediately broke#but my colleague said that we don't sell separating zips that short#and in fact no one does except this one guy in the city centre who makes zips himself#so the customer was very disappointed that she now had to trek all the way into the city#and I said 'what I would do is take the zip out and put in some ribbon in an appropriate colour and sew on some hooks and eyes'#which we have in abundance#so I found her a ribbon that was a good colour match (the top was an olive green satin fabric)#and a packet of silver hooks and eyes and some green embroidery floss#heroically saving her from taking the train into town#and getting the sale for us and not yer man in the city centre#my colleague and the customer were suitably awed by this quick thinking and creative problem solving#and both agreed that hooks and eyes would look much nicer than a horrible old zip#I am going to get a good grade in retail: a thing that is normal to want and possible to achieve#honestly though they are so fucking lucky to have me at [workplace]#I give great customer service and I am very knowledgable in craft-related areas#and the curtain stuff is coming to me!#it's not rocket surgery#I ordered a blind today all by myself using the manufactorer's online portal#although I did get the manager to double check everything before I converted it to an order and booked it in#so that if I had made any mistakes that she had cosigned them lol#but yeah I am such a good little cog in the capitalist machine#of Big Ribbon™#werq bitch

10 notes

·

View notes

Photo

TW: Taxidermy of vulnerable animals.

Michels is lying about the economy under Evers, only listing the shut downs that needed to happen and was state wide because people were dying from a contagious, deadly virus. The shut downs weren’t nearly long enough, and a lot of businesses that were opened were barely considered as “essential” because they had food in them. (Like Target.) So really most jobs were still up and running.

But besides all of that I want to point out a few little details-

Tony Evers has been going to cultural festivals lately, talking to the 99% of Wisconsinites. (He also lives in Wisconsin.)

Michels visits Wisconsin to hang out with a bunch of rich, white people at a fabrication company in a room filled with taxidermy, including a hippo.

Hippos don’t just appear in the wild in America. They’re on the “vulnerable” list and they’re illegal to hunt. One of these people either went overseas to hunt a hippopotamus for game or bought one off of someone who illegally kills and sells animals on the “illegal to hunt” list for money.

Crocodiles are also illegal to kill in America and depending on the breed are somewhere between “least risk” to “critically endangered.” Though it’s hard to tell what’s next to the hippo. People are speculating that it’s a crocodile.

Not enough people are talking about how Michels is hanging out with people who casually sits in a room with dead animals that are illegal to hunt so I’m going to.

Edit: I didn’t notice the obvious ivory tusk until @yardbitch pointed it out!

#hippo#tw: taxidermy#vulnerable species#weldall manufactoring#hippopotamus#illegal hunting#tim michels#wisconsin#tony evers#endangered species#animals#tw: ivory#tw: ivory tusk#ivory#ivory tusk

17 notes

·

View notes

Photo

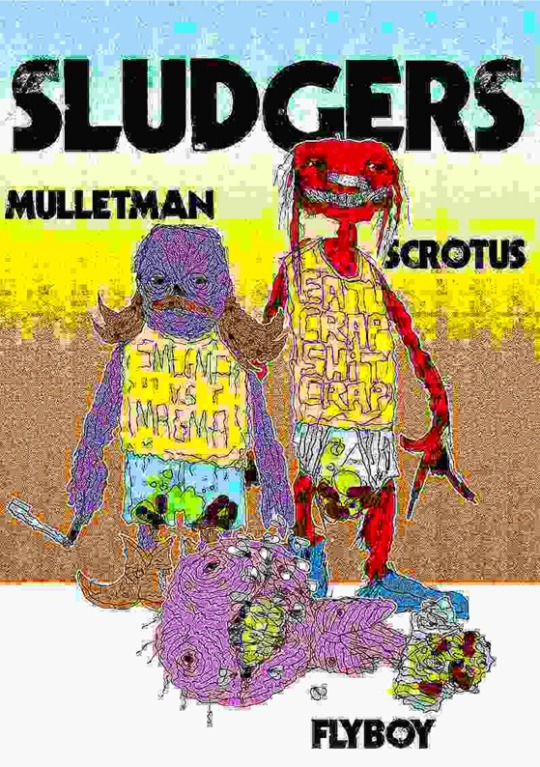

you guys like this one i spent a lot of time on it

#mtg#magic the gathering#custommtg#custom magic card#academy manufactor#modern horizons#modern horizons 2#MH2#card game#card games#robot#burger#phyrexia all will be one#phyrexia#new phyrexia#ONE

6 notes

·

View notes

Text

I’ve had a bad day so I’m getting some wine and chocolate and I’m going to take a foamy bath at 3 in the afternoon.

#Slept through 2 meetings#got to the second one 30 minutes late#had a migrane#have fcking CRAMPS#best buy canceled my computer order#and I can't buy one from the manufactorer until my money comes back to my account#which could be a week#I need a functioning computer for school which starts on MONDAY#still have a migraine#realized I misspelled so much crap in these notes#5 points to whoever can find all my misspellings

2 notes

·

View notes

Text

Speed Metal Zine in the process character study

6 notes

·

View notes

Text

THIS IS A WIN FOR THE KEICHROMS. YO. WHAT. SOBBING SHAKING

#ran talks nonsense#kei (technoroid)#chrom (technoroid)#techuni#I HAVE NO CREDITS TO PULL FOR THEM#well i do but. cobalt manufactoring day soon.....#alt hair cobalt. i wanna see.....#hoping i can get either of them from the gacha tickets

0 notes

Text

Preparations are ON AGRITECHNICA

Looking forward to meet the farming fraternity.

We are READY to showcase our robust AGRI MACHINES!

#lancer#allset#agritechnica2023#hanover#germany#agricultureexhibition#lanceragrico#agriculturemachinery#manufactorer#agritools#madeinindia

0 notes

Text

Pipe Spools vs. Traditional Piping: Advantages and Disadvantages

Pipe spools have emerged as a popular alternative to traditional piping systems in various industries. They offer several advantages that can significantly improve efficiency and streamline the installation process. However, like any other technology, pipe spools also have their limitations. In this blog post, we will explore the advantages and disadvantages of pipe spools, helping you understand their potential benefits and drawbacks.

Introduction

In the world of industrial piping, efficiency and cost-effectiveness are paramount. Traditional piping systems require extensive on-site fabrication, which can be time-consuming and labor-intensive. Pipe spools, on the other hand, offer a pre-fabricated solution that can be easily transported and installed. Let's delve deeper into the advantages and disadvantages of pipe spools to understand their impact on modern piping systems.

Advantages of Pipe Spools

1. Time and Cost Savings

One of the significant advantages of pipe spools is the time and cost savings they offer. Traditional piping systems involve on-site fabrication, which requires skilled labor, specialized equipment, and additional time for measurements and adjustments. Pipe spools, on the contrary, are prefabricated in controlled environments, reducing the need for on-site fabrication. This results in significant time savings and cost reductions, making pipe spools an attractive option for many industries.

2. Improved Quality Control

Pipe spools are fabricated in controlled environments, ensuring higher quality control compared to traditional piping systems. Skilled technicians and advanced machinery are employed to precisely cut, weld, and assemble the spools, eliminating the potential for human error. This enhanced quality control leads to improved system reliability, reduced maintenance requirements, and ultimately, enhanced safety.

3. Streamlined Installation Process

The prefabricated nature of pipe spools allows for a streamlined installation process. As the spools are fabricated off-site, they can be transported to the installation site and connected quickly and efficiently. This eliminates the need for extensive on-site welding and assembly, minimizing the risk of delays and errors. The streamlined installation process not only saves time but also reduces disruption to ongoing operations, making pipe spools an ideal choice for projects with tight deadlines.

Disadvantages of Pipe Spools

1. Limited Flexibility

While pipe spools offer numerous advantages, they lack the flexibility of traditional piping systems. Traditional piping allows for on-site adjustments and modifications, accommodating unforeseen changes during the installation process. In contrast, pipe spools are pre-fabricated according to specific measurements and designs, limiting the ability to make alterations on-site. This can be a disadvantage in projects where design changes are frequent or unpredictable.

2. Transportation Challenges

Transporting pipe spools to the installation site can sometimes present logistical challenges. Large-sized spools may require specialized transportation equipment, and the distance between the fabrication site and installation site can impact overall project timelines. Additionally, ensuring the safety and integrity of the spools during transportation is crucial to avoid damage or defects that could compromise the system's performance.

3. Higher Upfront Costs

While pipe spools offer long-term cost savings, their upfront costs can be higher compared to traditional piping systems. The need for specialized fabrication facilities, skilled technicians, and advanced machinery contributes to the initial investment required for pipe spools. However, it's important to consider the overall cost-benefit analysis, taking into account the time, labor, and maintenance savings that pipe spools offer over their lifespan.

Conclusion:

Pipe spools have revolutionized the piping industry by offering numerous advantages over traditional piping systems. Their time and cost savings, improved quality control, and streamlined installation process make them an attractive option for various industries. However, it's essential to consider their limitations, such as limited flexibility, transportation challenges, and higher upfront costs. By weighing the pros and cons, you can determine whether pipe spools are the right choice for your specific project or application.

In conclusion, pipe spools have proven to be a game-changer in the world of industrial piping, providing efficient and cost-effective solutions. As technology continues to advance, it will be interesting to see how pipe spools evolve further and address their limitations, making them an even more versatile option for piping projects worldwide.

0 notes

Photo

Academy Manufactor

Artist: Campbell White

TCG Player Link

Scryfall Link

EDHREC Link

#mtg#magic the gathering#tcg#$3.46#campbell white#academy manufactor#modern horizons 2#artifact#creature#assembly-worker

21 notes

·

View notes

Text

Precision in Practice: Unveiling the Techniques of Pipe Spooling and Fabrication

Pipe spooling and fabrication play a vital role in the construction industry, particularly in projects that involve the installation of complex piping systems. As the leading pipe spool manufacturer, supplier, stockist, and exporter in India, Metal Forge India offers a wide range of pipe spools in various sizes, specifications, and standards. Our seamless and welded fabricated pipe spools are available in different thicknesses, grades, and materials, including stainless steel, carbon steel, low-temperature carbon steel, duplex and super duplex steel, alloy steel, Monel, and Inconel. Whether you are looking for Inconel Pipe Spool manufacturers or any other materials we got you all covered. With our diverse product range, customers can choose the pipe spool that perfectly suits their project requirements.

In this article, we will delve into the technique of pipe spooling and fabrication, highlighting its significance and benefits for various industries.

Understanding Pipe Spooling:

Pipe spooling refers to the pre-fabrication of piping components in a controlled environment, such as a workshop or fabrication yard. It involves the cutting, fitting, and assembly of pipes, elbows, tees, flanges, and other fittings to create individual sections known as spools. These spools are then transported to the construction site for installation. The primary advantages of pipe spooling include enhanced efficiency, reduced on-site labor, improved quality control, and minimized project timelines.

The Importance of Precision in Pipe Spooling and Fabrication

Precision is of utmost importance in pipe spooling and fabrication due to the following reasons:

Optimal Functionality: Precisely fabricated pipe spools ensure the smooth flow of liquids, gases, or other materials through the piping system. This enhances overall functionality and reduces the risk of leaks or disruptions.

Safety: Precision in pipe spooling and fabrication ensures the structural integrity of the entire system, minimizing the chances of accidents, leaks, or failures that could jeopardize worker safety.

Efficiency: Well-fabricated pipe spools result in a more efficient and streamlined piping system. Precision eliminates unnecessary bends, obstructions, or misalignments, reducing energy losses and improving overall operational efficiency.

The Technique of Pipe Spooling and Fabrication

Material Selection:

The first step in pipe spooling and fabrication is the careful selection of materials. Depending on the project requirements, different materials are chosen to ensure optimal performance and durability. At Metal Forge India, we offer a wide range of materials, including stainless steel, carbon steel, low-temperature carbon steel, duplex and super duplex steel, alloy steel, Monel, and Inconel, providing our customers with the flexibility to choose the most suitable option.

Engineering and Design:

Once the materials are selected, the engineering and design phase begins. This involves creating detailed engineering drawings and 3D models that outline the dimensions, specifications, and configurations of the pipe spools. Our experienced engineers utilize advanced software and tools to ensure accurate designs that meet the project requirements.

Cutting and Preparation:

After the engineering and design phase, the cutting and preparation of the materials take place. Pipes, fittings, and other components are precisely cut according to the specifications outlined in the engineering drawings. This process requires skilled operators and cutting-edge machinery to achieve precise cuts and smooth edges.

Welding and Assembly:

Welding is a critical step in pipe spooling and fabrication. It involves joining the cut components together to form the spools. Skilled welders meticulously perform various welding techniques, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and SMAW (Shielded Metal Arc Welding), to ensure strong and secure connections. The assembly of the spools involves fitting flanges, valves, and other necessary components, following the engineering drawings and specifications.

Quality Assurance and Testing:

Ensuring the highest quality standards is paramount in pipe spooling and fabrication. At Metal Forge India, we have a comprehensive quality assurance process in place to verify the integrity and performance of our pipe spools. Non-destructive testing techniques, such as ultrasonic testing, radiographic testing, and hydrostatic testing, are employed to detect any flaws or defects. We also provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, along with test certificates certifying NACE MR0103 and NACE MR0175, to assure our customers of the quality of our products.

Surface Treatment and Finishing:

To enhance the durability and aesthetics of the pipe spools, surface treatment, and finishing are applied. This may include processes such as sandblasting, galvanizing, painting, or coating, depending on the project requirements and environmental factors. These treatments provide corrosion resistance and protect the spools from harsh operating conditions.

Specifications of Pipe Spools

Type: Steel Pipe Spool

Size: 114mm to 2500mm diameter (Seamless & Welded, Fabricated)

Operating Pressures: Maximum 3500kPa

Maximum Velocities: 6m/s for cement mortar lined fittings

Operating Temperatures: -40˚C to 70˚C

In Form: spool

Standard: ANSI / ASME B 36.10 & B 36.19

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40

Thickness: 10s/3 mm to XXS/70 mm

Specialize: As per the drawing

Dimensions: ANSI / ASME B 36.10 & B 36.19

Usage/Applications: Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects.

Benefits of Precise Pipe Spooling and Fabrication

Precise pipe spooling and fabrication offer numerous benefits to industries and construction projects:

Time Efficiency: Accurate fabrication reduces installation time by ensuring proper fit and alignment, minimizing adjustments or modifications during installation.

Cost Savings: Precision in fabrication reduces material waste, rework, and the need for additional fittings, resulting in cost savings for the project.

Reliability and Durability: Well-fabricated pipe spools are more reliable and durable, offering a longer service life with minimal maintenance requirements.

Improved Project Management: Precision in pipe spooling and fabrication enables better project planning, coordination, and resource allocation, leading to smoother execution and timely completion.

Pipe Spool: Product Size Range

Construction

Grade

Size Range

Schedule/Thickness

Min Thk (mm)

Max Thk (mm)

Seamless Fabricated

CS

0.5″ to 30″

10s/3 mm

XXS/85 mm

Seamless Fabricated

AS

0.5″ to 30″

10s/3 mm

XXS/85 mm

Seamless Fabricated

SS

0.5″ to 24″

10s/3 mm

XXS/70 mm

Welded Fabricated

CS

0.5″ to 96″

10s/8 mm

XXS/85 mm

Welded Fabricated

AS

0.5” to 48”

10s/8 mm

XXS/85 mm

Welded Fabricated

SS

0.5″ to 74″

10s/6 mm

XXS/70 mm

Pipe Spools: Materials & Grades Offered

Materials

Grade

Stainless Steel

ASTM A403 WP Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L

Carbon Steel

ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low-Temperature Carbon Steel

ASTM A420 WPL3, A420 WPL6

Alloy Steel

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel

ASTM A815, ASME SA 815 UNS 31803, UNS 32205 (Dual Certified).

Applications of Pipe Spools

Pipe spools are prefabricated sections of piping that are used in various industries for the construction of piping systems. They are typically made by cutting, bending, and welding pipes together to create a pre-assembled unit. Pipe spools offer several advantages, including increased efficiency, reduced installation time, and improved quality control.

Here are some common applications of pipe spools:

Industrial Plants

Oil and Gas Pipelines

HVAC Systems

Water Treatment Facilities

Pharmaceutical and Biotechnology Industries

Food and Beverage Processing

Pulp and Paper Mills

Construction Industry

Shipbuilding

Mining, Mineral Processing, and so on

Final Thoughts!..

Pipe spooling and fabrication play a vital role in the field of industrial construction, enabling the creation of intricate and dependable piping systems. The utmost precision and accuracy employed in these processes are of utmost importance to ensure optimal performance, safety, and efficiency. At Metal Forge India, we exemplify these values through our pipe spooling and fabrication services.With a wide range of pipe spools available in various sizes, specifications, and materials, we are able to cater to the diverse needs of our esteemed customers. Through the utilization of cutting-edge technology, skilled craftsmanship, and stringent quality control measures, we guarantee that our pipe spools meet the highest standards of excellence.

In addition to serving our domestic clientele, we also export our top-notch pipe spools to several countries worldwide, including the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. Our commitment to delivering exceptional quality and reliability extends to our international customers as well.

Whether you have a small-scale project or a large-scale industrial undertaking, Metal Forge India is your trusted Pipe Spools Supplier Partner, providing you with reliable and precision-engineered pipe spools. Get in touch with us today to discuss your requirements and witness the difference of collaborating with industry leaders.

0 notes

Text

Exclusive Range Of Brass Insert Parts Tailor-Made To Suite Your Requirements

https://www.surajbrassindustries.com/latest-news/exclusive-range-of-brass-inserts-parts/

Our company offers an exclusive range of brass insert parts meticulously crafted to meet your specific needs. With a focus on precision and quality, our tailor-made solutions ensure optimal performance and seamless integration for your projects. Experience the excellence of our brass insert parts designed to elevate your applications to new heights.

0 notes

Photo

Pencil Sketch of a Mouse Lady running some kinda cheese factory machine.

Was doodling various types of cartoon mice today because of @bethdehart‘s mousegilrmay prompt list. Not sure if I’ll more pencil sketches on on these prompts, as I do it to unwind when I have energy.

#MousegirlMay2023#mousegirl#Cartoon mouse#pencil sketch#Mousegirl May#rough sketch#sketch#art#my art#Furry#Furry art#Did something cheese factory themed specifically because of all the old abandoned cheese factories in my area#There's so many#If they weren't all fall-aparty I might want to start my own cheese manufactoring with one.

0 notes

Text

started lightfall and.. as i expected i missed destiny so much!!!!!!!!!!!

#still on the hunt for a good controller tho#my brother in law gave me his ps5 controller but its too big for my baby hands :(#mattie.txt#i had one that was rly good but it broke and was discontinued bc the manufactor got bankrupt or something??? it wasnt great quality tbh#but it fit perfectly in my hands and worked great

0 notes

Note

I would buy dca and narilamb pins, especially if there was a discount for buying more or something! Have you considered having them as a Patreon tier?

There would be an option for free shipping for multiple pins bought! Assuming that's something I can make avaliable on KoFi, though I cant imagine it wouldnt be

As for Patreon tier, it can take 3-5 weeks for pins to be made, and the manufactoring costs. A bit. So the tier would have to reflect that, and I'd only be able to send them out every 2-3 months

If I was a much bigger artist / small buisness owner then I might be able to do it, but I'm still kinda starting out with the physical stuff aside from stickers, I can't really afford to make pins every month lksdhglsdjgj

235 notes

·

View notes

Text

me: I want to be creative and innovative, passionate about making art, driven to create and express, and to never run out of new ideas.

Satan: Yeah, sure, that can be arranged... Hold on. According to our files here you don't have a soul. Some manufactoring error, I guess.

me: Ah. So no deal, then?

Satan: Well... Perhaps there is one arrangement I could make. May I have your attention?

me: Sure, yeah. I'm open to alternatives.

Satan: AHHAHHAHHAHHAH! We have a deal! You'll have infinite ideas for new projects, but good luck ever finishing one! [disappears in a puff of smoke and sulphur]

me: Ah. Rats.

my newfound ADHD: We should write a comic adaptation of Homer's Odyssey, but all the characters are gerbils on a spaceship.

461 notes

·

View notes