#flexible pcb board

Text

For flexible printed boards with a large number of components and complex wiring relationships, consider the design of mounting retention positions to increase product reliability during structural design.

#pcb#flex pcb#rigid-flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#fpcway#fpcway.com#www.fpcway.com#today on tumblr#art#artwork#artists on tumblr#digital art

0 notes

Text

The Flexible Future of Electronics: Exploring Flexible Circuit Boards

Introduction

In the fast-paced world of electronics, innovation is the name of the game. As our devices become smaller, more powerful, and increasingly integrated into our daily lives, the demand for flexible and adaptable solutions has grown exponentially. One of the key enablers of this revolution is the flexible circuit board, also known as a flexible PCB board or flex circuit PCB. In this blog post, we will dive into the world of flexible circuit boards, exploring what they are, how they work, and their myriad applications across various industries.

Understanding Flexible Circuit Boards

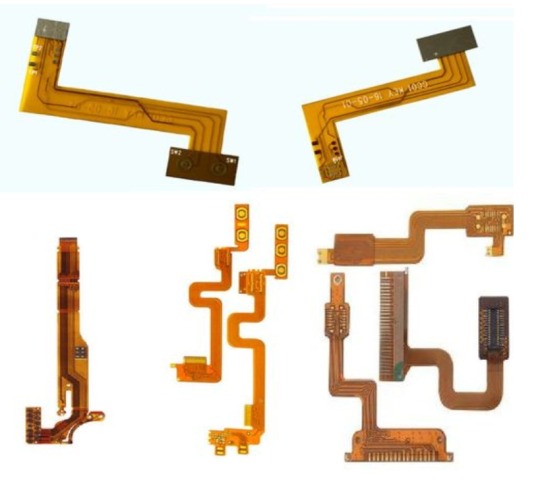

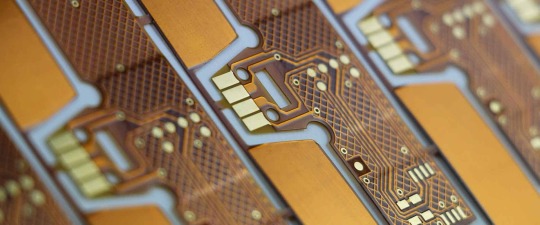

A flexible circuit board, or flex circuit PCB, is a specialized type of printed circuit board that offers a unique advantage over traditional rigid PCBs – flexibility. While traditional PCBs are typically made from rigid materials like fiberglass or epoxy, flex PCBs are built using flexible materials such as polyimide (PI), polyester (PET), or even a combination of both. This flexibility allows them to be bent, folded, or contoured to fit the specific requirements of a given application.

How Do Flexible Circuit Boards Work?

The basic structure of a flexible circuit board is similar to that of a rigid PCB, consisting of conductive traces, pads, and components. However, the key difference lies in the substrate material. Instead of a rigid substrate, flex PCBs use a flexible material that can withstand repeated bending and flexing without compromising the integrity of the circuit.

Flex PCBs are typically manufactured using a combination of additive and subtractive processes. The process involves printing or etching the conductive traces onto the flexible substrate and then adding the necessary components. The result is a lightweight and compact circuit board that can be shaped to fit the available space.

Applications of Flexible Circuit Boards

Consumer Electronics: Flexible circuit boards are widely used in smartphones, tablets, and wearables. Their flexibility allows for unique form factors and more robust, durable designs.

Automotive Industry: In vehicles, flex PCBs are used in airbags, navigation systems, and instrument clusters. They can withstand the vibrations and temperature fluctuations common in automotive environments. Medical Devices: Flexible circuit boards are crucial in medical devices like pacemakers and medical imaging equipment. Their compact size and flexibility make them ideal for implantable and portable devices.

Click here for more information: https://www.tumblr.com/fpcway/730881884594241536/exploring-the-world-of-rigid-flex-circuit-boards

0 notes

Text

Crimp Circuits is a renowned name in the realm of electronics manufacturing, offering a comprehensive suite of services to meet the diverse needs of our clients. With our cutting-edge Eagle software and extensive expertise in PCB designing, we specialize in crafting high-quality PCB solutions tailored to the unique specifications of each project. Whether you require flexible PCBs, rigid flex PCBs, or metal clad PCBs, we have the capabilities to bring your designs to life with precision and efficiency.

Our state-of-the-art facilities, located in Toronto, Canada, serve as the hub of our operations, allowing us to provide top-notch PCB manufacturing services to clients across the globe. From the initial stages of printed circuit board design to the final assembly and testing processes, we maintain the highest standards of quality and reliability at every step of the way.

As leading printed circuit board manufacturers, we understand the importance of flexibility and adaptability in today's fast-paced industry. That's why we offer full turnkey PCB services, covering everything from sourcing PCB parts to assembly and testing, providing our clients with a seamless and hassle-free experience from start to finish.

At Crimp Circuits, we take pride in being at the forefront of innovation and technology, offering PCB prototype services to help our clients bring their ideas to life quickly and efficiently. Whether you need a quick PCB quote or require prototype services in Canada, our dedicated team is here to assist you every step of the way.

For all your PCB manufacturing needs, trust Crimp Circuits to deliver excellence, reliability, and unmatched customer service. For more details visit our website: www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

0 notes

Text

Hitech Circuits Co.,Ltd is a professional flexible pcb, FPC printed circuit board manufacturer, supplier from China, due to its features of bendable, reducing product size, good heat dissipation and solderability, easy assembly and low overall cost etc, flexible pcb is widely used in mobile phones, wearable smart devices, automobiles, medical treatment, and industrial control etc. If you are looking for a reliable flexible PCB board partner in China, please don’t hesitate to contact [email protected] .

0 notes

Text

Discover everything you need to know about flexible circuit boards in this comprehensive guide. Learn about their applications, design considerations, manufacturing process, and more from Viasion's expert insights.

0 notes

Text

It is called "4 Layer Rigid-Flexible PCB",if you just engage in or somehow need this product or custom another new one,welcome contact me to know more details

#4 Layer Rigid-Flexible PCB#Rigid-Flexible PCB#4 Layer Rigid-Flexible#4 Layer PCB#4 Layer Printed circuited board#Rigid-Flexible printed circuited board

0 notes

Text

A Flexible Printed Circuit Board (FPCB), often referred to as a flex PCB, is a type of printed circuit board designed to be flexible and conform to various shapes. Unlike traditional rigid PCBs, which are made of inflexible materials like fiberglass or epoxy, flexible PCBs are constructed using flexible materials that allow them to bend, twist, and flex without damaging the electrical connections.

0 notes

Text

The Advancement of Printed Circuit Boards

High-level assembling procedures, like surface mount innovation, have made PCB get together more exact and productive at a flexible pcb cost. The development of PCBs has been instrumental in molding the cutting-edge hardware scene. From their modest starting points to the complex multi-facet sheets of today, PCBs keep driving development in innovation.

0 notes

Text

Quality Flexible Printed Circuits: A Must-Have Component in Modern Electronics

Flexible printed circuits (FPCs) have revolutionized the electronics industry, and their popularity continues to soar. As electronic devices become more compact and complex, the demand for flexible circuits with exceptional performance and reliability has never been higher. Northpoint Technologies is a leading PCB board manufacturer in the USA, specializing in the production of quality flexible printed circuits that meet the needs of various industries. In this post, we will discuss the importance of flexible circuits and how Northpoint Technologies can help you achieve your goals.

Why Quality Flexible Printed Circuits are Crucial

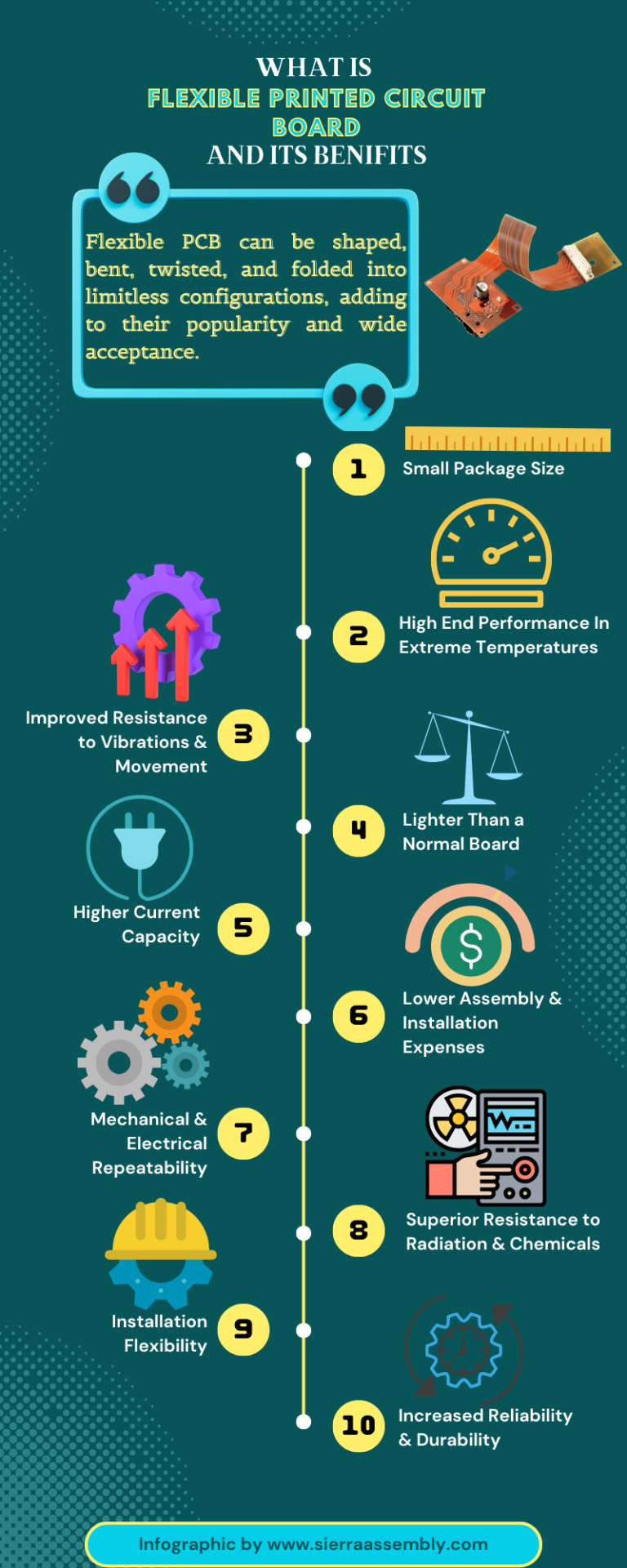

Flexible printed circuits have several advantages over traditional rigid PCBs, including:

1.Flexibility: FPCs are highly flexible and can bend and twist to fit into tight spaces or complex shapes. This flexibility allows for more efficient use of space and the design of unique products.

2.Lightweight: FPCs are lightweight, making them ideal for applications where weight is a concern, such as in aerospace and medical devices.

3.Reliability: FPCs have fewer components than traditional rigid PCBs, reducing the likelihood of failure due to component damage or connection issues. They are also more resistant to vibrations and other environmental factors.

4.Cost-Effective:FPCs can reduce manufacturing costs by simplifying the design process and reducing the number of components needed.

Northpoint Technologies:Your Trusted PCB Board Manufacturer.

If you're looking for a reliable and experienced PCB board manufacturer in the USA, Northpoint Technologies has got you covered. We specialize in producing quality flexible printed circuits that meet the unique needs of various industries. Here are some of the reasons why we stand out:

1.Expertise: Our team of engineers has over 30 years of experience in the PCB industry. We have the knowledge and expertise needed to design and manufacture high-quality FPCs that meet your requirements.

2.Customization: We understand that every project is unique, and we offer customized solutions that cater to your specific needs. We work closely with our clients to ensure that we deliver the best possible solution.

3.Quality Control: We have a strict quality control process that ensures that our FPCs meet the highest standards. We use only the best materials and equipment to ensure that our products are of the highest quality.

4.On-Time Delivery: We understand that time is of the essence in the electronics industry. We have a fast turnaround time, and we work tirelessly to ensure that we meet our clients' deadlines.

Conclusion

Quality flexible printed circuits are an essential component in modern electronics. They offer several advantages over traditional rigid PCBs, including flexibility, lightweight, reliability, and cost-effectiveness. At Northpoint Technologies, we specialize in producing quality FPCs that meet the unique needs of various industries. Our expertise, customization, quality control, and on-time delivery set us apart from the competition. Contact us today to learn more about our PCB board manufacturing services.

0 notes

Text

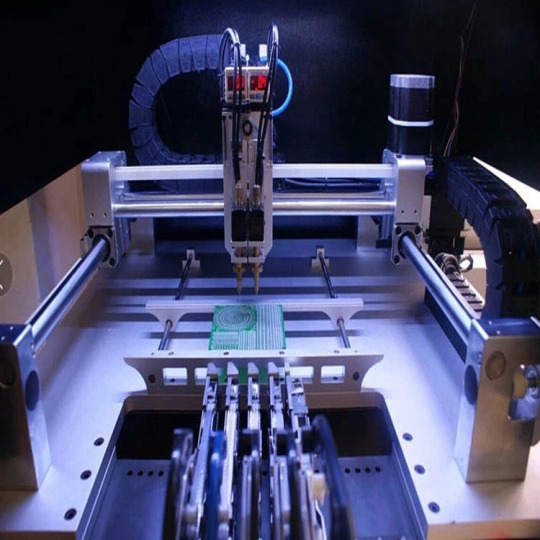

Up to now, primary equipment for accurate alignment includes BGA/CSP rework station and chip mounter among which precision of chip mounter reaches approximately 0.001mm.

#fpcway#flex pcb#pcb#flexible pcb board#flexible circuit board#flex circuit pcb#rigid-flex pcb#fpcway.com#www.fpcway.com#today on tumblr#art#my art#artwork#old art#digital art

0 notes

Text

Exploring the World of Rigid-Flex Circuit Boards and Flex PCB Prototypes

Introduction

In the ever-evolving world of electronics, innovation is the name of the game. With a constant demand for smaller, more efficient, and versatile electronic devices, manufacturers are continually pushing the boundaries of what's possible. One significant development in this field is the use of flexible printed circuits (FPCs), rigid-flex PCBs, and the intricate process of flex PCB assembly. In this blog post, we will explore these cutting-edge technologies, their applications, and the rigid flex PCB manufacturer behind them.

Flexible Printed Circuits (FPCs)

Flexible printed circuits, often referred to as FPCs or flex circuits, are a vital component in modern electronic devices. They offer a flexible alternative to traditional rigid PCBs, making them ideal for applications where space and weight are at a premium. FPCs are constructed using flexible base materials, typically polyimide, and are designed to be thin and lightweight. Here are some key advantages of FPCs:

Space Efficiency: FPCs can be bent and folded to fit into tight spaces, making them invaluable in compact electronic designs.

Weight Reduction: Since FPCs are lightweight, they help reduce the overall weight of electronic devices, a critical consideration in industries like aerospace and automotive.

Reliability: FPCs are known for their high reliability due to the absence of connectors and the reduced risk of solder joint failure.

Complex Shapes: They can be designed in intricate shapes to accommodate specific device designs, which is often challenging with rigid PCBs.

Flexibility: FPCs can withstand millions of flex cycles without compromising their functionality, making them suitable for applications with moving parts.

Rigid-Flex PCBs

Rigid-flex PCBs are a hybrid solution that combines the benefits of both rigid and flexible circuits. They consist of multiple layers of flexible substrates interconnected with rigid PCB sections. This combination allows for complex three-dimensional designs, improved reliability, and reduced assembly time.

Click here for more information: https://www.tumblr.com/fpcway/730768523049205760/the-evolution-of-electronics-flexible-printed

0 notes

Link

#Flex PCB manufacturing#Fine-Line Circuits Limited#Rigid-Flex & Medical PCB#Flexible Printed Circuit Boards#Printed Circuit Boards

0 notes

Text

Why Choose Blind Via Flex PCBs

Many of today's flex PCB designs incorporate high-density components similar to those found in rigid PCB designs. This necessitates the use of blind and buried vias to route signal lines out from within these high-density components or areas of the design. One of the primary drivers for this is the 0.4mm pitch BGA package.

Blind Vias for Signal Routing Efficiency

Blind vias allow signals to be dropped down to the next layer from within the BGA SMT pad and then routed out from there. In high pin count devices, additional blind and/or buried vias may be required. Differences exist in how blind and buried vias can be implemented in a Flex PCB design due to the materials and manufacturing processes required.

Via-in-Pad Design for Enhanced Density

For flexible PCB designs with high layer counts utilizing high-density outer layers, the extra area used for separate pads and SMT components severely limits the available space for trace fan-out. By incorporating via-in-pad design in flex and rigid-flex PCBs, it is possible to significantly increase density by utilizing vias as mounting pads. Copper- or silver-filled flat vias allow for soldering components directly onto via holes.

Challenges and Considerations

Utilizing via-in-pad will release extra surface area for routing of traces. However, as with any new technology, there are several points to consider when using this construction type with flex. When manufacturers fill rigid PCB vias for SMT pads, they typically use a conductive epoxy, followed by copper plating and planarization. The final sanding leaves a very smooth pad surface, enabling normal processing of the circuit board through the pick-and-place cycle.

Improved Process for Flat Via-in-Pad

A new and improved process for a flat via-in-pad on multilayer flex PCBs is to fill the vias with a special type of copper plating. On thin flex layers that are laser-drilled, the new copper fill plating chemistry is designed to fill the laser via from the bottom up, creating a reasonably flat top on the via. Though some small dimpling can usually be seen, it presents no problem for assemblers. This plating technology is used on a wide range of flex and rigid-flex PCBs.

Conclusion

In conclusion, the use of blind vias and via-in-pad design in flex PCBs offers significant advantages in terms of signal routing efficiency and density. Despite the challenges associated with these technologies, advancements in manufacturing processes have made them increasingly viable for a wide range of applications. As the demand for high-density and high-performance PCBs continues to grow, the use of blind vias and via-in-pad design is expected to become even more prevalent in the future.

4 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

The Advancement of Printed Circuit Boards

Today, PCBs are produced using different materials, including FR-4, adaptable substrates, and, surprisingly, artistic materials. High-level assembling procedures, like surface mount innovation, have made PCB get together more exact and productive at a flexible pcb cost.

0 notes