#flexible hose installations

Text

Stainless Steel Flexible Hose Installation

As a top stainless steel flexible hose manufacturer, we offer best quality products that meet the highest standards of durability, reliability, and performance. Our expertise in crafting stainless steel hoses that are useful in various industrial and commercial applications, providing superior flexibility, corrosion resistance, and longevity. With thorough attention to detail and advanced manufacturing techniques, we ensure that each steel hose fittings meets rigorous quality control measures to guarantee customer satisfaction. Whether you require hoses for fluid conveyance, gas transfer, or other specialized applications, our diverse range of stainless steel flexible hoses, stainless steel braided hoses is designed to meet your specific needs.

Properly installing stainless steel flexible hoses is essential to maximize their performance and longevity. A well-executed installation reduces the likelihood of accidents, injuries, and environmental damage. It's crucial to maintain the structural integrity of the steel hose fittings by employing appropriate installation methods, such as selecting compatible fittings and avoiding excessive bending or twisting.

Before installing stainless steel flex hose we need to look out below factors:

Application Requirements: Determine the specific application and operational conditions of the SS flexible hose will encounter, including pressure, temperature, fluid compatibility, and environmental factors.

Hose Material: Select a hose material compatible with the fluid being transferred and the operating environment. Factors such as chemical resistance, temperature tolerance, and flexibility should be taken into account.

Hose Size and Length: Choose the appropriate hose size and length to accommodate the flow rate, pressure, and distance required for the application.

End Connections:Select compatible end fittings for SS flexible hoses that ensure a secure and leak-free connection between the hose and the equipment or piping system.

Installation Environment: Assess the installation environment for potential hazards, such as sharp edges, abrasive surfaces, or exposure to extreme temperatures, that could damage the steel hose fittings.

Routing and Positioning:Plan the routing and positioning of the hose to minimize bends, twists, and kinks, which can restrict flow and reduce steel hose fittings lifespan.

Flexibility Requirements: Consider the flexibility requirements of the hose to accommodate movement, vibration, and thermal expansion within the system.

Installation Method: Follow manufacturer recommendations and industry best practices for steel flexible hose installation, including proper anchoring, support, and protection against external damage.

Inspection and Maintenance: Establish a regular inspection and maintenance schedule to monitor hose condition, identify wear or damage, and address any issues promptly to prevent leaks or failures.

By meticulously assessing these factors before installing stainless steel hoses, you can guarantee efficient operation, durability, and safety to implement in industrial applications.

Installing a Stainless Steel Hose:

Preparation: Gather all necessary tools and equipment, including appropriate fittings and adapters.

Inspect the Hose: Before installation, carefully examine the stainless steel hose for any defects, damage, or irregularities. Ensure it meets the required specifications and standards.

Prepare the Connection Points: Clean and inspect the connection points where the hose will be installed to ensure they are free of debris, corrosion, or damage that could affect the seal.

Cutting the Hose (if needed): If the hose needs to be trimmed to fit the installation, use a suitable cutting tool to make a clean, straight cut. Avoid damaging the hose or its reinforcement layers.

Attach Fittings: Install the appropriate fittings onto each end of the hose, ensuring they are securely tightened according to the manufacturer's recommendations. Use the correct type and size of fittings for the application.

Align and Position:Mount the stainless steel flexible hose assemblies according to their position in the installation area. Take care to protect the metallic lining from moisture, which can cause rust and affect hose functionality. While hose clamping is necessary, avoid using excessive clamps as it may have adverse effects.

Secure the Hose: Once properly aligned, securely tighten the fittings onto the connection points using suitable wrenches or tools. Avoid over-tightening, which could damage the fittings or distort the hose.

Test for Leaks: After installation, perform a pressure test to check for any leaks or abnormalities. Gradually increase the pressure to the specified level while inspecting all connection points for signs of leakage.

Final Inspection: Once the installation is complete and no leaks are detected, visually inspect the entire assembly to ensure it is properly installed, aligned, and supported.

By following these steps, you can ensure the proper installation of a stainless steel hose.

Common Mistakes to Avoid When Installing Stainless Steel Hoses

Steer Clear of Torque: Torque may occur in a hose due to twisting during installation or flexure. However, this issue can be addressed by including a floating or union flange at each end of the hose assembly. It's important to install the fixed flange ends securely before securing the floating flange ends.

Prevent Out-of-Plane Flexing: Secure the hose to restrict flexing to a single plane, preventing twisting during bending. As stated in the flexible steel hose Installation Guide, it's vital to avoid out-of-plane flexing during installation. Ensure that the bending plane aligns with the direction of bending.

Reduce Bending: Repeatedly bending a hose with a radius smaller than specified can cause the hose to fail prematurely. It's recommended to ensure adequate length to reduce excessive bending and alleviate stress on the hose.

Avoid Sharp Bends: Avoiding repeated sharp bends in hoses is crucial, as they can occur due to improper installation. To prevent such bends, make sure that the lowest centerline bend radius for intermittent bending never falls below the specified values provided in the technical data section.

Conclusion

Our guide provides essential tips for installing flexible steel hoses. It covers everything from application needs to hose sizing and safety precautions. Following these guidelines ensures a reliable installation, maximizing both performance and durability. Stainless flexible hoses are durable & corrosion-resistant suitable for various industries. Prioritize your requirements, make informed decisions, and focus on safety for smooth operations.

For top-quality SS flexible hoses, choose Qflex - Quality Foils India, a leading manufacturer in India. We offer effective installation services and high-quality products at competitive prices to meet all your needs.

#ss flexible hose installation#flexible hose installations#stainless steel flexible hoses#flexible metal hosese

1 note

·

View note

Text

5 Steps to Installing a Tap

The "5 Steps to Installing a Tap" guide on Tapron.co.uk offers a clear, step-by-step approach to fitting a new basin tap, emphasizing preparation, correct assembly, and installation techniques. It outlines essential tools and accessories needed, including sealing tape and wrenches, and covers everything from dismantling the old tap to connecting pipes and verifying the installation's success. This practical guide is aimed at ensuring a smooth DIY tap installation process. For a detailed walkthrough, check the full guide here.

#ap installation guide#DIY tap installation#Tools for tap installation#Flexible hose vs. rigid inlet#Step-by-step tap assembly#Sink tap installation process#Securing tap connections#Tightening stud-nut#Connecting water pipes to taps#Checking for leaks after tap installation

0 notes

Text

0 notes

Text

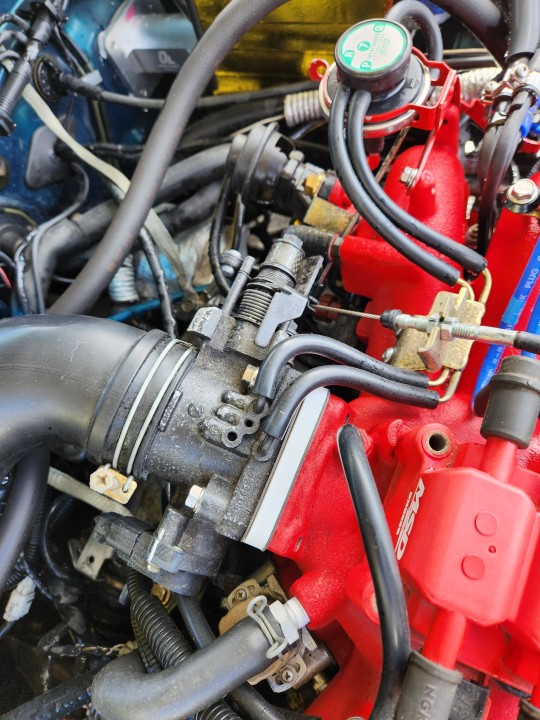

Since there has been some interest in my current intake, here is it broke down. I have tried numerous setups but this custom OEM+ version is the best and passes stupid SMOG visual check.

I also intensely studied the 2.5RS forums and looked at dyno charts showing that this IS the best when combined with a 2.25" cat back exhaust and equal length headers. Trust me!

This was a lot work as well as trial and error and willingness to start over again and redo it again several times. I think this was also the lightest combo if you trying to reduce weight.

One of a kind custom intake for the naturally aspirated Subaru EJ25D....

First up is you need the intake tract/duct and hoses from an earlier model Subaru Impreza or any Subaru that has this intake tube vs the stock version with the "torque box" behind the throttle body. Junkyard is your best buddy.

I had expensive high performance mandrel bent blah blah blah intakes which I constantly struggled with keeping the metal tubing cool (I used a laser temp gauge). This plastic is basically the same but rarely gets too hot to touch. So, actually a cold air intake if you keep reading.

Since the entire manifold needed to come out, I painted it wrinkle red and polished the runners and throttle inlet.

The reason I removed the manifold was to install stainless studs to make installing the 10mm thick teflon spacers and 2 sets of gaskets easier. Similar to 8mm Grimmspeed phenolic (previously installed) but thicker. This mod makes a big difference, the entire manifold now stays cool. No more engine block heat soak, only ambient engine bay heat.

"For every 5 degree reduction in temperature, increases power by 1%"

You have to extend the EGR tube and possibly grind your ignition coil pack mounts lower. Because the entire manifold assembly will be sitting ~12mm higher.

I was fortunate enough to work with the gasket maker. So he made 10mm teflon intake manifold spacers and a matching prototype 10mm throttle body spacer! Again 2 gaskets to ensure no leaks. Not sure if these were ever made available afterwards since I was the first car.

This spacer combo increased plenum volume as well as helped to keep heat transfer drastically reduced.

Using my custom ported, polished and knife edged throttle body that I did myself with the coolant hose permanently bypassed and the cruise control bits removed. Keep in mind you will need longer bolts if you use a spacer here. Definitely improved throttle response after just the throttle body swap.

I scored this GC8 v3 factory resonator/cold air intake inlet from the UK. It's what goes with those fender plugs. Grabs cold air from inside the fender behind the corner light up high, so no chance of sucking up water. FWIW, You really shouldn't just delete the "snorkus", seriously, it's just gonna mess up your MAF sensor.

I was also able to make the resonator from a SVX work in the 04 Outback with some persuasion. It too takes air from the same location but the box was hard to cram in the fender.

The intake tract will work with whatever air filter box but in order to use the EUDM WRX intake inlet/resonator you will need the matching filter housing box from an earlier model or have to drill a new mounting hole. You will need both halves!

BEST panel filter on the market IS made by Grimmspeed! Don't waste your money on any other filter! I also added a Filter Wears waterproof inlet cover/pre-filter to the resonator just incase of water spray. The factory option fender plug fills that hole.

And I'm not sure if this was an upgrade or not but here is the JDM JECS MAF I am also using. Used DEI gold heat reflective tape to keep it cool and extend the life. Possibly more consistent/accurate readings?

The only other things installed are a Weapon R catch can to the PVC, which DOES keep some crap out of the intake tract and off the throttle body but probably no real performance advantage. Plus a heat/flame resistant "sock", same as around my fluid reservoirs, over the bendy/flexible bit of the intake tract just after the MAF. That area is prone to splitting/cracking with heat and age!

Now for treasure at the end of the rainbow! I am actually gonna give you nerds the mother fucking part numbers! These can be life savers when searching for parts.

*You might have to make or reuse your PVC, crankcase, IAC valve hoses. So grab whatever is attached if your at the junkyard or hit up the auto parts store.

•Subaru PN's:

Intake duct/tract (EJ22): 14457AA111

Air filter housing/box: A53FA02 (upper) & A53FA01 (lower)

Fender resonator/snorkus (UK WRX): A21FA03 or A32FA01 or A21FA00

Fender plug: 46059FA000

•Grimmspeed PN's:

Dry-Con Air Filter: 060092

Intake manifold spacers (8mm phenolic): 015001

#subaru#custom#intake#mods#how to#diy#fyi#upgrades#naturally aspirated#ej25d#90s japanese cars#impreza#legacy gt#forester#my car#mecha gt#cold air intake#car parts#part numbers#oem+#the more you know#knowledge#tutorial#hp gains#boxer engine#subie#subienation#modified cars#2nd gen#bk6

17 notes

·

View notes

Text

AXOR Showers with a Blend of Perfection and Innovative Features

In the ever-evolving realm of home luxury, the AXOR bathroom Showers Composition emerges as a beacon of innovation, promising to redefine the way we experience the shower. Designed in collaboration with the visionary Philippe Starck, this exceptional shower control panel system transcends conventional boundaries, offering a seamless blend of modernity and timeless elegance.

UNVEILING THE AXOR SHOWER COMPOSITION EXPERIENCE

Step into the future of showering with AXOR bathroom accessories, where cutting-edge technology meets minimalist aesthetics to create an immersive and luxurious shower experience. The shower composition is more than just a collection of fixtures; it is a testament to the philosophy that a shower should adapt to an individual’s unique needs.

Renowned designer Philippe Starck’s vision comes to life in this architectural composition, characterized by sleek, flat surfaces and ultra-slim profiles. The system serves as a canvas for individual expression, offering both an all-in-one shower panel and modular components that can be arranged to cater to personal preferences. The result is an unparalleled shower experience that harmonizes technology and design seamlessly.

THE AXOR SHOWER COMPOSITION: REDEFINING INDIVIDUAL EXPRESSION

The AXOR Shower Composition challenges the conventional with a minimalist, rectilinear design. The showerhead and vertical panels extend slightly from the wall, creating a sense of space and sophistication in your shower haven. Installation is a breeze with the easy-to-install shower panel, providing comprehensive functionality in a single basic set.

This system celebrates versatility, allowing users to curate their shower experience through individual modules. Whether opting for an all-in-one shower panel or a combination of modules, users can tailor their shower to match their preferences. This bespoke approach ensures that the shower adapts to the user, not the other way around.

EFFORTLESS ELEGANCE: AXOR FINISH PLUS SURFACES

The AXOR Shower Composition is not just about performance; it’s about aesthetics. The system is available in a range of exclusive AXOR Finish Plus surfaces, including the sophisticated Matt Black. Each finish is meticulously crafted to enhance the overall look of your shower space, turning it into a design statement.

INNOVATIONS THAT TRANSFORM

AXOR Shower introduces innovative features that elevate the showering experience. The immersive Powder Rain spray mode envelops the body in ultra-fine droplets, providing a sensory delight. Selected overhead showers feature a conical spray for a luxurious touch, while the intuitive interaction design allows for separate control of temperature and water volume.

The dimensions of AXOR Shower Composition seamlessly complement those of the AXOR Universal Rectangular Accessories, ensuring a cohesive design language throughout the shower area. This attention to detail showcases AXOR’s commitment to providing a holistic and harmonious bathing environment.

TAILOR-MADE LUXURY: VERSATILITY IN CONFIGURATIONS

The AXOR Shower Composition caters to diverse needs with its versatile configurations. The all-in-one shower panel seamlessly integrates an overhead shower, body shower, thermostatic module, hand shower, and a textile-wrapped shower hose. Alternatively, users can opt for individual shower modules with various jet options, including a one-jet overhead shower, a one-jet overhead shower with a shoulder shower, or a two-jet overhead shower with a shoulder shower. For added flexibility, a separate one-jet adjustable shoulder shower module is also available.

EMBRACING THE FUTURE: WHERE INNOVATION MEETS DESIGN

The AXOR Shower Composition is not just a shower; it is a transformative experience. It represents the synergy of innovation and design, where flexibility meets luxury, and the future of showering unfolds. As you step into the shower space adorned with AXOR, you’re not just cleansing your body; you’re indulging in a sensorial journey that combines technology, design, and sheer opulence.

The AXOR Shower goes beyond the conventional boundaries of a shower system. It is a testament to the evolving demands of modern living, where luxury is not just a commodity but an experience. Elevate your daily ritual, embrace innovation, and immerse yourself in the future of showering with AXOR.

Maruthi Ceramics, the best Sanitary ware store in Bangalore proudly stands as the premier destination for a diverse range of AXOR bathroom products, inviting you to embark on a journey filled with opulence and innovation. Step into our showroom, where AXOR designer faucets and showers and revolutionize the bathing experience. These fixtures seamlessly blend cutting-edge technology with timeless design, promising a revitalizing encounter like no other. Immerse yourself in the sophistication and efficiency of AXOR’s washbasins and water closets showcased in our carefully curated collection.

From artistic aesthetics to advanced flushing systems, each piece reflects a dedication to both style and functionality. Our exclusive selection of AXOR bathtubs invites you to relax in style, boasting sleek lines and designs that ensure a therapeutic bathing experience. Maruthi Ceramics stands as your reliable sanctuary for AXOR products, providing a showroom where you can personally experience the unmatched quality and craftsmanship inherent in AXOR’s offerings. Our informed staff is ready to assist you in navigating through each product, ensuring your choice seamlessly aligns with your preferences. For those in pursuit of the utmost in bathroom luxury, a visit to Maruthi Ceramics is an opportunity to explore the fusion of technology, style, and innovation that defines AXOR.

Transform your bathroom into a haven of comfort by choosing AXOR at Maruthi Ceramics, where excellence converges with elegance. Elevate your space with the finest in bathroom fixtures, and let the seamless amalgamation of form and function redefine your daily rituals.

AXOR showers create a space for appreciation; their design, material, and the way they set the stage for the precious element of water lend the shower setting a flawless appearance. For the best AXOR shower products and AXOR bathroom accessories in Bangalore, visit our showroom and enjoy the perfection of AXOR brands with innovative features.

2 notes

·

View notes

Text

EPDM Hoses: The Heat-Resistant Tubing for Hot Water Applications

EPDM (ethylene propylene diene monomer) hoses have become a popular choice for hot water applications in recent years. As a versatile synthetic rubber material, EPDM offers superior heat resistance, flexibility, and durability compared to traditional rubber hoses.

In this article, we’ll explore the key benefits of using EPDM hot water hoses, their typical applications, what to look for when selecting one, and proper care and maintenance tips. Whether you need a hose for a dishwasher, washing machine, or just to conveniently transport hot water, read on to learn why EPDM is an ideal tubing material.

For More Information Please visit, epdm hot water hose

Key Benefits of EPDM Hot Water Hoses

Temperature resistance – EPDM rubber maintains its strength and flexibility in continuous temperatures up to 150°C and is safe for intermittent use up to 230°C. This makes it well-suited for hot water lines.

Chemical resistance – EPDM stands up well to water, detergents, oil, and other common chemicals. It won’t degrade or leach contaminants into the water flow.

Durability – Properly maintained EPDM hoses can last for many years. The material is ozone, weather, and abrasion resistant. It also has excellent tensile strength.

Flexibility – EPDM tubing remains pliable and kink-resistant even when subjected to repeated bending. This allows it to move freely without restricting water flow.

Cost-effective – EPDM is an affordable hose material that provides exceptional performance per dollar compared to other rubber, plastic, or metal options.

Typical Applications

Dishwasher supply lines – EPDM is perfect for the high heat sanitizing cycles dishwashers run. Flexible EPDM tubing won’t crack under the strain of repeated movements either.

Washing machine hoses – For hot water inlet lines that must withstand high pressures and temperatures over years of use.

Hot water transport – Durable EPDM hoses allow safe, convenient transport of hot water for cleaning, outside showers, etc.

Radiant heating systems – Flexible EPDM tubing can be bent around tight spaces to run in-floor home heating systems.

Solar water systems – High heat resistance makes EPDM ideal for solar water heating system transport lines.

Hose Selection Considerations

When selecting an EPDM hot water hose, key factors to consider include:

Temperature rating – Hoses rated for 190°F+ are best for typical residential hot water heating systems. Industrial applications may require 500°F+ rated EPDM.

Hose diameter – Standard sizes include 1⁄2”, 5⁄8”, and 3⁄4” for home use. Larger diameters provide increased water volume.

Pressure rating – Look for at least 100 PSI working pressure and a high burst pressure. industrial uses may require 500+ PSI rated hoses.

End fittings – Brass and stainless steel fittings offer maximum durability and temperature resistance. Plastic fittings can degrade over time.

Approvals – Look for EPDM hoses certified lead-free and drinking water safe by NSF, WRAS, or other standards organizations.

Proper Care and Maintenance

With proper care, EPDM hot water hoses can last 5-10 years or longer:

Inspect regularly – Check for damage, leaks, kinks, or corrosion. Replace suspect hoses.

Avoid overheating – Don’t exceed the hose’s rated working temperature.

Protect from UV light – Sunlight can degrade EPDM over time. Use UV-resistant covers outdoors.

Clean as needed – Flush out mineral deposits with vinegar. Don’t use solvents on EPDM.

Avoid kinks – EPDM is flexible but kinking can restrict water flow. Install with gentle bends.

Conclusion

Thanks to its durable, flexible, heat-resistant design, EPDM is the ideal tubing material for hot water applications ranging from dishwashers to radiant floor heating. Following the selection and care tips above will help ensure you choose the right EPDM hose and get the most service life out of it. Investing in a quality EPDM hot water hose will provide reliable performance for years to come.

2 notes

·

View notes

Text

Drain Line For Mini Split Wall Mount Indoor Units in Minisplitwarehouse.com

Get Drain Line For Mini Split Wall Mount Indoor Units.

Specially designed for mini split systems, this condensate drain tube is a flexible drain hose made from LLPDE 2181 Series UV Resistance 783 material and features a large, 5/8" inner diameter for condensate to be diverted away from your system and out of your building. It is sized for condensate removal from your indoor wall mount unit.

PRICE: $19.99 ex. tax

mini split accessories, ductless accessories, mini split install accessories, ductless install accessories, split ac accessories

mini split parts, ductless parts, ac parts, heat pump parts, split air conditioner parts

LINK:

https://www.minisplitwarehouse.com/category/accessories

https://www.minisplitwarehouse.com/category/mini_split_air_conditioner_parts_and_accessories

2 notes

·

View notes

Text

Plumbing Tips You Need To Hear Today

A problem with your plumbing can happen anytime. If it does, you need to know what to do about it. It is possible for you to take care of many of these problems on your own. Here are some helpful tips to teach you how to handle plumbing problems yourself.

Find a plumber that you can trust. Make sure to get referrals from friends and family so that you can prevent getting ripped off, which happens often. Also make sure not to pay the plumber before the work is completed. If you do that, there will not be an incentive to get the job completed in a timely manner.

Keep your bathtub drain running well by pouring a cup of baking soda followed by a cup of vinegar down the drain each month. Afterward, place a washcloth or towel over the top of the drain, to keep the chemical reactions contained. Let that sit for a while, and then run boiling hot water down it. This process should open up the pipes by clearing out hair build-up and soap scum.

Frozen pipes can lead to many problems, most of them expensive to fix. So you want to avoid that at all costs. To avoid frozen pipes, make sure the temperature in your home never drops below 55 degrees. Look for any air leaks around your pipes and make sure they're sealed up.

If you have a lot of hair in your shower drain, be sure to get a stopper and put it in the drain. This will catch the hair from going down the drain, which can clog it. Just make sure that you remove hair that is already in the drain before using the stopper.

Sometimes kitchen sinks can be clogged up due to a slow accumulation of solidified grease. One quick fix for this is to try pouring very hot grease down the sink, which will liquefy the grease clogging the drain and carry it down. Water won't work, because grease will not dissolve in water.

To get drain unblockers auckland from a plumber, shop around and keep notes. When you get a price quote from the first plumber you call, you can subtly mention that price to the second and see if they will beat it. If you keep doing this down a list, you can drive down the price considerably.

Teach kids how to shut off the toilet's water supply. Kids are notorious for putting large wads of toilet paper and other things into the toilet, which inevitably leads to the toilet overflowing. Especially if your bathroom has carpet, show kids how to turn the water valve off if the toilet water keeps rising, to prevent the mess of an overflow.

If you have a crack in your toilet tank, you can sometimes fix this with an epoxy resin. However, it is very difficult to keep up with this type of maintenance, and the best bet may be contacting the supplier and ordering a new tank to be installed in your bathroom. Nevertheless, keeping some epoxy resin on hand for emergencies is a good idea.

Beware of black water in your toilet tank. Chances are, the color is caused from too much magnesium or iron in your water. Although this is usually harmless, it can be annoying for some people. If it is iron or magnesium in your water, the only way to fix it is by filtering the water.

The water heater in your home needs to have regular flushing to its plumbing in order to work properly. There is usually a valve at the bottom of the water heater that a hose can be attached to. Connect a hose to this valve and open it up all the way to flush scale and deposits out of the system.

Check the plumbing in your home. If your home has the flexible gray polybutylene water pipes, you need to have a plumber come out and assess their condition. These types of pipe are prone to failure and can lead to very costly repairs if they have a failure within your home.

When you have a plumbing problem that comes up in your home, you do not necessarily have to pay a plumber a lot of money to come out and fix it for you. The helpful points you learned in this article will enable you to care for basic plumbing maintenance and repairs around your home yourself.

2 notes

·

View notes

Text

Caravan Gas Installation

The first step in a successful caravan gas installation is to install a shut-off valve. This valve should be clearly visible and easily accessible. After this, you need to connect your caravan gas appliances to a copper pipe that runs along the outside of your caravan. If there is room in the caravan, a branch pipe should be run into it. Avoid flexible hoses, as they do not offer the best safety and durability. It is also important to fasten the joints where the appliances are installed securely. This way, movement will not weaken the joints.

Depending on your type of caravan, you will need four parts for your gas system: the gas cylinder, regulator, copper pipes, and pigtail. The gas cylinder is a small round tank that stores liquefied petroleum gas. The cylinder is typically installed outside the caravan, as the gas is more flammable and can cause a fire. Copper pipes are used to connect the regulator to the appliances. In addition to a gas regulator, you will also need a gas bottle holder for safe storage.

When installing gas appliances in a caravan, it is important to follow all safety regulations, which include regulations for the use of gas. The gas installation must meet the essential safety requirements set out in AS/NZS 5601.2. The person who connects your installation to the gas supply should ensure that it is compatible, safe, and certified. Connection is the final gasfitting work, and includes the fitting of new gas connection hoses.

When it comes to ventilation, you need to make sure you choose a suitable size and placement for your caravan gas appliances. If you're installing a barbecue, you should choose one with a minimum of 15 megajoules of gas per hour. In addition, you should choose one that has two permanent vents and a roof hatch. The ventilation area should be at least 45 centimeters squared. The vents should be in an open space that is free of obstructions.

Ensure your regulator is in good condition before starting your new caravan gas installation. A faulty regulator is a big cause of gas problems, especially in older RVs. Make sure you install a new bottle regulator if your RV is more than 5 years old. This will help you use your appliances without any problems. The bottle regulator will also help keep your system leak-free. Before you start cooking or using a gas appliance, make sure the valve is closed. Only use the appliance for its intended purpose. Never use a stove or fridge as a room heater.

Next, you need to connect the regulator to the caravan appliances. You should choose a two-stage regulator, with the vent facing down and pointing downwards. The regulator's outlet pressure should be less than three kPa. You should also use copper pipe of appropriate size for your caravan, as well as the number of appliances you plan to use. Your professional gas fitter will be able to give you a specific recommendation for the size of copper pipe to connect to the regulator.

1 note

·

View note

Text

Demystifying Hydraulic Fittings: Understanding Their Importance and Types

Introduction:

Hydraulic fittings might not be something you think about every day, but they're crucial components in many machines and systems that power industries worldwide. Let's take a closer look at what hydraulic fittings are, why they're essential, and the different types available.

What are Hydraulic Fittings?

Hydraulic fittings are connectors used to join hydraulic hoses, tubes, and pipes in hydraulic systems. These systems use liquid fluid power to perform work, such as lifting heavy loads, operating machinery, or controlling equipment.

Why Are They Important?

Hydraulic fittings play a vital role in ensuring the proper functioning and efficiency of hydraulic systems. Here's why they're important:

1. Leak Prevention:

Hydraulic fittings create sealed connections between components, preventing hydraulic fluid from leaking out and air from entering the system. This is crucial for maintaining system integrity and preventing performance issues.

2. Flexibility:

Hydraulic fittings allow for flexible routing of hoses and pipes, enabling hydraulic systems to adapt to different configurations and operational requirements.

3. Pressure Management:

Properly selected and installed hydraulic fittings help manage fluid pressure within the system, ensuring safe and efficient operation without leaks or bursts.

4. Maintenance and Repair:

Hydraulic fittings facilitate easy assembly, disassembly, and maintenance of hydraulic systems, reducing downtime and maintenance costs.

Types of Hydraulic Fittings:

There are several types of hydraulic fittings, each designed for specific applications and connection requirements. Here are some common types:

1. Threaded Fittings:

These fittings have threads on their ends, allowing them to screw into corresponding threaded ports on hydraulic components. They come in various thread types, such as NPT (National Pipe Thread) and BSPP (British Standard Pipe Parallel).

2. Flared Fittings:

Flared fittings feature a conical flare on the end of the fitting, which mates with a matching flare on the hydraulic component. They provide a secure, leak-resistant connection and are commonly used in high-pressure applications.

3. Crimp Fittings:

Crimp fittings require a hydraulic crimper to attach them to hoses or tubes. They provide a strong, permanent connection and are widely used in heavy-duty hydraulic systems.

4. Quick Disconnect Fittings:

These fittings allow for fast and easy connection and disconnection of hydraulic hoses without the need for tools. They're ideal for applications requiring frequent hose changes or temporary connections.

Stainless Steel Hydraulic Fittings Manufacturer in India

Ladhani Metal Corporation is one of the leading SS Hydraulic Fittings Manufacturers in India. We are an experience-driven business that seeks to enhance both the organization and the lives of its clients by making the best use of available resources and technological advancements. For its manufacturing facility, we also have access to approved subcontractors and outside vendors, which helps us support urgent orders as well as large project orders.

Conclusion:

Hydraulic fittings are essential components in hydraulic systems, enabling seamless connections, efficient fluid power transmission, and reliable operation. Understanding the different types of hydraulic fittings and their applications is crucial for designing, assembling, and maintaining hydraulic systems across various industries. Whether it's in construction, agriculture, manufacturing, or aerospace, hydraulic fittings play a vital role in powering the machinery and equipment that drive modern civilization.

0 notes

Text

Some Important Things you need to know about Bar Faucets

You know how important Bar Faucets are. They provide you with that use and comfort.

Also, they make your tasks such as washing glasses, filling pitchers, and rinsing utensils easier.

Bar Faucets are overlooked in many spaces. But you shouldn’t do that.

Choosing the right type of bar faucet will make sure about the use and look of your overall home bar.

So, diving in you’ll get to know some important things about the bar faucets.

Understanding Bar Faucets

Let’s start with a little understanding of Bar Faucets.

They are specially designed faucets and are smaller in size. They are generally installed in wet bars, prep sinks, or in kitchen islands.

Also, they are purposefully designed to fit the overall look of your bar areas. They offer comfort for bartending and some other entertaining purposes.

They are similar in function to kitchen faucets. But don’t doubt them, because they are more compact and they feature a higher spout height.

Types of Bar Faucets

Now, comes the types of Bar Faucets. Whenever you choose a bar faucet for your home bar, you should keep in mind about the designs and installation requirements of them.

Some of the bar faucets are:

1. Single-Handle Faucets: They feature a single lever or handle for controlling both the temperature and flow of water. They offer simplicity and ease of use.

2. Dual Handle Faucets: Dual handle-bar faucets offer two different handles for hot and cold water. It allows you for precise temperature control and customization.

3. Pull-Down Faucets: Pull-down bar faucets feature a flexible hose or spout that can be pulled down or extended for easier rinsing and cleaning tasks.

4. Wall-Mounted Faucets: Wall-mounted bar faucets are installed directly onto the wall above the sink. It saves space on the countertops, giving us a modern and catchy look.

5. Bridge Faucets: Bridge bar faucets have a unique design with a bridge connecting the hot and cold water handles to the spout, offering a classic and elegant aesthetic.

Features to Consider

There are several features you can think of when selecting a bar faucet. The faucet you’re choosing must fit your needs and preferences.

Some of the key features you should consider are:

1. Spout Height and Reach: Choose a bar faucet with a proper spout height and reach to help your sink or prep area and provide plenty of clearance for filling and rinsing tasks.

2. Finish Options: Bar faucets come in a range of finishes, including chrome, stainless steel, brushed nickel, and bronze. Choose a finish that goes with your existing kitchen decor and matches other fixtures and hardware.

3. Spray Options: If you choose a pull-down or pull-out bar faucet, I need you to think about the spray options available, such as aerated spray, stream, and pause function, for added flexibility and comfort.

4. Installation Compatibility: Make sure that the bar faucet you choose fits well with your existing sink or prep area and can be installed easily without the need for extensive modifications.

5. Quality and Durability: Invest in a high-quality bar faucet made from durable materials such as solid brass or stainless steel to ensure long-lasting performance and reliability.

Installation Tips

Now, here are the installation tips. Installing a bar faucet is a very simple and easy process if you have the right amount of tools and know-how.

Here are some tips on installing bar faucets.

1. Turn Off the Water Supply: Before beginning the installation process, shut off the water supply to the sink or prep area to prevent any leaks or water damage.

2. Follow Manufacturer Instructions: Refer to the manufacturer's instructions included with your bar faucet for step-by-step installation guidance and any specific requirements or recommendations.

3. Use Proper Tools: Make sure you have all the required tools and equipment on hand, including wrenches, screwdrivers, and plumber's tape, to complete the installation safely and effectively.

4. Check for Leaks: Once the bar faucet is installed, check for any leaks or drips and tighten connections as needed to ensure a secure and watertight seal.

Maintenance and Care

If you want your bar faucet to operate smoothly and keep looking your best. You should do regular maintenance and care of it.

Here are some tips to follow:

1. Clean Regularly

2. Avoid Harsh Chemicals

3. Check for Leaks

4. Inspect Connections

Conclusion

Choosing the bar faucet which fits your home bar or entertainment area is very important.

You must understand the different bar faucet types, features, installation tips, and maintenance.

It doesn’t matter what you prefer, whether you choose a modern bar faucet or a traditional one. You can find the perfect faucet as per your need, with the right amount of research.

0 notes

Text

Single-button stainless steel hose anti-pressure plating wire protection metal hose

Length can be customized to give you more flexibility and freedom.

Made of solid copper swivel core, very intuitive, flexible and kink-free. Easy to install by twisting with both hands and tightening.

The chrome-plated surface of the outer tube is resistant to corrosion and abrasion and has good abrasion resistance. The chrome-plated layer has a low coefficient of friction, especially the dry friction coefficient, which is the lowest among all metals. So the chrome plated layer has good wear resistance.

Rigorously tested to ensure quality performance, the standard size solid copper connector fits most shower fixtures with 1/2 inch ends for easy installation.

0 notes

Text

Industrial Fittings Supplier in Bengaluru

Simplex Steels is a Manufacturer, Stockiest, and Industrial Fittings Supplier in Bengaluru, Karnataka.

Simplex Steels specializes in stainless steel products, including sheets, plates, coils, pipes, tubes, bars, wires, rods, channels, flats, and industrial flanges.

They are corrosion-resistant, durable, and available in different dimensions, sizes, and standards like ASTM, ASME, AISI, DIN, BS, EN IS, JIS, and other international standards.

Our products are manufactured using high-quality materials and precision engineering techniques to ensure durability, reliability, and performance.

Fittings are utilized for both rigid pressure line pipelines and flexible hose lines, facilitating the connection of installation elements.

Clips, clamps, and crimping ferrules secure the fittings to hoses. Furthermore, assembly clips and clamps actively affix pipes and hoses to the base construction.

We understand that every industrial application is unique, which is why we offer customized solutions to meet specific requirements.

We adhere to stringent quality control measures at every stage of the manufacturing process to ensure that our fittings meet the highest standards of quality and performance.

You can trust our products to deliver consistent and reliable results, even in the most demanding industrial environments.

We are offering various types of Industrial Fittings:

Buttweld Fittings

Forged Fittings

Socket Weld Fittings

Features:

Corrosion Resistant

High Tensile Strength

Very Durable

Temperature Resistant

Environmentally Friendly

Low-maintenance (long-lasting)

Attractive appearance

Long Durability

High Strength

Bend Fittings

Simplex Steels is an Industrial Fittings Supplier in Bengaluru, Karnataka, including various locations like

Kolar, Mangaluru, Kalaburagi, Udupi, Tumakuru, Vijayapura, Hosapete, Belagavi, Kalaburagi, Koppal, Uttara Kannada, Chitradurga, Hassan.

For further details, please feel free to contact us.

Read the full article

0 notes

Text

The Humble Plastic Tube: Uses and Benefits in Our Everyday Lives

Plastic tubing is a hidden workhorse in countless applications around us. From your car to your garden hose, and even the medical equipment in hospitals, plastic tubing plays a vital role. But what makes it so useful? Let’s delve into the world of plastic tubing and explore its advantages.

Benefits of Plastic Tubing:

Durability: Plastic tubing is built to last. It’s resistant to corrosion, weathering, and even shocks in many cases. This makes it ideal for underground irrigation systems or applications exposed to the elements.

Flexibility: Unlike rigid pipes, plastic tubing can bend and maneuver around obstacles. This is particularly beneficial in tight spaces or for applications requiring intricate routing, such as medical devices or fish tanks.

Lightweight: Plastic tubing is significantly lighter than metal alternatives. This translates to easier transportation, handling, and installation, reducing overall costs.

Chemical Resistance: Different plastic types offer varying degrees of resistance to chemicals. This allows them to safely transport a wide range of liquids, from potable water to harsh industrial fluids.

Cost-Effective: Plastic tubing is generally less expensive than metal pipes. Additionally, its lightweight nature and ease of installation contribute to lower overall project costs.

Versatility: Plastic tubing comes in various sizes, diameters, and materials to suit a wide range of applications. Whether you need it for plumbing, medical equipment, or electrical cable protection, there’s a plastic tubing option for you.

Uses of Plastic Tubing:

Construction and Plumbing: Plastic tubing is extensively used in potable water distribution, drainage systems, and irrigation.

Automotive Industry: From fuel lines to coolant hoses, plastic tubing plays a crucial role in car function.

Medical Field: Sterile plastic tubing is vital in medical equipment for fluid transfer and administration.

Aquaculture and Aquariums: Flexible and inert plastic tubing is perfect for water circulation and air supply in fish tanks and ponds.

Electrical Applications: Plastic tubing provides insulation and protection for electrical wires and cables.

Beverage Industry: Many beverage dispensing systems utilize plastic tubing for efficient transfer and dispensing.

Packaging: Plastic tubing is sometimes used for product packaging, particularly for delicate or stringy items.

In Conclusion:

Plastic tubing, while often unnoticed, is an essential component in our daily lives. Its versatility, affordability, and durability make it a go-to choice for various applications across industries. As technology advances, we can expect even more specialized plastic tubing solutions to emerge in the future.

#plastic bags#plastic tubing#printed plastic bags#plasticmanufacturer#clear plastic bags#plasticsheeting#plastic bags south africa

0 notes

Text

Elevating Your Entrance: Exploring the Benefits of the EMI ALU Primary Entrance Mat System

Entryways serve as the gateway to buildings, welcoming guests and occupants while also bearing the brunt of foot traffic. To ensure cleanliness, safety, and aesthetic appeal, investing in a robust entrance mat system is paramount. Among the array of options available, the EMI ALU Primary Entrance Mat System stands out as a versatile and effective solution. Let's delve into its features, benefits, and why it's a wise choice for enhancing your entrance.

Understanding the EMI ALU Primary Entrance Mat System

The EMI ALU Primary Entrance Mat System is engineered to excel in high-traffic areas, offering superior dirt and moisture control. Its construction comprises a durable aluminum base with a variety of insert options, including carpet, rubber, and abrasive materials. This modular design allows for customization to suit specific aesthetic and functional requirements.

Key Features and Benefits

1. Exceptional Dirt and Moisture Control:

The primary function of any entrance mat system is to trap dirt and moisture effectively, preventing them from being tracked further into the building. The EMI ALU system achieves this with precision, thanks to its highly absorbent insert options and well-engineered construction.

2. Durability and Longevity:

Constructed with high-quality materials, including corrosion-resistant aluminum, the EMI ALU system is built to withstand heavy foot traffic and harsh weather conditions. Its robust design ensures longevity, offering a reliable solution for years to come.

3. Versatility in Design:

With a range of insert materials and colors available, the EMI ALU system provides flexibility in design. Whether you prefer a sleek, modern look or a more traditional aesthetic, there's an option to complement any entrance décor.

4. Easy Maintenance:

Keeping entrance areas clean and presentable can be a challenge, but the EMI ALU system simplifies maintenance tasks. Its removable inserts facilitate easy cleaning, while the durable base requires minimal upkeep, saving time and effort for facility managers.

5. Enhanced Safety:

Slip-and-fall accidents are a significant concern in public buildings, but the EMI ALU system helps mitigate this risk. Its textured surface options provide traction even when wet, reducing the likelihood of slips and falls and enhancing overall safety.

Applications

The versatility of the EMI ALU Primary Entrance Mat System makes it suitable for various applications, including:

- Commercial buildings: From office complexes to retail spaces, the EMI ALU system can handle the foot traffic demands of busy commercial environments.

- Educational institutions: Schools and universities can benefit from the dirt and moisture control provided by the EMI ALU system, helping to maintain clean and safe entryways.

- Healthcare facilities: In hospitals and clinics, where cleanliness is paramount, the EMI ALU system contributes to a hygienic environment by trapping contaminants at the door.

- Hospitality sector: Hotels, resorts, and restaurants can create a welcoming first impression with the customizable design options offered by the EMI ALU system.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for maximizing the performance and lifespan of the EMI ALU Primary Entrance Mat System. Here are some tips to ensure optimal results:

- Follow manufacturer guidelines: Adhere to the recommended installation procedures provided by EMI to ensure the system functions as intended.

- Regular cleaning: Establish a routine cleaning schedule to remove dirt and debris from the mat inserts. Vacuuming or hosing down the inserts can help maintain their effectiveness.

- Inspect for damage: Periodically check the condition of the mat system and replace any worn or damaged inserts or components promptly.

- Address drainage issues: Ensure proper drainage around the entrance area to prevent water from pooling beneath the mat system, which could lead to mold or corrosion.

Conclusion

In conclusion, the EMI ALU Primary Entrance Mat System offers a comprehensive solution for maintaining clean, safe, and visually appealing entryways. With its durable construction, customizable design options, and superior performance, it's an investment worth considering for any building looking to elevate its entrance experience. By implementing the EMI ALU system, you can make a lasting impression on visitors while enhancing the overall functionality and aesthetics of your space.

0 notes

Text

Choosing the Right EPDM Rubber Sheets: A Buyer's Guide for Industrial Needs

EPDM rubber sheets are essential components in various industrial settings, offering durability, flexibility, and resistance to weathering and chemicals. This comprehensive buyer's guide aims to assist industrial buyers in selecting the right EPDM rubber sheets for their specific needs. We'll delve into the properties, applications, types, and key considerations to ensure a well-informed purchasing decision.

Understanding EPDM Rubber Sheets

Definition and Composition: What is EPDM rubber, and how is it manufactured?

Physical and Chemical Properties: Explore the key characteristics such as resistance to heat, weather, ozone, and chemicals.

Advantages and Limitations: Highlight the benefits and potential drawbacks of using EPDM rubber sheets in industrial applications.

Applications of EPDM Rubber Sheets

Automotive Industry: Discuss EPDM's role in automotive seals, gaskets, hoses, and weatherstripping.

Building and Construction: Explore its use in roofing membranes, seals, and expansion joints.

HVAC Systems: Explain how EPDM sheets are utilized in HVAC gaskets and insulation.

Electrical Industry: Touch upon EPDM's electrical insulation properties in cables and wires.

Marine and Outdoor Applications: Discuss its suitability for marine seals, pond liners, and outdoor equipment.

Types of EPDM Rubber Sheets

Solid EPDM Sheets: Describe solid EPDM sheets and their applications in static sealing.

Sponge EPDM Sheets: Explain the characteristics and uses of sponge EPDM for cushioning and sealing.

Reinforced EPDM Sheets: Discuss reinforced EPDM sheets with fabric or metal inserts for added strength.

FDA-Approved EPDM Sheets: Highlight EPDM sheets compliant with FDA regulations for food and beverage applications.

Key Considerations for Choosing EPDM Rubber Sheets

Temperature Resistance: Consider the operating temperature range and thermal stability required.

Chemical Compatibility: Evaluate the resistance to oils, acids, alkalis, and other chemicals as per application needs.

Durability and Longevity: Assess the expected lifespan and performance under continuous use and environmental exposure.

Compression Set and Elasticity: Examine the ability to recover from compression and maintain sealing properties.

Thickness and Dimensions: Determine the optimal thickness and dimensions based on sealing requirements and equipment specifications.

Certification and Standards: Look for EPDM sheets compliant with industry standards such as ASTM, FDA, and NSF.

Selecting EPDM Rubber Sheets for Specific Industries

Automotive Sector: Recommend EPDM sheets with high resistance to automotive fluids and weathering.

Construction and Roofing: Suggest EPDM membranes with excellent UV resistance and waterproofing properties.

HVAC and Plumbing: Highlight EPDM gaskets and seals suitable for HVAC systems and plumbing applications.

Electrical and Electronics: Emphasize EPDM's electrical insulation properties for cables and electrical enclosures.

Food and Beverage: Discuss FDA-approved EPDM sheets for food processing equipment and seals.

Installation and Maintenance Tips

Surface Preparation: Guide on cleaning and preparing surfaces for optimal adhesion and sealing.

Cutting and Fabrication: Provide instructions on cutting, shaping, and fabricating EPDM sheets for custom applications.

Sealing Techniques: Explain the proper sealing methods using adhesives, tapes, or mechanical fasteners.

Maintenance Guidelines: Offer maintenance tips to prolong the lifespan and performance of EPDM rubber sheets.

Top Manufacturers and Suppliers

Profile leading manufacturers and suppliers of EPDM rubber sheets, detailing their product range, certifications, and customer support.

Compare product offerings, pricing, delivery options, and customer reviews to aid buyers in choosing reliable suppliers.

Cost Analysis and Budgeting

Break down the cost factors including material prices, quantity discounts, shipping, and installation expenses.

Provide a budgeting framework and cost-saving tips for optimizing the purchase of EPDM rubber sheets.

Future Trends and Innovations

Discuss emerging trends in EPDM technology such as enhanced chemical resistance, eco-friendly formulations, and smart materials.

Highlight ongoing research and development efforts aimed at improving EPDM performance and sustainability.

Conclusion:

Choosing the right EPDM rubber sheets is crucial for ensuring performance, durability, and cost-effectiveness in industrial applications. This buyer's guide equips buyers with essential knowledge, considerations, and resources to make informed decisions and select EPDM sheets that meet their specific requirements.

SantopSeal uses a Thermoplastic rubber Santoprene TPE/TPV material to create custom profile extrusions of various shape and size of Seals & Gaskets as a solution to all your sealing needs. Using Thermoplastic elastomer Santoprene™, we supply major industries with a wide variety of inexpensive and customizable options. We offer various Tpe Pipe Santoprene tubing including Food grade, Thermoplastic Tubing, and general grade tubing, Extruded Seals and Gaskets, Extruded EPDM Sponge Rubber Seal, Standard & Flange Gaskets, and Digital knife cutting services. Contact us today via web, email, or phone and someone from our engineering or support team will be happy to answer any of your questions.

0 notes