#ss flexible hose installation

Text

Stainless Steel Flexible Hose Installation

As a top stainless steel flexible hose manufacturer, we offer best quality products that meet the highest standards of durability, reliability, and performance. Our expertise in crafting stainless steel hoses that are useful in various industrial and commercial applications, providing superior flexibility, corrosion resistance, and longevity. With thorough attention to detail and advanced manufacturing techniques, we ensure that each steel hose fittings meets rigorous quality control measures to guarantee customer satisfaction. Whether you require hoses for fluid conveyance, gas transfer, or other specialized applications, our diverse range of stainless steel flexible hoses, stainless steel braided hoses is designed to meet your specific needs.

Properly installing stainless steel flexible hoses is essential to maximize their performance and longevity. A well-executed installation reduces the likelihood of accidents, injuries, and environmental damage. It's crucial to maintain the structural integrity of the steel hose fittings by employing appropriate installation methods, such as selecting compatible fittings and avoiding excessive bending or twisting.

Before installing stainless steel flex hose we need to look out below factors:

Application Requirements: Determine the specific application and operational conditions of the SS flexible hose will encounter, including pressure, temperature, fluid compatibility, and environmental factors.

Hose Material: Select a hose material compatible with the fluid being transferred and the operating environment. Factors such as chemical resistance, temperature tolerance, and flexibility should be taken into account.

Hose Size and Length: Choose the appropriate hose size and length to accommodate the flow rate, pressure, and distance required for the application.

End Connections:Select compatible end fittings for SS flexible hoses that ensure a secure and leak-free connection between the hose and the equipment or piping system.

Installation Environment: Assess the installation environment for potential hazards, such as sharp edges, abrasive surfaces, or exposure to extreme temperatures, that could damage the steel hose fittings.

Routing and Positioning:Plan the routing and positioning of the hose to minimize bends, twists, and kinks, which can restrict flow and reduce steel hose fittings lifespan.

Flexibility Requirements: Consider the flexibility requirements of the hose to accommodate movement, vibration, and thermal expansion within the system.

Installation Method: Follow manufacturer recommendations and industry best practices for steel flexible hose installation, including proper anchoring, support, and protection against external damage.

Inspection and Maintenance: Establish a regular inspection and maintenance schedule to monitor hose condition, identify wear or damage, and address any issues promptly to prevent leaks or failures.

By meticulously assessing these factors before installing stainless steel hoses, you can guarantee efficient operation, durability, and safety to implement in industrial applications.

Installing a Stainless Steel Hose:

Preparation: Gather all necessary tools and equipment, including appropriate fittings and adapters.

Inspect the Hose: Before installation, carefully examine the stainless steel hose for any defects, damage, or irregularities. Ensure it meets the required specifications and standards.

Prepare the Connection Points: Clean and inspect the connection points where the hose will be installed to ensure they are free of debris, corrosion, or damage that could affect the seal.

Cutting the Hose (if needed): If the hose needs to be trimmed to fit the installation, use a suitable cutting tool to make a clean, straight cut. Avoid damaging the hose or its reinforcement layers.

Attach Fittings: Install the appropriate fittings onto each end of the hose, ensuring they are securely tightened according to the manufacturer's recommendations. Use the correct type and size of fittings for the application.

Align and Position:Mount the stainless steel flexible hose assemblies according to their position in the installation area. Take care to protect the metallic lining from moisture, which can cause rust and affect hose functionality. While hose clamping is necessary, avoid using excessive clamps as it may have adverse effects.

Secure the Hose: Once properly aligned, securely tighten the fittings onto the connection points using suitable wrenches or tools. Avoid over-tightening, which could damage the fittings or distort the hose.

Test for Leaks: After installation, perform a pressure test to check for any leaks or abnormalities. Gradually increase the pressure to the specified level while inspecting all connection points for signs of leakage.

Final Inspection: Once the installation is complete and no leaks are detected, visually inspect the entire assembly to ensure it is properly installed, aligned, and supported.

By following these steps, you can ensure the proper installation of a stainless steel hose.

Common Mistakes to Avoid When Installing Stainless Steel Hoses

Steer Clear of Torque: Torque may occur in a hose due to twisting during installation or flexure. However, this issue can be addressed by including a floating or union flange at each end of the hose assembly. It's important to install the fixed flange ends securely before securing the floating flange ends.

Prevent Out-of-Plane Flexing: Secure the hose to restrict flexing to a single plane, preventing twisting during bending. As stated in the flexible steel hose Installation Guide, it's vital to avoid out-of-plane flexing during installation. Ensure that the bending plane aligns with the direction of bending.

Reduce Bending: Repeatedly bending a hose with a radius smaller than specified can cause the hose to fail prematurely. It's recommended to ensure adequate length to reduce excessive bending and alleviate stress on the hose.

Avoid Sharp Bends: Avoiding repeated sharp bends in hoses is crucial, as they can occur due to improper installation. To prevent such bends, make sure that the lowest centerline bend radius for intermittent bending never falls below the specified values provided in the technical data section.

Conclusion

Our guide provides essential tips for installing flexible steel hoses. It covers everything from application needs to hose sizing and safety precautions. Following these guidelines ensures a reliable installation, maximizing both performance and durability. Stainless flexible hoses are durable & corrosion-resistant suitable for various industries. Prioritize your requirements, make informed decisions, and focus on safety for smooth operations.

For top-quality SS flexible hoses, choose Qflex - Quality Foils India, a leading manufacturer in India. We offer effective installation services and high-quality products at competitive prices to meet all your needs.

#ss flexible hose installation#flexible hose installations#stainless steel flexible hoses#flexible metal hosese

1 note

·

View note

Text

Demystifying Hydraulic Fittings: Understanding Their Importance and Types

Introduction:

Hydraulic fittings might not be something you think about every day, but they're crucial components in many machines and systems that power industries worldwide. Let's take a closer look at what hydraulic fittings are, why they're essential, and the different types available.

What are Hydraulic Fittings?

Hydraulic fittings are connectors used to join hydraulic hoses, tubes, and pipes in hydraulic systems. These systems use liquid fluid power to perform work, such as lifting heavy loads, operating machinery, or controlling equipment.

Why Are They Important?

Hydraulic fittings play a vital role in ensuring the proper functioning and efficiency of hydraulic systems. Here's why they're important:

1. Leak Prevention:

Hydraulic fittings create sealed connections between components, preventing hydraulic fluid from leaking out and air from entering the system. This is crucial for maintaining system integrity and preventing performance issues.

2. Flexibility:

Hydraulic fittings allow for flexible routing of hoses and pipes, enabling hydraulic systems to adapt to different configurations and operational requirements.

3. Pressure Management:

Properly selected and installed hydraulic fittings help manage fluid pressure within the system, ensuring safe and efficient operation without leaks or bursts.

4. Maintenance and Repair:

Hydraulic fittings facilitate easy assembly, disassembly, and maintenance of hydraulic systems, reducing downtime and maintenance costs.

Types of Hydraulic Fittings:

There are several types of hydraulic fittings, each designed for specific applications and connection requirements. Here are some common types:

1. Threaded Fittings:

These fittings have threads on their ends, allowing them to screw into corresponding threaded ports on hydraulic components. They come in various thread types, such as NPT (National Pipe Thread) and BSPP (British Standard Pipe Parallel).

2. Flared Fittings:

Flared fittings feature a conical flare on the end of the fitting, which mates with a matching flare on the hydraulic component. They provide a secure, leak-resistant connection and are commonly used in high-pressure applications.

3. Crimp Fittings:

Crimp fittings require a hydraulic crimper to attach them to hoses or tubes. They provide a strong, permanent connection and are widely used in heavy-duty hydraulic systems.

4. Quick Disconnect Fittings:

These fittings allow for fast and easy connection and disconnection of hydraulic hoses without the need for tools. They're ideal for applications requiring frequent hose changes or temporary connections.

Stainless Steel Hydraulic Fittings Manufacturer in India

Ladhani Metal Corporation is one of the leading SS Hydraulic Fittings Manufacturers in India. We are an experience-driven business that seeks to enhance both the organization and the lives of its clients by making the best use of available resources and technological advancements. For its manufacturing facility, we also have access to approved subcontractors and outside vendors, which helps us support urgent orders as well as large project orders.

Conclusion:

Hydraulic fittings are essential components in hydraulic systems, enabling seamless connections, efficient fluid power transmission, and reliable operation. Understanding the different types of hydraulic fittings and their applications is crucial for designing, assembling, and maintaining hydraulic systems across various industries. Whether it's in construction, agriculture, manufacturing, or aerospace, hydraulic fittings play a vital role in powering the machinery and equipment that drive modern civilization.

0 notes

Text

Elevating Home Efficiency with Mcneil Instruments - India's Top Hose Pipe Manufacturer

Introduction:

Hose pipes function as essential pipes that guarantee the smooth flow of water and other necessary liquids in every home. As the leading hose pipe manufacturer in India, Mcneil Instruments' dedication to quality is evident in the variety of goods we offer.

From hydraulic hoses to industrial hoses, SS corrugated hoses to PTFE hoses, and bellows, our offerings cater to diverse needs with uncompromising quality.

Types of Hose Pipes:

1. Hydraulic Hose: Hydraulic hoses are crucial in hydraulic systems and are designed for high-pressure applications offering flexibility and durability.

2. Industrial Hose: Industrial hoses are versatile and used in various industries for conveying fluids, chemicals, and gases.

3. SS Corrugated Hose: Made of stainless steel, SS corrugated hoses are flexible and resistant to pressure, ideal for conveying liquids and gases.

4. PTFE Hoses: PTFE hoses, made of Teflon, are chemical-resistant and can withstand extreme temperatures, enhancing the durability of piping systems.

5. Bellows: Bellows are used to absorb vibration and expansion in piping systems, ensuring smooth operation and longevity.

Pros and Cons of Hose Pipes:

Pros:

Versatility: Hose pipes can be used in various applications, from household to industrial settings.

Flexibility: Hose pipes offer flexibility, allowing for easy installation and maneuverability around obstacles.

Durability: High-quality hose pipes, like those manufactured by Mcneil Instruments, are durable and long-lasting, reducing the need for frequent replacements.

Safety: With features like anti-static and flame resistance, hose pipes ensure safety in various environments.

Cons:

Vulnerable to Damage: Hose pipes may be susceptible to damage from sharp objects or heavy loads, requiring regular inspection and maintenance.

Limited Temperature Range: Some hose pipes may have limitations in terms of temperature range, affecting their suitability for certain applications.

Uses of Hose Pipes:

1. Residential: Hose pipes are essential in homes for activities such as watering plants, washing cars, and filling swimming pools.

2. Industrial: In industries like manufacturing, construction, and agriculture, hose pipes are used for fluid transfer, ventilation, and equipment operation.

3. Commercial: Commercial establishments like restaurants, hotels, and hospitals utilize hose pipes for sanitation, food processing, and HVAC systems.

4. Automotive: In the automotive industry, hose pipes are used for coolant systems, fuel lines, and air conditioning.

Conclusion:

At Mcneil Instruments, we take pride in being India's premier hose pipe manufacturer, offering top-quality products tailored to meet diverse needs. Our range of hose pipes, including hydraulic hoses, industrial hoses, SS corrugated hoses, PTFE hoses, and bellows, are designed for durability, reliability, and safety. With our commitment to excellence and customer satisfaction, we aim to enhance home efficiency and productivity across industries. Trust in Mcneil Instruments for all your hose pipe needs and experience unparalleled quality and service.

0 notes

Text

The Advantages of Using SS Corrugated Hoses in Bangalore's Industrial Sector: Durability, Flexibility, and More

In Bangalore’s bustling industrial sector, where precision and reliability are paramount, the choice of equipment plays a pivotal role in ensuring seamless operations. Among the myriad components employed in industrial settings, stainless steel (SS) corrugated hoses are indispensable. These versatile conduits offer numerous advantages, ranging from durability to flexibility, making them indispensable in various applications across the SS corrugated hoses in the Bangalore industrial landscape.

Understanding SS Corrugated Hoses

Durability: A Cornerstone of Reliability

In Bangalore’s industrial sector, where operations often entail exposure to harsh chemicals, extreme temperatures, and high pressures, durability is non-negotiable. SS corrugated hoses excel in this aspect, exhibiting remarkable resistance to corrosion, abrasion, and fatigue. This inherent robustness ensures prolonged service life, mitigating the need for frequent replacements and minimizing downtime — a critical factor in maintaining productivity and efficiency.

Whether conveying aggressive chemicals in chemical processing plants or handling high-pressure steam in manufacturing facilities, SS corrugated hoses in Bangalore prove their mettle by withstanding the most demanding operational environments with unwavering resilience.

Flexibility: Adapting to Varied Applications

Versatility is another hallmark of SS corrugated hose, making them indispensable across diverse industrial applications in Bangalore. Their inherent flexibility enables easy manoeuvrability, facilitating installation in tight spaces and complex configurations. This adaptability is particularly advantageous in automotive, pharmaceutical, and food processing industries, where space constraints and intricate layouts are commonplace.

Furthermore, SS corrugated hoses can flex and bend without compromising structural integrity, thereby accommodating dynamic movements and vibrations — a crucial requirement in applications involving machinery and equipment subjected to constant motion.

Superior Performance under Pressure

In Bangalore’s industrial landscape, where operations often involve handling pressurized fluids and gases, conveying systems must be reliable. SS corrugated hoses excel, offering superior performance under high-pressure conditions. Their robust construction and precise engineering ensure leak-free operation even at elevated pressures, safeguarding personnel and equipment from potential hazards.

Whether hydraulic systems in manufacturing plants or pneumatic applications in automotive facilities, SS corrugated hoses in Bangalore assure safety and efficiency, even in intense pressure environments.

Temperature Tolerance: Thriving in Extreme Conditions

Bangalore’s industrial sector experiences a spectrum of temperature extremes, from scorching heat to sub-zero conditions. In such environments, equipment’s ability to withstand thermal fluctuations is crucial. SS corrugated hoses excel in this regard, exhibiting exceptional temperature tolerance across a wide range.

Whether conveying hot fluids in industrial ovens or transporting cryogenic gases in refrigeration units, these hoses maintain their structural integrity and performance, ensuring uninterrupted operations regardless of temperature variations.

Hygienic Compliance: Meeting Stringent Standards

Maintaining stringent hygiene standards is paramount in industries such as pharmaceuticals, food processing, and biotechnology. SS corrugated hoses in Bangalore are preferred choices in such applications due to their hygienic properties and ease of cleaning. Stainless steel’s smooth, non-porous surface discourages bacterial growth and facilitates thorough sanitation, minimizing the risk of contamination and ensuring product integrity.

Conclusion: A Testament to Excellence

In conclusion, stainless steel hoses, are indispensable assets in Bangalore’s industrial sector. They embody a perfect blend of durability, flexibility, and performance. Their ability to withstand harsh conditions, adapt to varied applications, and ensure safety and efficiency is significant in enhancing operational excellence.

From chemical processing plants to automotive manufacturing facilities, SS corrugated hoses play a pivotal role in streamlining operations, optimizing productivity, and ensuring compliance with stringent industry standards. As Bangalore continues to evolve as a hub of industrial innovation, the reliance on these versatile conduits is set to grow, reaffirming their status as indispensable components in the machinery of progress.

0 notes

Text

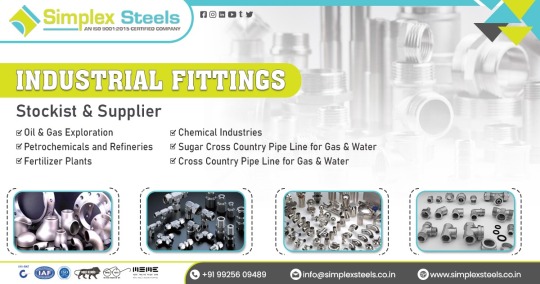

Stainless Steel Flanges Manufacturer

Simplex Steels is one of the leading Stainless Steel Flanges Manufacturer in Ahmedabad, Gujarat, India.

Simplex Steels specializes in offering a wide range of stainless steel and mild steel products, including SS sheets, plates, coils, pipes, tubes, bars, wires, rods, angles, channels, flats, SS fittings, pipes, tubes, industrial flanges, SS fasteners, and SS dairy valves.

Discover our range of stainless steel, super duplex, alloy, aluminum, carbon, duplex, Hastelloy, Inconel, and Monel flanges.

Explore diverse grades, sizes, and finishes in stainless steel pipe fittings.

Enjoy competitive prices and global delivery on our extensive flange stock.

Our flanges are crafted for various piping needs, ensuring top-notch quality and performance.

We Are Offering Various Types Of Industrial Fittings :

Buttweld Fittings

Forged Fittings

Socket Weld Fitting

Features:

Corrosion Resistant

High Tensile Strength

Very Durable

Temperature Resistant

Environmentally Friendly

Low-maintenance (long-lasting)

Attractive appearance

Long Durability

High Strength

Bend Fittings

They use them to equip rigid pressure lines pipelines or flexible lines hoses, connecting the elements of an installation. Clips, clamps, and crimping ferrules mount the fittings to the hoses.

Manufacturers use other types of assembly clips and clamps to attach pipes and hoses to the base construction.

Simplex Steels is a Stainless-Steel Flanges Manufacturer in Ahmedabad, Gujarat, India Supplier of Stainless Steel Flanges in Hyderabad, Telangana, and locations like Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon.

For further information, feel free to contact us.

Read the full article

0 notes

Text

What are the advantages of using stainless steel in corrugated hoses?

In the dynamic world of technology, where the demand for efficient and reliable air conditioning in server racks is paramount, choosing materials becomes critical. One such material that has proven its mettle in this domain is stainless steel. Specifically, SS corrugated hoses have emerged as a preferred solution, offering many advantages that cater to the unique needs of stainless steel.

Before delving into the advantages of SS corrugated hoses it's essential to comprehend the basics of their construction. These hoses are crafted from high-quality stainless steel, renowned for its durability, corrosion resistance, and strength. The corrugated design adds flexibility to the hoses, making them ideal for applications where movement, vibration, and thermal expansion are common – characteristics frequently encountered in the operation of stainless steel.

Stainless steel is synonymous with durability, which is especially crucial in the demanding environment of server racks. The constant operation, varying temperatures, and potential physical stressors require a material that can withstand the test of time. SS corrugated hoses excel in this regard, providing a robust and long-lasting solution that ensures the continuous and reliable performance of the air conditioning system.

One of the primary challenges faced by any material in the server rack environment is corrosion. The combination of moisture, temperature fluctuations, and the presence of various elements can lead to the deterioration of materials over time. Stainless steel's inherent corrosion resistance is ideal for corrugated hoses in stainless steel. This resistance ensures that the hoses maintain their structural integrity, preventing leaks and ensuring the longevity of the entire system.

Air-conditioned server racks often require intricate and flexible solutions due to the complexity of the installation. S corrugated hoses in bangalore are designed flexibly, allowing easy manoeuvring and installation even in tight spaces. The corrugated structure enhances the hoses' flexibility, enabling them to adapt to the unique configurations and movements within the server rack environment without compromising performance.

Maintaining an optimal temperature is critical for the efficient operation of server racks. Stainless steel corrugated hoses exhibit high temperature tolerance, ensuring that they can withstand the heat generated by the servers and cooling systems. This characteristic is essential for preventing hose degradation and maintaining the overall effectiveness of the air conditioning system, even in challenging thermal conditions.

In the fast-paced world of technology, minimizing downtime is crucial. Stainless steel corrugated hoses contribute to this objective by requiring minimal maintenance. Their resistance to corrosion and wear means they can operate for extended periods without requiring frequent inspections or replacements. This reliability is a significant advantage for businesses that rely on uninterrupted server operations.

Safety is paramount in any technological infrastructure, and choosing materials is crucial in ensuring a secure environment. Stainless steel corrugated hoses boast enhanced safety features, such as resistance to fire and high-pressure applications. These hoses are designed to meet stringent safety standards, providing peace of mind to operators and minimizing the risk of accidents within the server rack facility.

Air-conditioning systems in server racks often involve the circulation of different fluids, including refrigerants and coolants. Stainless steel corrugated hoses offer excellent compatibility with a wide range of fluids, making them versatile for diverse applications. This compatibility ensures that the hoses can effectively handle the specific requirements of air-conditioned server racks without the risk of material degradation or fluid contamination.

In an era where sustainability is a key consideration for businesses, choosing environmentally friendly materials is a responsible decision. Stainless steel is inherently recyclable, contributing to a more sustainable and eco-friendly solution for stainless steel. The recyclability of stainless steel corrugated hoses aligns with the growing emphasis on green practices in the technology and data center industries.

Conclusion:

In conclusion, the advantages of using stainless steel corrugated hoses in air-conditioned server racks are undeniable. From unparalleled durability and corrosion resistance to flexibility, high-temperature tolerance, and enhanced safety features, these hoses offer a comprehensive solution for the unique challenges posed by server rack environments. Their minimal maintenance requirements and compatibility with various fluids further solidify their position as a top choice for businesses seeking a reliable and efficient air conditioning solution.

Incorporating SS corrugated hoses ensures the optimal performance of air-conditioned server racks and reflects a commitment to durability, safety, and environmental responsibility. As technology advances, the reliance on robust materials like stainless steel becomes increasingly imperative to support the seamless operation of critical infrastructures. Embrace the future of air conditioning in server racks with the unparalleled advantages of stainless steel corrugated hoses – the backbone of a reliable and efficient cooling system.

0 notes

Text

Ss flexible hose Pipe - Easyflex

Discover the ultimate versatility with Easyflex SS flexible hoses. Engineered for durability and performance, these hoses offer seamless connections for various applications. With corrosion resistance and easy installation, Easyflex hoses ensure reliability. Ideal for plumbing, HVAC, and industrial use. Upgrade your systems today with Easyflex.

For More Info : https://easyflex.in/braided-ss-hose-connections-with-different-end-fittings/

#ss flexible hosePipe #ss flexible hose pipe # hose pipe ss

Kanwal Industrial CorporationB- 168, Phase – II, Distt. Gautam Budh Nagar -201 305 Noida, Uttar Pradesh , India

Phone: 91-0120-4734500 | +91-9811319020

0 notes

Text

Petra Streamline Hand Trigger Spray Set - Chrome

Petra Streamline Hand Trigger Spray Set in Chrome is a versatile and stylish accessory for your bathroom. It consists of a handheld showerhead with a chrome finish, a stainless steel hose, and a mounting bracket for easy installation.

The shower head has a unique hand trigger design that allows you to control the flow of water with ease. This feature is particularly useful for those who prefer to conserve water while showering. The chrome finish of the showerhead and mounting bracket give it a sleek and modern look that can complement any bathroom decor.

The stainless steel hose is flexible and durable, making it easy to maneuver and resistant to kinks and tangles. It is also easy to clean and maintain, ensuring that your shower set remains in top condition for years to come.

Overall, the Petra Streamline Hand Trigger Spray Set in Chrome is a high-quality and functional accessory that can enhance your showering experience while adding a touch of style to your bathroom.

Features

Elegant design for a beautiful look in the bathroom.

120cm SS Chrome hose.

Wall Mounting.

Ergonomic and comfortable to hold and use.

Reliable design that will ensure long service life.

Designed for comfortable feel wide spray nozzles.

Stainless Steel.

Advanced finger swipes s

0 notes

Text

The Various Types of Tube Fittings, and how to choose the right one for your needs

Tube fittings are an essential component of many industrial systems. They are used to connect and disconnect tubes or pipes, and they come in a variety of shapes and sizes to fit different applications. This blog will list the various types of tube fittings.

What exactly are Tube Fittings?

A fitting is essentially a piece of produced metal that connects one component to another. They can connect the following tube fittings:

from one tube to another

a hose to a tube

a tube connecting to a hydraulic component such as a valve

These fittings serve two purposes: sealing under pressure and retaining the tube under pressure. The idea is to make the transition from one item to the next as smooth as possible. In the case of tubes, if you want to link one tube travelling one way and another tube going the opposite direction, you would insert a fitting between the two to join them together as one.

Because we're largely going to be discussing tube fittings, it's vital to first comprehend some tube vocabulary. When discussing fitting sizes, the tube OD is always used (outside diameter). The size designation has nothing to do with the dimensions of the fitting itself, but solely with the OD of the tube that is meant to function with that fitting.

At Nakoda Metal Industries, We manufacture Swagelok Tube Fitting to suit various applications and are Manifold Valve Manufacturers.

Types of Tube Fittings:-

Here are some of the most common types of tube fittings:

Compression fittings: Compression fittings use a ferrule and nut to secure the tube to the fitting. The ferrule is a ring-shaped component that compresses onto the tube as the nut is tightened, creating a tight seal. These fittings are easy to install and disassemble, making them popular in applications where frequent maintenance is required.

Flare fittings: Flare fittings use a conical seat and a threaded nut to create a seal. The end of the tube is flared outwards to create a mating surface, and the nut compresses the flare onto the seat. These fittings are commonly used in applications that involve high pressure or vibration.

Push-to-connect fittings: Push-to-connect fittings are designed for quick and easy installation. They use a collet mechanism to hold the tube in place, and the fitting can be disconnected by simply pressing on a release ring. These fittings are commonly used in pneumatic systems and other low-pressure applications.

We also sell ss swagelok tube fitting globally.

Barbed fittings: Barbed fittings have a ridged end that is pushed into the inside of a flexible tube, creating a seal. These fittings are often used in low-pressure applications and are easy to install and remove.

Threaded fittings: Threaded fittings use a threaded connection to secure the tube to the fitting. These fittings are commonly used in applications that involve high pressure or temperature.

When selecting a tube fitting, it's important to consider factors such as the type of fluid or gas being transported, the pressure and temperature requirements of the application, and the size and shape of the tubes or pipes involved. Proper installation and maintenance are also critical for ensuring the longevity and safety of the system.

Manufacturer of superior manifold valves and Swagelok Tube Fittings

Nakoda Metal Industries is a prominent Swagelok Tube Fitting Manufacturer in India.

Our Swagelok Tube Fitting products undergo various quality checks, ensuring they meet the highest standards.

We offer all of our customers market-leading pricing on ss swagelok tube fitting, with a supply of standard, sizes, and varieties available for fast delivery. We are named as one of the best leading Manifold Valve Manufacturers in India .

For more details:-

Websites : nakodametalind.com

#Manifold Valve Manufacturers in India#Swagelok Tube Fitting Manufacturer in India#Swagelok Tube Fitting Manufacturer#Nakoda Metal Industries

0 notes

Text

These meters provide accuracy in batch processing

Loading skids There are two types of loading skids top and bottom loading skids. The loading skids are highly cost efficient units and are widely used for the loading of distilled products. With a variety of designs available each unit gets designed and installed as per the specifications from customer. Loading skids are meant to meet the petroleum industry standards that help them to be applied in the other related industries. Its specific features make it ideal for the gas or petroleum industry like its electronic or mechanical metering, colour coded hoses for easy identification of the correct hose , overfill prevention monitor, thermal relief system etc. All loading skids are designed, built, delivered as well as installed to meet the standards and specifications of the customer. Positive displacement flow meters The Liquid controls positive displacement flow meters are usually constructed from cast iron, brass, stainless steel and aluminium.

These meters provide accuracy in batch processing, blending and custody transfer of liquids over a wide range of products, flow rate control, viscosities, pressures and temperatures. Positive displacement flow meters are supplied with both mechanical counters and register or sometimes supplied with liquid controls pulse output device. Such systems provide compatibility with liquid controls or other pulse-driven counters and flow computers or batch controllers. The positive displacement flow meters can be easily install in to any process China SS 304 Flexible Corrugated Metal Tube For Gas company plant or line as there is a wide range of connections like ANSI flange, NPT or BSPT threads and slip-on weld flange to choose when ordering. Popular industries for PD meters are food industry for metering liquid sweeteners and the petrochemical for all petrochemical products. Refuelling couplers and Adaptors Refuelling couplers and adaptors, The equipment can be supplied separately to the customer or as replacement part or as a complete tested hose assembly.

These items consists of materials that require low maintenance. Any servicing should be carried out by the engineers who are based in the field to repair the fault. The refuelling couplers and adaptors ensure that the flow of the product is smooth and is done without any spillage or other issues related to the transfer of liquids to the trucks or tanks. They are used for transferring petroleum or oil products and many such related industries. Rail loading Rail loading arms are very common and normally seen in depots and petroleum or oil terminals. And they can be either top loading arms or bottom loading arms.

They are used for the loading of petroleum or other fluids without any spillage and without any issues. This make the rail loading arms very reliable to withstand any climatic condition and also for accurate connection with the couplings at the time of transfer. The balance mechanism can help in adjusting the height and thereby ensuring perfect blending and transfer.

0 notes

Text

Top 5 Best Shower Systems Reviews And Buying Guide [Latest Picked in 2020]

How can we take a good shower? What is the best shower system? Do you want to know all that? If your answer is yes then this is for you. Today in this article we are gonna talk about the way of taking the best shower and its system reviews? Lets started...

Little things in life matter a lot. In fact, you will be surprised how a slight change in any certain thing can affect all of your moods. We take showers every day at least once and often more than once. If the 15-20 minutes spent in taking a shower is as relaxing as possible, can you imagine how much it will make our attitude more positive and us jollier?

When the water pressure or temperature does not fulfill our expectations, we do not get the comfort or refreshment we were seeking. Therefore, we cannot control the most basic task of life so how can we control the big tasks? In order to make your shower the only positive thing on a bad day for you, we are here to introduce you to the best shower system features with 5 of the best shower systems reviews.

The 5 Best Shower Systems Reviews Buying Guide

Here’s a buying guide that will help you narrow down your choices to the best shower systems:

Showerhead

The most important component of a shower system is definitely the showerhead. Apart from checking the quality of the materials used, you should find out which style of shower head you prefer. Would you like a showerhead that’s fixed and mounted on the wall or would you like a more flexible handheld shower? If it’s a fixed showerhead you prefer, make sure the height it's installed in is convenient for everyone.

In contrast, if you want a handheld shower, the length of the hose, the flexibility are important factors to consider. However, a handheld shower is a much better option as it is suitable for people with physical disabilities and also very handy when cleaning anything thoroughly.

Water Pressure And Flow

If you want to reduce your water bill and increase environment conservation, you can go for water-saving showerheads that have relatively low water flow to save water. Even if you don’t check the water flow of the showerhead as in case of shortcomings, you will feel dissatisfied with low water flow during a shower.

Temperature And Flow Control Handles Or Valves

Whether you want a single-handled shower system or dual handled shower system is completely up to you. With the dual handling systems, you can control flow and temperature through separate valves. In case of a single-handled shower system, a thermostatic temperature control system will go a long way.

Ease Of Installation

You definitely do not want to buy a shower system that does not even meet your plumbing requirements. Therefore, firstly look for systems that are compatible with your plumbing style. Then, choose the ones that are very easy to install. Check out the drains as well.

Best Shower System Reviews In 2020

Here we go for the 5 best shower system :

01. Delta Faucet T1749-SS-I Linden Monitor 17 Series Trim Shower Only With In2ition Two-In-One Hand Shower

If a traditional looking, easy to maintain and convenient to use shower system is in your mind, then Delta Faucet’s T17494-SS-I shower system would be a great choice for you. It includes the showerhead, a hand shower and is dual handled. Apparently, the curvy, sleek design is definitely going to steal second glances from your visitors.

A very convenient feature of this system is the pause option on the hand spray. When shaving or doing tasks that need periodic sprays of water, you can pause the flow and pick up again at the same temperature you were working with. Therefore, it saves you from the trouble of controlling the settings every time you pause.

Moreover, the 69-inch Ultraflex hose gives you the flexibility that you will rarely find in other systems. Apparently, the 4 spray modes help you get your desired water flow. You can enjoy both a massage style soothing waterfall and a rain-like refreshing water flow with the spray modes.

The dual valves give you independent control over the temperature and flow. In fact, the water flow is 2.5 gallons per minute or 9.5 liters per minute. Also, the system is quite easy to maintain and also durable. In fact, the lime and calcium build-up can easily be dealt with by the Delta Touch-Clean Spray Holes. This is why we pick this shower faucet for the best shower system.

Pros

Flexible

Brilliance Steel finish saves from corrosion and tarnish

Upgrades do not require touching the plumbing sector

MultiChoice Universal Valve allows easy installation

Lifetime limited warranty

Cons

Many parts are made of non-durable plastic

02. Grohe 124312 Retro-Fit

Looking for luxury in every aspect? Grohe 124312 provides your bathroom with the luxury that most systems fail to provide. Whether it is the looks, function or ease, Grohe disappoints you not even in one of these aspects. In fact, the world praises Grohe’s marvelous StarLight finish for both the shiny look and the protection it provides. Apparently, a combination of copper, nickel and chrome layers protects the parts from corrosion, pores and tarnishes.

Grohe StarLight finishes for scratch and tarnish-resistant surfaces for a lifetime of beauty. It is a wall-mounted diverter shower system that can make your shower relaxable.

The DreamSpray spraying style gives you the best time when it comes to comfort. In fact, the 2.5(+_GPM water flow with its four multi-function modes will provide you with any type of shower you are seeking. Moreover, the thermostat with CoolTouch features never lets the water temperature reach a level where it hurts you. Therefore, you can control the temperature and also protect yourself from unexpected exposure to extreme temperatures.

You will, in fact, get flexibility at its best with the 1711/16-inch shower hose and the swiveling shower arm. Also, you can use the showerhead and spray simultaneously because of the built-in diverter. Grohe 124312 is horizontal 45-degree swivel 1711/16 inch. Shower Arm.

Lastly, the SpeedClean anti-lime system makes cleaning the shower system itself easier. It prevents the build-up of lime and calcium.

Pros

Simultaneous usage with diverter

Flexibility

Easy to use

The top-notch features for each important task

Cons

A bit difficult to install

03. Moen 8342 Commercial Posi-Temp Two-Handle Shower

It’s a shower system that can handle both perfect usage and erroneous usage for a long time. Because it uses top-notch materials in its usage to withstand pressures. Besides, the chrome and top finishing processes give this shower an eternally fresh, shiny look and protection against corrosion, tarnish and pores.

If you prefer separate controls for temperature and water flow then Moen 8342 is one of the best choices. As it’s equipped with the Posi-Temp valves, you will be able to control the temperature and water flow very accurately. Moreover, the 69-inch long metal-hose with an adjustable 30-inch slide bar keeps your tasks easy as well. Also, it gives you ample flexibility while using spiral construction.

As for the feel, the Concentrated Spray Heads leave you satisfied with a thorough and intense rinse of 2.5 GPM water flow. Apart from that, you do not have to adjust the water flow every time you stop, you can just pause the flow and restart where you left off with the previous setting.let's see the pros and cons of one of the best shower system faucet.

Pros

Easy to clean

Flexible with the long hose and slide bar

Accurate control

5-year warranty

Cons

Showerhead and hand spray are not suitable for simultaneous use

04. Pfister 3-Function Handheld Shower

If the price doesn’t concern you, you can check this mighty Pfister shower out. As the title suggests, it has three reliable and versatile spray modes. Whether you want a soothing rainy feel or an energetic, refreshing water flow, Pfister provides you with whichever you prefer. In fact, its various modes will relieve you of any kind of tension you might be facing. Moreover, the handle of the shower provides you with great flexibility for cleaning.

Moreover, Pfister gives your bathroom a classy look no matter which type of bathroom it is. It’s bright yet soothing chrome finish makes it suitable for any bathroom style and also protects against corrosion and pores. Moreover, the slide-bar has a simple and modern design to adorn your bathroom.

All these might give you the impression that this great product must be difficult to install. Wrong! It is in fact quite easy to install and it requires only one hole for installation!

Pros

3 invigorating spray-modes

The great water flow of 2.5 GPM

Easy to install

Great finish

Flexible

Warranty

Cons

Expensive

05. Symmons 5406 Degas Shower Unit

When you are looking for both durability and performance in one shower system, Symmons 5406 is hard to miss. In fact, it assures carefree long-term use with its complete construction of Brass, Steel and Solid Bronze. Sturdy, right? And, no plastic involved either. With the durability checked, let’s come to the performance.

In fact, it’s a great choice for people who take showers as refreshments not just as a basic need. In addition, the adjustment nodes with 3 different spray modes which definitely meet your requirements for a great shower. With water flow of 2.5 GPM, you will enjoy a non-interrupted and generous rinse. This will definitely leave you in high spirits for the rest of your day.

Moreover, it features a separate triple outlet valve with a built-in diverter for better accuracy in the case of controls. This product, as a matter of fact, was encouraged by Edgar Degas in its style to be both strong and flexible. Therefore, you can expect no less than great flexibility from this shower system.

Pros

Full-metal construction

Efficient spray modes

Flexible build

Temporal valves

Easy to upgrade and maintain

Lifetime warranty

Cons

Expensive

Initial installment is difficult

Here Is The Short Video Of The Best Shower System

In this video, you will get 5 best shower system reviews.

We hope this video and the article will help you to find the best shower system for your shower. Let's see the video

youtube

FAQ Of Best Shower System Reviews

Question: Can a dual or three handled shower system be replaced with a single-handled shower faucet and vice versa?

Answer: As most shower systems are built with a standard size, you can replace dual handles with single handles and vice versa. However, there are a few systems with exceptional dimensions. Therefore, you have to check the sizes yourself first. The standard distance between the two handles of dual handling systems is generally 8 inches

Conclusion

In our busy schedules, a shower often becomes our momentary respite. However, a faulty, low-quality shower with inadequate water-flow and inaccurate temperature control can greatly hamper this sought to be a refreshing moment. Therefore, you have to be extra careful while buying a shower system for your house. You obviously do not want to be stuck with constant disappointment alongside other pressures. Today’s article should definitely help you find the shower system you deserve. In fact, it might even be one of our best shower system reviews! But, whichever you buy, check all the functionality and authenticity of all components included. We will be back with more ways to help you! Until then bye!

8 notes

·

View notes

Text

CORRUGATED SS HOSE: ASSEMBLY COMPONENTS AND VALUE

From your kitchen to extensive industrial uses, hoses are widely being used; they play an essential role in transferring any medium from one place to another. The hoses should bear high pressure and fluctuating temperature and prevent any cracking or bursting for the safest operations possible. Corrugated hoses are an excellent option for robust construction and durability. The corrugations on the tube are made for stability with flexibility. The hoses essentially comprise tubes, braid, braid collars and fittings. The corrugated hoses come in two variants which are braided and non-braided. The industries which require less pressure operations can use non-corrugated hoses as well. Every element in the hose has its importance, and the hose cannot function without any one of it. Let us see in detail each of the components:

Fittings:

The fittings help hold up the hoses; the fittings must be of the correct size and withstand the required pressure. Poly SS Hose assemblies is a great option to choose for your hosing system.

Braid Collars: Braid collars are used to join the inner corrugated hose and braid together during the welding process. The braided collar helps isolate the last few grooves from the movement; it is also vital that the braid collars are adequately sized to weld.

Braid

To give the capacity to withstand high pressure, they are braided with stainless steel wires or any other alloy wire for protection. The braid depends upon the inner and outer radius of the hose, number of cables per bobbin, number of carriers, and you can buy multiple braided wires according to your needs for the best insulation.

Tube:

The tube is the main corrugated tube through which all the components pass through. The tube with corrugations help in high resistance and provides flexibility for various industrial requirements.

There are mainly four factors you should see before purchasing your corrugated hoses:

Pressure rating

Flexibility

Corrosion resistance

Cost

Pressure rating: it is crucial to see if the hose is compatible with your pressure requirements, various hoses bear different pressure, so it is essential to know which one suits your needs the best. Steam turbine hoses are an excellent choice of your industry deals with extreme pressure fluctuations.

Flexibility: Corrugated hoses are used for extreme flexibility, and it is essential to know how much flexibility you need for your operations.

Corrosion resistance: it is vital to select the alloy as per your requirement because the material can easily corrode if it is not compatible with your medium.

Cost: it is one of the most important factors to be considered, but low-cost hoses don't have to be essentially bad quality, and high priced hoses are excellent in quality. Always go with the rating and reviews and trust a company to buy your hoses.

For an efficient hosing system, you must install hoses of high quality and serve the purpose of transferring components efficiently.

Flexo Tech is a leading gas hose manufacturer making high-quality products for customers. They manufacture a variety of products which are used in various hosing facilities. If you want more information regarding any hoses or want to buy one, you can visit the following website

https://flexotechproducts.com/stainless-steel-hose-assemblies/

0 notes

Text

ALTON SHR20940 Dual Flow Health Faucet with SS-304 Grade 1.25 Meter Flexible Hose Pipe and Wall Hook (Chrome Finish), Polished, Acrylonitrile Butadiene Styrene, Silver

ALTON SHR20940 Dual Flow Health Faucet with SS-304 Grade 1.25 Meter Flexible Hose Pipe and Wall Hook (Chrome Finish), Polished, Acrylonitrile Butadiene Styrene, Silver

Price: (as of – Details)

Product Description

Package Content: 1-Piece Health Faucet, 1-Piece Hose Pipe, 1-Piece Wall Hook and Installation Accessories.Type: Dual Flow For Male (Spray) & Female (Foam)1 Year Warranty Against Manufacturing DefectMirror look technology, is highly reflective for a mirror-like look and keep it a life long bright

View On WordPress

0 notes

Text

What are the main types of stainless steel

Stainless Steel pipes are prone to corrosion if left untreated. A common treatment for corrosion is galvanization. This includes covering the steel pipe with a zinc coating. This zinc coating oxidizes instead of the protective steel, but very slowly.

Stainless steel pipes are rarely used in household plumbing fixtures except for hoses or hoses, some landfills, and quack lines. The problem is the high price of raw materials and the know-how required to install equipment.

They are more commonly found in various accessories (towel rails, rods, handles) and building components (lamps, guardrails, railings).

Stainless steel pipe: Definition

Stainless steel is an alloy containing at least 10.5% chromium and less than 1.2% carbon (European Standard 10088-1). Other components (nickel, molybdenum, manganese, titanium) can change their mechanical resistance and adapt rust prevention performance to the relevant environment.

ss 304 pipe suppliers manufacture different type of steels.

Three common types of stainless steel pipe

Hard stainless steel pipe

Naturally healthy rigid stainless steel pipes ensure the durability of water networks for food and are exposed to corrosive or salty atmospheres.

These tubes are sold in 4-7 meter bars with common metric dimensions (1, 1.5, or 2 mm thickness) and gas standards. There are many carbon steel pipe suppliers in india offers quality products.

Fittings must be TIG welded (in an inert gas atmosphere) by high frequency or laser, but in the field, they may be crimped using certain stainless steel fittings (elbows, tees, sleeves). Stainless steel ss 316 pipe suppliers providegood material which can be threaded and connected using suitable fittings.

Soft or flexible stainless steel hose

Flexible stainless steel pipes have become very common for connecting plumbing and sanitary equipment (faucets, valves, water heaters, boilers). They immediately take all forms and easily adapt to the most winding paths.

These accessories secure the connection; eliminate most of the vibration and save a lot of assembly time.

Flexible stainless steel hoses generally consist of a braided stainless steel wire or a synthetic tube covered with a coil of stainless steel tape stapled. The screw connections are crimped on both ends. All combinations of male-male, female-female, or male-female of different sizes are possible. They are sold in various lengths, but they can be measured.

Stainless steel pipe

Rigid or flexible stainless steel flues are extraordinarily durable equipment for discharging acid gases (fuel oil, wood) and withstanding condensates (condensation boilers of all energy).

It is rigid, available in 25, 30, 50, 66, or 100 cm interlocking profiles, and comes with various accessories (elbows, T-types, reducers, flanges). It is sold in all common diameters. stainless steel pipe suppliers in India

It consists of a flexible, crimped, rolled sheet metal ribbon. This assembly gives it a certain degree of flexibility, allowing the manufacture of very long pipes, especially in chimney casings (exteriors).

Price of stainless steel pipe

The stainless steel pipe suppliers in India provide products that are used in different industries. A good stainless steel supplier offers products according to requirement of their customers.

0 notes

Text

Supplier of Industrial Fittings in Uttar Pradesh

Supplier of Industrial Fittings in Uttar Pradesh

Simplex Steels, an ISO 9001:2015 certified manufacturing unit located in Ahmedabad, Gujarat, India, boasts extensive industry experience.

Renowned for high-quality SS Round Bars, Simplex Steel excels in manufacturing and exporting Industrial Flanges, stainless steel bars, wires,

rods, Industrial Fittings and other products.

This range includes a diverse selection of couplings, quick-release couplings, hose fittings, adapters, and connectors. They serve to terminate or

equip rigid pressure lines or flexible hoses in pipelines.They connect the components of an installation together.

The components of industrial fittings comprise materials such as carbon steel, stainless steel, brass, polypropylene, and various other materials.

They come equipped with different types of seals.FeaturesAvailable in different sizes, shapes, and materials to meet specific needs.

Suitable for various industries and applications.

Engineered with accuracy to ensure proper connections and functionality.

Designed for consistent and safe operation, enhancing overall industrial processes.

Simplex Steels is a prominent Supplier of Industrial Fittings in Uttar Pradesh, serving various locations including Kanpur, Lucknow, Ghaziabad, Agra, Varanasi, Meerut, Allahabad, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffainagar, Mathura, Rampur, Shahjahanpur, Farrukhabad, Maunath Bhanjan, Hapur, Faizabad, Etawah Etc.For comprehensive details on our product catalog, kindly reach out through the provided contact information.

Read the full article

0 notes

Text

Exploring the Benefits of SS Corrugated Hoses

Stainless steel corrugated hoses offer several benefits, making them a popular choice in various industrial applications. Here are some key advantages associated with SS (Stainless Steel) corrugated hoses:

Flexibility:

SS corrugated hoses are highly flexible, allowing for easy installation in tight spaces and accommodating movement and vibration within industrial systems. This flexibility is crucial in applications where conventional rigid piping may not be suitable.

High Temperature Resistance:

Stainless steel is known for its excellent high-temperature resistance. SS corrugated hoses can withstand elevated temperatures, making them suitable for conveying hot fluids and gases in industrial processes.

Corrosion Resistance:

Stainless steel is inherently corrosion-resistant. This property ensures that SS corrugated hoses remain durable and resistant to rust or corrosion, even when exposed to aggressive chemicals or harsh environmental conditions.

Pressure Resistance:

The corrugated structure enhances the strength of the hose, allowing it to withstand high pressures. This makes SS corrugated hoses suitable for applications where pressure resistance is critical, such as in hydraulic systems.

Long Service Life:

Stainless steel is a durable material with a long service life. SS corrugated hoses are resistant to wear and tear, ensuring a reliable and extended operational lifespan.

Versatility:

SS corrugated hoses are versatile and can be used in various industries and applications, including petrochemical, pharmaceutical, food and beverage, automotive, and more. They can handle a wide range of fluids and gases.

Leak Resistance:

The construction of SS corrugated hoses minimizes the risk of leaks. The corrugated design provides flexibility while maintaining a tight seal, reducing the chances of fluid or gas leakage.

Easy Maintenance:

Maintenance of SS corrugated hoses is typically straightforward. The smooth interior surface of the hose minimizes the risk of deposits or buildup, making cleaning and maintenance more manageable.

Hygienic Properties:

Stainless steel is a hygienic material, making SS corrugated hoses suitable for applications where cleanliness and sterility are essential, such as in the food and pharmaceutical industries.

Absorption of Movement and Vibration:

The flexibility of SS corrugated hoses allows them to absorb movement and vibration in industrial systems, preventing stress on the piping and connected components.

Fire Resistance:

Stainless steel has inherent fire resistance properties. While the hoses themselves may not be entirely fireproof, the use of stainless steel contributes to fire safety in certain applications.

Compliance with Standards:

SS corrugated hoses can be manufactured to comply with various industry standards and specifications, ensuring that they meet the required safety and performance criteria.

When considering the use of SS corrugated hoses, it's important to assess the specific requirements of your application and ensure that the selected hose meets industry standards and regulations. Additionally, proper installation and maintenance practices contribute to the optimal performance and longevity of these hoses.

0 notes