#drill rod for sale

Text

Buy Drill Rods From India's Best Manufacturer | Techo Enterprise

If you are looking to buy drill rods, Techo Enterprise is the best choice. ✔️ Call 98304 25937 ✔️ Live Chat With Us ✔️ Call Us Today .

#Buy Drill Rods#drill rods#drill bit extension rod#drill rod for sale#drill rod and tool steel#rock drill rods#drilling rods and bits#stainless steel drill rod#oil hardening drill rod#best welding rod for drill stem#drill rod for sale near me#drill rod price#earth rod drilling#extension drill rod

1 note

·

View note

Text

Delivering Precision and Power: The Impact of Drill Rods, Drilling Muds, and Horizontal Directional Drills on Drilling Projects

In the realm of drilling projects, achieving precision and power is essential for successful outcomes. Three crucial elements play a pivotal role in this process: Drill Rods, Drilling Muds, and Horizontal Directional Drills (HDD). Let's delve into the significance of each of these components and explore how they collectively contribute to the efficiency and effectiveness of drilling projects.

Drill Rods: The Backbone of Drilling

Drill Rods form the fundamental link between the drilling rig and the drilling bit. These sturdy, hollow tubes are available in various materials like steel, aluminum, and composite alloys. Their primary function is to transmit the rotational force and torque from the drilling rig to the bit while enabling the circulation of drilling fluids to carry away cuttings and maintain stability.

Precision in drilling heavily relies on the strength, durability, and quality of the Drill rods. High-quality drill rods ensure minimal bending or deflection during drilling, which helps maintain the desired trajectory and minimizes the risk of deviations. Additionally, precision-made drill rods also reduce the likelihood of equipment failures, ensuring smoother operations and increased productivity.

Drilling Muds: Enhancing Efficiency and Performance

Drilling Muds, also known as drilling fluids, are a crucial aspect of any drilling project. These specially formulated mixtures serve multiple purposes during drilling operations. They cool and lubricate the drill bit, clean the borehole by carrying away cuttings, and create hydraulic pressure to stabilize the wellbore.

Achieving power and efficiency in drilling largely depends on selecting the appropriate Drilling muds for specific geological conditions. The right combination of drilling mud properties, such as viscosity, density, and filtration control, is essential to overcome challenges like formation instability and wellbore collapse. Furthermore, high-quality drilling muds help minimize downtime and improve the overall drilling performance, thereby impacting the project's success.

Horizontal Directional Drills (HDD): Pioneering Drilling Technology

Horizontal Directional Drills (HDD) have revolutionized the drilling industry, particularly for infrastructure projects, utilities, and pipeline installations. Unlike traditional vertical drilling methods, HDD allows drilling at various angles, including horizontally, which significantly reduces surface disruption and environmental impact.

The power of Horizontal Directional Drill lies in its ability to navigate challenging terrains and obstacles while ensuring precision and accuracy in drilling. With advanced steering and tracking systems, HDD operators can precisely control the bore path, avoiding potential hazards and obstacles underground. This technology not only delivers power and accuracy but also increases project efficiency, lowers costs, and enhances safety.

The Collective Impact on Drilling Projects

The successful execution of drilling projects heavily relies on the harmonious interplay of drill rods, drilling muds, and horizontal directional drills. When combined, these elements create a synergy that results in enhanced precision, increased power, and improved overall project performance.

Precision is achieved through the use of top-quality drill rods, which maintain the desired drilling trajectory and reduce potential deviations. The choice of suitable drilling muds, tailored to specific geological conditions, ensures seamless drilling operations, efficient cuttings removal, and borehole stability. And finally, the incorporation of HDD technology enables drilling in challenging environments with minimal surface disruptions, reducing project timelines and environmental impact.

In conclusion, the impact of drill rods, drilling muds, and horizontal directional drills on drilling projects cannot be overstated. The marriage of precision and power achieved through these elements contributes to the success of drilling operations, allowing for efficient completion of projects with minimal disruptions and improved overall performance. By recognizing the significance of these components and their collective impact, the drilling industry continues to advance, delivering exceptional results in various sectors worldwide.

For more information......

Contact us : JB Trenchless

0 notes

Text

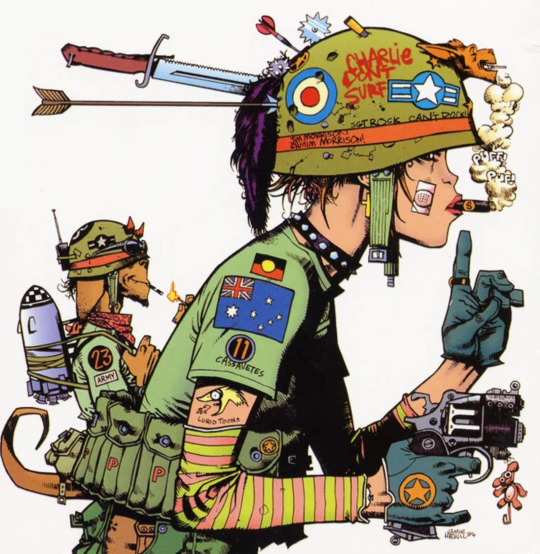

As any Tank Girl fans out there will know, our gal can often be seen wearing customised army helmets. They’re a super fun accessory, so I decided a few months back to have a go at making one. I started off by picking out a couple of ones I liked in the comics (see above for an example) and worked out a design. There were a lot of sticky out bits, so I had a feeling putting it together was going to be easier said than done, but I’ve never let that stop me before and didn’t this time. I could have taken the easy route and bought a plastic helmet, which would have been soooo simple to attach things to, but me being me, I decided to go with something authentic, namely (and I quote) a ‘genuine vintage Bulgarian army M72 steel combat helmet’ which was going cheap on good ol’ ebay 👍👍. I was totally expecting to have to drill holes in this for some of the attachments, but as luck would have it, there were some readymade ones 😊. These are the other bits I used…

1 x plastic creature head – I was looking for something which resembled the head on the attached reference picture and stumbled on something perfect while rummaging through a box of random toys in a thrift store.

1 x neodymium magnet – Used to fix the creature head onto the front of the helmet.

1 x dart – To stick in one of the holes. My only complaint here was I had to buy a pack of 3 and don’t know what to do with the other 2. Maybe I can use them in some future cosplay project.

1 x wooden rod + craft feathers + 1 x plastic wall plug – Used to make an arrow to poke in another of the holes. I had to make my own arrow, as none of the ones I saw for sale would have fit.

1 x kitchen fork – Another thrift store find which looked like it would be a good stand-in for the knife in the picture if I chopped the top off.

Some straps and buckles from an old bag – Stitched together to make a carrying strap for the helmet (which I needed to hang things off).

3 x old bullets for decoration

Some bits of leather to make a bandolier type thing to hold the bullets.

1 x old cigarette box for decoration.

1 x gun keyring – This was an impulse thrift store buy, which wasn’t in the original design, but I thought would be another good decoration (there were actually so many impulse buys like this I couldn’t use them all and ended up making a Tank Girl baseball cap for the overflow – more about that another time).

One of my old teddy bears (Flapjack) to hang from the knife (really a kitchen fork) handle.

1 x old white shoelace to make a hangman’s noose for my teddy (poor Flapjack 🎻).

Acrylic paint and brushes - I’m sure y’all can guess what these were for.

1x target sticker – I bought this in a craft store, because it looked just like the target on the helmet in the picture and I wanted to save myself a tricky painting job.

It took me a while to get all of that together (as you can imagine), but eventually I was ready to go. I eased myself in gently by sticking on the target sticker. Then I did the painting bits. I seem to be getting better at this, as I managed to get through it with no major screw-ups😊. I left the paint to dry for a day and sprayed on some fixative to protect it. It seems to be doing the job, though I have no clue how long it will last.

I made my arrow from the bits mentioned above and sawed off the top of the kitchen fork to make my stand-in knife. Then I worked out how I was going to attach everything. As I said, I used a magnet for the creature head. I stuck the arrow into one of the holes and the dart into another with a plastic bung on the other side to hold it in place. For the knife, I pushed a long screw through the last hole and screwed it into the top of the handle. You can see the screw from some angles, but it was the best I could come up with and it does the job.

I hung Flapjack from the knife handle, clipped on the carry strap with its various decorations and that’s pretty much it. It’s not a bad take on the Tank Girl originals if I do say so myself, though it takes some getting used to. I can’t tell you how many times I’ve bashed one of the sticky out bits on something when I’ve been walking around. Also it’s heavier at the back, so it has a tendency to slip off. As always, this isn’t a proper tutorial, but maybe it will be helpful if anyone out there is thinking of making their own Tank Girl helmet. Have fun if you do. I’m on Ko-fi if anyone is feeling generous and wants to support me in my cosplay adventures… ༻ko-fi.com/christabelq༺ It’s always super-appreciated. Bye for now. ❤️🧡💛💚💙💜

#tankgirl#tank girl#tankgirlcomic#cosplaygirl#cosplayers#ukcosplayer#cosplaygirls#comicbooks#follow for follow#follow back#followback#followforfollow#like for like#likeforlike#costume design#prop design#cosplay tutorial#rocket launcher#alan martin#jamie hewlett#helmet

69 notes

·

View notes

Text

The Ultimate Guide to Buying Plexiglas: Unlocking the Potential of پلکسی پامنار

youtube

In the realm of modern business and design, finding the perfect materials for your projects is crucial. Among these materials, Plexiglas stands out for its versatility, durability, and aesthetic appeal. If you're on the lookout for high-quality Plexiglas products, look no further than پلکسی پامنار. In this comprehensive guide, we'll delve into everything you need to know about buying Plexiglas from پلکسی پامنار, ensuring you make informed decisions for your projects.

Understanding Plexiglas:

Plexiglas, also known as acrylic glass or PMMA (polymethyl methacrylate), is a transparent thermoplastic. It offers exceptional clarity, weather resistance, and strength, making it a popular choice across various industries. From signage and displays to architectural applications and DIY projects, Plexiglas serves a multitude of purposes with style and functionality.

Why Choose پلکسی پامنار:

When it comes to purchasing Plexiglas, quality and reliability are paramount. پلکسی پامنار emerges as a leading supplier, renowned for its commitment to excellence and customer satisfaction. Here's why choosing پلکسی پامنار is a decision you won't regret:

Extensive Product Range: پلکسی پامنار offers a diverse range of Plexiglas products tailored to meet the needs of various industries and applications. Whether you require sheets, tubes, rods, or custom-cut pieces, you'll find a comprehensive selection to choose from.

Superior Quality: Quality is non-negotiable at پلکسی پامنار. They source their Plexiglas from trusted manufacturers, ensuring each product meets stringent quality standards. With their commitment to excellence, you can trust that you're investing in top-tier materials for your projects.

Customization Options: Recognizing that every project is unique, پلکسی پامنار provides customization options to suit your specific requirements. Whether you need precision cutting, drilling, or shaping, their skilled craftsmen can accommodate your needs, delivering tailored solutions with precision and efficiency.

Competitive Pricing: Despite offering premium quality products and services, پلکسی پامنار maintains competitive pricing, ensuring affordability without compromising on quality. With transparent pricing and no hidden costs, you can shop with confidence, knowing you're getting the best value for your money.

Exceptional Customer Service: At پلکسی پامنار, customer satisfaction is paramount. Their team of dedicated professionals is committed to providing personalized assistance, from product selection to after-sales support. Whether you have questions, require guidance, or need assistance with your order, they're always ready to help.

How to Buy Plexiglas from پلکسی پامنار:

Buying Plexiglas from پلکسی پامنار is a seamless process designed to provide convenience and efficiency for customers. Here's a step-by-step guide to purchasing Plexiglas from پلکسی پامنار:

Browse the Product Catalog: Start by exploring پلکسی پامنار's extensive product catalog online or visit their showroom to view their offerings firsthand. Take note of the specifications, dimensions, and customization options available for each product.

Request a Quote: Once you've identified the Plexiglas products that meet your requirements, request a quote from پلکسی پامنار. Provide details such as quantity, dimensions, and any specific customization requirements to receive an accurate price estimate for your order.

Review and Confirm: Upon receiving the quote, review the details carefully to ensure accuracy. If everything meets your satisfaction, confirm your order with پلکسی پامنار, either online, via email, or by phone.

Payment and Processing: Complete the payment for your order using the available payment methods accepted by پلکسی پامنار. Once payment is confirmed, your order will be processed promptly, and you'll receive updates on its status every step of the way.

Delivery or Pickup: Depending on your preference, choose between delivery or pickup options for receiving your Plexiglas products. پلکسی پامنار offers reliable shipping services to deliver your order safely and efficiently to your desired location, or you can arrange to collect it from their showroom.

Conclusion:

When it comes to buying Plexiglas, choosing a reputable supplier like پلکسی پامنار can make all the difference in the success of your projects. With their commitment to quality, customization options, competitive pricing, and exceptional customer service, you can trust پلکسی پامنار to deliver top-tier Plexiglas products tailored to your needs. Unlock the potential of Plexiglas for your projects today with پلکسی پامنار.

0 notes

Text

Exploring Soapstone Powder Production

Introduction

Soap Stone Powder Manufacturers play a pivotal role in catering to diverse industries, offering a versatile mineral-derived product with a wide array of applications. Soapstone, also known as steatite or soaprock, is a metamorphic rock primarily composed of talc, magnesium, and other minerals. The transformation of raw soapstone into fine powder involves a series of processes, culminating in its use across various sectors. Let's delve deeper into the world of soapstone powder manufacturers and their contributions.

The Manufacturing Process

Soapstone powder is derived from soapstone rocks extracted from quarries worldwide. Once obtained, these rocks undergo several stages of processing to yield the fine powder form. The primary steps include:

Mining and Extraction: Raw soapstone rocks are extracted from quarries using techniques like drilling, blasting, and excavation.

Crushing and Grinding: The extracted rocks are crushed into smaller chunks and then ground into finer particles using crushers and grinders.

Pulverization: The ground soapstone undergoes pulverization, further reducing particle sizes to achieve the desired fineness.

Purification: To meet quality standards, the powder may undergo purification processes to remove impurities, enhancing its quality and purity.

Applications Across Industries

Soapstone powder, due to its unique properties, finds applications in various industries:

Cosmetics and Pharmaceuticals: Talc, a primary component of soapstone, is widely used in cosmetics and pharmaceuticals for its absorbent and softening properties. It's a common ingredient in talcum powders, lotions, and various skincare products.

Paper and Pulp Industry: As an effective anti-stick agent and filler, soapstone powder is used in the paper and pulp industry, enhancing paper quality and providing a smoother surface finish.

Plastics and Rubber: In plastics and rubber manufacturing, soapstone powder serves as a reinforcing filler, improving the mechanical properties and increasing durability.

Paints and Coatings: Due to its high heat resistance and chemical inertness, soapstone powder is utilized in manufacturing heat-resistant paints, coatings, and ceramics.

Industrial and Electrical Applications: Soapstone's ability to withstand high temperatures and its electrical insulation properties make it valuable in various industrial applications, including as a component in welding rods and insulators.

Choosing Reliable Manufacturers

1. Quality Standards

Sudarshan Group maintains stringent quality control measures throughout the manufacturing process. Their adherence to international quality standards ensures the delivery of high-grade soapstone powder consistently.

2. Technical Expertise

With years of expertise in mineral processing, Sudarshan Group possesses extensive knowledge in soapstone extraction, refining, and powder manufacturing. Their technical proficiency guarantees products meeting precise industry specifications.

3. Customization Options

Sudarshan Group understands the diverse needs of different industries. They offer customizable solutions, allowing clients to tailor soapstone powder specifications to match specific requirements, ensuring optimal performance.

4. Ethical and Sustainable Practices

The Sudarshan Group prioritizes environmentally friendly practices. They employ sustainable extraction methods and responsible production techniques, minimizing their ecological footprint.

5. Customer Service and Support

Known for their excellent customer service, Sudarshan Group values client satisfaction. They offer exceptional support, from initial inquiries to after-sales services, ensuring a seamless experience for their customers.

Conclusion

Choosing Sudarshan Group as a soapstone powder supplier ensures access to premium-grade products backed by a reputation for reliability, quality, and sustainability. Their commitment to excellence, technical prowess, and customer-centric approach make them a top choice for industries seeking high-quality soapstone powder tailored to their specific needs.

0 notes

Text

Miller OHV 4 Banger For Sale

Quite unusual to see one of these for sale here in the UK

Text from the listing on the NSRA UK Website

“Miller Schofield cast iron ohv head, Model B diamond block rebored and converted to shell bearings, c type balanced crankshaft re ground and drilled for high pressure oil system, Crower rods with shell main bearings, New pistons rings and fudge on pins, New Inlet and exhaust valves and…

View On WordPress

0 notes

Text

The price listed for this is making these people prohibited but people are going to buy this anyways and make their own hot rod but we would be selling this and we can make it match up with the John Deere front end and will put a new front end grill on and it would be for sale too as a kid but we do know that there are people who make these for the lawn mowers and they're extended and we do know where they are and we're going to try and put them onto our order form and we might give them a heads up since they might have to make tons and the frame too they make that and the enclosure and it's really inexpensive the one they sell is about $300 with the frame and enclosure and when they start pumping them out they'll get cheaper for them it doesn't cost so much to make and the front ends parts and so forth everything be like a thousand dollars but that would mean you would have to do the rear differential but that would include the control changes and the seats and interior and everything and it's kind of a rough interior but it's not goimg to have any unfinished edges. It is right to extended you cut the frame twice and you put tube steel on the inside or 2C channel on each frame member and you drill through bolt it up and weld it if you have an access to a welder if not bolting it up is sufficient and you would have a panel on the floor and we provide that in the kit as a supplier number and it's all going to be in there and we're putting that kid together now there's other vehicles that look like this that we're going to get kits together for and we have to find them that's the hard part

Thor Freya

Olympus

0 notes

Text

NW Casing Shoe

NW Casing Shoe

Casing shoes and rod shoes are used for the period of hole opening widely in the industry of mineral exploration, the shoes manufactured from us with most reliable quality to make sure the hole opening is smoothly. CGET manufactures two types of diamond impregnated casing shoes and rod shoes. One is standard profile and another is flat face crown profile. The STD diamond impregnation depth from us is 8 mm (3.2 inch). For the details please contact with our sales representative for more information.Get more news about Bq Rod Shoe,you can vist our website!

CGET supplies casing and rod shoes with four waterway channels or multi waterway channels depending on the requirements and conditions of the job site from our customers. The inside and outside gauge diameters are protected by intensive hard materials. The hard materials are the combination of TSP diamond elements and abrasion resistant tungsten-carbide pads to assist in maintaining the critical gauge diameters throughout the life of the shoe.

CASING & ROD SHOES (1)

The casing and rod shoes are threaded to the end of the outer drill string for penetration through overburden. It assists in seating the outer drill string into the bedrock, providing a tight seal for the drilling fluids to return to the surface. A casing shoe can be used to ream the casing downward when advancing a casing string in an existing hole with the rod string still in place.

The casing shoe inside diameter is flush or has clearance to the inside diameter (ID) of the casing which allows free passage of the core barrel through the shoe. Casing shoes are available in standard and oversize diameters.

CASING BITS (2)

These are less commonly used and differ from casing shoes in that the inside diameter of the casing bit is smaller. It will not permit the passage of the core barrel due to the overlap of dimensions.

Casing bits are used when deep or difficult overburden is encountered.

0 notes

Text

Water Well Drilling Services Market Can Touch Approximately USD 3.9 billion by 2027, Developing at a Rate of 4.7%

the global water well drilling services market size was valued at $$2.8 billion in 2019, and is projected to reach $3.9 billion by 2027, registering a CAGR of 4.7% from 2021 to 2027.

Request The Samplet: https://www.alliedmarketresearch.com/request-sample/8017

Water well drilling services offering the service of drilling a hole in the ground to make water well or borewell. These water well drilling services are provided to various sectors industrial sectors, agricultural sectors, household sectors, commercial sectors, educational sector, and others for various uses. There are different types of water well drilling methods that include rotary method, jetting method, cable tool method, auger drilling method and others.

The lockdown scenario caused due to the COVID-19 pandemic has caused the water well drilling services market to witness loss in their business. This is because the activities of water supply through borewells to a high number of households, or industries, were already directed to protect public health especially from pathogens .Thus, due to this the demand for new drilling of water well was low in various sectors including municipality, education sector , agriculture sector, industrial sector and others. This has negatively impacted the growth of the water well drilling services market in terms of value sales, thereby, restricting the growth of the market.

The global water well drilling services market is segmented into application, drilling method types and region. Based on application, the market is divided into residential, irrigation and institutional. On the basis of drilling method type, the market is segregated into rotary method, cable tools drilling & auger drilling method and others. Region-wise, the market is analyzed across North America (the U.S., Canada, and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and the rest of Europe), Asia-Pacific (China, India, Japan, Australia & new Zealand , Korea, ASEAN and the rest of Asia-Pacific), and LAMEA (Brazil, Saudi Arabia ,South Africa, Turkey, and others).

Procure Complete Report @ https://www.alliedmarketresearch.com/checkout-final/ad983ff02daeb55c18bcef9f9801860b

In addition, by drilling method types, the others segment is anticipated to be the fastest-growing segment, in terms of value sales, during forecast period. Sonic drilling is one of the fastest and advanced water well drilling method. Municipal water wells provide water supply to entire communities or operational facilities. With rise in population globally the demand for water well is expected to rise the demand for water well through this segment, which in turn is expected to offer immense opportunities for the growth of water well drilling services in terms of value sales during the forecast period.

Furthermore, by drilling method type, the others segment is anticipated to be the fastest-growing segment, in terms of value sales, during water well drilling services forecast period. Sonic drilling is one of the fastest and most advanced water well drilling method. This method is ideal for scrutinizing heavy metal, organic as well as other contamination while drilling water wells. Moreover, sonic drilling method offers easy identification of perched water tables. It has a greater depth capability and is a safer method to operate because of the use of smooth rods and casing. It also reduces manual labor and has ability to tackle difficult ground condition. Thus, these advantages of sonic method has made it popular among the water well service provider as it helps them to provide good water well drilling services to their client. Thus, contributing in driving the water well drilling services market growth in terms of value sales.

Key findings of the study

By application, the residential segment accounted for the highest water well drilling services market share in 2019, growing at a CAGR of 4.3% from 2021 to 2027.

By drilling method type, the others segment accounted for the highest market share in 2019, growing at a CAGR of 5.9% from 2021 to 2027.

By region, Asia-Pacific occupied maximum share in the water well drilling services market in 2019 and is expected to dominate the market during the forecast period.

Inquiry Before Buying @ https://www.alliedmarketresearch.com/purchase-enquiry/8017

The key players operating in the global water well drilling services industry analyzed in this report include caster drilling, Jim Jeffers Well Drilling, Casey Well Drilling, LOMAN Drilling Inc., CRAIG Water well & Drilling Ltd, TAMPA WELL DRILLING, INC., Gordon & Sons Water Well Drilling, Weninger Drilling, LLC , Barco Well Service LP and Johnson Water well Drilling.

0 notes

Text

What is rock bolt mine support?

Rock bolt mine support is a key technology in coal mining. Rock bolt mine support materials play a vital role in rock bolt mine support technology. Supporting materials with superior performance are the necessary prerequisite for giving full play to rock bolt mine support effect and ensuring roadway safety. Today, we will introduce the relevant precautions for the use of anchor rods, so that you can have a better understanding of anchor rods.

(1) The tail of anchor rod is the most complex and easily damaged part in the whole rod body. The stress analysis of bolt thread section is carried out, and it is found that the stress concentration of thread section is 2-3 times locally due to diameter change Because the spherical rotation center between the tray and the ball pad is unreasonable, self-locking occurs between the two spherical surfaces, which makes the stress of the anchor bolt deteriorate sharply and even break.

(2) Tension-bending-torsion, tension-shearing-torsion, and combination of tension-bending-shearing-torsion are common stress states in the process of underground anchor installation, and the stress increases closer to the fixed end, so the most unfavorable position is the fixed end.

(3) When the installation angle of anchor rod is too large and the tensile stress reaches a certain value, long-term loading will cause the thread section at the tail of anchor rod to bend and crack or even break; When the pre-tightening torque is greater than 600N'm, the composite stress of the bolt is close to the yield stress of the material, and the bolt cracks from the bend first, and then the crack expands, causing the bolt to break before reaching the breaking force.

(4) Some optimization schemes are put forward, such as vertical setting of corner bolt, redesign of self-aligning ball pad, full-length anchoring of pre-stressed bolt, and adjustment of pre-tightening torque of bolt to 400N.m, so as to reduce the influence of harmful force on the rod body.

If you have any need, please feel free to ask for advice or leave us a message on the website. We believe that with your advice and help, we will do better.

Hebei Jiufu Industrial and Mining Parts Co., Ltd.It is a manufacturer specializing in the supply of supporting materials for coal mining, construction engineering and large-scale concrete projects. It mainly produces self-drilling bolts, friction bolts, glass fiber reinforced plastic solid bolts, Post-TensioningBar, resin bolts and other coal mine engineering support We export 12,000 tons of materials a year, with annual sales of 50 million U.S. dollars. Supporting materials are exported to more than a dozen countries and regions including the Philippines, Thailand, and Russia. We are one of China's important anchor material manufacturers and exporters.

0 notes

Text

【Hot Sale】Top Brand Lock Rod Rotary Drilling Rig Machine Factory Price

High Quality And High Performance

Max. Drilling Diameter 1500mm

Max. Drilling Depth 50m

Max. output torque 150kN.m

【Want Price?】Leave your needs and WhatsApp/WeChat/Email, and we will send it to you.

【Whatsapp/Wechat/Phone】+8618237175581

Email:[email protected]

0 notes

Text

Service King SK 575 Workover Rig in Excellent Condition

youtube

Watch video on YouTube here: https://youtu.be/KLR8kJgkN1w https://inventory.freeoilfieldquote.com/product/service-king-sk-575-workover-rig-for-sale

Name : Service King SK 575 Workover Rig For Sale

Code : 27507038

Type : Standard

Brand : Service King

Category : Rigs

subcategory : Onshore Rigs

Price : $1,500,000.00

Unit : Each (Each)

In Stock : Yes

Location : Oklahoma

Condition : Excellent

Available Quantity : 1

Service King SK 575 Workover Rig For Sale

• Service Depth: 16,000 Feet

• Workover Depth: 10,000 Feet

• Drilling Depth: 7,000 Feet – 3 1/2 inch Drill Pipe

• Carrier: 5 Axles, High Tensile Alloy Wide Flanged Beam

• Front Axles: 20,000# Capacity

• Suspension: Spring

• Rear Axles: 46,000# Tandem

• Suspension: Walking Beam

• Push Axle: 25,000# Capacity

• Front Tires: 385/65R22.5

• Rear Tires: 11R22.5

• Power Train

• Engine: MTU S1300 T4

• Transmission: 4500 OFS Allison

• Main Drum

• Brakes: 42 inch diameter x 12 inch wide

• Water spray brake cooling

• Double 48 inch Air Cooled Disc Assist

• Barrel: 16 inch diameter x 38 inch wide

• Chain: Double 140 Clutch: 324

• Shaft: 6.60 inch LeBus Grooving: 1 inch or optional 1 1/8 inch

• Sand Drum

• Brakes: 42 inch diameter x 8 inch wide

• Barrel: 16 inch diameter x 43 inch wide

• Chain: Double 140 Clutch: 224

• Shaft: 5.90 inch

• Water spray brake cooling

• Capacity: 14,400 Feet – 9/16 inch or 11,800 Feet – 5/8 inch

• 104 Feet MAST

• Clear Height 104 Feet

• Maximum Static Load:

230,000# Capacity with 6 lines

200,000# Capacity with 4 lines

250,000# Capacity with 6 lines

Tubing Board Capacity: 110,600# Pipe Setback Load

Rod Board Capacity: 31,208# Static Rod Load

from Oilfield Equipment Manager https://rignetwork.wordpress.com/2023/03/18/service-king-sk-575-workover-rig-in-excellent-condition/

0 notes

Text

The Importance of Proper Maintenance for Your Horizontal Directional Drill-Jbtrenchless

Proper maintenance not only ensures that your HDD operates efficiently, but it can also prolong the lifespan of your equipment and help prevent costly repairs. In this blog post, we will discuss the importance of proper maintenance for your horizontal directional drill.

Ensures Safe Operation

Proper maintenance of your Horizontal Directional Drill (HDD) is essential for safe operation. A well-maintained HDD will operate efficiently, reducing the risk of accidents and injuries. It is important to perform regular maintenance tasks such as inspecting and tightening bolts, checking fluid levels, and replacing worn or damaged parts.

Prolongs the Lifespan of Your Equipment

Proper maintenance can help prolong the lifespan of your HDD. By keeping your equipment in good working condition, you can prevent premature wear and tear, which can lead to costly repairs or even the need for a replacement unit. Regular maintenance can also help you identify potential issues before they become major problems.

Improves Performance

Proper maintenance can help improve the performance of your HDD. Regular maintenance tasks such as changing filters and fluids, and cleaning the machine can help ensure that your HDD is operating at peak efficiency. This can result in increased productivity and reduced downtime, which can ultimately benefit your bottom line.

Saves Money

Proper maintenance can help you save money in the long run. Regular maintenance tasks can help prevent major breakdowns, which can be costly to repair. Additionally, a well-maintained HDD will operate more efficiently, reducing fuel and maintenance costs over time.

Maintains Resale Value

If you plan on selling your Horizontal Directional Drill HDD in the future, proper maintenance can help maintain its resale value. Buyers are more likely to purchase a well-maintained machine, and a machine that has been properly maintained will likely fetch a higher price than one that has not.

In conclusion, proper maintenance is essential for the safe and efficient operation of your horizontal directional drill. Regular maintenance can help prolong the lifespan of your equipment, improve its performance, save you money, and maintain its resale value. If you are unsure of how to properly maintain your HDD, consult the manufacturer's maintenance manual or contact a professional for assistance.

1 note

·

View note

Text

Cnc Router Bits Glossary Toolstoday Com- Your Source For Industrial Chopping Instruments

The most difficult half was getting the linear rails lined up appropriately. When marking the precise hole places, I clamped two items of aluminum profiles to the sides of the plate to line up the rails. Once I had marked the opening places, I drilled and tapped them with an M5 thread. When attaching the rails to the gantry, you want to ensure that the space between the rails over the entire size is completely even . For the Z-axis I used top quality stainless steel M10 threaded rod, with a selfmade delrin nut. You can save a lot of money by buying a package that includes linear rails and ball screws.

CNC wood cutting machines are extensively used within the woodworking trade to supply practical and ornamental components for fantastic furniture. Should you run into any bother along with your CNC router machine, you’ll be pleased to know that we now have a free remote entry assist service that can assist you out in pressing situations. DIY CNC router, additionally called do-it-yourself CNC router, principally applies to the mini CNC machines, just like the desktop CNC router, pastime CNC router, and so forth. DIY CNC router requires you to have a comparatively high stage of CNC basic knowledge, good hands-on functionality, and likewise enough time and vitality. It also requires you to buy all the wood CNC machine elements, together with the CNC router bits, by yourself.

CNC wood router machines for sale

The firm ShopBot Tools, Inc. is predicated in North Carolina, and all of the machines are designed and constructed in the USA. In addition, you get a VCarve Pro license that is price $700 to make use of as your design software program. VCarve is a beginner-friendly design software program for CNC machining and is really easy to use. If an error is detected, the motor is stopped, and a warning is displayed on the monitor.

If you propose to routinely reduce lengthy parts, get an envelope massive enough to minimize tiling. Let Mother Nature be your co-designer as you construct dazzling tasks with wavy edges, bristly burrs, bark inclusions, and different “flaws” that give wood a look of unrefined beauty. The Rover B FT machining center for nesting raises the quality and productivity standards on this sector. Thanks to its structure and the variety of potential configurations, it could hold abreast of the work rhythm of medium and enormous companies for the production of pieces for each sort of application. Browse 438 skilled cnc router wood stock pictures, photographs & pictures available royalty-free.

You may use the body to enclose the outer edges of a mirror, portray, or picture. At the same time, utilizing a CNC machine to create a stand ensures that the frame and base fit completely. It eliminates unnecessary wobbles that may be witnessed if unskilled carpenters made the stand. You can use CNC machines to carve out a automotive, truck, ship, or airplane from a block of wood. You can also rest assured that the CNC product might be accurate.

I have seen wooden CNC routers that may cut aluminum , however this went very gradual and the machines should be very well constructed. Because I wanted to chop aluminum with this CNC router, I built it out of aluminum. I might have used metal, but that is more difficult to machine and I didn’t have the proper instruments for that.

The CNC router table 4x8 is sturdy and can withhold the strain of even the toughest materials. Our wood CNC machine 4x8 is assured to serve you well for the years to come. Every 4x4 CNC router purchase additionally comes with a lifetime of technical help so you can all the time rely on our experts that can assist you out in instances of need. Tork's SS-3 sequence forty four is a cost-effective, space-saving 4x4 CNC router machine. It’s a conveniently sized working platform that delivers on worth.

#CNC wood router machines#CNC machine wood router#CNC router wood#CNC wood router machine#CNC wood router machines for sale

1 note

·

View note

Text

A Guide to Stainless Steel Rods

Stainless Steel Rods:

Stainless steel rods are cylindrical pieces of steel alloy that are usually used in construction, fabrication, and industrial applications. They are highly corrosion-resistant and durable, making them ideal for many different types of projects. Stainless steel rods are made from a combination of iron, chromium, nickel, and other metals and alloys, which makes them strong, long-lasting materials that can be used in a variety of ways.

They are commonly used in manufacturing, automotive, and aerospace industries, as well as in structural, mechanical, electrical, and other engineering applications. They can be used to create a variety of shapes, sizes, and lengths, and can be easily cut and bent to fit any project.

Stainless steel rods are also used to reinforce concrete structures and are often used in medical and surgical applications. They are easily welded and are often used to create custom parts for machines and for other types of projects. Stainless steel rods are extremely versatile and can be used in a variety of applications, from construction projects to decorating.

Characteristics of Stainless Steel Rods

Stainless steel rods are highly corrosion-resistant and strong metal rods used in many applications. They are composed of at least 10.5% chromium and are highly resistant to oxidation, rust, and corrosion. They are used in a variety of industries, including construction, marine, automotive, and industrial. Stainless steel rods are strong and durable and can withstand extreme temperatures and pressures. They are also non-magnetic and non-combustible. Stainless steel rods are available in a variety of shapes, sizes, and grades to suit different applications.

They are easy to cut, drill, and weld, making them suitable for many engineering and construction projects. Stainless steel rods are also highly resistant to staining and discoloration, making them an ideal choice for aesthetic purposes. They are also non-toxic, which makes them suitable for medical applications. Stainless steel rods are a popular choice because they are low maintenance and require little special attention. They are also recyclable, making them a great choice for those looking to be environmentally conscious.

Properties of Stainless Steel Rods

1. Stainless steel rods are highly durable, corrosion-resistant, and heat-resistant.

2. They have excellent mechanical properties, making them ideal for a variety of applications.

3. They can withstand high temperatures and pressures, making them suitable for use in extreme environments.

4. Stainless steel rods are strong and provide excellent wear resistance.

5. They are non-magnetic and non-staining, making them ideal for food preparation and medical instruments.

6. They can be machined, welded, and formed into a variety of shapes.

7. Stainless steel rods are relatively inexpensive compared to other metals.

Conclusion

Stainless steel rods are versatile, durable, and corrosion-resistant materials that can be used in a variety of applications. They are commonly used in the construction of machinery, buildings, and other structures, as well as in the manufacturing of various consumer products. They can come in a variety of sizes and grades, allowing them to meet the needs of a variety of applications. Stainless steel rods are also relatively inexpensive compared to other metals, making them an attractive option for many projects. you can get a discount on SS products at stainless steel rods for sale

#stainless steel rods for sale#stainless steel rods#stainless steel rod#SS Rods#SS Rods sale#SS Rods For Sale

0 notes

Text

Price: [price_with_discount]

(as of [price_update_date] - Details)

[ad_1]

DIWANGUS kitchen pot rack is an ideal choice for you to save space in the kitchen. It can also be used as an exquisite gift for family and friends who are good at cooking. product features: 1. Wall-mounted kitchen pot racks are very suitable for use in kitchens, bathrooms, cloakrooms, balconies, corridors, garages, storage rooms and other places. 2. A variety of purposes, can hang all kinds of things: soup spoons, knives, forks, pots, pot covers, whisks, keys, towels, etc. 3. The kitchen pot rack can be used as an exquisite gift for mothers, girlfriends and friends who are good at cooking. It is an excellent gift for saving kitchen space. 4. The wall-mounted design makes full use of the unused wall space in the kitchen and saves kitchen space. 5. It is made of stainless steel material, the stainless steel pipe is widened, and the base is thickened to make it more stable and stable without falling off. 6. Easy to install, follow the instructions, you can easily install the kitchen pot rack. installation steps: 1: Measure the distance between the two holes on the wall, make a mark and drill a hole with a percussion drill. 2: Use a hammer to drive the stud into the wall. 3: After installing the studs, align the product with the holes and install the screws to fix it. The installation is complete. Product parameters: --Product material: stainless steel, chrome plated --Installation method: wall-mounted --Scope of application: kitchen, bathroom, balcony, utility room, etc. --Product size: 40 * 7 * 6.5 cm Parts List: 4X hanging rod 1X base bag 1X hook bag 2X screw pack If you have any questions about our products, please contact us on Amazon, we will answer you within 24 hours, and we will provide you with a refund or replacement after-sales service! ! !

✔【STURDY & DURABLE】The wall-mounted pot rack kitchen pot rack is made of high-quality stainless steel material, with a widening and thickening design, using thick stainless steel pipes, which have strong bearing capacity and make it more stable. The thickened base is flat and close to the wall without falling off or loosening.

✔【SAVE SPACE IN THE KITCHEN】The pot rack adopts a wall-mounted design, which makes full use of the unused wall space in the kitchen. Placing messy kitchen utensils on the pot rack can make the kitchen look neater and save the kitchen countertops and cabinets Space.

✔【POT RACK STRUCTURE】The kitchen pot rack is 16 inches long. The kitchen pot rack is composed of two parts, and the inner hanging rod can place the pot cover. The outer hanging rod can be placed with hooks. We have equipped you with 16 hooks. The hooks can easily move back and forth on the hanging rod. At the same time, you can adjust the gap between the hooks and the number of hooks according to the size of your kitchen utensils.

✔【WIDE USE】In addition to installing in the kitchen, you can also install the wall-mounted rack in other places, such as: bathrooms, cloakrooms, balconies and other places. It can be used to hang bathroom towels, clothes, jewelry, handbags, keys, green plants, etc. It is very suitable for family kitchens and utility rooms.

[ad_2]

0 notes