#Thermoplastic

Text

5 notes

·

View notes

Text

This one's for the monsterfuckers.

I made myself some fun teef. These are clearly fun, and not at all creepy, uncanny or scary.

I can be even more of a fucking cryptid now, muahahaha!

3 notes

·

View notes

Text

That right there 👆

Is the bane of my existence and my current reason why my carpal tunnel is acting up.

I HAND CUT the stain glass windows on the top of the cup. 2 times. It's Worblas pearly art. I used a pair of scissors and a scalpel.

This is for the Hellish Debut project. Which is due this Saturday!

I still need to add the stain glass, add the filigree, paint and gild with gold leaf. (Plus weather it) in 2 DAYS.

It better be worth it.

#costume#costume design#original character#current wip#baldursgate 3 fanart#thermoplastic#worbla#worblas pearlyart#worbla's crystal art#cosplay

3 notes

·

View notes

Photo

New Unicorn Knight pic! So glad I was able to shoot this, again! 📷 @scoundrel.run #thibra #thermoplastic #foamsmith https://www.instagram.com/p/Cl37zAkuCJq/?igshid=NGJjMDIxMWI=

8 notes

·

View notes

Text

Top Five Advantages And Applications Of Powder-Coated Thermostat

Thermostats play a vital role in different sectors, providing temperature adjustment and enhancing the efficiency of machinery and equipment. The application of protective coating is one important part of the production process.

Thermoplastic Powder Coating is becoming widely used for various reasons such as durability, efficiency, and environmental friendliness. Continue reading to learn about thermostat powder coating and its advantages.

Understanding Thermostat Powder Coating

Powder coating is a dry finish technique where particles of powdered pigment and resin are electrostatically sprayed onto a surface. Then, the coated surface is placed in an oven to bake it.

The powder melts and forms an ultratough, uniform and attractive finish. This deposition method is extremely suitable for thermostat components. Its unique property is to deposit a thick, corrosion-resistant coating, which can function well at high temperatures.

Advantages of Powder Coating For Thermostats

Advantages of powder-coated thermostats include:

1. Durability: The powder-coated thermostats are very durable and hardly affected by chipping, scratching, fading, and general wear. This leads the thermostats to stay longer which in turn results in less replacement.

2. Corrosion Resistance: The corrosion is lower with the powder coatings significantly. This property is what makes them suitable for thermostats. They work in extreme environments or are submerged in moisture and chemicals.

3. Uniform Finish: The powder coating process ensures an outstanding uniform finish even on the most complicated thermostat components. It makes them more attractive to look at.

4. Environmentally Friendly: Unlike liquid coatings, powder coatings do not contain volatile organic compounds (VOCs). It uses fewer resources and corresponds to specific environmental rules and regulations.

5. Cost-Effective: The initial outlay might be more than that for the conventional coatings at the installation stage. This lowers the long-term costs due to the reduced maintenance and replacement. This makes it an attractive option for thermostat manufacturers.

Applications Of Powder-coated Thermostats

Thermostat powder coating finds versatile applications across a wide range of industries:

1. Automotive Industry: Engine, cooling systems and climate control systems use power-coated thermostats. These devices are made to withstand extreme temperatures and tough environments. It guarantees smooth running and extends the lifespan cycles.

2. Aerospace Industry: Spacecraft has to perform optimally while withstanding such harsh forces of nature. Powder-coating thermostats are used basically in aerospace engineering to make output temperature normal at any complex setup.

3. Electronics Industry: These gases are utilised in machines that need to be maintained at the proper temperature. It includes computer servers, industrial controllers and medical equipment. The Thermostats' chemical resistance and resistance to corrosion allow them to be used in these complex parts without problems.

4. HVAC Industry: Heating, ventilation, and air conditioning (HVAC) systems can be controlled with thermostats to achieve temperature regulation. The dust-free thermostats are used in residential, commercial and industrial sectors. The HVAC systems are defined by their high effectiveness and additional confidence in temperature control.

5. Industrial Ovens and Furnaces: Thermoplastic used in industrial furnaces and ovens withstand high temperatures and rough conditions of operation. The most suitable option for this is the powder-coated thermostat. They provide reliable temperature control but also their durability stands the test of time.

Conclusion

Thermoplastic Powder Coating delivers a variety of advantages, including longevity, corrosion protection, temperature stability, colour options and chemical resistance. Powder coating is the most preferred coating system for thermostat manufacturers.

It seeks to elevate its products' performance and longevity. The use of powder coating technology can result in thermostats of high quality. They are capable of meeting the stringent specifications set by various industries.

0 notes

Text

Thermoplastic Elastomers Market: Top 3 Industrial Applications

According to UNEP, energy accounts for approximately 60%of global greenhouse gas emissions, making energy efficiency a top priority across various industries. In this context, thermoplastic elastomers (TPEs) have emerged as a viable solution, reducing energy consumption by nearly 75%. They have gained recognition among product developers and designers as an advanced alternative to thermoset elastomers. Triton’s estimates suggest that the global thermoplastic elastomers market is expected to grow at a CAGR of 6.37% in revenue and 2.61% in volume during 2023-2030.

Another significant factor is the increasing trend of 3D printing. Due to their durable, flexible, chemically resistant, and user-friendly properties, TPEs serve as filaments in additive manufacturing methods like selective laser sintering (SLS) and fused deposition modeling (FDM). For instance, renowned companies such as New Balance, Under Armour, and Nike have adopted thermoplastic polyurethane-based 3D printing for robust and flexible midsoles.

In this blog, we’ll explore the wide-ranging applications of TPEs and their significant presence in the top three industries.

· Automotive:

In terms of industrial vertical, automotive leads with $9325.51 million

These high-performance polymers have gained significant traction in the automotive industry. Polystyrene TPE, for example, is used in multiple auto parts like instrument panels, wheel covers, dashboard elements, pillar trims, door liners, seat belt components, etc. These plastics, unlike metals, are cost-effective and improve vehicle energy efficiency by reducing weight.

Moreover, their lightweight quality boosts vehicle fuel efficiency, with a 10% weight reduction translating to 5-7% lower fuel consumption. This has prompted TPE manufacturers like Covestro AG to introduce new production lines for high-performance thermoplastic polyurethanes to produce paint production films.

Regional Focus: Asia-Pacific set to be the fastest-growing region at 6.46%

Asia-Pacific is the world’s largest automotive producer, with China, India, Japan, and Indonesia leading the way. Nations like India and Indonesia are attracting investments in locomotive and high-speed rail manufacturing, further bolstering the demand for TPE in the region. Additionally, China is actively boosting production, aiming for 7 million annually by 2025, constituting 20% of total new car production. This surge in EV production is set to drive demand for polyurethane and polystyrene in automotive applications, driving the Asia-Pacific thermoplastic elastomers market.

· Electrical & Electronics:

Thermoplastic elastomers are preferred for electrical insulation due to their strength, flexibility, and resistance to corrosive substances like acids. Besides this, TPE composites, including polycarbonate, enhance impact and flame resistance in electronic devices and household appliances. Given these benefits, several companies have entered into partnerships or acquisitions to expand their footing. For example,

- Arkema SA acquired Polytec PT in May 2023 to expand offerings and serve the electronics sector.

- Avient Corporation collaborated with BASF SE to offer colored grades of Ultrason® high-performance polymers to provide users in the electrical & electronics sector with comprehensive technical support.

Widely Employed Material Type:

Thermoplastic polyolefin serves multiple purposes in the sector, finding use in low-voltage wire and extruded hoses. TPOs are preferred over TPVs in wire and cable applications due to their cost-effectiveness, excellent electrical properties, and temperature versatility. As per Triton’s report, polyolefin is expected to register a CAGR of 6.30% during the forecast period 2023-2030 in terms of material type.

· Adhesives & Sealants:

Thermoplastic elastomers have gained popularity in providing strong bonds and flexibility without mixing or high-temperature curing. Since TPE adhesive grades offer durability, electrical insulation, and chemical and water resistance, companies strive to expand footing in the adhesives sector. Arkema SA, for instance, acquired Ashland’s performance adhesive branch in February 2022 to strengthen its adhesives solutions segment.

Regional Analysis: Asia-Pacific dominates the market based on volume

In Asia-Pacific, China dominates paint and coating production, while India is experiencing robust growth due to rapid industrialization and construction activities. Besides this, thermoplastic elastomer manufacturers are expanding in ASEAN countries like Thailand. Hence, the region’s expanding position in adhesive and sealant production fuels the region’s market, spearheaded by China.

Regulations & Shortages Prompt Innovation

Due to increasingly stringent environmental regulations and sustainability goals, elastomer manufacturers are compelled to create more recyclable tire options. This has led to a noticeable shift towards sustainable TPE materials, including bio-based TPEs. Shortages in raw materials further exacerbate the need for recyclable products. Notably, China has witnessed a significant increase in recycled rubber production, capturing more than 80% of the global production landscape.

In summary, the growing demand for eco-friendly solutions, regulatory pressures, and raw material shortages have spurred the adoption of TPEs as an effective means to reduce costs associated with waste tire management. Looking ahead, the industrial commitment to resource efficiency is expected to create lucrative opportunities within the thermoplastic elastomers market.

FAQs:

Q1) How big is the thermoplastic elastomers market in terms of volume?

Based on volume, the thermoplastic elastomers market recorded 7298.81 kilotons in 2022, expected to advance with a CAGR of 2.61% during 2023-2030.

Q2) Which are the 5 key thermoplastic elastomers?

Five key TPEs are polystyrene, polyamide, polyolefin, polyurethane, and elastomeric alloy.

#ThermoplasticElastomersMarket#ThermoplasticElastomers#Thermoplastic#tritonmarketresearch#marketresearchreports

0 notes

Text

Thermoplastic Vulcanizates TPV Market

0 notes

Text

Plastic Granules Manufacturer | Polypropylene Compounds(PP) Supplier

Bakelite Engineering is the well-known Manufacturer, Supplier and Exporter of Polypropylene Compounds, Plastic Granules, PPHP/PPCP, PP/EPDM, HDPE, ABS, PC, PBT, NYLON 66, in Ahmedabad, Vadodara, India.

#plasticcompounds#plasticmanufacturer#thermoplastic#ppcompounds#abscompounds#sancompounds#pbtcompounds#pccompounds

1 note

·

View note

Text

MAS engineering solutions is committed to providing a holistic array of electrical products that adhere to stringent quality standards. Our offerings cater to numerous sectors, including infrastructure, power generation, transmission and distribution, solar manufacturing, and original equipment manufacturers (OEMs), among others. In addition to these, we deliver an expansive selection of products for industrial connectivity, comprising durable plugs and sockets, as well as reliable solutions for cable management and enclosures. We take great pride in our protective solutions, which encompass both surge protection and lightning protection/earthing, designed to serve the diverse requirements of multiple industries. Our commitment is to ensure that our products embody excellence, uphold safety, and deliver performance that our customers can rely on.

#electrical products#Thermoplastic#Polycarbonate#FRP Enclosure#Outdoor#UV resistance#UL 746C#Flammability rating UL 94 V0#Glow wire tested 960°C#Electrical Insulated#Ingress Protection(IP)65/66#Impact Resistance (IK) 08/09/10#UL Listed

1 note

·

View note

Text

Which material is commonly used in the construction of Guardio Handrails for durability and strength?

a. Glass

b. Wood

c. Metal

d. Thermo Plastic

#quiz#architecturequiz#wallprotectionquiz#wallprotectionmcq#DamagePrevention#Handrailsquiz#Handrails#letsconnect#ArchitectureDesign#GuardioHandrails#ConstructionMaterials#DurabilityAndStrength#HandrailDesign#MetalCraftsmanship#SafetyFirst#ArchitecturalChoices#BuildingMaterials#ThermoPlastic#GuardioFAQs

0 notes

Text

Thermoplastic Pipe Powerhouse: Market Trends and Insights

Thermoplastic pipes have unique properties such as flexibility, excellent chemical resistance, low installation cost, high mechanical strength, greater flow and rust resistant features. Owing to above unique properties, these pipes are preferred over metal pipes and considered as the best option for oil and gas offshore drilling practices.

Increasing applications of thermoplastic pipe across sectors such as oil & gas, chemical, mining & dredging and municipal along with application in deep water and ultra-deep-water is a key factor driving the growth of the market. Greater acceptance of thermoplastic materials in engineering processes and large diameter pipe applications are other important factors expected to drive the demand of the market along the forecast period. In addition, increasing number of horizontal wells during oil and gas activities is expected to be a major growth opportunity for the thermoplastic pipe market. However, higher production cost of thermoplastic pipes across oil and gas sector coupled with rising safety concerns are the key factors hampering the growth of the market.

The world thermoplastic pipe market is segmented on the basis of types, applications and geography. On the basis of types, the market is segmented into PVC, PE, PA, PP, PVDF and others. On the basis of applications, the report segments the market into oil & gas, municipal, chemical, mining & dredging. On the basis of geography, the market is segmented into North America, Europe, Asia-Pacific and Latin America & Middle East and Africa.

KEY BENEFITS FOR STAKEHOLDERS

The study provides an in-depth analysis of the world thermoplastic pipe market with current and future trends to elucidate the imminent investment pockets in the market

The report provides information regarding key drivers, restraints and opportunities with impact analysis

Porters five forces and SWOT analyses of key market players in the industry have been provided to highlight the growth strategies adopted by them

The value chain analysis of the industry signifies the key intermediaries involved and elaborates their roles and value additions at every stage in the value chain.

Key Market Players : IPEX Inc., Technip, Chevron Phillips Chemical Company, Georg Fischer Piping Systems Ltd., Advanced Drainage Systems Inc., Airborne Oil & Gas B.V., KWH Pipe, Prysmian Group, National Oilwell Varco

0 notes

Text

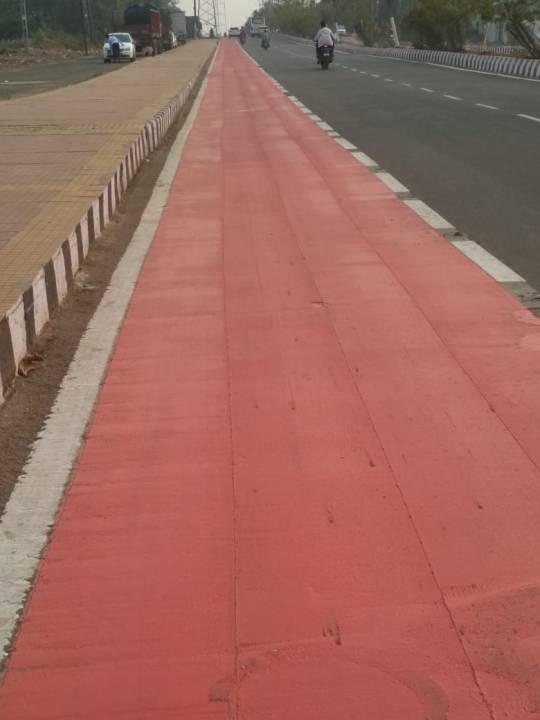

Alpha Thermoplastic Paint Manufacturer is a leading manufacturer of high-quality thermoplastic paint in India. Our paint is made with the finest materials and craftsmanship, and is designed to provide our customers with the ultimate in durability and performance.

We offer a wide range of thermoplastic paint products to meet the needs of a variety of industries, including:

Road construction and maintenance

1.Airports

2.Parking lots

3.Sports facilities

4.Industrial facilities

5.Warehouses

Our thermoplastic paint is known for its durability, adhesion, and visibility. It is also resistant to abrasion, chemicals, and UV rays.

We are committed to providing our customers with the best possible products and services. We have a team of experienced and knowledgeable professionals who are always happy to help you choose the right thermoplastic paint for your needs.

#road safety#thermoplastic#architecture#manufacturer#road construction#road maintenance#airport markings

0 notes

Text

https://www.dowellmoulds.com/blog/processes-for-molding-thermosetplastics-and-thermoplastics

#Dowell Moulds#plastic mould manufacturers in India#Injection molding#Compression molding#Transfer molding#Blow molding#Extrusion molding#Thermoset#Thermoplastic#Mold cavity#Gate#Pellets

0 notes

Text

I have a thermoplastic based ask for science side of Tumblr: do you know of thermoplastics that stick to pla and print at similar temperatures but have a higher glass transition point because I want to make the case for pla filament coextruded with another polymer to prevent warping while annealing pla, as annealed pla yields stronger and more temperature resistant parts.

1 note

·

View note

Text

PBT Excellence: Elevate Your Product's Quality to New Heights

Are you searching for a versatile and high-performance material to enhance your product designs? Look no further! Welcome to the world of Polybutylene Terephthalate (PBT) – a cutting-edge engineering plastic revolutionizing various industries. At OWCable, we proudly present our exceptional PBT products that offer unparalleled strength, durability, and flexibility for your manufacturing needs.

Unrivaled Strength and Durability:

Our Polybutylene Terephthalate (PBT) is renowned for its outstanding mechanical properties. With an impressive tensile strength and excellent resistance to impact, PBT ensures your products can withstand rigorous environments and heavy usage. From automotive components to electrical connectors, our PBT solutions provide the durability required to exceed performance expectations.

Superior Chemical and Heat Resistance:

When it comes to chemical and heat resistance, our PBT products excel. Whether exposed to harsh solvents, oils, or extreme temperatures, PBT remains steadfast, maintaining its structural integrity and functionality. This remarkable feature makes it ideal for a wide range of applications, including electrical insulation, electronic devices, and household appliances.

Enhanced Flexibility and Moldability:

PBT is known for its exceptional flexibility and moldability, allowing you to bring your intricate designs to life. With its high flow characteristics, our PBT material effortlessly fills complex molds, ensuring precise and intricate detailing. Its inherent flame retardancy also makes it a top choice for safety-critical applications.

Excellent Electrical Properties:

When it comes to electrical applications, our PBT products truly shine. With superb electrical insulation properties, low dielectric constant, and low water absorption, PBT guarantees reliable and consistent performance in demanding electrical and electronic environments. Trust in our PBT solutions to deliver outstanding electrical functionality and ensure the safety and reliability of your products.

Customizable Solutions:

At OWCable, we understand that every project has unique requirements. That's why we offer customizable solutions tailored to meet your specific needs. Whether you require specific color variations, enhanced UV resistance, or additional additives for improved performance, our team of experts is dedicated to providing you with the perfect PBT solution that aligns perfectly with your project goals.

Unleash the Potential of PBT with OWCable:

Discover the immense potential of Polybutylene Terephthalate (PBT) for your manufacturing needs. Trust OWCable as your reliable partner, offering exceptional PBT products and unrivaled technical expertise. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the highest level of support throughout your project.

0 notes

Text

Anthony Fineran (B 1981), Thermoplastic Milwaukee, 2023

0 notes