#Stainless Steel Clamp Importers.

Text

SS Clamp Manufacturers

We are giving an extensive variety of SS Clamps. These are made of unadulterated stainless steel and have safe body. Broadly utilized as a part of business and local locations, our clips are generally valued by the clients for their high solidness. Accessible in various sizes and shapes, every one of our clasps guarantee indicate ideal execution even in unfavorable utilize.

Features

Reliable performance

Durable

Corrosion proof

For More Details:

Website - https://www.chhajedbrassfittings.com

Phone No. - 9821513630

Email - [email protected]

#SS Clamp#SS Clamp Manufacturers#SS Clamp Suppliers#SS Clamp Exporters#SS Clamp Importers.Stainless Steel Clamp Manufacturers#Stainless Steel Clamp Suppliers#Stainless Steel Clamp Exporters#Stainless Steel Clamp Importers.

0 notes

Text

MAKE, IT, COOK!

(Kiln repair)

Ended up doing a little maintenance on a kiln. The bricks had been so worn down at the top that ceramics placed too close to the top front were getting a draft, and weren't getting fully cooked. Lucky there was an organ donor nearby

They aren't the most complex machines in the world. It's not much different from a lightbulb on a timer, with a lot of insulation. The heating elements connect to relays, and the controller opens and closes the relays based on how fast you want to reach a temperature

These things are built in layers and can be ripped apart like a wedding cake. To retain the bricks, they just kinda sit there, and a stainless steel sheet is wrapped around with a hose clamp welded at the seam to tighten it. There's then 2 clamps to lock it to the other segments, and it's arranged to have 1 heating element per segment

To spiff it up, I put the bottom layer of the donor as the top layer, but used the steel sheet from the original to avoid unscrewing the hindge brackets from it. I had a feeling if those hindge screws came out, they were never going back in strong enough to resist that honker chonk of a spring. That thing is eager to kill someone

The lid from the donor was also taken by just unloading the spring and removing a spring cotter pin for a dowel

It actually decided to be a bitch when connecting the elements back to the controller, and kept cracking. It was a hell of a lot more brittle at room temperature than I thought (Tho if it's nichrome, I guess neither the nickle OR chromium does its malleability any favors). Anyways, a quick hit from a propane torch got the wire nice and bendy at red hot temps. (I didn't use a Bic™ lighter to bend it.... Well I did, but then I got a propane torch out, because fuck that) It's kinda important to double up on the wire at the terminals, so the terminal doesn't get melting temperatures hot

She cooks perfectly now and knocked the firing time from over 10 hours to 7 🔥

#mechanical engineering#repair#big oven#diy repair#she be spiffen now#material science#I used a Bic lighter for metal bending

4 notes

·

View notes

Text

The Precision Craftsmanship of Surgical Instruments: Tools That Heal

Introduction

In the world of modern medicine, the art of surgery relies heavily on the precision and efficacy of surgical instruments. These remarkable tools, crafted with painstaking attention to detail, play a crucial role in the hands of skilled surgeons. They are the silent heroes in the operating room, helping to save lives and improve the quality of life for countless patients worldwide. In this article, we will delve into the fascinating world of surgical instruments, exploring their history, types, materials, and the importance of their design and maintenance.

A Brief History

The history of surgical instruments dates back thousands of years. Early examples of rudimentary surgical tools have been found in archaeological digs from ancient civilizations such as Egypt, Greece, and Rome. These early instruments were often made of materials like bronze and iron and were limited in their functionality.

It wasn't until the Renaissance that surgical instruments began to evolve into more specialized and effective tools. The works of pioneering surgeons like Ambroise Paré and Andreas Vesalius paved the way for the development of instruments tailored to specific surgical procedures. The Industrial Revolution further accelerated the production of surgical instruments, with advancements in metallurgy and manufacturing techniques.

Types of Surgical Instruments

Surgical instruments are incredibly diverse, designed to serve a wide range of medical needs. They can be broadly categorized into several groups:

Cutting and Dissecting Instruments: These instruments are used to cut through tissues, such as scalpels, scissors, and dissectors. Scalpels, in particular, come in various shapes and sizes to accommodate different surgical tasks.

Grasping and Holding Instruments: Forceps and clamps fall into this category, allowing surgeons to grasp and manipulate tissues, sutures, or other objects within the surgical field.

Hemostatic Instruments: Hemostasis is the control of bleeding during surgery. Instruments like hemostatic forceps and clamps help clamp blood vessels and prevent excessive bleeding.

Retractors: Retractors are used to hold tissues or organs aside, providing better visibility and access to the surgical area. Common retractors include wound retractors and self-retaining retractors.

Suturing and Stapling Instruments: These tools are essential for closing incisions or wounds. They include needle holders, suture scissors, and skin staplers.

Materials and Manufacturing

The materials used in surgical instrument production have evolved significantly over time. Stainless steel, due to its corrosion resistance and strength, is the most common material in modern surgical instruments. Some specialized instruments, such as those used in minimally invasive surgeries, are made from materials like titanium and carbon fiber, which offer unique advantages like reduced weight and enhanced durability.

Crafting surgical instruments is a meticulous process that demands precision and attention to detail. Manufacturers utilize advanced techniques such as CNC machining, laser cutting, and electro-polishing to ensure the instruments are of the highest quality. These instruments must meet strict regulatory standards to ensure patient safety and maintain their sterile condition.

Design and Ergonomics

Surgical instruments are designed with the utmost care to enhance the surgeon's performance. Ergonomics play a significant role in their design, as they must be comfortable to use for long periods. Grips, handles, and the arrangement of controls are carefully considered to minimize hand fatigue and improve maneuverability.

Maintenance and Sterilization

Proper maintenance and sterilization are paramount to the functionality and safety of surgical instruments. They undergo rigorous cleaning and sterilization processes to ensure they are free from contaminants and pathogens. Many instruments are designed for repeated use after thorough sterilization.

Conclusion

Surgical instruments are marvels of modern engineering and craftsmanship. Their evolution from basic tools to highly specialized, precision instruments has revolutionized the field of medicine. Surgeons rely on these instruments every day to perform life-saving procedures and improve the quality of life for patients around the world. As technology continues to advance, we can expect further innovations in the design and manufacturing of surgical instruments, enhancing their effectiveness and improving patient outcomes.

3 notes

·

View notes

Text

Get to Know About Polishing Fixtures Care

The polishing procedure using fiber polisher is arguably the most important stage in the construction of fiber optic cables to ensure high-quality assemblies that adhere to standards. Because of this, it's crucial to choose the optical fiber polishing equipment and polishing fixtures that are appropriate for your demands. You may have several polishing fixtures to create various connection types, depending on the product offers of your cable assembly business.

For your business, the polishing fixtures' quality—also known as the polishing plates or jigs' quality—is crucial. Your business will want to maintain these tools to create a high number of items with few quality concerns over the long term, given the high cost of manufacturing equipment and components.Polishing equipment must be properly maintained.

High-precision machining tools are used to construct the fiber polishing fixture for optical fiber polishing machines. Steel and aluminum fixtures tend to bend and warp with time, which will affect your polishing procedure and the quality of your finished product. On the other hand, polishing equipment composed of stainless steel that has been hardened prevents this wear effect. Hardened stainless steel does increase the danger of corrosion, though, because there is more iron in the alloy. This is a major factor in why regular maintenance is so important.

Moreover, a plastic latch or clamp used to secure the three most popular fiber optic connections to the polishing fixture might deteriorate over time if not kept clean. Moreover, improper cleaning procedures might inhibit proper locking. This may have a considerable effect on the polishing machine's performance and, therefore, product quality. Your business will want to maintain these tools to create a high number of items with few quality concerns over the long term, given the high cost of manufacturing equipment and components.

As was already said, polishing may be the phase that makes or breaks high-quality fiber optic cable assemblies. We believe that following these upkeep and cleaning instructions along with a fiber polishing machine will enable you to make better use of these indispensable instruments and prevent quality issues and quick depreciation of this pricey equipment.

2 notes

·

View notes

Text

What Is the Function of a pipe clamp ? And Types of it - Arcellor Controls

The elaborate global of business piping structures is predicated on a network of unseen heroes – pipe clamps. These apparently simple additives play an important position in making sure the secure, steady, and efficient operation of those systems Arcellor Controls, a leading issuer of industrial automation solutions arcellor controls ON Arcellor Controls is familiar with the significance of superb pipe clamps. In this blog, we'll delve into the characteristics of pipe clamps, explore numerous sorts, and speak about their applications.

The Function of Pipe Clamps

Pipe clamps, additionally known as pipe becoming clamps or clamp pipe fittings, are mechanical gadgets designed to soundly maintain and guide pipes inside a system. They prevent undesirable movement, vibration, or misalignment, safeguarding in opposition to capacity leaks, harm to pipes, and even system failure. Pipe fitting clamps work with the aid of gripping the pipe with a saddle or band and securing it to a wall, ceiling, or other helping shape the use of bolts or other fasteners.

Types of Pipe Clamps: Catering to Diverse Needs

A huge variety of pipe clamps exist, catering to particular pipe sizes, materials, and applications.

Here are some not unusual kinds:

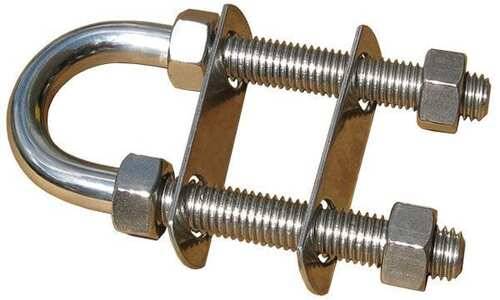

U-Clamp: A versatile and fee-effective alternative, presenting a U-fashioned frame that encircles the pipe and tightens with a bolt. U-clamps are suitable for various pipe sizes and substances, making them a famous preference for general-reason packages.

Saddle Clamp: This clamp capabilities a half-spherical frame that fits across the pipe and secures it to the mounting floor. Saddle clamps offer right guidance and are frequently used for large diameter pipes or situations requiring high load bearing ability.

Clevis Clamp: Ideal for putting pipes from ceilings or overhead structures, a clevis clamp features a U-formed frame with a threaded rod and a clevis on the lowest for attaching to a hanger or bracket.

Band Clamp: A flexible choice including a metallic band that wraps across the pipe and tightens with a screw mechanism. Band clamps are suitable for packages requiring frequent changes or wherein particular positioning is wanted.

pipe clamp fittings: Made from a light-weight and corrosion-resistant plastic material, PVC pipe clamps are specifically designed for securing PVC pipes in low-pressure packages like irrigation systems or drainage lines.

Specifications and Standards for Pipe Clamps

The selection of appropriate pipe clamps requires considering specifications and requirements:

Pipe Size: Clamps need to be compatible with the particular diameter of the pipe they're intended to aid.

Material: Pipe clamp fabric choice depends on elements just like the pipe cloth, working environment, and load necessities. Stainless steel is a common desire for its sturdiness and corrosion resistance, at the same time as nylon or PVC clamps are suitable for low-strain applications.

Load Rating: Clamps are rated for the maximum load they are able to correctly assist. Choosing a clamp with a good enough load score is critical for making sure device integrity.

Standards: Reputable manufacturers adhere to industry requirements like ASTM International (ASTM) or American Society of Mechanical Engineers (ASME) for cloth residences and overall performance requirements.

Applications of Pipe Clamps: Spanning Various Industries

pipe clamp pvc discover software in a wide range of industries:

Plumbing Systems: Securing pipes in residential and industrial buildings for water supply, drainage, and waste disposal.

HVAC Systems: Supporting pipes sporting hot or bloodless water, refrigerant lines, and ductwork in heating, ventilation, and aircon structures.

Industrial Piping: Providing aid for pipes carrying fluids, gasses, or chemical compounds in diverse commercial methods.

Fire Sprinkler Systems: Securing pipes inside hearth sprinkler networks to make certain proper functionality and safety.

Electrical Conduit Systems: Supporting electric conduit and cable trays for safe and prepared wiring.

Conclusion

Pipe clamps, though reputedly easy, play a crucial function in making sure the smooth and safe operation of business piping systems. Understanding the different types, specs, and programs of pipe clamps empowers you to make knowledgeable decisions for your particular needs. When it comes to outstanding pipe clamps and different industrial automation answers, Arcellor Controls is your dependent on companions. We offer a comprehensive variety of clamps to fulfill your task necessities and make sure of the most advantageous performance of your piping structures.

#pipe clamp types#pipe fitting clamp#pipe clamp fittings#clamp pipe fittings#pvc pipe clamp#pipe clamp pvc

0 notes

Text

Top Trendy Best Kitchen Canisters Sets Of The Year

Kitchens may be the heart of the home, but let's be honest - they can also become a bit of an eyesore if disorganized. Between spices strewn about, snacks sitting out on countertops, and potatoes and onions rolling recklessly around in the bottom of your pantry, keeping your kitchen completely clutter-free can feel downright impossible.

That's where kitchen canisters come to save the day! These storage containers are engineered to neatly contain all your bulk foods, keep them fresher for longer, and give your kitchen a sense of tidy sophistication. Plus, with so many gorgeous and functional canisters to choose from these days made from glass, stainless steel or ceramic, they add a decorative element to your space.

In this post, we've researched and reviewed dozens of options to round up the definitive list of the very best kitchen canisters available in 2024. We'll share our top overall picks as well as the best containers for specific needs like storing coffee or tea, keeping pet food sealed and fresh, creating beautiful matching sets and more.

We have recommendations at every price point, style and size to help you organize your kitchen like a pro! Whether you need an airtight flour holder that seals in freshness or lidded glass jars that display your ingredients in style, we've got you covered. Let's get started transforming your chaotic kitchen into a neat and tidy dream space!🌮✨

What to Look for When Buying Kitchen Canisters

So you've decided to invest in some kitchen canisters - excellent choice! But between materials, sizes, and special features, there's a lot to consider to find the best options for your needs. This comprehensive buying guide will walk you through the key factors to keep in mind.

Airtightness: An Airtight Seal is a Must 🌿

The number one job of any food storage container is preserving freshness by preventing air and moisture from getting in. You want canisters with lids that seal completely air tight.

- Rubber gaskets around the lid create a tight vacuum seal when closed

- Locking mechanisms like clamps or clips compress the lid down extra tight

- For staples like flour, coffee, and sugar, go with airtight models to maximize shelf life

- Allowing air to escape compromises freshness and flavor

Level of Air Tightness Storage Items Completely Airtight Flour, coffee, sugar, other grains Mostly Airtight Pasta, coffee beans, dried fruit Somewhat Airtight Packaged snacks, baking needs

Visibility: To See or Not to See🧙♂️

There's something so satisfying about a clear display of neatly lined up ingredients...but complete visibility isn't always necessary:

- Glass or plastic models allow you to view contents

- Stainless steel often has small viewing windows

- Opaque ceramic, tin, or stainless steel still stores food well!

- Consider if you will display the canister or keep it in your pantry

Determine what's more important - enjoying the view or retaining maximum freshness.

Durability: Long-Lasting 💪

The longevity of your containers comes down to investing in durable designs:

- Glass - Risk of cracking or breaking over time

- Stainless steel - Withstands frequent use without dents or corrosion

- Ceramic - Chips and cracks unlikely but not unheard of

- High quality materials that don't fade or degrade

Consider the placement in your kitchen, the use frequency, the types of food being stored inside and choose durable canisters suited for your habits!

Material: The Beauty Contest 🏆

Beyond functionality, storage canisters are available in stunning styles to coordinate with your kitchen's aesthetic:

- Glass - Sophisticated transparency shows off contents

- Stainless steel - Sleek, modern, polished or brushed look

- Ceramic - Vibrant, colorful glazes and painted designs

- Tin - Retro charm reminiscent of old-school general stores

You'll find brilliant colors, gorgeous patterns like florals, warm wooden lids, charming distressed finishes, and more! Determine the look you love before choosing models that reflect your taste and kitchen style.

Size/Shape: A Canister for Every Culinary Creation 🍲

Consider the bulk ingredients, snacks, and food items you want contained before deciding on dimensions:

- Individual canisters or full sets

- Capacities ranging from less than 1 cup to over 5 cups

- Measure dimensions of your cupboards and pantry shelves

- Uniform sizing for organized rows or a mix of heights

Coffee beans, large bags of flour and sugar, giant boxes of oats - assess your quantity needs so your containers can house everything with room to spare!

Now that you know what features provide the best functionality and style, review your options with this knowledge in mind. With so many exceptional kitchen canisters available today, you'll easily discover choices perfect for your home that keep ingredients fresh as can be!

Sets vs Individual: To Mix or Match 🤹♂️

Are you the Picasso of pantry aesthetics, or do you prefer the simplicity of a matching set? Let's weigh the options:

- Buy a whole matching set: Cohesiveness personified.

- Mix and match: Flexibility for the creative souls out there.

Now that you're armed with canister wisdom, it's time to explore the 15 best kitchen canisters that'll transform your pantry into a symphony of organized perfection. Stay tuned for our canister showcase – your pantry will thank you! 🍽🔍

The 15 Best Kitchen Canisters!

The moment we've all been waiting for has arrived – it's time to explore the cream of the canister crop. From the elegance of glass to the sleekness of stainless steel, we've scoured the culinary landscape to bring you the 15 best kitchen canisters that'll revolutionize your pantry.

The Best Glass Canisters: Gorgeous Glass for Displaying Your Goods 🌟

Glass kitchen canisters offer the ultimate combo: a clear display to highlight your ingredients in style while keeping them fresh as can be. When it comes to glass containers, not all models are created equal. Let's explore the creme de la creme - featuring innovative air tight seals, brilliant visibility, and gorgeous designs to elevate your kitchen aesthetic.

Weck Tulip Glass Canisters

These stunning Weck Tulip Glass Canisters made our number one slot for their show-stopping looks and impressive airtight seal. Each jar features a curved tulip shape tapered at the top for visual appeal.

- The European glass construction feels solid and durable.

- The unique glass lid forms an incredibly tight seal when clamped down with the stainless steel fastener band.

- Sizes range from petite 0.5 cup capacity to large 2.5 cup jars.

- Choose from clear glass or colored tinted shades like amber or green.

We love displayng spices, nuts, grains and other cute tiny ingredients in these Weck glass beauties on our countertop. They add gorgeous flair while keeping contents factory-sealed fresh!

OXO Good Grips 10-Piece Canister Set

For an affordable and coordinating set, you can't go wrong with the brilliant OXO Good Grips Glass Canisters. With airtight push button lids, flour, sugar, coffee and more stay fresh for months. We're obsessed with:

- The perfectly stackable sizes in this 10-piece total set.

- Clever labeled lid buttons show what's inside - coffee, tea, flour, and more.

- Mix large 1.3 L capacity jars with smaller mini canisters.

- Dishwasher safe strong soda lime glass.

Organize your whole pantry or baking station with one fell swoop using this smart OXO Good Grips glass canister set. Say bye bye to plastic bags and hello to perfect portions sealed fresh everytime.

Anchor Hocking Presence Glass Canisters

On a budget but still craving charming glass canisters? Meet the Anchor Hocking Presence Glass Canisters - an affordable option providing impressive utility.

- The glass body allows visibility of contents from all angles.

- Stainless steel shaker lids are included for easy dispensing.

- Lid rim accommodates measuring cups for handy pouring right from storage.

- 4 handy sizes from 0.7 cups to 1.8 cups.

For a reasonably priced glass container set with helpful bonus features, Anchor Hocking delivers quality and value combined.

More Amazing Glass Options

Beyond our top three, other glass kitchen canisters we adore include:

- Lenox Butterfly Meadow

- Jarmazing Products Airtight Storage Jars

- Estilo Space Saving Stackable

- Fido 1 Liter Jars with Clamp Lid Closures

Trust us, your ingredients have never looked so gorgeous than in these glass masterpieces! Ditch flimsy bags and bowls for beautiful, functional glass canisters to showcase your staples in style.

Best Stainless Steel Canisters: The Strongest & Stylish Canisters 🔒

Stainless steel kitchen canisters deliver unbeatable durability along with sleek, modern visual appeal. Compared to glass, stainless steel constructs resist denting if accidentally dropped and never succumb to chips or cracks. Let's review resonant, rustic-free stainless canisters to rely on for years.

Chef's Path Airtight Stainless Canisters

Our top choice stainless canister hails from Chef's Path - a brand proven in commercial kitchens now available for home use. We're swooning over:

- The fully airtight lid with rubber gasket seal.

- Slick fingerprint-proof brushed stainless exterior.

- The satisfying chrome lever locking clamp.

- Generous 1 liter to 2.2 liter volumes.

Chef-approved for maintaining optimum food freshness, these Chef's Path canisters beautifully store coffee, tea, sugar, flour and other ingredients.

Estilo Stainless Steel Canisters with Copper Lids

For a touch of chic style, Estilo's stainless steel canister set takes the crown. We adore:

- The gorgeous hammered copper lid accents.

- The convenient viewing window to glimpse contents.

- Matching ceramic iterations in vibrant colors.

- Airtight seals keep baking ingredients fresh.

Infuse your kitchen with charming personality using Estilo's stainless charmers dressed up with beautiful copper tops.

Home Airtight Stainless Steel Containers

Home Airtight Stainless Steel presents a budget-friendly pantry storage solution:

- Durable 18/8 food-grade stainless won't rust.

- Stackable sizes from 0.8 L to 2.3 L.

- Great value for an air-sealing 10 piece set under $50.

- Crystal clear lid windows.

On a budget? Home Airtight offers quality stainless canisters to neatly organize ingredients while resisting wear, stains, odors and corrosion over their long lifespan.

More Great Stainless Options

Other stainless steel options providing reliable, rust-resistant storage:

- Estilo Space Saving Stackable Cylinders

- IRIS Airtight Pet Food Containers

- KitchenTour Vacuum Sealed Canister Set

- Let's Lock It Stackable Storage Containers

Pristine stainless steel construction lends an ultra-modern look while protecting precious pantry goods. Ditch flimsy plastic and leaky bags for strong, sturdy stainless steel to keep baking basics and snacks fresh for ages!

Best Ceramic Canisters: The Prettiest & Toughest Canisters 🎨

Ceramic kitchen canisters infuse storage with artisan beauty and handcrafted allure. Beyond cute colors, ceramic constructs are actually incredibly durable and maintain an airtight seal well. Check out our favorite ceramic charmers adding style and substance to pantries everywhere.

Lenox Butterfly Meadow Porcelain Canisters

For stunningly elegant ceramic canisters, it's love at first sight with Lenox Butterfly Meadow. We are head over heels for:

- Gorgeous floral motifs with butterflies, blooms and vines.

- High quality chip-resistant porcelain material.

- Airtight seal preserves freshness.

- Matching dinnerware and decor available.

Bring a garden party right to your countertop with Lenox's swoon-worthy butterfly meadow porcelain cannisters!

Mint Julep Kitchen Canisters

Channeling delightful southern charm, Mint Julep Kitchen ceramic canisters flaunt unique regional themes. Our favorite highlights include:

- Charming artwork like Magnolias, Fleur De Lis and Roosters.

- Bamboo lid accents providing tight seal.

- Upgrade from worn-out tin containers.

- Variety of height and width combinations.

Mint Julep cannisters add a lively punch of personality to pantries and kitchens needing more happy vibrations!

Prepworks 6-Piece Ceramic Canisters

On a budget but want basic ceramic canisters without the frilly extras? Prepworks delivers with their straightforward but totally functional ceramic set:

- Durable stoneware ceramic material.

- Pop top plastic lids form decent seal.

- Labeled buttons display flour, coffee, etc.

- Affordable pricing under $30.

Sometimes simple is best! Prepworks offers reasonably priced ceramic canisters in a rainbow of colors to brighten up your kitchen.

More Top Ceramic Contenders

Some other ceramic charmers catching our eye include:

- Glass Jar Company Airtight Storage Jars

- Estilo Garden Ceramic Canister Set

- Home Basics Talavera Ceramic Canisters

- Primitive Country Ceramic Apothecary Jars

Handcrafted stoneware and terra cotta constructions lend rustic farmhouse vibes while keeping coffee, flour and more sealed fresh every single day. Choose ceramic canisters to add artisan appeal and functionality to your space!

Best Value/Budget Canisters: Best Bang For Your Buck 💰

Kitchen canisters can quickly get pricey, especially for larger collections. We've scouted out the very best budget options providing serious utility without emptying your wallet. Invest in these value containers confidently knowing ingredients stay fresh and your pennies are preserved.

IKEA 365+ Canister Set

Our #1 budget pick is from IKEA. Yes, really! The IKEA 365+ Canister Set offers:

- Airtight rubber gaskets sealing lids shut.

- Streamlined design - shaped taller than wide.

- Glass material shows off contents.

- Less than $25 for a 4-piece set!

Despite the low cost, these IKEA jars are well-constructed using durable soda glass to house pantry ingredients in style without insane pricing.

Anchor Hocking Storage Set

Another wallet-friendly choice, Anchor Hocking presents a longstanding legacy creating kitchenware since 1905. Their storage set captures savings with:

- Presence glass reveal contents clearly.

- Stainless steel lid option for secure seal.

- Convenient measuring guides inside.

- Under $35 for 11 handy pieces.

Quality craftmanship meets affordable pricing with Anchor Hocking's classic glass and stainless kitchen canisters.

Home Basics Textured Ceramic Canisters

Love ceramic character but on a fixed income? Not to worry - Home Basics textured ceramic cannisters checks all the boxes without breaking budgets:

- Cute diamond pattern with neutral tones.

- Screw on lids keep contents sealed.

- Set of 3 for around $27 bucks.

- Provides pantry organization on a dime!

The low-cost doesn't compromise the pleasing aesthetic Home Basics' textured ceramic trio contributes to kitchens.

More Top Budget Buys

Other kitchen canisters offering big value for tiny prices:

- Anchor Hocking 3 Piece Glass Presence Set

- FAVOLCANO Glass Food Storage Containers

- Estilo Mini Stainless Steel Canisters

- Elegant Home Fashions Kitchen Canisters

Just because money matters doesn't mean you can't score sweet storage! With the market flooded with so many quality choices, attractive and affordable kitchen canisters cater to all financial situations!

Best for Flour and Sugar: Canisters for Baking za Basics 🍬

Every baker knows, allowing precious baking ingredients like flour and sugar to go stale compromises recipes and taste. That's why airtight canisters are essential to lock in flour and sugar freshness for all your cookie, cake and bread endeavors.

Taylor Kitchen Canisters

Our top pick for storing flour and sugar is Taylor Kitchen Canisters. We're sweet on them for:

- Airtight seals keep baking staples factory-fresh.

- Round silhouettes with wide openings.

- Built-in levelers and 1⁄4 cup mini scoops included.

- Generous 1.9 liter capacity.

Taylor's round-shaped flour and sugar jars allow easy access for scooping while keeping precious ingredients protected.

Home Airtight Flour Container

If you'd prefer rectangular stacking vessels, Home Airtight flour containers are the choice for you. Our baking wishlist loves:

- Crystal clear lid windows show flour supply levels.

- Stackable sizes available from 1.5 liters up to 4 liters.

- Durable stainless steel builds resist odors, stains and more over time.

- Under $20 each so you can buy multiple!

The Home Airtight stainless steel flour jars lend a shiny sleek look to pantries while competently containing all the flour your heart desires!

Estilo Flour & Sugar Canister Set of 2

Estilo strikes again but this time with their brilliant flour and sugar duo stealing our hearts:

- Chic hammered copper lid accents add flair.

- Twin pack provides his and hers matching storage.

- Acrylic window shows remaining ingredient levels.

- Locking clasps seal air out completely.

Bring coordinated style to your baking station using Estilo's picturesque pair designed especially for housing flour and sugar in seriously cute fashion.

Oggi Acrylic Sugar Dispenser

If sugar is your main squeeze, Oggi makes a specialized acrylic sugar dispenser to cater to your sweet tooth. We applaud:

- BPA-free acrylic acts as a see-thru display case.

- Twist and pour spout with flip up cover for easy dispensing.

- Airtight seal to keep sugar fresh for over 200 days!

- Holds a whopping 4.5 cups of sugar!

For baristas, bakers and sweet treat makers alike - Oggi's clear-view sugar jar perfectly showcases, stores and dispenses everyone's favorite sweetener! 🚀🍯

Specialty Canisters and Space-Saving Marvels: Unveiling More Kitchen Magic!

Read the full article

0 notes

Text

How to Cut Stainless Steel Cable

Whether you're a DIY enthusiast or someone who needs to cut stainless steel cable for a home improvement project, it's important to know how to do it right. In this article, we'll guide you through the process of cutting stainless steel cable safely and efficiently. We'll cover everything from choosing the right tools to cutting techniques and safety tips. By the end of this guide, you'll have all the information you need to confidently cut stainless steel cable.

Choosing the Right Tools

To cut stainless steel cable effectively, you need the right tools. Here are the most common options:

Cable Cutters: These are designed specifically for cutting cables and provide a clean, smooth cut. They're the go-to tool for cutting stainless steel cable.

Angle Grinder: An angle grinder with a metal cutting wheel can also be used for cutting cable, but it may not provide as clean a cut as cable cutters.

Bolt Cutters: While they can cut through stainless steel cable, they may not provide the precision you need.

Safety Tips

Before you start cutting stainless steel cable, take these safety tips into account:

Wear Safety Gear: Always wear gloves and safety goggles to protect your hands and eyes from flying debris.

Secure the Cable: Make sure the cable is secured and won't move during the cutting process.

Work in a Well-Ventilated Area: Cutting stainless steel can generate sparks and dust, so ensure you work in a safe environment.

How to Cut Stainless Steel Cable

Now that you have the right tools and safety measures in place, let's get down to the actual cutting process:

Measure: Determine the length you need to cut and mark it with a permanent marker.

Secure the Cable: Use a vice or clamp to hold the cable in place.

Position Your Tool: If you're using cable cutters, place the blade around the marked spot. For an angle grinder, position the wheel just above the mark.

Cut: Apply steady pressure to cut through the cable. For thicker cables, you may need to make multiple passes with an angle grinder.

Conclusion

Cutting stainless steel cable doesn't have to be a daunting task. With the right tools, safety precautions, and techniques, you can achieve clean and precise cuts for your projects. Remember to take your time and prioritize safety throughout the process.

0 notes

Text

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

Phone Table Stand: The Ultimate Guide

In today’s digital age, our smartphones are our constant companions. Whether we’re browsing social media, watching videos, or working on important tasks, having a reliable phone table stand can make a world of difference. In this comprehensive guide, we’ll explore everything you need to know about phone table stands, from their benefits to choosing the perfect one for your needs.

1. Why You Need a Phone Table Stand

Enhanced Comfort and Ergonomics

Using your phone for extended periods can strain your neck, wrists, and hands. A phone table stand elevates your device to eye level, reducing neck strain and promoting better posture. Whether you’re reading recipes in the kitchen or participating in virtual meetings, a stand ensures comfort and convenience.

Hands-Free Convenience

Imagine having both hands free while following a recipe or watching a tutorial. A phone table stand allows you to multitask effortlessly. Whether you’re cooking, working, or enjoying a movie, your phone remains accessible without occupying your hands.

Stability and Security

A well-designed phone table stand keeps your device stable and secure. No more worrying about accidental slips or falls. Plus, it prevents scratches and damage to your phone’s surface.

2. Types of Phone Table Stands

Adjustable Foldable Stands

These versatile stands are perfect for travelers and minimalists. They fold flat for easy storage and can be adjusted to various angles. Look for sturdy materials like aluminum or reinforced plastic.

Desktop Cradle Stands

Ideal for home or office use, desktop cradle stands provide a stable base for your phone. They come in various designs, including sleek metal stands and wooden holders. Choose one that complements your decor.

Lazy Bracket Stands

For ultimate flexibility, consider a lazy bracket stand. These adjustable arms can be clamped onto your desk, bed frame, or any other surface. They allow you to position your phone exactly where you want it.

3. How to Choose the Perfect Phone Table Stand

Consider Your Usage

Think about where you’ll use the stand most. If it’s for your home office, a desktop cradle stand may be ideal. For travel or outdoor use, opt for a foldable stand.

Compatibility

Ensure the stand fits your phone’s dimensions. Most stands accommodate various phone sizes, but double-check before purchasing.

Material and Build Quality

Look for durable materials that can withstand daily use. Aluminum, stainless steel, and high-quality plastics are excellent choices.

Reviews and Recommendations

Read user reviews and seek recommendations from friends or online communities. Real-world experiences can guide you toward the best options.

0 notes

Text

Fasteners in the Pharmaceutical Industry: What Are They and How Do They Work?

Introduction to Fasteners

Fasteners serve as important components used in a variety of sectors to connect or secure various sections of machinery, equipment, or buildings. While they might look small, their importance in maintaining safety and efficiency cannot be pointed out, particularly in vital areas like the pharmaceutical industry.Rebolt Alloys is market-leading Stainless Steel Fasteners Manufacturers in India and SS Fasteners Manufacturers in mumbai.

Types of Fasteners used in Pharmaceutical Industry

Screws and bolts: are frequently employed as fasteners in pharmaceutical equipment, providing secure connections between various components.

Nuts and Washers: Nuts are used together with bolts to provide a tight connection, even with washers aid to spread the weight and avoid surface damage.We are awarded as fasteners manufacturers in pune and fasteners suppliers in kuwait.

Clips and clamps: are used to secure tubing, cables, and other components, ensuring that pharmaceutical machinery functions properly.

Functionality in the Pharmaceutical Industry

Fasteners play an important role in the construction of pharmaceutical equipment and machinery. They guarantee that all components are securely fastened to one another, reducing the possibility of accidents or malfunctions.

Sterilisation Compatibility: Pharmaceutical industry fasteners must be sterilization-compatible. They must tolerate extreme temperatures and chemical exposure without losing their integrity.We additionally serve as SS Fasteners Manufacturers in India and fasteners manufacturers in coimbatore

Preventing Contamination: Properly attached fasteners contribute to the cleanliness and sterility of pharmaceutical settings. Loose or defective fasteners can cause contamination, compromising the quality and safety of pharmaceutical items.you might also like Nut bolt weight chart in kg pdf and stud bolt weight chart in kg

Conclusion

In short, although sometimes ignored, fasteners play an essential role in the pharmaceutical sector. These apparently minor components serve an important role in protecting both workers and customers while contributing to the smooth running of pharmaceutical manufacturing plants, ranging from maintaining safety and product purity to increasing efficiency and promoting innovation.

#Stainless Steel Fasteners Manufacturers in India#SS Fasteners Manufacturers in India#SS Fasteners Manufacturers in mumbai#fasteners manufacturers in coimbatore#fasteners manufacturers in pune#Nut bolt weight chart in kg pdf#fasteners suppliers in kuwait#stud bolt weight chart in kg

0 notes

Text

How are Forged Pipe Fitting Made?

In the tricky global of piping systems, the reliability and durability of fittings play a pivotal function. Among diverse kinds of fittings available, solid pipe fittings stand out for their robustness and resilience, making them integral components in industries ranging from oil and gasoline to chemical processing. But have you ever wondered how those vital additives are made? Let's delve into the fascinating system of forging pipe fittings.

Understanding Forged Pipe Fittings:

Forged pipe fittings are manufactured thru a manner known as forging. Unlike cast fittings, which might be made by using pouring molten metal into molds, cast fittings are crafted by way of applying heat and stress to form solid pieces of metal into the preferred shape. This method complements the mechanical residences of the fittings, making sure superior power and integrity.

The Forging Process:

1. Selection of Raw Materials:

The first step in crafting cast pipe fittings is the cautious selection of raw materials. High-first-rate metals inclusive of stainless-steel, carbon steel, and alloy metal are usually used because of their energy and corrosion resistance.

2. Heating:

The selected steel stock is heated to a temperature where it turns into malleable but does now not attain the melting factor. This temperature varies relying at the form of metallic used and the preferred houses of the final product.

3. Forming:

Once the steel reaches the premiere temperature, it is positioned right into a forging die, which contains the poor influence of the favored fitting. A hydraulic press or hammer applies severe stress to the metallic, forcing it to take the form of the die. This procedure may be achieved in a couple of degrees to gain elaborate designs and precise dimensions.

4. Trimming and Finishing:

After the forging process is complete, the fittings may additionally go through additional trimming and completing operations to dispose of extra fabric and refine the surface finish. This guarantees uniformity and enhances the aesthetics of the very last product.

Advantages of Forged Pipe Fittings:

The precise manufacturing system of forged pipe fittings gives numerous benefits over other forms of fittings:

Strength and Durability: Forged fittings showcase superior mechanical residences, including higher tensile energy and effect resistance, making them perfect for excessive-pressure and excessive-temperature programs.

Enhanced Corrosion Resistance: The dense grain shape of solid fittings minimizes the danger of corrosion, prolonging their provider life in corrosive environments.

Dimensional Accuracy: The precision forging manner permits for tight tolerances and regular dimensions, making sure right suit and alignment inside piping systems.

Versatility: Forged fittings are available in a wide range of sizes, shapes, and configurations to house numerous piping requirements.

Conclusion:

In conclusion, the meticulous art of crafting cast pipe fittings entails a mixture of metallurgical knowledge and advanced production strategies. By subjecting solid metal to warmness and stress, producers create fittings renowned for his or her power, durability, and reliability. Whether inside the oil and gasoline industry, chemical processing plants, or other vital packages, cast fittings play a important function in retaining the integrity of piping systems.

When it comes to the sector of tube clamps and dairy pharma fittings, one call sticks out as a leader within the enterprise - Bu-Lok. Renowned for their understanding and superb products, Bu-Lok makes a speciality of hydraulic pipe tube clamps, heavy-responsibility tube clamps, and mild-responsibility tube clamps. As pioneers inside the subject, they may be devoted to sharing their information and offering pinnacle-notch answers for all tube clamping wishes.

In essence, whilst solid pipe fittings ensure the structural integrity of piping systems, Bu-Lok ensures the efficiency and reliability of tube clamping answers, making them critical companions in various commercial sectors.

Through their commitment to excellence, Bu-Lok continues to set the standard for first-class and innovation in the realm of tube clamps and fittings.

0 notes

Text

Exploring the Functionality of Key Cable Gland Components?

Introduction

Cable glands play a crucial role in ensuring the proper installation and functionality of electrical and data cables in various industries and applications. These glands not only provide a secure and waterproof seal around cables but also protect them from environmental factors such as dust, moisture, and chemicals. Understanding the components of cable glands is essential for ensuring their effectiveness and reliability in different settings. In this blog post, we will explore the functionality of key Cable gland components and their importance in cable management systems.

Body:

1.1. Cable Gland Basics:

Before delving into the components of cable glands, it's important to understand their basic structure and function. A cable gland, also known as a cable connector or fitting, is a device designed to attach and secure the end of a cable to an electrical or mechanical enclosure. It typically consists of a threaded body, a sealing element, and various other components that ensure a tight seal and provide strain relief for the cable.

1.2. Threaded Body:

The threaded body of a cable gland serves as the main housing for the gland assembly. It is usually made of metal, such as brass, stainless steel, or aluminum, although plastic versions are also available for less demanding applications. The threaded body is designed to screw into a corresponding threaded hole in the enclosure, providing a secure connection that prevents the gland from coming loose under vibration or tension.

1.3. Sealing Element:

The sealing element is perhaps the most critical component of a cable gland, as it is responsible for creating a watertight and dustproof seal around the cable. Common sealing materials include neoprene, silicone, rubber, and thermoplastic elastomers (TPE). The choice of sealing material depends on factors such as the application environment, temperature range, and chemical resistance requirements.

1.4. Compression Nut:

The compression nut is used to compress the sealing element against the cable and the threaded body, forming a tight seal that prevents moisture and contaminants from entering the enclosure. It is typically made of metal and features internal threads that match those on the threaded body. By tightening the compression nut, installers can adjust the compression force applied to the sealing element, ensuring a secure and reliable seal without damaging the cable insulation.

1.5. Clamping Device:

Some cable glands feature a clamping device or mechanism designed to provide strain relief for the cable, preventing it from being pulled out of the gland or becoming damaged due to excessive bending or tension. This is especially important in dynamic applications where cables are subject to movement or vibration. Common types of clamping devices include rubber grommets, spiral cable glands, and adjustable clamps.

1.6. O-Ring or Washer:

In addition to the main sealing element, many cable glands incorporate an O-ring or washer at the interface between the gland and the enclosure. This secondary seal helps to further enhance the waterproof and dustproof properties of the gland assembly, especially in outdoor or harsh environments where moisture ingress is a concern. The O-ring or washer is typically made of rubber or silicone and is compressed between the gland and the mounting surface when the gland is installed.

Importance of Cable Gland Components:

2.1. Environmental Protection:

One of the primary functions of cable glands is to provide environmental protection for cables and electrical connections. By sealing the entry point of the cable into the enclosure, cable glands help to prevent moisture, dust, dirt, and other contaminants from entering sensitive equipment and causing damage or malfunction. This is particularly important in outdoor or industrial settings where cables are exposed to harsh conditions.

2.2. Safety and Reliability:

Proper cable gland installation ensures the safety and reliability of electrical and data systems by minimizing the risk of short circuits, electrical arcing, and equipment failure. By creating a secure and watertight seal around cables, cable glands help to prevent accidental contact with live conductors, reducing the risk of electrical hazards and fire.

2.3. Compliance with Regulations:

In many industries, compliance with regulatory standards and codes is mandatory to ensure the safety and integrity of electrical installations. Cable glands that are properly designed and installed according to industry standards help companies meet these requirements and avoid potential fines or legal liabilities. Common standards governing cable gland design and installation include the National Electrical Code (NEC), the International Electrotechnical Commission (IEC), and the European Union's Restriction of Hazardous Substances (RoHS) directive.

2.4. Long-Term Performance:

The quality and durability of cable gland components directly impact the long-term performance and reliability of cable management systems. High-quality materials, precision engineering, and rigorous testing ensure that cable glands can withstand the rigors of daily use and continue to provide effective sealing and strain relief over their operational lifespan. Investing in premium Cable gland components upfront can save time and money on maintenance and replacement costs down the line.

Conclusion:

Cable glands are essential components of electrical and data cable installations, providing protection, safety, and reliability in a wide range of applications. By understanding the functionality of key cable gland components such as the threaded body, sealing element, compression nut, clamping device, and O-ring or washer, installers can ensure the proper selection, installation, and maintenance of cable glands for optimal performance and compliance with industry standards. Whether in industrial, commercial, or residential settings, cable glands play a critical role in safeguarding equipment, infrastructure, and personnel against the hazards of environmental exposure and electrical faults.

0 notes

Text

Can Super Glue Work on Metal? Discover the Power Behind this Adhesive

Yes, Super Glue can effectively bond metal surfaces together for a strong and durable connection. Super Glue is a versatile adhesive suitable for many materials, including metal.

It forms a secure bond quickly, making it ideal for various household and DIY projects requiring metal-to-metal adhesion. Whether you are repairing a metal object or creating a new metal structure, Super Glue provides a reliable and long-lasting solution. Its fast-drying formula and high strength make it a popular choice for bonding metals in diverse applications.

With Super Glue, you can trust that your metal surfaces will be securely joined with a minimal wait time for the adhesive to set.

Credit: www.loctiteproducts.com

The Science Of Super Glue And Metal

When it comes to bonding materials, super glue is a popular choice due to its strong adhesive properties. Let's explore how super glue works specifically for metal surfaces.

Chemical Composition

- Super glue consists of cyanoacrylate monomers.

- When exposed to moisture, these monomers undergo a polymerization process.

Bonding Process

- The polymerization process creates long chains of molecules that form a durable bond.

- These molecules create an insta-bond when they come into contact with metal surfaces.

Super glue is highly effective in creating strong bonds with metal due to its chemical composition and bonding process.

Credit: www.loctiteproducts.com

Factors Affecting Super Glue's Effectiveness On Metal

Factors affecting the effectiveness of super glue on metal are pivotal for successful bonding. Achieving a strong and lasting bond with metal surfaces depends on several key considerations.Surface Cleanliness

- Clean the surface with a solvent to remove any dirt, grease, or residues that can hinder adhesion.

- Roughen the surface slightly to provide more area for the glue to grip onto.

- Ensure the surface is dry before applying the super glue to prevent any moisture interference.

Metal Type And Texture

Metal Type

Texture

Aluminum

Smooth surfaces may require sanding for better adhesion.

Stainless Steel

Highly polished surfaces may need etching to improve bond strength.

Iron

Rust should be removed, and a primer might be necessary for porous surfaces.

Tips For Using Super Glue On Metal

When it comes to using super glue on metal, it's important to follow the right tips to ensure a strong and durable bond. By preparing the surface correctly and applying the adhesive with the proper techniques, you can achieve the best results. Here are some essential tips to keep in mind when using super glue on metal.Surface PreparationBefore applying super glue to metal, it's crucial to prepare the surface to ensure optimal adhesion. Clean the metal thoroughly using a mild detergent to remove any dirt, grease, or debris that could interfere with the bond. Use a solvent such as acetone to degrease the metal and create a clean, dry surface for the glue to adhere to. Roughen the surface lightly with sandpaper to improve the bonding strength, providing a slightly rough texture that the super glue can grip onto effectively.Application TechniquesWhen applying super glue to metal, it's important to use the right techniques to achieve the strongest bond. Apply the adhesive sparingly to one surface, using just enough to create a thin layer. Press the surfaces together firmly and hold them in place for the recommended curing time to allow the glue to set properly. Avoid any movement or disturbance during the curing process to prevent weakening the bond. Use clamps or weights to hold the pieces in position if necessary, ensuring even pressure across the bond.

Credit: www.amazon.com

Common Applications Of Super Glue On Metal

Super glue, also known as cyanoacrylate adhesive, is a versatile adhesive that can be used for numerous applications on metal surfaces. Its quick-drying and strong bonding properties make it a popular choice for both DIY repairs and art and craft projects. In this article, we will explore the common applications of super glue on metal and how it can be a practical solution for various needs.Diy RepairsSuper glue can be a lifesaver when it comes to quick fixes and repairs on metal objects. Whether it's a broken metal hinge, a loose handle, or a snapped metal part, super glue is often the go-to adhesive for repairing these issues. Its strong bond creates a durable hold that can withstand daily wear and tear, making it ideal for fixing household items like kitchen utensils, appliances, or even metal furniture. In addition to its strength, super glue is also resistant to moisture and high temperatures, making it suitable for repairing outdoor metal structures such as fences, gutters, or even car parts. Its ability to bond different metals together, including steel, aluminum, and copper, makes it a versatile adhesive for various DIY projects involving metal.Art And Craft ProjectsSuper glue is not only practical for repairs but is also a valuable tool for various art and craft projects involving metal. Its fast bonding time and clear finish make it an excellent choice for artists and crafters who require a strong adhesive for their metal creations.One common application is in jewelry making, where super glue can be used to securely attach metal findings, beads, or gemstones to different metal components. Its precision applicators allow for accurate and controlled application, ensuring that the glue is only applied where needed.Furthermore, super glue can also be used in metal sculptures, model building, or even DIY home decor projects. Its ability to bond metal pieces together provides stability and longevity to these creations, making them resilient to accidental bumps or movements. Whether you're a hobbyist, artist, or simply need a reliable adhesive for everyday metal repairs, super glue is a versatile and effective solution. Its wide range of applications on metal surfaces, combined with its strength and durability, make it an invaluable tool for any DIY enthusiast or creative individual.

https://www.youtube.com/watch?v=w-iHL3tN__A

Safety Precautions And Alternatives

Opting for safety precautions and alternatives is crucial when deciding on suitable adhesives for metal surfaces. While super glue may bond metal effectively, it's essential to consider safety measures and also explore alternative bonding options. Assessing the specific metal type and intended application will determine the best adhesive choice for optimal results.

Proper VentilationWhen working with super glue on metal surfaces, it is important to ensure proper ventilation to minimize the risk of inhaling toxic fumes or developing respiratory issues. Super glue, also known as cyanoacrylate adhesive, releases fumes that can be irritating to the eyes, nose, and throat.To safeguard your health, it's best to work in a well-ventilated area. Open windows and doors to allow fresh air circulation, or consider using a fan or exhaust system to remove fumes. Additionally, wearing a mask during application can provide an extra layer of protection against inhalation.Alternative Adhesive OptionsWhile super glue is a popular choice for bonding metal objects due to its strength and quick setting time, there are alternative adhesive options that you can consider if safety is a concern or if you prefer to avoid using cyanoacrylate adhesives.

- Epoxy: Epoxy adhesive is a versatile and strong bonding agent that can be used on various materials, including metal. It consists of two components, a resin and a hardener, which need to be mixed before use. Epoxy offers excellent bonding strength and is resistant to heat, chemicals, and moisture.

- Superglue gel: Superglue gel is a thicker and more viscous version of traditional super glue. It is less runny and provides better control during application, reducing the risk of accidental contact with skin. However, it may take slightly longer to set compared to regular super glue.

- Silicone adhesive: Silicone adhesive is a flexible and waterproof alternative to super glue. It works well on metal surfaces and offers a more cushioned and shock-absorbent bond. Additionally, silicone adhesive is resistant to temperature changes and can withstand exposure to UV rays.

These alternatives provide different properties and adhesive strengths, so be sure to choose one that best suits your specific project requirements.

Frequently Asked Questions On Can Super Glue Work On Metal

Can Super Glue Be Used On Metal?

Yes, super glue can be used on metal surfaces. Super glue is known for its strong bonding properties, and it works well on various materials, including metal. It creates a durable bond that can withstand everyday use and provide a secure hold.

Just make sure to clean and dry the metal surface before applying the super glue for optimal adhesion.

Is Super Glue Suitable For Repairing Metal Objects?

Yes, super glue is suitable for repairing metal objects. It can effectively bond and repair small cracks, breaks, or gaps in metal items. Whether it's fixing jewelry, metal ornaments, or household appliances, super glue provides a quick and reliable solution.

However, for larger or load-bearing repairs, it's best to consult a professional or consider other specialized metal adhesives.

How Long Does Super Glue Take To Dry On Metal?

Super glue dries quickly on metal surfaces, generally within minutes. The exact drying time may vary depending on factors like temperature, humidity, and the amount of adhesive applied. It's important to hold the surfaces firmly together during the drying process to ensure a strong and secure bond.

For best results, follow the instructions provided on the super glue packaging.

Conclusion

Super glue can indeed work on metal, providing a strong and reliable bond. When selecting a super glue for metal, it’s important to consider the type of metal and the specific requirements of your project. With the right preparation and application, super glue offers a convenient and effective solution for various metal bonding needs.

Read the full article

0 notes

Text

What Is the Function of a pipe clamp ? And Types of it - Arcellor Controls

The elaborate global of business piping structures is predicated on a network of unseen heroes – pipe clamps. These apparently simple additives play an important position in making sure the secure, steady, and efficient operation of those systems Arcellor Controls, a leading issuer of industrial automation solutions arcellor controls ON Arcellor Controls is familiar with the significance of superb pipe clamps. In this blog, we'll delve into the characteristics of pipe clamps, explore numerous sorts, and speak about their applications.

The Function of Pipe Clamps