#PackagingMachines

Text

Gempac revolutionizes packaging with seamless excellence. Our cutting-edge solutions simplify the packaging process, guaranteeing efficiency and accuracy from start to finish. Trust Gempac to enhance your packaging journey, providing intelligence, simplicity, and enhanced effectiveness📦✨

For more details contact us.

🌐 www.gempac.in

📧 [email protected]

📲 +91 6238340124

📲 +91 6238341146

📲 +91 9847559184

#GEMPAC#PackagingMachines#SmartPackingMachine#SmartPacking#PackagingMachinery#FoodPackaging#PrecisionPackaging#StreamlinedSolutions

0 notes

Text

Packaging Machinery Market to Reach $62.43 Billion by 2030

Meticulous Research®, a prominent international market research firm, released a report titled, ‘Packaging Machinery Market by Type (Carded Packaging Machines, Filling Machines, Labelling Machines), by Function, Automation (Automatic, Semi-automatic), End-use (Food & Beverages, Healthcare & Pharmaceuticals,) and Geography - Global Forecasts to 2030.’

The global packaging machinery market is expected to achieve a value of $62.43 billion by 2030, with a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. In terms of volume, it is forecasted to reach 13,603 thousand units by 2030, with a CAGR of 6.2% during the same period.

The expansion of this market is propelled by the rise in production across various industries, supportive governmental regulations ensuring product safety, and advancements in fill-finish manufacturing technologies. Nonetheless, the substantial upfront investments required for installing packaging machinery and strict regulations aimed at reducing plastic consumption hinder the market's growth. Opportunities for growth are anticipated due to escalating concerns regarding foodborne illnesses and the growing demand for processed and packaged goods. However, a significant obstacle to market expansion is the shortage of proficient operators.

The packaging machinery market worldwide is categorized based on type, function, automation level, end-use sector, and geographical location. The research also assesses competitors in the industry and examines markets at both country and regional levels.

Based on type, the global packaging machinery market is divided into several segments including carded packaging machines, cartoning machines, case erectors, filling machines, stretch wrappers, shrink wrapping machines, case packers, labeling machines, bottle packaging machines, and other packaging machines. In 2023, it is projected that the carded packaging machines segment will hold the largest portion of the market. This dominance is primarily driven by the growing adoption of carded packaging in industries such as pharmaceuticals and consumer electronics, where product safety is a key concern.

Based on function, the global packaging machinery market is categorized into single function and multi-function segments. By 2023, it is anticipated that the multi-function segment will dominate the market. This is primarily due to the versatility of these machines, which can perform multiple tasks such as vertical form-filling-sealing, horizontal packing, bag placing, and rotary packing. Multi-function packaging machinery is known for features like automated controls, high-speed operation, and user-friendly interfaces, enabling operators to configure and operate the equipment swiftly and effectively.

Based on automation mode, The global packaging machinery market is divided into automatic and semi-automatic packing machines. By 2023, it is predicted that the automatic packing machines segment will dominate the market. This is primarily due to the advantages provided by automatic packing machines, including enhanced efficiency, cost reduction, and better product quality and safety. Automatic packing machines can package goods at a quicker and more efficient rate compared to manual labor, enabling businesses to boost production capacity and meet rising consumer demands.

Based on end-use industry, the global packaging machinery market is categorized into various end-use industries including food & beverages, healthcare & pharmaceuticals, agriculture, chemicals, personal care, consumer electronics, apparel & footwear, and others. It is projected that in 2023, the food & beverages segment will hold the largest portion of the market. This dominance is credited to changing consumer preferences, heightened competition in the packaged food sector, and an increase in the demand for packaged food products.

Based on geography, the packaging machinery market is segmented across regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa (MEA). By 2023, it is forecasted that Asia-Pacific will hold the largest portion of the global packaging machinery market, with Europe, North America, Latin America, and the Middle East & Africa following in succession. This significant market share is primarily due to factors such as governmental efforts to encourage the adoption of environmentally friendly packaging, continuous innovations in packaging technology by key industry players, and growth in the food industry.

Key Players

Major players in the global packaging machinery market include Adelphi Group of Companies (U.K.), Barry-Wehmiller Group, Inc. (U.S.), COESIA S.P.A. (Italy), ISHIDA CO., LTD. (Japan), Krones AG (Germany), TETRA PAK INTERNATIONAL S.A. (Switzerland), FUJI MACHINERY CO., LTD. (Japan), Syntegon Technology GmbH (Germany), SIG Group AG (Switzerland), Marchesini Group S.p.A. (Italy), KHS GmbH (Italy), GEA Group Aktiengesellschaft (Germany), OPTIMA Packaging Group GmbH (Germany), Omori Machinery Co., Ltd. (Japan), TNA Australia Pty Limited (Australia), and MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany).

Download Sample Copy Here: https://www.meticulousresearch.com/download-sample-report/cp_id=5492

Key Questions Answered in the Report:

Which segments are experiencing significant growth in terms of type, function, automation level, end-use sector, and geographical location?

What is the past market size of packaging machinery worldwide?

What are the projected market forecasts and estimations for the timeframe spanning from 2023 to 2030?

What are the primary factors motivating growth, hindering progress, presenting opportunities, and posing obstacles in the global packaging machinery market?

Who are the key players in the market, and what proportions of the market do they hold?

What does the competitive scenario look like in the global packaging machinery market?

What are the latest advancements or updates in the global packaging machinery sector?

What are the various approaches employed by the leading market players?

What are the significant patterns observed in different geographical regions, and which countries are experiencing notable growth in the market?

Who are the emerging local contenders in the global packaging machinery market, and what strategies do they employ to compete with established players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#PackagingMachineryMarket#CardedPackagingMachines#CartoningMachines#FillingMachines#LabellingMachines#ShrinkwrappingMachines#PackagingMachines

0 notes

Text

Achieve Packaging Perfection with Every Seal!

Looking for a reliable and efficient way to seal your products? Choose Finepack's band sealer! This versatile machine is perfect for a variety of applications, including food, pharmaceuticals, agriculture, chemicals, and logistics.

For more details, contact us:

📲 +91 8086830370, 8086881815

🌐 www.finepackindia.com

📧 [email protected]

💬 WhatsApp: wa.link/z9pm60

#AceFinepack#PackagingMachinery#SealingMachine#BandSealer#PackagingMaterials#PackagingMachines#LogisticsPackaging

0 notes

Text

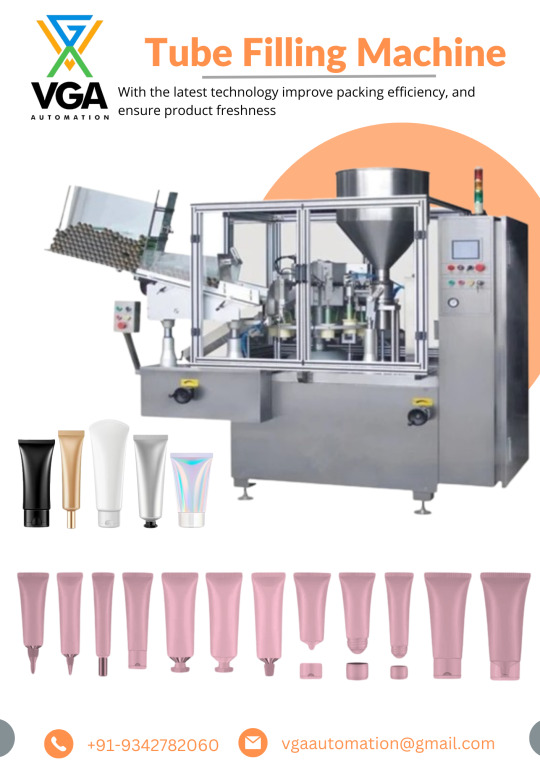

Tube Filling Machine - VGA Automation

VGA Automation Tube filling machines are specialized industrial devices used to fill various types of tubes with products in the form of liquids, pastes, or creams. These machines are commonly employed in industries such as pharmaceuticals, cosmetics, food, and chemicals to automate the process of filling, sealing, and packaging products in tubes.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationtubefiller#TubeFillingMachine#VGATubeFillingMachine#vgatubefiller#FillingMachines#PackagingMachines#FillingAndSealing#TubeFilling#AutomationSolutions#cosmeticsfilling#ointmentfilling#gelfilling#creamsfilling#saucesfilling#ediblepastesfilling#adhesivesfilling#lubricantsfilling#medicalgelfiling

1 note

·

View note

Text

Automatic Rotary Gripper Type Washing Machine in Sri Lanka

Company Overview:

Laxmi Pharma Equipment, headquartered in India, is a prominent Manufacturer, Supplier, and Exporter of Automatic Rotary Gripper Type Washing Machine in Sri Lanka.

Established in 1985 in Phase III, Vatva, Ahmedabad, Gujarat, India, Laxmi Pharma Equipment is a prominent player in the pharmaceutical machinery sector.

The industry recognizes Laxmi Pharma Equipment as a top manufacturer, exporter, and supplier of premium-grade equipment, including Washing Machines, Filling Machines, Stoppering Machines, Capping Machines, Labelling Machines, Packaging Machines, Process Equipment, and more.

The company specializes in the production and export of Automatic Rotary Gripper Type Washing Machines.

Engineers design the Automatic Rotary Gripper Type Washing Machine as a rotary unit suitable for vials ranging from 2ml to 30ml. It incorporates a Pneumatic Vial Lifting Device and an infeed Turn Table to facilitate the washing process.

Features:

GMP Model

Suitable for 2ml to 30ml Vials

Gripper Assembly for Vials

Stainless Steel Tanks

High-Quality Stainless Steel Centrifugal Pumps

SS-16 Filter Housing with Nylon/PP Cartridges

Pressure Gauges by Pointer

A.C. Frequency Drive for Speed Control

Individual Solenoid Valve for Wash Media Operation

SS-316 Pipe Fittings for Water Contacts

Push Button Operating Controls

Emergency Switch on Control Panel

Outfeed Connection to Other Machines or Tray Collection

Service Availability:

Laxmi Pharma Equipment offers its services as an Exporter of Automatic Rotary Gripper Type Washing Machine in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#AutomaticRotaryGripperTypeWashingMachine#AutomaticRotaryGripperTypeWashingMachineinSriLanka#CappingMachines#Colombo#Dehiwala-MountLavinia#ExporteerofAutomaticRotaryGripperTypeWashingMachineinSriLanka#Exporter#FillingMachines#India#Jaffna#Kalmunai#Kandy#LabellingMachines#Manufacturer#Moratuwa#Negombo#PackagingMachines#PneumaticVialLifting#ProcessEquipment#rotaryunit#SriJayawardenepura#SriLanka#StopperingMachines#Supplier#SupplierofAutomaticRotaryGripperTypeWashingMachineinSriLanka#TurnTable#Vavuniya#WashingMachines

0 notes

Text

Packaging And Weighing Machines Manufacturers In Gujarat, India

Tulsi Vista pack solution, Manufacturer, Supplier of Packaging machine & FFS Automatic Pouch Packaging Machine and our product range also comprises of Sealer Machine and Fully Pneumatic Machine in Ahemdabad, Gujarat, India. We have wide range of packing machineries. Our vision is very futuristic and we stand as a recognized brand in today's competitive market. This is due to tremendous effort & excellent input done to attain a quality & effective products. Cutact Us Today at Call us-9925926100 OR Mail Us- [email protected].

1 note

·

View note

Text

Explore the most reliable and innovative solution for packaging dosa batter! Our cutting-edge packaging technology is designed to guarantee maximum freshness and convenience, ensuring that your dosa batter stays irresistibly delicious for longer periods. With our advanced packaging solution, you can trust that your dosa batter will remain perfectly preserved, maintaining its authentic flavor and quality until it reaches your plate.

Contact us today to learn more!

🌐 www.gempac.in

📧 [email protected]

📲 +91 6238340124

📲 +91 6238341146

📲 +91 9847559184

#Gempac#PackagingMachines#FoodPackaging#PackingMachine#BatterPackagingMachine#DosaBatterPackagingMachine#IdliBatterPackagingMachine

1 note

·

View note

Text

FULLY AUTOMATIC BUCKET FILLING MACHINE IS SUITABLE TO FILL YOGURT, FRUIT YOGURT, CREAM CHEESE, LABNEH, ICE CREAM, HUMMUS, MAYONEISSE, CHOCOLATE, JELLY, CREAM, TOMATO SAUCE, OIL, DETERGENT AND OTHER FLUID PRODUCTS YOU HAVE THANKS TO HIGH PERFORMANCE AND EASY MAINTENANCE.

Performance and Quality: We present the quality and high performance together thanks to the materials supplied from the brands that leader of it’s sector.

Multi – Format : You can have the most suitable format thanks to the diameter changing wishedly, our wide – scale with the changible nozzle quantity based on your capacity and volumetric and flowmetric filling systems based on your needs.

Fast and Easy Maintenance : Only one person is enough to fast, easy, and fully automatic usage of the machine thanks to the filling settings system on the touch screen.

Maximum Security : Your safety is provided by plexiglass protection cabin frames and protection switches on the door during and after the filling.

Maximum Hygiene :When the sterilization of the machine is provided by Hepa filter, thr inner cleaning of the machine after the filling is provided by the CIP system. The sterilization of the filling cuos is provided by the UV Lamp Unit. All the materials of the machine are stainless steel and the conformity of food is provided by materials have food conformity certificate.

--------------------------------------------------------------------------------------------------------------

ADDRESS: İvedik Osb Mah. 1371 Sok. No:23 Ostim/ANKARA

PHONE: +90 (312) 395 02 78

EXPORT: +90 (542) 675 12 07

E-MAIL: [email protected]

E-MAIL: [email protected]

-----------------------------------------

www.pdmmakina.com.tr

#PackagingMachinery#FillingMachinery#LiquidPackaging#YogurtPackaging#AyranFilling#MilkPackaging#Viscosity#PackagingTechnology#IndustrialPackaging#FoodPackaging#PlantEquipment#AutomationSystems#ProductionSolutions#TechnologyInnovation#FoodIndustry#PackagingSolutions#IncreaseEfficiency#LiquidFillingMachine#HighViscosity#IndustrialMachinery#YogurtFilling#PackagingMachines#LiquidProducts#HygieneStandards#FoodFacilities#ProductionLine#MachineTechnology#QualityControl

0 notes

Text

OVERCOMING CHALLENGES IN JAR FILLING FOR GRAIN PACKAGING: TIPS AND SOLUTIONS

#nichrome#food#grainpackaging#foodpackaging#packaging#jarfilling#jar#snackpackaging#machines#packagingmachines#nichromeindia#nichromepackagingmachine#tips#solution#jarfillingmachines#india

0 notes

Text

Different Industries with Use of Packaging Machines are food, chemicals, cosmetics, pharmaceuticals, oil, perfume, dairy, pesticides, lubricant, shampoo, etc.

For more details, visit us at https://www.parthec.com/

#parthec#packagingmachinery#packagingmachines#foodindustry#chemicalindustry#cosmeticsindustry#pharmaceuticalindustry#oilindustry#perfumeindustry#dairyindustry#shampooindustry#lubricantindustry#pesticidesindustry

0 notes

Text

Understand The Need For Automation Packaging!

Automation in manufacturing is frequently used to produce components and put them together to create completed goods. But for manufacturers, it's equally important that their products be transported to their final location promptly, safely, and affordably.

Human operators still have a vital role in this process in many industries. But most of the time, the work is dull and challenging. The strain on employees' physical and mental capacities might result in more production failures, delays, and injuries.

But by using automated packaging, producers can get rid of these issues. With this advanced industrial packing machine equipped with robotics technology, automated processes can handle packaging needs.

The benefits of automation packaging are discussed below:

Increased efficiency and speed

A higher production rate than manual packaging is the most evident advantage of automated packaging. The same programmed actions may be carried out faster, more reliably, and without risk of damage using modern robot integration and software. Additionally, they can securely handle even the most complex components thanks to the remarkable precision of modern technology.

2. Decreased workplace injuries

Worker strain from lifting heavy goods, repetitive motion injuries from making the same motion repeatedly, difficulty focusing after hours on the job, and other factors all contribute to the demanding nature of packaging, which hurts employees in different ways. By automating these systems, staff can work on more challenging projects while avoiding the financial costs of accidents and missed time.

3. Increased standardisation and quality control

Humans are more mistake-prone than automated systems in tasks that require a great deal of repetition. A lack of homogeneity in the final packing job or more mishandled or broken products might come from manual packaging techniques. Modern methods make it simpler to detect production irregularities throughout the packing process and eliminate inferior goods before they are sold to customers.

4. Lesser bottlenecks

Manual packing procedures can cause bottlenecks in the production line when mistakes are made. This bottleneck can be removed with automated packing procedures since a custom machine will be made to keep up with the production line's output. This industrial packing machine also reduces the possibility of packaging mistakes, which reduces downtime and bottlenecks.

5. Flexibility

Production rates, packaging profiles, new goods and combinations, and quality inspections are just a few of the constant changes in packaging operations. It is crucial to plan for effective switchovers. Robotic automation allows for greater flexibility in managing these changes, which may involve simple re-programming, end effector adjustments, and software interfacing to allow for the execution of numerous formulas or styles.

6. Enhanced Customer Services

An automated packing system significantly reduces product flaws and recalls risks, allowing you to provide better service to your clients while increasing your production capacity. Better customer service results in a higher percentage of repeat business from loyal customers, which increases your company's profitability.

Conclusion:

As a result, this industrial packing machine may simplify tasks and avoid any inconveniences for an industry. It works well for high-volume, consistent, and repeatable processes. Even per experts' futuristic predictions, automation and robotics will play a crucial role in the industrial sector.

0 notes

Text

Gempac redefines packaging with effortless excellence. Our innovative solutions streamline the packaging process, ensuring efficiency and precision from concept to delivery. Trust Gempac to elevate your packaging experience, making it simpler and more effective than ever before. 📦✨

For more details, contact us.

🌐 www.gempac.in

📧 [email protected]

📲 +91 6238340124

📲 +91 6238341146

📲 +91 9847559184

#GEMPAC#PackagingMachines#PackingMachine#Packing#PackagingMachinery#FoodPackaging#PrecisionPackaging

0 notes

Text

Packing machines

Grocery packing machine

Supermarket packing machine

Hypermarket packing machine

Grocery stores Packing machine

Grains packing machine

Granule packing machine

Sugar packing machine

Pulses packing machine

Dal packing machine

Low price packing machine

Packing machine low price

Grocery packaging machine

Automatic grocery packing machine

Packing machine for Supermarket

Packaging machine for Grocery stores

pouch packing machine

automatic packing machine

new packing machine

packaging machine

small business ideas

business ideas

business

packing machine automatic

pouch packaging machine

pouch packing machines

milk packing machine

masala packing machine

detergent powder packing machin

packing machine of masala

tea packing machine

masala packing machines

Spices packing machine

spices sachet packing machine

Cardamon packing machine

Automatic sachet packing machine

Automatic spices packing machine

10gms spices packing machine

sachet machine

food packing machine

spices packing machine

Oil packing machines

Instant mix packing machines

Dosa batter packing machines

Edible oil packing machines

Paste packing machines

Packing machines kerala

#pulses #pouchpackingmachines

#business #businessideas #entrepreneurship

#powderpackingmachines #oilpackingmachines

#milkpackingmachine

#sugarpackingmachines

#masalapackingmachines

#sipuppackingmachines

#offer

#instantmixpackingmachines

#dosabatterpackingmachines

#Multiheadweigherpackingmachines

#christmas #youtube

#oilpackingmachines#pouchpackingmachines#powderpackingmachines#packingmachineskerala#snackspackingmachines#packing machine#packingmachinesnearme#milkpackingmachines#spicespackingmachines#masalapackingmachines#packingmachines#sipuppouchpackingmachinestubepackingmachineice candy packing machinepacpack packing machinespacking machines keralachoclate packing#packagingmachines#packagingsolutions#packaging#multiheadmachines

0 notes

Text

Best code Continuous Inkjet (CIJ) printer - from Ace Finepack.

(Marking and Coding Specialist designed and manufactured in the USA)

The continuous inkjet (CIJ) method is used commercially for the marking and coding of products and packages.

~ CIJ Key Benefits ~

🔅 A most affordable and reliable method to print real-time lot/date codes.

🔅 Print on virtually any surface or substrate.

🔅 High-speed Printing in any direction or angle.

🔅 Non-contact printing, print distance is ½” (12mm) plus.

🔅 Variety of ink types and colours for immediate dry times on porous and non-porous products.

For more details, contact us:

📲 +91 8086830370, 8086881815

🌐 www.finepackindia.com

📧 [email protected]

💬 WhatsApp: wa.link/z9pm60

#AceFinepack#PackagingMachinery#CodingMachine#PackingMachine#PackagingMaterials#PackagingMachines#BatchCodingMachines#InkjetPrinter

0 notes

Text

Automatic Eye Ear Drop Filling Machine in Jammu and Kashmir

Automatic Eye Ear Drop Filling Machine in Jammu and Kashmir

Company Overview:

Laxmi Pharma Equipment, established in 1985, is located in Phase III, Vatva, Ahmedabad, Gujarat, India.

The company is a prominent manufacturer, exporter, and supplier in the pharmaceutical machinery domain, offering a wide range of products.

The extensive product range includes Washing Machines, Filling Machines, Stoppering Machines, Capping Machines, Labelling Machines, Packaging Machines, Process Equipment, and more.

The spotlight is on automatic and semi-automatic eye/ear drop liquid filling machines, which minimize contamination risks and cater to sterile environments.

The machines feature an innovative un-scrambler design to eliminate dead ends and challenging-to-clean spots, enhancing hygiene and efficiency in the filling process.

Features:

GMP Compliance ensures adherence to Good Manufacturing Practices for the highest quality standards.

Integrated Design combines filling, inner cap placement, and screw capping units into a single body structure.

Precision and Compact Design with co-eccentric nozzles for quick and precise setting, making the unit compact and manageable.

Efficient Stop System ensures operational control by incorporating a stop system for enhanced efficiency.

Ease of Operation facilitated by the easy-reach compact panel for user-friendly operation.

Quick Changeovers allow minimum changeover time from one container size or fill size to another.

Autoclavable Parts enable easy removal of individual parts required for autoclaving/sterilization, ensuring hygiene.

Versatile Applications across industries such as pharmaceuticals, food and beverages, cosmetics, pesticides, and chemicals.

Serving Jammu and Kashmir and Beyond:

Laxmi Pharma Equipment proudly serves as a Manufacturer, Exporter, and Supplier of Automatic Eye Ear Drop Filling Machine in Jammu and Kashmir Including Anantnag, Baramula, Doda, Gulmarg, Jammu, Kathua, Punch, Rajouri, Srinagar, Udhampur.

For further details, feel free to contact us.

Read the full article

#Anantnag#AutomaticEyeEarDropFillingMachine#AutomaticEyeEarDropFillingMachineinIndia#AutomaticEyeEarDropFillingMachineinJammuandKashmir#Baramula#CappingMachines#Doda#Exporter#ExporterofAutomaticEyeEarDropFillingMachine#FillingMachines#Gulmarg#India#Jammu#JammuandKashmir#Kathua#LabellingMachines#Manufacturer#ManufacturerofAutomaticEyeEarDropFillingMachine#PackagingMachines#ProcessEquipment#Punch#Rajouri#Semi-AutomaticEyeandEarDropLiquidFillingMachines#Srinagar#StopperingMachines#Supplier#SupplierofAutomaticEyeEarDropFillingMachine#WashingMachines

0 notes

Text

At Machine Dalal, find #preownedsheetfeed, offset, pre-press, post-press, #cutters, #digitalpress, three-knife trimmers, and packaging machines listed from around the world. Visit us today at: http://machinedalal.com

0 notes