#Logistics Automation

Text

#Logistics Automation Market#Logistics Automation#Warehouse Automation#Logistics Warehouse Automation#Automated Logistics Systems#Automated Warehouse#Supply Chain Automation

0 notes

Text

Navigating the Future: Advancements in Warehouse Robotics Technology

As we look to the future of logistics and supply chain management, one technology stands out as a driving force behind innovation and efficiency: warehouse robotics. Rapid advancements in robotics technology are reshaping the way warehouses operate, offering unprecedented levels of automation, precision, and scalability.

Exploring the Latest Advancements:

Enhanced Mobility and Flexibility: The latest advancements in Warehouse Robotics technology are focused on enhancing mobility and flexibility. Robots are becoming more agile and adaptable, capable of navigating complex warehouse environments with ease. This increased mobility allows for greater flexibility in warehouse layout and optimization of space.

Integration of Artificial Intelligence: Artificial intelligence (AI) is playing a crucial role in the evolution of warehouse robotics. AI-powered robots can analyze vast amounts of data in real-time, allowing them to make intelligent decisions and adapt to changing circumstances on the fly. This level of autonomy and decision-making capability is revolutionizing warehouse operations.

Embracing Collaborative Robotics:

Collaborative Robots (Cobots): Collaborative robots, or cobots, are another exciting development in warehouse robotics technology. Unlike traditional industrial robots, cobots are designed to work alongside human workers, enhancing efficiency and safety in the warehouse environment. These robots can perform tasks that require dexterity and precision, while humans focus on more complex operations.

Human-Robot Collaboration: The integration of cobots into warehouse workflows enables seamless human-robot collaboration. By working together, humans and robots can leverage their respective strengths to optimize productivity and achieve higher levels of efficiency. This collaborative approach to warehouse robotics ensures a smooth transition towards fully automated warehouse operations.

Get More Insights On This Topic: Warehouse Robotics

#Warehouse Robotics#Automation#Robotics Technology#Supply Chain Efficiency#Logistics Automation#Robotic Automation#Warehouse Management#Industrial Robotics

0 notes

Text

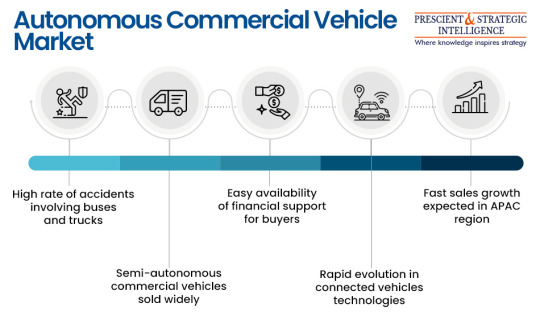

Driving the Future: Autonomous Commercial Vehicle Market Revolution

The autonomous commercial vehicle market is experiencing growth and is projected to reach USD 1,302.1 billion by 2030. This development can be ascribed to the continuing development in commercial vehicle technologies, growing government aid for autonomous commercial cars, and rising requirement for effective advantages and well-organized and safer driving options.

In recent years, the semi-autonomous category, on the basis of vehicle autonomy, contributed a higher revenue share. Vehicles must be fortified with electronic stability control or at least one of the progressive driver-assistance system ADAS features (either for steering or acceleration) to attain level 1 automation. Most of the European nations and the U.S. have forced the acceptance of basic ADAS features in all new commercial vehicles, which essentially makes all of them semi-autonomous.

In recent years, the truck category held the larger market share, and the category is projected to remain dominant in the vehicle type segment of the industry during the projection period. This can be credited to the growing utilization of autonomous trucks for logistical processes, like domestic logistics transportation, automated material handling, logistics digitalization, and yard management.

In the coming few years, on the basis of the application segment, the public transportation category is projected to advance at the fastest rate. This can be credited to the rising acceptance of autonomous shuttle facilities for public mobility reasons. Numerous start-ups and recognized businesses are coming up with strategies to grow level 5 autonomous shuttles for public transport. Such shuttles will not need human drivers for the process, which will aid transportation agencies save on working prices.

In the past few years, the North American region dominated the industry with the highest revenue for the autonomous commercial vehicle market, and the region is also projected to remain in the top spot during the projection period. This can be mainly credited to the increasing research and development activities on autonomous automobiles and growing aid from the federal and state governments for advancing autonomous driving technologies.

The APAC region is projected to witness the fastest development because of the booming vehicle industry here. APAC is the globe's largest vehicle maker, responsible for almost half of the annual production.

Hence, the continuing development in commercial vehicle technologies, growing government aid for autonomous commercial cars, and rising requirement for effective advantages are the major factors propelling the market.

#Autonomous Commercial Vehicles#Self-Driving Trucks#Logistics Automation#Transportation Industry#Freight Efficiency#Connectivity Solutions#Driverless Technology#Market Trends#Fleet Management#Autonomous Delivery#Truck Platooning#Market Players#Freight Transportation#Urban Mobility#Automation Innovation#Autonomous Trucking#Safety Systems#AI-driven Logistics#Long-Haul Trucking#Commercial Vehicle Automation

0 notes

Text

Benefits of Implementing Logistics Automation for Efficient Supply Chain Management

In today's highly competitive business environment, companies are increasingly turning to logistics automation to improve their supply chain management efficiency. The use of advanced technologies, such as robotics, artificial intelligence, and automation, can help businesses reduce costs, improve accuracy, and enhance customer satisfaction. In this article, we will explore the benefits of implementing logistics automation for efficient supply chain management and how it can help businesses in Australia gain a competitive edge.

Improved Efficiency

Logistics automation can streamline and optimize supply chain management processes, resulting in increased efficiency. Automated systems can help reduce the time required for routine tasks, such as order processing, inventory management, and shipping, while minimizing the risk of errors. This can lead to faster turnaround times, lower labor costs, and improved productivity, allowing businesses to operate more efficiently.

Increased Accuracy

Logistics automation can significantly improve accuracy in supply chain management. Automated systems can eliminate the potential for human error, such as misplacing items, incorrect labeling, or incorrect order fulfillment. With automated tracking and inventory management, businesses can quickly locate and track products, and ensure that they are delivered to the right location at the right time. This can lead to higher customer satisfaction, improved customer retention, and increased profitability.

Cost Savings

Logistics automation can help businesses save costs in a variety of ways. By automating routine tasks, businesses can reduce labor costs and optimize workforce management. Automation can also help businesses reduce inventory carrying costs by providing real-time tracking and inventory management, allowing businesses to accurately forecast demand and optimize inventory levels. Additionally, automation can reduce transportation costs by optimizing route planning and reducing fuel consumption. All of these cost savings can help businesses operate more efficiently, and invest more resources in growth and innovation.

Enhanced Customer Satisfaction

Logistics automation can significantly enhance customer satisfaction, by improving accuracy, reducing delivery times, and enhancing product quality. Automated systems can provide real-time tracking and status updates to customers, allowing them to know exactly when to expect their products. With automation, businesses can also ensure that products are delivered on time, with accurate labeling and packaging, leading to higher customer satisfaction and better customer retention.

Competitive Advantage

Finally, logistics automation can help businesses gain a competitive advantage by operating more efficiently, reducing costs, and enhancing customer satisfaction. With automation, businesses can focus on innovation and growth, rather than routine tasks, giving them a competitive edge in the marketplace. By investing in logistics automation, businesses can stay ahead of the competition and drive sustainable growth.

In conclusion, the benefits of implementing logistics automation for efficient supply chain management are clear. With increased efficiency, accuracy, cost savings, enhanced customer satisfaction, and a competitive advantage, businesses in Australia can improve their bottom line and stay ahead of the curve. By investing in logistics automation, businesses can optimize their supply chain management, drive growth, and achieve long-term success.

0 notes

Text

0 notes

Text

Discovering the Future of Logistics: 5 Influential Trends! 🚛 Explore the factors driving the evolution of the industry, from automation to sustainability.

Stay informed and gain insights into the future of supply chain management.

2 notes

·

View notes

Photo

#this is what i believe in#sorta related i was reading an article a few weeks ago#where they discussed the idea of using dirigible drones to load and unload cargo ships off the coast#instead of waiting for them to enter port#at least partly#i just love airships and i'm hoping they make a comeback#also on a related note i'm just really excited to see how automation/robotics changes logistics#things are about to get really efficient#logistics have largely been the same for like a century#we're about to witness a supply chain revolution#and at all levels of the supply chain#just imagine#autonomous cargo ships unloading at autonomous ports#ships waiting in line are unloaded by drones#then fleets of autonomous trucks#and revitalized trains#then smaller drones to directly deliver packages from stores/warehouses to consumers

5 notes

·

View notes

Text

The Future of Logistics is Here! Dive into the power of AI and automation in warehouse management. From predictive analytics to AI-powered robots, discover how technology is reshaping the logistics landscape.

Ready for the future of logistics?

2 notes

·

View notes

Text

0 notes

Text

#Here are the tags for “How To Bridge Data Gaps in the Food Supply Chain Warehouses with AI”:#food supply chain#AI in food industry#data gaps#supply chain management#warehouse technology#artificial intelligence#food logistics#inventory management#food safety#smart warehouses#AI solutions#data integration#food industry trends#supply chain optimization#warehouse automation#food distribution#predictive analytics#tech in food supply#AI applications#digital transformation

0 notes

Text

#Automation#StartupLife#Entrepreneurship#TechStartup#InnovativeSolutions#BusinessGrowth#Logistics#TechInnovation#FounderLife#CEO#StartupFounder#DigitalTransformation#BusinessAutomation#TransportIndustry#TruckSuvidha#SarvodayaInfotech#IShuBansal#TechEntrepreneur#FutureOfWork#SmartLogistics#TechLeaders#BusinessTech#Industry4_0#DigitalEntrepreneur#InnovationInTech#Resume#CV#CareerTips#JobSearch#CareerAdvice

0 notes

Text

0 notes

Link

OSARO employs a diverse & talented team of experts in the specialized field of machine and deep learning (Software Development).

#fulfillment #robotics #logistics #ecommerce #warehouse #kitting #etail #pickandplace #automation @OsaroAI

0 notes

Text

#Rackspace Technology#AI#Machine_Learning#technologies#sectors#transportation#logistics#automation#scalability#electronicsnews#technologynews

0 notes

Text

Unlock the potential of your warehouse operations with Matiyas Solutions! 🚀 Streamline, automate, and excel with our tailored ERP system designed to revolutionize warehouse management. From precise inventory tracking to seamless order fulfillment, we've got you covered. Scale your business with efficiency, accuracy, and productivity. Ready to elevate your operations? Book a free demo now! https://www.matiyas.com/request-demo

#MatiyasSolutions#WarehouseManagement#SupplyChain#Logistics#BusinessProductivity#Automation#Efficiency#ScaleWithConfidence#warehousesoftware#warehouseerpsoftware#erpsoftware#warehousemanagementaoftware#erpnext#frappe#logisticsoftware

0 notes

Text

Load Port Module: The Essential Link Between Wafer Transport System and Process Tool

A Load Port Module serves as the interface between a wafer transport system and a semiconductor process tool such as an etcher or deposition system. It facilitates the safe and ultra-clean transfer of wafers from cassettes stored in the transport system into the vacuum environment of the process chamber for semiconductor fabrication steps. Let's take a closer look at the key components and functions of this critical module.

Wafer Cassette Access

The front end of a loadlock in Load Port Module includes a cassette-loading station where standard 25mm wafer cassettes containing up to 25 wafers can be automatically loaded and unloaded. A robotic handler on the transport system sets the cassette into place and latches it securely. An environmentally sealed door then closes to maintain isolation of the cleanroom air from the vacuum system. Sensor inputs confirming cassette presence and door closure status are relayed to the process tool's control system.

Vacuum-Compatible Design

Since wafers must be transferred between the atmospheric cassette environment and high-vacuum process chambers, a Load Port Module needs vacuum-compatible construction. Chambers, bellows sections, and sealing joints are machined from non-outgassing stainless steel or aluminum alloys certified for ultra-high vacuum contact. Viton O-rings, metal gaskets, and precision actuators enable dependable closure and integrity testing of all interfaces down to vacuum pressures below 1x10^-7 Torr.

Wafer Transfer Mechanisms

Various transfer mechanisms are incorporated into load port designs depending on the specific process tool interface. Common configurations include a linear motor-driven blade that reaches into the cassette to pick wafers one at a time or a robotic arm capable of lifting an entire shelf of wafers simultaneously. Cameras and light sources aid alignment while sensors confirm contact and monitor for particles during extraction and placement into the loadlock chamber.

Loadlock Chamber

Contained within the load port housing is a small, sealable loadlock chamber where wafers can be coated or undergo vacuum bake-out procedures before entering the process chamber. Magnetic or mechanical end effectors gently grip wafers during transfer to stationary wafer pedestals inside the chamber. A turbo pump then evacuates air from the chamber to prepare for opening the valve to the process tool. Closing this valve isolates the loadlock to allow venting back to atmospheric pressure for wafer removal.

Chemical Delivery Ports

Some advanced load port designs accommodate ports for purge gas, chemical, or vapor delivery into the loadlock chamber or direct wafer surfaces. This enables pre-etch surface treatment, post-process cleaning, or thin film deposition capabilities directly on the wafers without needing to move them to a dedicated tool. Integrated mass flow controllers ensure precise chemical dosing and vacuum-safe plumbing routes all lines to the chamber.

Get More Insights On This Topic: Load Port Module

#Load Port Module#Semiconductor Industry#Manufacturing#Automation#Material Handling#Robotics#Semiconductor Equipment#Integrated Systems#Industrial Technology#Port Logistics#Container Handling

0 notes