#Industrial Water Treatment

Text

What Is an Industrial Water Treatment System and How Does It Work?

Water is the lifeblood of countless industrial processes. But unlike the kind that comes out of your tap, industrial water often needs a little extra TLC before it's ready for action. That's where industrial water treatment systems come in. At PureBact, we understand the importance of clean, reliable water for your facility's operations.

Here's a breakdown of what industrial water treatment systems are and how they work:

What is an Industrial Water Treatment System?

An industrial water treatment system is a customized set of processes designed to remove impurities and adjust the properties of water to make it suitable for a specific industrial application. This could involve anything from making boiler feed water ultra-pure to treating wastewater before it's released back into the environment.

Why is Industrial Water Treatment Important?

Untreated water can wreak havoc on your industrial processes. Minerals can cause scaling and corrosion in pipes and equipment, while contaminants can affect product quality. Proper water treatment helps to:

Protect equipment: By removing impurities that can cause corrosion and scaling, you can extend the lifespan of your valuable machinery.

Ensure product quality: Consistent water quality is essential for producing consistent, high-quality products.

Minimize environmental impact: Industrial wastewater treatment helps to remove pollutants before they are released back into the environment.

Reduce operating costs: By preventing equipment damage and ensuring efficient operation, proper water treatment can save you money in the long run.

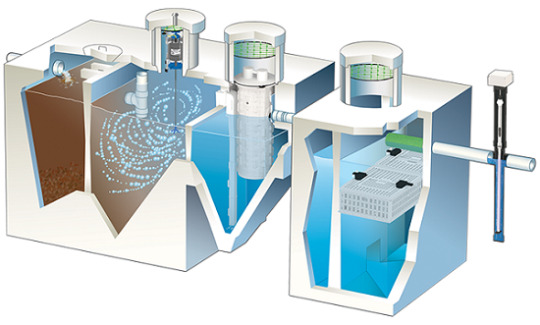

How Does Industrial Water Treatment Work?

The specific treatment processes used will vary depending on the source water and the desired end product. However, some common methods include:

Pre-treatment: This stage removes large particles such as sand, debris, and organic matter through filtration or sedimentation.

Clarification: Coagulation and flocculation techniques help suspended solids clump together and settle out of the water.

Filtration: Various filtration technologies, like sand filters or membrane filters, remove finer particles and contaminants.

Ion exchange: This process removes unwanted ions by exchanging them for harmless ones.

Deionization: A specialized form of ion exchange that removes both positively and negatively charged ions to create high-purity water.

Disinfection: Chemicals like chlorine or ultraviolet light can be used to kill bacteria and other microorganisms.

PureBact: Your Partner in Industrial Water Treatment

At PureBact, we offer a comprehensive range of industrial water treatment solutions. Our team of experts will work with you to assess your specific needs and design a custom system that ensures optimal water quality for your operations.

Contact PureBact today to learn more about how we can help your business thrive with clean, reliable industrial water.

2 notes

·

View notes

Text

Enhancing Efficiency and Sustainability: Industrial Water Treatment Solutions

Maintaining proper management of water resources is essential in the hectic world of industry. Supporting a healthy environment and high-quality operation are important factors in industrial water treatment and wastewater treatment.

0 notes

Text

Aquarius Projects | Innovative Process Application Systems

Aquarius Projects provides innovative water treatment systems focusing on efficiency, reliability & performance while prioritizing environmental sustainability

#Aquarius Projects#Process application systems#Water treatment technology#Industrial water treatment#Environmental sustainability#Advanced water treatment solutions

0 notes

Text

WETS designed and installed 200 gpm Arsenic Removal Plant at Point Blank, TX

WETS LLC is an ISO 9001 certified company founded in 1976. We are a professional engineering registered company proud to serve municipal and industrial water treatment needs in the USA. We have installed hundreds of filtration, aeration, clarifier, cooling tower, and GST ventilation units in water systems ranging in capacity from under 50 gpm to over 5000 gpm

Does your facility need help with industrial water, wastewater, process separation, or filtration treatment solutions?

We look forward to providing you with the best water treatment solutions. Please contact us with the details provided below.

Address: 8614 Fairbanks N Houston Road, Houston, TX 77064

Contact Number: 713 409 3366

Email: [email protected]

#water treatment company#water treatment supplier#industrial water treatment#water treatment solution#industrial water treatment company#municipal water treatment

0 notes

Text

Water and Wastewater Treatment Equipment Market, Analyzing Market Forces, Technological Advancements, and Environmental Impacts

The global water and wastewater treatment equipment market size is anticipated to reach USD 90.0 billion by 2030, registering a CAGR of 4.6% over the forecast period, according to a new report by Grand View Research, Inc. The market is driven by increasing demand for clean and safe water in both developed and emerging economies. This is due to growing concerns over water pollution and scarcity, and the need for effective wastewater management.

Water And Wastewater Treatment Equipment Market Report Highlights

Asia Pacific accounted for the largest revenue share of the global market in 2023, accounting for 35.1%, and is expected to maintain its dominance throughout the forecast period. This can be attributed to the presence of a strong consumer base that has led to significant demand for water and wastewater treatment equipment

By application, the municipal segment dominated the market with a revenue share of 66.0% in 2023. The increasing initiatives undertaken by governments, strict environmental regulations, and increasing awareness regarding water treatment are some of the factors contributing to the growth of the municipal segment over the forecast period

By process, the tertiary treatment segment dominated the market with a revenue share of 44.2% in 2023. Some of the drivers for the increasing demand for tertiary wastewater treatment are environmental protection, water scarcity, and the increasing demand for clean water. As these issues continue to be major concerns across the world, the demand for tertiary wastewater treatment is expected to grow over the forecast period

Major key players frequently engage in mergers & acquisitions and new product launches to maintain their market shares. For instance, in March 2022, Pentair plc, announced the definitive agreement to acquire Manitowoc Ice. The move was taken by the company to enhance its commercial water solutions platform and cater to the demand from the food service industry

For More Details or Sample Copy please visit link @: Water And Wastewater Treatment Equipment Market Report

Furthermore, the demand for decentralized wastewater treatment systems is expected to increase over the projected period, as these systems offer several advantages such as low operating costs, high treatment efficiency, and easy maintenance. Several companies are focusing on developing innovative decentralized wastewater treatment systems that can be easily installed in residential and commercial buildings.

Population growth, urbanization, increasing industrialization, and the need for clean water for various purposes such as drinking, agriculture, and industrial processes all drive demand for water and wastewater treatment equipment. Government regulations aimed at protecting the environment and ensuring public health also have an impact on the demand for water and wastewater treatment equipment.

The market players are constantly undertaking strategic initiatives such as mergers, acquisitions, partnerships, and new product launches to gain a competitive advantage. For instance, Ceco Environmental, a provider of air pollution control solutions, announced the acquisition of Compass Water Solutions, a provider of water and wastewater treatment equipment. The acquisition will enable Ceco Environmental to integrate Compass Water Solutions’ critical engineered solutions with its industrial water capabilities.

WaterAndWastewaterTreatmentEquipmentMarket #WaterAndWastewaterTreatmentEquipment #WaterTreatment #WastewaterManagement #EnvironmentalEngineering #SustainableTechnology #CleanWaterSolutions #IndustrialWaterTreatment #WaterPurification #GreenInfrastructure #InnovationInWaterManagement #WaterQualityControl #WastewaterRecycling #MarketTrends #EnvironmentalCompliance #SmartWaterTechnologies #RegulatoryFrameworks #EcoFriendlySolutions #EmergingTechnologies #ResourceRecovery

#Water and Wastewater Treatment Equipment Market#Water and Wastewater Treatment Equipment#Water Treatment#Waste water Management#Environmental Engineering#Sustainable Technology#Clean Water Solutions#Industrial Water Treatment#Water Purification#Global Market Analysis#Green Infrastructure#Innovation In Water Management#Water Quality Control#Waste-water Recycling#Environmental Compliance#Smart Water Technologies#Regulatory Frameworks#Eco-Friendly Solutions#Emerging Technologies#Resource Recovery

0 notes

Text

Exploring the Importance of Water Treatment Equipment

Industrial water treatment systems are crucial for maintaining the quality of water used in various industrial applications. The utilization of suitable water treatment equipment ensures optimal purification results. By understanding the basics of these systems and acknowledging the significance of reliable equipment, industries can ensure sustainable use of this precious resource while adhering to environmental regulations

0 notes

Text

Harnessing Nature: Insights into the Organic Coagulant Market

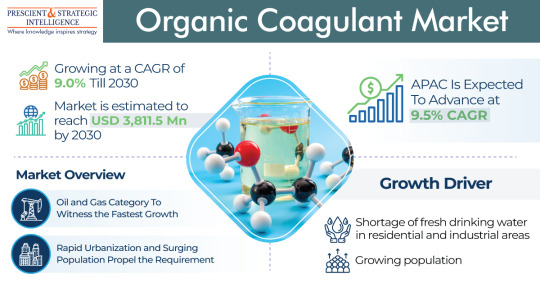

The organic coagulant market is projected to reach at USD 3,811.5 million in 2030 with a CAGR of 9% in the years to come.

The major reasons for this development of the industry are the scarcity of drinking and fresh water in residential and industrial areas along with the rising population, and urbanization.

And the rising demand for facilities like sewage treatment, industrial water treatment, fertilizer production, food & beverage industry, and paper manufacturing helps the demand for the chemical to grow.

And another major reason for the increasing demand is the growing population, which is creating an enormous demand for clean water and for which a need for advanced purification methods and also with the expansion of infrastructure for water treatment by government to meet the demand are all contributing the growth of eco-friendly water purification.

The oil & gas category will grow at a highest CAGR of 10% over the years, which is driven by the increasing use of organic chemicals with water at a required concentration for drilling and petroleum extraction purposes.

While, onshore and offshore operations both require different filtration processes as in onshore normal water is available, whereas offshore require advanced system to filter seawater.

In addition, research and development activities are also contributing to the demand for organic coagulants, with eco-friendly solutions being explored for wastewater treatment.

Moreover, the increasing government focus to implement policies for water quality monitoring because of the increasing population all over the world. Strict regulations to prevent the direct release of harmful chemicals from industries and untreated sewage into water bodies.

APAC will grow the fastest in the organic coagulant market at a CAGR of 9.5% in the years to come due to the rapid urbanization and industrialization with rising population along with the rising investments in water treatment plant development and strict regulations on sewage disposal. Countries like India, China, South Korea, and Japan are expanding their contribution for the water treatment.

#organic coagulant#water treatment#wastewater treatment#coagulation solutions#eco-friendly chemicals#sustainable water treatment#natural coagulants#organic flocculants#water purification#organic coagulant applications#environmental sustainability#industrial water treatment#market growth#coagulation technology#organic chemicals

0 notes

Text

Industrial Water Treatment Systems | Industrial Water Treatment

Choose MAGNETIZER® industrial water treatment systems to enhance water quality, minimize contaminants, and ensure compliance with regulations. Visit us now!

0 notes

Text

#sandfiltration#water filtration#waterfiltrationplant#treatment#industrial water#industrial water treatment

0 notes

Photo

Choose Advanced Industrial Water Treatment Services

Industrial and commercial water treatment are essential for ensuring the quality and safety of water in various settings. With our expertise in this field, Culligan Industrial Water offers comprehensive solutions for industrial and commercial water treatment needs. Our services include designing, installing, and maintaining water treatment systems that cater to specific requirements and industry standards. Our team of experts uses cutting-edge technology and advanced techniques to deliver reliable and cost-effective water treatment services to our clients. Contact us today to learn more about our industrial and commercial water treatment services.

0 notes

Text

0 notes

Text

0 notes

Text

Me when doing my environmental science homework, at every available opportunity:

#wish there were a class discord or a chill teacher so i could share it#fr though I'm like “oh we're talking about freshwater? hey did you know that agricultural runoff is causing accelerated eutrophication?”#and that a lot of the runoff is bc of erosion caused by the destruction of ecosystems and their vegetation that would've kept soil in place#and the runoff is mostly compromised of fertilizer and bacteria and pesticides from the agriculture and sediment from the eroded land#and that crop irrigation is so inefficient that literally 40% of irrigation water never reaches the crops#and don't even get me started on the FUCKING CORN SUBSIDIES#god those fucking corn subsidies#“hey boudicca what's the worst policy choice the us government made in the 1930s–40s?”#“was it American isolationism? maybe increased militarization? the garbage treatment of women and minorities?”#wrong! it was not stopping those fucking corn subsidies#(this is a joke obviously those other things were worse)#(I'm not actually saying this silly little agricultural practice was worse than Japanese internment don't worry)#but i AM saying that at some point they should've fucking phased out those goddamn corn subsidies#do you wanna know why California grows so much corn even though it's an incredibly water intensive crop and California is dry as shit?#I'll give you three guesses#anyway sorry for rambling my point is fuck industrial agriculture#agriculture#described

9 notes

·

View notes

Text

Industrial, Cleaning, Oil Field, Water treatment, Painting, Food, Mining, Construction, Power plant, Ceramic Chemicals Dubai, UAE | Coil cutting Service Dubai, UAE

The chemical industry in Dubai and the United Arab Emirates (UAE) is a vital component of the country's economy, as it is used in a wide range of industries such as construction, manufacturing, and oil and gas. The region is known for its high-quality chemicals, which are exported to various countries worldwide. However, with so many chemical suppliers in the market, it can be challenging to find the right one that meets your needs. This is why it is important to have a reliable and trustworthy chemical supplier that you can count on for all of your chemical needs.

In this blog post, we will discuss the role of chemical suppliers in Dubai and the UAE, the factors to consider when selecting a chemical supplier, and key players in the chemical supplier market. We'll also give tips on how to research and compare chemical suppliers in the region, so you can make an informed decision when choosing the right supplier for your business.

The role of chemical suppliers in Dubai and the UAE

The role of chemical suppliers in Dubai and the UAE is to provide a variety of chemical products to different industries in the region. These products include raw materials, industrial chemicals, and specialty chemicals that are used in a wide range of applications.

Construction industry is one of the major industries that rely on chemical suppliers in Dubai and the UAE. These chemicals are used in the production of construction materials such as cement, concrete, and asphalt. They are also used in the construction process, for example, as a waterproofing agent, fire-resistant coating, and for surface treatment.

Manufacturing industry is another sector that heavily depends on chemical suppliers. Chemicals are used in the production of various products such as plastics, textiles, and pharmaceuticals. These chemicals play a crucial role in the manufacturing process, as they are used as raw materials, catalysts, and intermediates.

Oil and gas industry is also a major user of chemicals. In the exploration, production, and refining process of oil and gas, various chemicals are used. These chemicals are used for drilling, production enhancement, and refining process.

Specialty chemicals are also an important part of the chemical industry in Dubai and the UAE. These chemicals have specific properties and are used for specific applications, such as in the food and beverage industry, personal care products, and agriculture.

In summary, chemical suppliers in Dubai and the UAE play a crucial role in supplying a wide range of chemicals to various industries, which in turn, enables the smooth functioning of these industries, and contributes to the overall economic growth of the region.

Choosing a chemical supplier in Dubai and the UAE

Choosing a chemical supplier in Dubai and the UAE can be a challenging task due to the large number of suppliers in the market. However, by considering the following factors, you can ensure that you select a supplier that meets your needs and provides you with high-quality chemicals at a reasonable price.

Quality: The quality of the chemicals supplied is of utmost importance. Make sure that the supplier has a good reputation in the market and that their chemicals meet the required industry standards.

Price: Compare the prices of different suppliers and choose one that offers competitive prices without compromising on quality.

Customer Service: A good supplier should provide excellent customer service, including timely delivery of products and prompt response to any queries or concerns you may have.

Certifications: Ensure that the supplier is certified by relevant authorities and that their chemicals have passed all necessary safety and quality tests.

Product Range: Check if the supplier has a wide range of products, so you can find all the chemicals you need from a single supplier, which can save you time and money.

Location: It is important to consider the location of the supplier, as this can affect delivery times and costs.

Environmental & Safety Consideration: Consider the supplier's environmental and safety policies, to ensure that the supplier is following the regulations and not impacting the environment negatively.

When researching potential suppliers, it is important to read reviews, check their websites, and ask for references from other businesses that have used their services. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs.

Key players in the chemical supplier market in Dubai and the UAE

Dubai and the UAE have a large number of chemical suppliers, but some stand out as key players in the market. Here are a few examples of major chemical suppliers in the region:

Al Rama International: Al Rama International Chemical Suppliers Company in Dubai, UAE. We are Specialized Chemicals Our Service Industrial Chemical, Cleaning Chemical, Oil field Chemical, Water treatment Chemical, Painting Chemical, Food Chemical, Mining Chemical, Construction Chemical, Power plant Chemical, Ceramic Chemical in Dubai, UAE. Al Rama has been a significant player in the G.C.C. & East African chemical trade, for over 20 years. We stock a wide variety of products ranging from food ingredients, oil exploration chemicals, sanitization chemicals, petroleum derivatives and industrial process raw materials. We possess extensive in-house expertise in blending and repacking of various products. Our facilities include open, closed ambient storage, as well as temperature-controlled storage. We operate our own fleet of road tankers, ISO tanks and pick-up trucks, to ensure full supply chain traceability.

Gulf Petrochem Group: Based in Dubai, Gulf Petrochem is a leading supplier of industrial and specialty chemicals in the region. They have a wide range of products, including petrochemicals, base oils, and lubricants. They also have a strong presence in the Africa, Asia, and Europe market.

National Chemical Corporation (NCC): NCC is a well-established chemical supplier based in Abu Dhabi. They have a wide range of products, including specialty chemicals, petrochemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

Emirates National Chemical Industries (ENCI): ENCI is a leading chemical supplier based in Dubai. They have a wide range of products, including petrochemicals, specialty chemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

These are just a few examples of major chemical suppliers in Dubai and the UAE. There are many other suppliers in the market, and it's important to research and compare different suppliers to find the one that best meets your needs.

Conclusion

In conclusion, chemical suppliers play a crucial role in the UAE and Dubai by supplying a wide range of chemicals to various industries. These industries include construction, manufacturing, oil and gas and specialty chemicals. When choosing a chemical supplier in Dubai, UAE, it is important to consider factors such as quality, price, customer service, certifications, product range, location and environmental & safety consideration. The key players in the chemical supplier market in Dubai and the UAE include Gulf Petrochem Group, National Chemical Corporation (NCC), Emirates National Chemical Industries (ENCI), and Al Rama International. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs and helps you to run your business efficiently.

#Chemical Suppliers#Industrial Chemicals#Cleaning Chemicals#Oil Field Chemicals#Bulk Chemicals#Water Treatment Chemicals#Painting Chemicals#Food Chemicals#Mining Chemicals#Construction Chemicals#Ceramic Chemicals#Powerplant Chemicals#Coil Cutting Service

2 notes

·

View notes

Text

Leading the Charge: Water Treatment Plant Manufacturers Shaping Tomorrow's World

Water treatment plant manufacturers are pivotal in ensuring access to clean and safe water globally. As environmental concerns and water scarcity issues become more pressing, these manufacturers are at the forefront of developing and implementing innovative solutions. Their efforts are crucial in shaping a sustainable future for our planet. This article explores how water treatment plant manufacturers are leading the charge in environmental protection and water conservation.

The Growing Importance of Water Treatment

Water treatment is essential for public health, industrial processes, and environmental protection. Contaminated water can lead to severe health issues, disrupt industrial operations, and harm ecosystems. Water treatment plants address these problems by removing pollutants, pathogens, and other harmful substances from water sources.

Key Functions of Water Treatment Plants

Water treatment plants perform several critical functions:

Purification: Removing contaminants to make water safe for consumption.

Filtration: Eliminating particles and sediments.

Disinfection: Killing bacteria, viruses, and other pathogens.

Softening: Reducing water hardness to prevent scaling in pipes and appliances.

Advanced Technologies in Water Treatment

Water treatment plant manufacturers utilize a range of advanced technologies to ensure efficient and effective water treatment. These technologies include:

(a) Membrane Filtration

Membrane filtration uses semi-permeable membranes to separate contaminants from water. Techniques like reverse osmosis and ultrafiltration are highly effective in removing dissolved substances and tiny particles.

(b) UV Disinfection

Ultraviolet (UV) disinfection employs UV light to inactivate microorganisms. This method is chemical-free and environmentally friendly, as it leaves no residuals.

(c) Advanced Oxidation Processes (AOPs)

Advanced oxidation processes involve powerful oxidants like ozone and hydrogen peroxide to break down organic pollutants. These processes are effective against contaminants resistant to traditional methods.

(d) Biological Treatment

Biological treatment uses microorganisms to degrade organic pollutants. Methods such as activated sludge and biofiltration are commonly employed in wastewater treatment to remove organic matter and nutrients.

Custom Solutions for Diverse Needs

Water treatment plant manufacturers offer tailored solutions to meet the specific needs of various sectors. These solutions address the unique challenges of different industries:

(i) Municipal Water Treatment

Municipal water treatment plants ensure that water supplied to households meets safety standards. Manufacturers design systems capable of handling large volumes of water, incorporating advanced filtration and disinfection technologies.

(ii) Industrial Water Treatment

Industries require water for processes such as cooling, cleaning, and manufacturing. Water treatment systems for industrial applications must meet stringent quality standards to protect equipment and ensure product quality.

(iii) Desalination

In regions with limited freshwater resources, desalination plants convert seawater into potable water. These plants use techniques like reverse osmosis to remove salt and other impurities, providing a reliable source of freshwater.

(iv) Wastewater Treatment

Treating wastewater is crucial for environmental protection. Wastewater treatment plants remove contaminants from sewage and industrial effluent, ensuring safe discharge into the environment.

Sustainability and Environmental Impact

Water treatment plant manufacturers are committed to sustainability and minimizing environmental impact. Key strategies include:

1. Energy Efficiency

Manufacturers are developing energy-efficient technologies to reduce the carbon footprint of water treatment processes. Solar-powered systems and energy recovery techniques are increasingly common.

2. Waste Reduction

By optimizing processes and using advanced treatment methods, manufacturers can reduce waste generated during water treatment. This includes minimizing sludge production and finding beneficial uses for by-products.

3. Water Reuse and Recycling

Promoting water reuse and recycling is essential for sustainable water management. Manufacturers design systems that treat and reuse wastewater, reducing freshwater demand and conserving resources.

Leading Water Treatment Plant Manufacturers

Several companies are recognized as leaders in the water treatment industry. These manufacturers are known for their innovation, reliability, and commitment to quality:

(a) Veolia Water Technologies

Veolia Water Technologies is a global leader in water and wastewater treatment solutions. The company offers a comprehensive range of technologies and services, from design and construction to operation and maintenance.

(b) SUEZ Water Technologies & Solutions

SUEZ provides advanced water treatment solutions for various industries and municipalities. Their expertise includes desalination, industrial water treatment, and smart water management systems.

(c) Xylem Inc.

Xylem Inc. is dedicated to solving water challenges through innovative technology. Their products and services cover the entire water cycle, from collection and distribution to treatment and reuse.

The Future of Water Treatment

The future of water treatment lies in continued innovation and sustainable technology development. Key trends include:

(i) Smart Water Management

The integration of digital technologies, such as sensors and data analytics, is transforming water treatment. Smart water management systems enable real-time monitoring and optimization, improving efficiency and reducing costs.

(ii) Decentralized Treatment

Decentralized water treatment systems bring treatment closer to the point of use. These systems are ideal for remote areas and small communities, offering a cost-effective and scalable solution.

(iii) Enhanced Recovery Techniques

Advancements in recovery techniques, such as zero-liquid discharge (ZLD) systems, aim to maximize resource recovery and minimize waste. These technologies are particularly important in industries with high water usage.

Conclusion

Water treatment plant manufacturers are essential to ensuring access to clean and safe water. Through innovative technologies and sustainable practices, they help protect public health and the environment. As the demand for clean water continues to grow, these pioneers in environmental protection will play a crucial role in shaping a sustainable future. By staying at the forefront of technology and embracing new challenges, water treatment plant manufacturers are truly making a difference in the world.

If You want To Explore More About Water Treatment Plant Manufacturers then Visit the Site: Jasmino

#technology#manufacturing#manufacturing industry#manufacturer#watermanagement#safe drinking water#water treatment technology#water treatment plant#water treatment solutions#water treatment#water treatment system#filtration system#water filtration

0 notes