#Batch Coding Printing Machine

Link

Inkjet Coder Mounting Machine manufacturers, suppliers, and exporters in Inkjet Coder Mounting Machine, in any paper, film, and foil conversing industries, the Winder/Rewinder (Doctor Machine) is used widely for online printing of Mfg. Dt., Exp. Dt. B. No. etc. using Inkjet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

#Inkjet Coder Mounting Machine#inkjet batch code printer#batch coder mini printer#batch printing machine#batch coding machine#manual batch coding machine#automatic batch coding machine#batch printer machine#batch coding printing machine

1 note

·

View note

Text

Coding and batch Printing machines Pune India

Discover cutting-edge Coding and Batch Printing machines in Pune, India, exclusively brought to you by Nexgen Drying Systems Pvt. Ltd. Our state-of-the-art machinery ensures precision and efficiency in coding processes, catering to diverse industrial needs. Contact us at +91 95943 53681 or reach out via email at [email protected] or [email protected] for inquiries. Explore our comprehensive range of innovative solutions on our website http://www.nexgendrying.com/. Nexgen Drying Systems Pvt. Ltd. is your trusted partner for advanced coding technology, providing reliable and high-performance batch printing solutions tailored to elevate your production processes.

0 notes

Text

Batch coding Machine

UV coating, also known as ultraviolet coating, is a transparent, lustrous liquid coating applied to printed materials. This coating is a popular printing technique for protecting items that are handled often during delivery. The coating is a type of coating that is applied to printed material.

The batch coding system is crucial for quality control, traceability, inventory management, and compliance with regulatory standards. It ensures that essential information is clearly and accurately displayed on the product packaging, allowing manufacturers, retailers, and consumers to easily identify and track individual batches of products. This information is particularly important in industries such as food and beverages, pharmaceuticals, cosmetics, and consumer goods, where product freshness, safety, and quality are paramount.

Batch coding machine

Uv Coating machine supplier

Die Cutting Machines

Die Punching machines

1 note

·

View note

Link

0 notes

Text

Election Fraud Is Hard

I just got back from being the Democratic observer at a "Risk Limiting Audit."

Here in Georgia, the Dominion scanners read either the mail-in ballot or the machine-printed ballot that is created when you use the machine to select your votes in person. The scanners read a QR-style barcode, but there's also a plain-text summary of the person's vote for every race printed on it.

But how do we know the scanners are reading the mail-in ballots correctly, or that the QR code actually matches the voter's picks? That's what this audit is for. The state generates random numbers that are then used for every county in Georgia to pick a few batches - the in-person votes from a specific precinct, or a specific 100-vote group of the mail-ins, or one of the bundles of early votes. While it doesn't show in the public results, the state keeps a record of the results from EACH batch as it was reported by the machines on or after Election Day.

So on Audit Day, each county pulls out those randomly selected batches, puts each batch on a table with two paid election workers (to double-check each other), and they hand-count them. They use their human eyes to read the printed text, ignoring the barcode, or they visually count the check marks on the mail-in ballots. Those human-generated results are then checked against the machine-generated results, and we see if they match.

So next time you hear someone talking about the machines changing the vote, or wondering about those QR codes, or whatever, let 'em know - there really are humans going back and double-checking this stuff. And not just one human - there's two at each table, and election supervisors organizing it, and partisan observers sitting there keeping an eye on the process. And this is just ONE of the many checks and precautions. Other states have different procedures, but they're all careful and thorough. Election fraud is HARD, y'all - and that's why there's so little of it.

2 notes

·

View notes

Text

Training a ML combined AI technologies and code in Phyton

Training a machine learning (ML) model, including a large language model (LLM), often involves a combination of AI technologies and Python code. Here are the general steps and considerations for training an LLM in Python:

1. Data Preprocessing: Prepare and preprocess the training data, which may involve cleaning, tokenization, and splitting into training and validation sets.

2. Model Selection: Choose a suitable LLM architecture, such as GPT-2 or GPT-3, and select a deep learning framework like PyTorch or TensorFlow for model implementation.

3. Hyperparameter Tuning: Adjust hyperparameters such as learning rate, batch size, and regularization techniques to optimize the model's performance.

4. Training the Model: Use the selected deep learning framework to train the LLM on the preprocessed data. This step involves instantiating the model and iterating through the training data to update the model's weights.

5. Evaluation and Refinement: Evaluate the trained model using appropriate metrics and iterate on the training process to improve the model's quality over time.

6. Utilizing AI Libraries and APIs: Leverage AI libraries and APIs, such as OpenAI's ChatGPT or other LLM platforms, to facilitate the training and use of LLMs for specific tasks.

By following these steps and leveraging the available AI technologies and Python code, developers can effectively train and utilize LLMs for various natural language processing tasks.

A snippet code in Phyton as POC to this

Here is a simple Python code snippet for linear regression using scikit-learn:

```python

import pandas as pd

import numpy as np

from sklearn.model_selection import train_test_split

from sklearn.linear_model import LinearRegression

# Load data

data = pd.read_csv('data.csv')

x = data.drop('target', axis=1)

y = data['target']

# Split data into training and test sets

x_train, x_test, y_train, y_test = train_test_split(x, y, test_size=0.2, random_state=42)

# Train the linear regression model

model = LinearRegression()

model.fit(x_train, y_train)

# Make predictions

predictions = model.predict(x_test)

# Evaluate the model

score = model.score(x_test, y_test)

print("Model score:", score)

```

This code assumes that you have a CSV file named 'data.csv' with a target column and other features. It splits the data into training and test sets, trains a linear regression model, makes predictions on the test set, and evaluates the model using the R^2 score.

Here is a Python code snippet for training a simple neural network using the PyTorch library:

python

import torch

import torch.nn as nn

import torch.optim as optim

from torch.utils.data import DataLoader, TensorDataset

# Define the neural network model

class Net(nn.Module):

def __init__(self):

super(Net, self).__init__()

self.fc1 = nn.Linear(784, 256)

self.fc2 = nn.Linear(256, 10)

def forward(self, x):

x = x.view(-1, 784)

x = torch.relu(self.fc1(x))

x = self.fc2(x)

return x

# Load data

train_data = torch.randn(1000, 784)

train_labels = torch.randint(0, 10, (1000,))

test_data = torch.randn(500, 784)

test_labels = torch.randint(0, 10, (500,))

# Create a TensorDataset and DataLoader

train_data = TensorDataset(train_data, train_labels)

test_data = TensorDataset(test_data, test_labels)

train_loader = DataLoader(train_data, batch_size=64, shuffle=True)

test_loader = DataLoader(test_data, batch_size=64, shuffle=False)

# Instantiate the model, loss function, and optimizer

model = Net()

criterion = nn.CrossEntropyLoss()

optimizer = optim.SGD(model.parameters(), lr=0.01)

# Train the model

for epoch in range(10):

model.train()

for batch_idx, (data, target) in enumerate(train_loader):

optimizer.zero_grad()

output = model(data)

loss = criterion(output, target)

loss.backward()

optimizer.step()

# Evaluate the model

model.eval()

test_loss = 0

correct = 0

with torch.no_grad():

for data, target in test_loader:

output = model(data)

test_loss += criterion(

0 notes

Text

Modern Marking Machine Innovations are Transforming Manufacturing Processes

In the dynamic landscape of manufacturing, precision, efficiency, and traceability are paramount. With the advent of cutting-edge marking machines, industries are witnessing a transformative shift in how products are identified, tracked, and managed throughout the production cycle. From automotive to aerospace, pharmaceuticals to electronics, marking machines are playing a pivotal role in enhancing productivity, ensuring quality control, and streamlining operations.

The Development of Marking Machines:

Marking machines have come a long way from traditional methods such as manual engraving or stamping. Today, advanced technologies such as laser marking, dot peen marking, and inkjet printing have revolutionized the marking process, offering unparalleled precision, speed, and versatility.

Laser Marking:

Laser marking utilizes a focused laser beam to etch or engrave a wide range of materials, including metals, plastics, ceramics, and more. With its non-contact process, laser marking ensures high-quality, permanent marks without causing damage to the substrate. Furthermore, its ability to produce intricate designs, barcodes, and serial numbers makes it indispensable in industries where traceability is crucial.

Dot Peen Marking:

Dot peen marking, also known as pin marking or dot marking, employs a pneumatically driven stylus to create indentations on the surface of the material. This method is ideal for marking alphanumeric characters, logos, and 2D data matrix codes on various substrates, including metals and plastics. Dot peen marking offers excellent durability and readability, making it ideal for applications requiring robust identification solutions.

Inkjet Printing:

Inkjet printing technology has made significant strides in industrial marking applications. High-resolution inkjet printers can apply permanent, high-quality marks on a variety of surfaces, including paper, cardboard, plastics, and metals. With the ability to print variable data in real-time, such as date codes, batch numbers, and product information, inkjet printers are invaluable in industries with fast-paced production environments.

Benefits and Features:

Enhanced Traceability:

Marking machines enable manufacturers to implement robust traceability systems, allowing them to track each product throughout its lifecycle. From raw material identification to final product authentication, marking technologies ensure complete visibility and accountability, thereby minimizing the risk of counterfeiting and ensuring regulatory compliance.

Improved Quality Control:

By integrating marking machines into their production processes, manufacturers can implement stringent quality control measures. Permanent marks provide assurance of product authenticity and quality, while real-time data encoding allows for immediate identification of defects or discrepancies, enabling timely corrective actions.

Increased Efficiency:

The speed and accuracy of modern marking machines contribute to significant improvements in operational efficiency. Rapid marking cycles minimize downtime and increase throughput, optimizing production workflows and reducing overall manufacturing costs. Moreover, automated marking systems can seamlessly integrate with existing manufacturing equipment, enhancing overall productivity without disrupting existing processes.

Case Studies:

Automotive Industry:

In the automotive sector, marking machines play a critical role in part identification, serialization, and traceability. By implementing laser marking systems, automotive manufacturers can ensure compliance with industry standards and regulations while enhancing supply chain visibility. For example, BMW implemented laser marking technology to mark critical components with unique identification codes, enabling precise tracking and authentication throughout the vehicle’s lifespan.

Aerospace Sector:

In the aerospace industry, where safety and reliability are paramount, marking machines are instrumental in ensuring component integrity and traceability. Airbus, for instance, utilizes dot peen marking systems to mark aerospace-grade materials with permanent, high-contrast identifiers. These marks withstand extreme environmental conditions and provide crucial information for maintenance, repair, and overhaul operations.

Conclusion:

The latest advancements in marking machines are reshaping the manufacturing landscape, offering unprecedented levels of precision, efficiency, and traceability. From laser marking to dot peen marking and inkjet printing, these technologies empower manufacturers to enhance product identification, streamline operations, and maintain stringent quality standards. As industries continue to evolve, marking machines will remain indispensable tools for driving innovation, ensuring product integrity, and meeting the demands of a dynamic market environment.

0 notes

Text

Laser Printing Machine on Plastic

In the landscape of modern manufacturing, laser printing machines have emerged as game-changers, particularly in the realm of plastic production. The ability to precisely mark, engrave, and cut plastic components offers a myriad of advantages, from enhancing product aesthetics to improving traceability and compliance. In this exploration, we delve into the transformative impact of Laser Printing Machine on Plastic manufacturing processes, uncovering their benefits and potential applications.

The Versatility of Laser Printing on Plastic: Laser printing on plastic encompasses a wide range of applications, revolutionizing traditional manufacturing processes in numerous industries. Unlike conventional methods such as screen printing or mechanical engraving, laser printing offers unparalleled precision, flexibility, and efficiency. Whether it's creating intricate designs, adding serial numbers, or implementing barcodes, laser printing machines empower manufacturers to achieve high-quality results with minimal waste and downtime.

Applications Across Industries: The versatility of laser printing machines on plastic extends across various industries, including:

Electronics: Laser marking enables the permanent labeling of plastic enclosures, circuit boards, and connectors, facilitating product identification and branding in the electronics sector.

Medical Devices: Laser printing ensures the precise marking of medical-grade plastics for regulatory compliance, including CE and FDA requirements, while also supporting traceability and sterilization processes.

Automotive: From dashboard panels to engine components, laser printing machines facilitate part serialization, branding, and customization in the automotive industry, enhancing both aesthetics and functionality.

Packaging: Laser printing on plastic packaging materials offers efficient solutions for product labeling, batch coding, and anti-counterfeiting measures, enhancing consumer safety and brand integrity.

Aerospace: Laser marking on plastic components used in aircraft interiors and structural elements enables part identification, maintenance tracking, and compliance with stringent aviation standards.

Benefits of Laser Printing on Plastic: The adoption of laser printing machines in plastic manufacturing brings forth a host of benefits, including:

Precision and Consistency: Laser technology ensures precise and consistent markings, even on complex geometries and irregular surfaces, minimizing errors and enhancing product quality.

Flexibility and Customization: Manufacturers can easily customize designs, logos, and text using laser printing machines, offering greater flexibility to meet customer preferences and market demands.

Efficiency and Cost Savings: Laser printing reduces production time and labor costs associated with traditional marking methods, leading to improved operational efficiency and competitive pricing.

Durability and Longevity: Laser markings on plastic exhibit superior resistance to abrasion, chemicals, and environmental factors, ensuring durability throughout the product lifecycle.

Environmental Sustainability: Laser printing produces minimal waste and emissions compared to conventional printing processes, aligning with sustainable manufacturing practices and reducing environmental impact.

Conclusion: Laser printing machines have revolutionized plastic manufacturing processes, offering unprecedented precision, versatility, and efficiency across a multitude of industries. By embracing laser technology, manufacturers can unlock new possibilities for product customization, branding, and compliance while enhancing operational efficiency and sustainability. As the demand for high-quality plastic components continues to rise, laser printing stands poised to reshape the future of manufacturing, driving innovation and excellence in the pursuit of excellence.

0 notes

Text

private labelling in india

In the ever-evolving landscape of the spice industry in India, one company stands out as a pioneer in delivering both purity and innovation - Swani Spice. With a constant commitment to providing the highest degree of purity in spices, Swani Spice has ventured into the world of private labelling in india , redefining the way we perceive spices and their packaging.

In a world where consumer trends change rapidly, building a competitive edge is crucial for gaining better bargaining power over other suppliers. Private labelling allows us to create cost-effective leadership and offer better margins with wider price options for our clients. This, in turn, leads to increased customer loyalty.

One of the critical aspects of delivering pure spices is ensuring their quality remains untarnished from the moment they are packed until they reach the client. Swani has taken a leap into the future by investing in advanced packaging machines that not only save floor space but also enhance product sterility and quality.

Fill, Seal (FFS) Machines have four vertical forms, each designed to cater to specific packaging requirements:

FFS Machines with Dual Feeding System - Precision in packaging is assured, providing a competitive edge.

Multi-head Filling System - Ideal for packing whole products, it ensures the spices' freshness remains intact.

Auger Filling System - Perfect for powders, this system preserves the texture and flavour of the spices.

Pouch Orientation - Versatile options like pillow pouches with three-sided seals meet varied packaging needs.

Packaging is not merely about aesthetics; it plays a pivotal role in preserving the quality of spices throughout their shelf life. Swaniconsiders packaging a top priority, offering a wide array of options to cater to diverse products and sizes.

Depending on the physical characteristics of a product, different packaging requirements need to be met. Swani is fully equipped to meet these demands, offering a wide range of packaging options:

Plain Laminated Print -

A simple yet effective solution with stickers or print directly on the pouch for quick identification.

Generic Printed Film –

Featuringprinting of product names and batch codes for efficiency and accuracy.

Product-Specific Printed Laminated Films –

Customized packaging highlights the uniqueness of each spice, enhancing brand identity.

Sustainability and Beyond

Swanis’ commitment extends beyond delivering purity; it's about sustainability too. The emphasis on organic and sustainable cultivation ensures that our spices are free from synthetic pesticides, herbicides, and other chemical fertilizers.

By partnering with local farmers, we support sustainable agriculture while promoting the economic well-being of farming communities. Swani’sjourney encompasses the entire lifecycle of spices, creating a cycle of purity and sustainability.

private labelling in india has become an essential aspect of the business landscape in India. It allows companies to differentiate themselves from their competitors, offer better margins, and build their brand identity. At Swani, we understand the importance of private labelling and have taken steps to ensure that our products meet the highest quality standards while offering a wide range of packaging options to our clients.

You can reach out to us with just a click on the link and enquire more.

0 notes

Text

Frequently Asked Questions(FAQs) about Ink Pumps for Continuous Inkjet Printers(CIJ)

You will find the following information here:

What is CIJ?

What is the primary application of continuous inkjet printers?

How does continuous inkjet printing work?

How is a continuous inkjet system formed?

Common issues with ink pumps in continuous inkjet printers

TOPSFLO CIJ ink pumps Solution

How to Get in Touch with TOPSFLO for Expert Assistance?

What is CIJ?

CIJ stands for Continuous Inkjet, CIJ is a small character inkjet printing technology that uses a single inkjet nozzle to rapidly spray ink into tiny droplets, forming printed images or text. CIJ printers are widely used worldwide and are a non-contact printing method, making them suitable for marking on both flat and curved surfaces. They are primarily used in industrial applications for product packaging, labeling, and coding.

What are the Main Applications of Continuous Inkjet Printers?

Continuous inkjet printers are primarily used to mark production dates, batch numbers, barcodes, and other information on the surfaces of various materials such as plastic, metal, glass, cardboard, and wood. Typical applications include beverage cartons, cans, and bags, pharmaceuticals, small cardboard boxes, cables, and components. Virtually any product or packaging that moves on a conveyor belt or extrusion machine is suitable for continuous inkjet printing.

How does Continuous Inkjet Printers Work?

Continuous inkjet printers create a continuous stream of ink, which is broken down into numerous ink droplets through high-frequency vibrations. Once the ink droplets are formed, the selected ones are charged by electrodes and then directed by a deflection plate that generates an electrostatic field.

Charged ink droplets pass through the deflection plate, causing them to deviate at a specific angle before being sprayed from the print head onto the product to create the desired printed information. Uncharged ink droplets remain unaffected and return directly to the CIJ ink system.

During this printing process, the solvent base of the ink evaporates, and the viscosity of the ink changes accordingly. To ensure the optimal droplet formulation, viscosity must be strictly controlled within specified values.

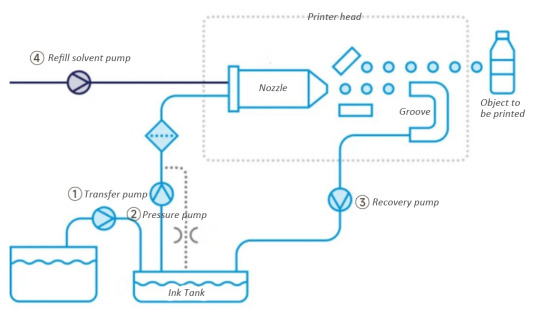

How is a Continuous Inkjet System Formed?

In continuous inkjet (CIJ) printing, ink circulates continuously throughout the printer, from the fluid system to the printhead, and then back to the fluid system. The entire ink path system involves several pumps working in coordination.

Initially, ink is transported from a large container to an ink reservoir using a transfer pump (①).

Subsequently, the ink is pressurized and transferred to the printhead using a pressure pump (②). Inside the printhead, the ink flows through nozzles, forming a continuous array of small ink droplets, each of which can be individually charged. Charged droplets are deflected by electrodes and hit the object to be printed.

Additionally, uncharged ink droplets fly in a straight line into a gutter, and excess ink is recirculated from this point back to the ink reservoir using a recirculation/suction/recovery pump (③).

To prevent the ink from drying and damaging the system when the printer is not in use, a refill solvent pump (④) is typically included in the continuous inkjet system. This pump delivers solvent to the nozzles to flush out any residual ink.

Through these steps, a continuous inkjet system can continuously supply ink and achieve high-speed, efficient inkjet printing.

Common Issues with Ink Pumps in Continuous Inkjet Printers

1. In the current market, there is a wide variety of ink types used in CIJ printers, each with different viscosities. These different ink compositions may contain additives, some of which can be corrosive, leading to compatibility issues with pump materials that can cause malfunctions or a very short lifespan.

2. Instability in the liquid circuit pressure and ink flow during the operation of the inkjet printer can affect the printing results.

Continuous inkjet printing requires prolonged periods of operation. Over time, continuous use may result in wear and tear, potentially leading to a decline in performance or malfunctions, thus compromising the printer's lifespan.

TOPSFLO CIJ ink pumps Solution

Diverse Pump Materials

Topsflo printer ink pumps offer a variety of pump material configurations to accommodate common CIJ ink types, such as MEK, dye-based inks, pigment inks, and soft pigment inks. The pump head materials for diaphragm pumps can be selected from PA, PPS, or PP, while membrane materials can be chosen from EPDM or PTFE. For valve materials, options include EPDM, FKM, or FFKM. YT alloy gear pumps are mainly used for pigment inks, while PEEK gears can be used for dye-based inks.

Carefully Selected Pump Types for Precise Applications

Topsflo offers two pump options tailored for printer applications: diaphragm pumps and gear pumps.

- Diaphragm liquid pumps, especially those designed for low-flow rates, provide relatively stable flow and pressure output. They are more suitable for handling liquids containing solid particles or particulate matter because their design is better suited for handling suspended particles. However, in high-flow applications, diaphragm pumps may produce larger pulses, which could lead to vibration or noise issues.

- Gear pumps are suitable for printers that require a large volume of ink. They offer stable flow and pressure output with lower pulsation. Compared to ordinary gear pumps on the market, TOPSFLO gear pumps use high-precision gears and component control to ensure smooth flow, minimal pulsation, and adjustable output pressure stability.

TOPSFLO engineers can determine which pump is better suited for your application based on your printing requirements, including the desired flow rate, accuracy, pulsation, noise level, ink properties, and whether they contain solid particles, among other factors.

Long-lasting Lifetime for Stable Printing Assurance

Both Topsflo diaphragm pumps and gear pumps are equipped with high-performance brushless motors developed in-house.

The coreless brushless motor in the diaphragm pump boasts a lifespan of up to 15,000 hours, while the gear pump utilizes a high-performance, in-house designed and manufactured brushless three-phase motor with a lifespan exceeding 30,000 hours, requiring no maintenance.

These brushless motors do not produce sparks, static electricity, or electromagnetic interference during operation, ensuring safety and allowing the pumps to run continuously in high-demand inkjet printing tasks.

How to Get in Touch with TOPSFLO for Expert Assistance?

Maintaining a consistently stable flow and using ink fluids with the appropriate viscosity are crucial for overall printing quality. Any abnormalities in the ink supply system can lead to poor printing quality, error messages, and even costly product recalls. Therefore, choosing the right ink pump for your continuous inkjet printer is of utmost importance.

TOPSFLO specializes in the development and production of various micro pumps for printers. They have extensive experience and pump solutions, and they offer customized services to meet different customer needs. Please contact their sales engineers for printer pump application cases and pump information! Email: [email protected] or [email protected]

youtube

0 notes

Text

#Batch Coding machines#Variable data printing machines#single color mini offset printing machine#offset printing machines

1 note

·

View note

Text

Everything To Need To Know About Case Coding Printers

Introduction:

When it comes to businesses and brands keeping track of their range of products, proper codes and labels are a must. Therefore having Case Coding Printers Virginia is worth investing in to make business seamless, easy to track, and worth keeping packaging remarkable for the team & customers. Check out some details about the case coding process of printing.

Why Is Case Coding Important?

Case coding is an essential step in the production process. It provides quality control, tracks inventory, and ensures returned products are delivered to the correct location. Furthermore, it is important for the correct delivery of the goods sent.

The Base Of Case Coding:

Applying variable data, such as a barcode, to identify a product is known as case coding. Also, it can be used for quality control monitoring, product tracking, etc. Each crate or crate containing that specific batch of products will have a crate code. Scanners, often used in grocery stores to prevent theft and inventory errors, can read this code. It is very helpful to locate the correct place inside the product box.

The Terminology and Technology for Case Coding:

Applying codes or markers to secondary packaging or labeling is known as case coding and box coding, a term often used in the pharmaceutical industry. This helps identify packages for drug recalls and product recalls using case coding. Case coding technology reads a barcode on a product and transmits the information, for example, to an RFID reader. The data is then transmitted to a computer system, which converts it into data that software applications can use for analysis.

The Importance Of Case Coding In Production & Manufacturing Process:

Case coding is crucial for businesses with product catalogs, large quantities, and ranges. It helps to easily track products, identify products and their packaging, and reorganize manufacturing processes. Moreover also great to improve quality control and reduce the chances of human error in counting, tracking, and inspection. Coding and marketing also help in adding efficiency to workflow.

Conclusion:

If you have a business, you must go with Case Coding Printers in Virginia. Invest in high-resolution case coding printing machines to give products easy reading and proper labeling. This is widely used in the industrial sector, including pharmaceuticals, food packaging, chemical development, and cosmetics.

0 notes

Text

youtube

Watch the 2024 American Climate Leadership Awards for High School Students now: https://youtu.be/5C-bb9PoRLc

The recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by student climate leaders! Join Aishah-Nyeta Brown & Jerome Foster II and be inspired by student climate leaders as we recognize the High School Student finalists. Watch now to find out which student received the $25,000 grand prize and top recognition!

#ACLA24#ACLA24HighSchoolStudents#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental education#environmental justice#environmental protection#environmental health#high school students#high school#youth#youth of america#school

15K notes

·

View notes

Video

best manufacturer: Box Embossing Batch Coding Expiry Date Stamping Printing Batch Coding Machine

0 notes

Text

Choose CO2 laser marking machine or fiber laser marking machine?

Regarding co2 laser marking machine and fiber laser marking machine, which is better? First of all, this should be determined according to the materials and customer needs. Some materials are suitable for CO2 carbon dioxide laser marking machines, some materials are suitable for fiber laser marking machines, and some are general-purpose laser marking machines. Although the application range of fiber laser marking machine is wide, the materials used for co2 laser marking machine are not necessarily suitable for fiber laser marking machine, and each has its advantages and disadvantages.

What are the differences between CO2 laser marking machine and fiber laser marking machine?

The carbon dioxide laser marking machine is mainly for marking non-metallic materials, such as plastic, glass, etc., but after a period of use, it needs to be filled (carbon dioxide). The fiber laser marking machine can mark metal and non-metal materials. Simply put, it combines the functions of a carbon dioxide laser marking machine and a semiconductor laser marking machine, and the speed is more than 3 times that of a semiconductor, and there is no need to change parts for 100,000 hours. , High-power, high-brightness, high-precision, is currently more advanced laser marking equipment.

Performance characteristics of CO2 laser marking machine:

1. The marking accuracy is high, the speed is fast, and the engraving depth can be controlled at will;

2. The laser power is large and can be used for engraving and cutting a variety of non-metal products;

3. No consumables, low processing cost, laser operating life up to 20,000 to 30,000 hours;

4. Clear marking, not easy to wear, fast engraving and cutting efficiency, environmental protection and energy saving;

5. Use the 10.64nm laser beam to expand, focus, and finally control the deflection of the galvanometer;

6. Act on the work surface according to the predetermined trajectory to vaporize the work surface to achieve the marking effect;

7. Good beam pattern, stable system performance, low maintenance, suitable for industrial processing sites with large batches, multiple varieties, high speed and high precision continuous production;

8. The most advanced optical path optimization design and unique graphics path optimization technology, coupled with the unique super pulse function of the laser, make the cutting speed faster.

Industry application and applicable materials of CO2 laser marking machine:

Suitable for paper, leather, cloth, plexiglass, epoxy resin, woolen products, plastics, ceramics, crystal, jade, bamboo and wood products. It is widely used in all kinds of consumer goods, food packaging, beverage packaging, pharmaceutical packaging, architectural ceramics, clothing accessories, leather, textile cutting, craft gifts, rubber products, shell brands, denim, furniture and other industries.

Performance of fiber laser marking machine:

1. The marking software is very powerful, compatible with application software such as Coreldraw, AutoCAD, Photoshop, etc.; supports PLT, PCX, DXF, BMP, etc., and can use SHX and TTF fonts; supports automatic encoding, printing serial numbers, batch numbers, dates, bar codes , QR code, automatic number skipping, etc.;

2. Adopt an integrated structure, equipped with an automatic focusing system, and the operation process is humanized;

3. Use the original imported isolator to protect the fiber laser window, increase the stability and laser life;

4. No maintenance required, long service life, small size, suitable for working in harsh environments;

5. The processing speed is fast, 2-3 times of the traditional marking machine;

6. The electro-optical conversion rate is high, the power consumption of the whole machine is less than 500W, which is 1/10 of the lamp pumped solid laser marking machine, which greatly saves energy consumption;

7. The beam quality is much better than the traditional solid laser marking machine. It is the basic mode, TEM00, and the output focused spot diameter is less than 20um. The divergence angle is 1/4 of the semiconductor pump laser. Especially suitable for fine and close marking.

Applicable materials used in fiber laser marking machine industry:

Metal and various non-metal materials, high-hardness alloys, oxides, electroplating, coating, ABS, epoxy resin, ink, engineering plastics, etc. Widely used in plastic translucent buttons, ic chips, digital product components, compact machinery, jewelry, sanitary ware, measuring tools, clocks and glasses, electrical appliances, electronic components, hardware accessories, hardware tools, mobile phone communication components, automobile and motorcycle accessories, Plastic products, medical equipment, building materials, pipes and other industries.

DOTSLASER has 10 years experience in industrial laser equipment, we are a professional laser equipment production base, all equipment are researched,developed,assembled by ourselves.Our products mainly include fiber laser cutting machine, fiber laser marking machine, fiber laser welding machine, UV laser marking machine, CO2 laser marking machine, CO2 laser cutting machine, etc.

#Fiber Laser Marking Machine Manufacturer China#CO2 Laser Marking Machine Manufacturer China#Fiber Laser Engraving Machine Manufacturer China

0 notes

Text

How Packaging Machinery Can Save Your Business Time and Money

When packaging machinery breaks down it interrupts production – this costs companies time, money and customer satisfaction. This is the main reason it is essential to invest in regular maintenance. Relying on best quality packaging machinery is inevitable.

Human error – overfilling containers, damaging packaging and applying incorrect labels or tightening caps – wastes products and leads to unhappy customers. Automation enables greater consistency in output.

Flow Fillers for Portion-Counted Product Packaging

Using packaging machinery can increase productivity and reduce production costs, while improving hygiene standards. It can also eliminate hand contact with food and medicine to ensure high product quality and safety standards. However, the cost of purchasing and operating this equipment is a significant dynamic that needs to be considered carefully.

Flow fillers are designed for products that are counted by portions, instead of weight. These machines use a hopper that’s set up to scan count candy pieces or tablets and can fill small bottles. They’re best suited for liquids, oils, and thin edible products.

Blister Packing Machines: These machines form a platform in a plastic shell, then add blister board backers that are adhered with glue or by hand to the back of the plastic. Then, the products are placed on the platform and a heated soft plastic layer shapes itself around them to create a sealed blister pack. They’re commonly used for food and pharmaceutical products.

Tablet Fillers for Portion-Counted Product Packaging

Packaging machinery can be utilized to fill a pouch or bottle with products that are counted by portions. These machines include a hopper that scan counts product pieces or tablets before placing them in the bottle, and a filler head that pushes the correct number of items into the bottles accurately. Some examples of such products are heavy sauces, cosmetic creams and thick shampoos.

Another form of packaging equipment is the vertical form fill seal machine, which makes stand-up pouches and plastic bags from a continuous flat film roll and fills them simultaneously with products and seals the filled bags. This type of packaging is capable of handling liquids and solids.

Having representatives from several packaging machinery manufacturers examine existing packaging procedures can help find ways to improve production efficiency and lower costs prior to progression to new equipment. Understanding math included in cost per film utilization will also aid the business to budget properly and exploit packaging materials with efficiency.

Vertical Form Fill Sealing Machine

VFFS machines (also known as vertical baggers) are an effective packaging solution for powdered products. Typically, these machines start with a roll of film that’s pulled by belts to a forming tube that shapes it into the desired pouch size.

Once the bag is formed, a dosing system positioned around the forming tube can fill it with your product. Then, the same sealing jaws that formed the bag form a seal on its top edge, creating a finished and ready-to-ship package.

If you have a need for additional printing, the machine can add date/batch codes and graphics to each completed package. It’s also possible to add a tear notch or euro punch so that the bag can hang on a display for easy retail sales. Depending on how your bags will be used, you can even choose to have the machine add a zipper for added convenience and security. You can find a number of trustworthy packaging machinery companies offering a range of vertical form fill seal machines to fit any type of product and bag.

Liquid Filling Machine

A liquid filling machine pours a fluid into containers that may be bottles, vials, cans, or pouches. Liquid packaging machines may also wash and sterilize containers to remove dust, contaminants, or microbial growth. Some machines have multiple fill heads that increase a machine’s top speed and capacity.

While the exact specifications of liquid filling machinery vary, most systems follow the same general principle. Bottles or jars pass along a conveyor in the machine and are filled before continuing on to the next step of production. The precise technology varies by product and container type, but inline liquid packaging systems are less expensive and more easily upgraded than rotary systems.

Overflow filling machines are especially useful for clear containers because they can produce consistent levels of liquid in each bottle even if the contents of each bottle differ slightly. You must also consider your desired automation level and production capacity when selecting liquid filling machines. Buying from the best supplier will help you get quality and advanced machinery in customized specifications at lucrative costs.

Conclusion

Business means investment. Packaging machines are a major investment to run any business. First choose the right packaging machines for your needs considering the health and well-being of your production line and ensuring that you get the most value out of your investment.

0 notes

Text

How to pass a variable into Connexion Flask app context?

I run Connexion/Flask app like this:

import connexionfrom flask_cors import CORSfrom flask import gapp = connexion.App(__name__, specification_dir='swagger_server/swagger/')app.add_api('swagger.yaml')CORS(app.app)with app.app.app_context(): g.foo = 'bar' q = g.get('foo') # THIS WORKS print('variable', q)app.run(port=8088, use_reloader=False)

somewhere else in code:

from flask import abort, g, current_appdef batch(machine=None): # noqa: E501 try: app = current_app._get_current_object() with app.app_context: bq = g.get('foo', None) # DOES NOT WORK HERE print('variable:', bq) res = MYHandler(bq).batch(machine) except: abort(404) return res

This does not work - I am not able to pass variable ('bla') to second code example.

Any idea how to pass context variable correctly? Or how to pass a variable and use it globally for all Flask handlers?

I've tried this solution (which works): In first code section I'd add:

app.app.config['foo'] = 'bar'

and in second code section there would be:

bq = current_app.config.get('foo')

This solution does not use application context and I am not sure if it's a correct way.

https://codehunter.cc/a/flask/how-to-pass-a-variable-into-connexion-flask-app-context

0 notes

Text

youtube

Watch the American Climate Leadership Awards 2024 now: https://youtu.be/bWiW4Rp8vF0?feature=shared

The American Climate Leadership Awards 2024 broadcast recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by active climate leaders. Watch to find out which finalist received the $50,000 grand prize! Hosted by Vanessa Hauc and featuring Bill McKibben and Katharine Hayhoe!

#ACLA24#ACLA24Leaders#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental justice#environment protection#environmental health#Youtube

15K notes

·

View notes