#ABSORPTION COEFFICIENT

Text

refractive index

#gintama#art tag#ABSORPTION COEFFICIENT#cant look at this anymore tommorow im gonne be so annoyed with it. lmao. I hate drawing faces more than anything on this earth#takasugi shinsuke#gintoki

69 notes

·

View notes

Text

man phthalocyanines are great, super easy to tell at a glance if my synthesis succeeded or not based on whether it lets zero light into the vial lol

137 notes

·

View notes

Text

Ferrari - La Ferrari

F1 (and cars) MASTERLIST

Italians just do it better…

The car is equipped with a version of the F140 engine, a 65° V12 Otto cycle, direct injection and atmospheric fuel, mounted in a central position, of 6262 cm³ delivering 800 HP at 9000 rpm, 700 N m of torque at 6750 rpm, with compression ratio of 13.5:1; in addition, the HY-KERS energy recovery system, with the additional 163 HP developed by the relevant electric engine, brings the combined power and torque values to, respectively, 963 HP and over 900 N·m. Thanks to the hybrid scheme, combined fuel consumption is 14.2 l/100 km (7.2 km/l), also managing to limit CO2 emissions to 330 g/km.

The chassis and bodywork, with a dry weight of 1255 kg, are entirely made of four different types of carbon fiber and Kevlar, differentiating themselves in the various areas, adapting to the specific rigidity and shock absorption needs of each. The aerodynamic drag coefficient (Cx) is 0.299 in the minimum drag configuration; but it can vary, increasing, depending on the configuration assumed by the active aerodynamics with which the car is equipped. The suspensions are overlapping wishbones at the front and multilink at the rear. The brakes are made of carbon-ceramic composite material by Brembo, and power to the rear wheels is managed through a 7-speed dual-clutch F1 gearbox.

The data that the company provides regarding acceleration are the following: 0-100 km/h in less than 3 seconds, 0-200 km/h in less than 7 seconds and 0-300 km/h in 15 seconds; the maximum speed indicated is over 350 km/h. This made it the most high-performance and fastest road Ferrari ever produced up to that point.

#italy#italian#italia#ferrari#la ferrari#classic cars#fast cars#cars#formula uno#formula 1#formula racing#formula one#f1#ferrari f1#ferrari formula 1#ferrari formula one#enzo ferrari#dino Ferrari

20 notes

·

View notes

Text

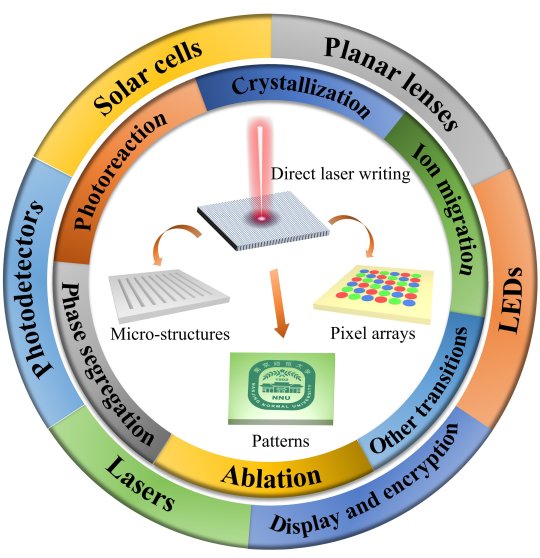

Direct laser writing on halide perovskites: From mechanisms to applications

Metal halide perovskites have become well-deserved "star" materials among a variety of semiconductors owing to their excellent optoelectronic properties, such as high photoluminescence (PL) quantum yield (QY), high absorption coefficient, tunable bandgaps, long carrier diffusion lengths, and high defect tolerance, attracting enormous attention from both academia and industry.

Meanwhile, direct laser writing (DLW), based on the interaction between light and matter, is an efficient, contactless, mask-free, and depth-resolved micro-patterning technique. It is typically performed by coupling a laser beam with a high-resolution microscope to minimize the output focal spot. The resolution of DLW is dependent on the diameter of the output focal spot and the threshold response of the material.

Read more.

8 notes

·

View notes

Text

Permaculture In Action: Water Retention Landscaping

The first priority is to manage water in order to rehydrate soil, reduce the need for irrigation, restore the water cycle, and preserve the soil.

There is a runoff coefficient of roughly 622 gallons per 1,000 square feet of water impervious surface.

Traditional Turf Grasses have a runoff coefficient of 80%- meaning 80% of water runs off the surface of the grass rather than entering the soil.

Soil Percolation Rate (or the water absorption rate of soil) also affects runoff rates and amounts.

The intent of Water Retention Landscaping is to slow water flow, build the area's capacity to hold water, and allow time for the water to replenish as a resource within the area rather than eroding it.

This is from my own notes during the Permaculture in Action class hosted by the Shades of Green Permaculture company. If you found this helpful or interesting, please consider Tipping or Leaving a Ko-Fi (being Disabled, even $1 helps); you can see my other "Original Content" here.

#Original Content#Original Herbal Content#Lawns Aren't Bad Lawn Culture Is#Master Gardeners#Master Gardener#Witch's Garden#Oklahoma#2024#Brandy Hall#Shades of Green Permaculture#Permaculture in Action#Gardening#Gardenblr#Plantblr#Water Priestess

1 note

·

View note

Text

Let's appreciate some cases of Xinyiguang's LED floor screen

Stay at home, go shopping, and walk on the road. Our common floor materials include carpet, wood plank, marble, cement road, asphalt and other types, but no matter how fancy, pattern, and color change, they all have a common feature-slightly "dull". Some people say that it is fun and convenient, just change it frequently. It sounds very embarrassing, you can change the carpet every day, but you can't pry the floor every day.

Have you heard of Xinyiguang LED floor tile screen? Through the LED display, the visual interactive experience is immersive, giving people: the indoor floor tile screen with the experience of "sitting at home, the world is under the feet"; stepping and jumping, and the intelligent interaction of playing and dancing floor tile screen; waterproof and dustproof, super heavy outdoor floor tile screen. It can be tiled on the ground and displayed slowly, or it can be used to create a dreamy and flashing stair screen that climbs up the steps.

Onlooker No. 1: It sounds amazing, do floor tile screens with so many functions really exist?

Onlooker No. 2: Need to be powered on? Is it safe?

Onlooker No. 3: Will it be crushed?

Yes, yes, all of the above! Chinese people don’t lie to Chinese people. The editor of Digital Audio-Video Engineering Network couldn’t stand everyone’s urging, and decided to go to Xinyiguang with everyone to learn about it. It was an eye-opener. Experience the fun of "seeing is owning".

2022 CCTV Spring Festival Opera Gala-P2.976-300 square meters

Shenyang-TV Station-106.25 square meters

Yinchuan-Planning Pavilion-330 square meters

Xinjiang-Museum-P3.91-250 square meters

Zhejiang - Qiandao Lake Tourist Attraction - 240 square meters

Shanghai-Audi Flagship Store-P3.91

Russia - Stavropol - P2.976-288 square meters

Wuhan K11-P6.25 Indoor - 280 square meters

Q&A session

1. Is it safe?

Quiet heat dissipation The power box of the LED intelligent interactive floor tile screen box adopts a die-cast aluminum box with good heat dissipation, and a special heat dissipation device is designed by a professional R&D team to achieve a better silent heat dissipation function.

2. Is it waterproof?

The bottom case, mask, power cord and signal line of the waterproof and moisture-proof LED floor tile screen module are specially designed and equipped with waterproof and moisture-proof materials. They are made of raw materials with low moisture absorption coefficient. The front and back of the body can reach the waterproof level of IP45.

3. Is it reliable?

The anti-slip and wear-resistant LED intelligent interactive floor tile screen mask is made of imported PC materials, which has high wear resistance and flexibility, and good high and low temperature resistance. And designed according to the principle of mechanics, Xinyiguang mask has good anti-slip and load-bearing functions.

4. Is it hard?

Super load-bearing Each component of Yiguang LED intelligent interactive floor tile screen, according to different mechanical designs, has an ultimate load-bearing capacity of up to 3 tons per square meter.

Onlookers 1, 2, and 3: Awesome! Is that brand okay?

Editor: Founded in 2012, Xinyiguang is a professional supplier of global application products and solutions. Xinyiguang has a modern manufacturing plant of 8,000 square meters. The core R&D team has more than 20 years of experience in professional research and development. The company has obtained a number of valid patent certificates and a number of test reports to provide users with high-quality products and services. And in December 2021, it was awarded the "2021 Famous Brand of LED Floor Tile Screen" by Digital Audio Video Engineering Network. The trophy is still warming up, what do you think?

Onlooker No. 1: Wow, it's so powerful, I will arrange a basketball court with LED floor tiles for the village immediately, the cubs in our village must not lose to the next village! Low-key arrangement...

Onlooker No. 2: I heard it a long time ago! We have 4 in our village, 1 each in the east, west, north, and south.

Onlooker No. 3: Tsk tsk tsk, you guys are so naive. I want to arrange a big floor tile screen for the entrance of my house, so that everyone will envy my house!

The indoor LED floor tile screens, intelligent interactive floor tile screens, and outdoor LED floor tile screens developed and produced by Xinyiguang have various installation styles of floor tile screens and stair screens. The product cabinets are made of hard materials such as die-casting aluminum, aluminum plates, and iron. Increase the strength of the box, strong and wear-resistant. It's really good, the boss remembers to stock up for the New Year, because it will be a big hit in 2022!

Read the full article

2 notes

·

View notes

Note

“werewolves have higher body temperatures” is a pretty popular headcanon, but if a werewolf’s body temperature was higher than a human’s, wouldn’t they get colder quicker than humans when it’s cold outside and wouldn’t they get very sweaty when it is just warm outside?

I.... may regret getting so far into the maths of Ruby's wolf size, now my first instinct to fictional werewolf headcanons is to start reading up on thermodynamics....

Don't quote me on that, I'm no scientist, but I believe heat loss and heat production depend on the body's natural core temperature and its metabolic functions to keep it safely constant, which varies from person to person (and human to werewolf).

A human's body reaction and a werewolf's supernatural body reaction to the same temperature aren't equal, as their bodies function differently, require different amounts of energy and preserve, produce or lose heat differently.

Now for an actual quote:

(...)

Our body needs to keep its temperature constant. That means it needs to dissipate heat at the same rate it generates it. But the rate of heat dissipation is determined by the outside temperature and the heat transfer coefficient (this is determined by wind, blood circulation pattern, sweating, clothing, ...). So our body has to modify its processes in response to the outside temperature.

We feel cold, when our body needs to produce more heat to keep its temperature constant. We feel warm when our body needs to either produce less heat, or dissipate it more efficiently (by sweating or changing the blood circulation pattern).

So we feel warm at lower than body temperature, when the natural metabolic rate of our body produces more heat that can be dissipated without extra effort such as sweating.

What we call feeling cold or warm is not a measure of the temperature, it is a signal for our body to modify behavior to keep its temperature constant.

[source]

Think of a fever. A human that, let's say, exceeds that ~36ºC~ range of safe body temperature mighty feel cold, because the body is working to dissipate the heat and bring back the temperature to a healthy state. A human can't self-regulate their temperature past a certain point, so it's a danger to overheat. While it can regulate itself, the body sheds heat and as heat leaves the body, they feel cold.

A werewolf that operates safely and normally at a higher temperature wouldn't dissipate the "extra" heat, because, for them, it's not "extra" — nor dangerous to the same extent it would be to a human.

The kind of heat is their normal. They're using it, the heat is a product of their natural faster metabolism, as energy is required for their supernatural bodies to function at higher levels than a human, making for super strength, speed, stamina, senses, etc.

Another quote:

Heat Production

Heat production is a function of metabolism.

Basal metabolism

Muscle activity, by shivering and muscle contractions

Extra metabolism caused by the effect of sympathetic stimulation and norepinephrine, epinephrine on the cells

Extra metabolism caused by increased chemical activity in the cells, especially when the cell temperature increases

Extra metabolism caused by thyroid hormone and, to a lesser extent, testosterone and growth hormone on the cells

Extra metabolism needed for digestion, absorption, and storage of food

Most of the heat produced in the body is generated in the liver, brain, heart, and skeletal muscles during exercise.

Heat Loss

The rate at which heat is lost is determined almost entirely by:

How rapidly heat transfers from the skin to the surroundings

How rapidly heat is conducted from where it is produced in the body core to the skin

[source]

A werewolf, like a normal wolf, would also have a body better adapted to the cold, being able to keep their body temperature at a comfortable and safe point for longer than a human. Maybe their skin functions differently, keeps them insulted, able to keep heat from dissipating at extremally low temperatures, making them excellent winter creatures.

At the same time, they'd have more productive ways of dissipating excessive heat, when it gets too hot even for them. Yes, sweating included. But also a faster heart beating, faster breathing, all around an even faster metabolism.

Simply put, a human and a werewolf are different, with different biology.

#RL HC#doctor konako at your service#graduated at google search university of fuck round and find out

13 notes

·

View notes

Text

[Current status regarding epilepsy medical procedures vacation. Summation and awareness].

Although it protected against endotoxic shock, this particular ROS-mediated superinduction associated with ATF3 brought on high the likelihood of microbial and also yeast attacks with the reduction of interleukin 6 (IL-6). Because of this, Atf3(-/-) rodents had been resistant to microbe as well as yeast attacks, perhaps underneath conditions regarding ROS anxiety, whilst Atf3(-/-)ll6(-/-) mice were remarkably vulnerable to these microbe infections. Additionally, in a label of SAIS, secondary infections brought on considerably less fatality rate in Atf3(-/-) rodents compared to wild-type rats, indicating that will ROS-induced ATF3 vitally establishes inclination towards second bacterial infections in the course of SAIS.The present study looked into the results of a microinjection involving GABA(A) receptor agonist (muscimol) and antagonist (bicuculline) to the key nucleus of the amygdala (CeA) in sodium-depleted rodents. All of us calculated the particular sea salt absorption along with discovered the actual neuronal initial in the brainstem brought on by activating the GABA(A) receptors inside the CeA employing Fos immunohistochemistry. Muscimol (Zero.30, 0.Thirty five or perhaps 0.55 nmol, throughout 0.A couple of mu t) that's inserted bilaterally into the CeA lowered your 3.Three M NaCl and intake of water within a dose-dependent method. Microinjection regarding Zero.10 ICI-176334 clinical trial nmol/0.Two mu m muscimol furthermore diminished the particular NaCl absorption, but did not have any influence on the water consumption. The particular inhibitory aftereffect of muscimol (2.Twenty nmol) about the salt as well as drinking habits might be blocked by simply pretreatment using bicuculline intra-CeA microinjection (3.Four nmol). Nonetheless, bilateral shots regarding bicuculline by yourself into the CeA did not modify the NaCl or even intake of water. Furthermore, microinjection of muscimol (2.Something like 20 nmol) in to the CeA elevated the amount of Fos-like immunoreactive (FLI) nerves in the caudal and also intermediate aspects of your nucleus of the tractus solitarius (cNTS and also iNTS) and also the side parabrachial nucleus (LPBN). These kinds of final results suggest that Gamma aminobutyric acid(A new) receptors within the CeA may be linked to mediating the actual salt consumption inside the sodium-depleted rat, and the cNTS, iNTS along with LPBN ended up possibly involved with this particular procedure. (d) This year IBRO. Provided by Elsevier Ltd. Almost all legal rights set-aside.Launch: The purpose of this study ended up being to assess the stability as well as credibility with the China version of the Continual Oral Mucosal Ailments Questionnaire (COMDQ). Approaches: A new successive test associated with 190 patients with long-term dental mucosal diseases was enrolled to perform the list of questions following its translation and also cross-cultural adaptation. Your toughness for chinese people version of COMDQ was firm by way of inner regularity and also testretest strategies. The particular create quality associated with COMDQ has been evaluated through exploratory element analysis (EFA). Final results: Cronbach's alpha dog benefit for the overall COMDQ credit score was 2.894, and the testretest intraclass connection coefficient benefit for that total COMDQ rating ended up being Zero.Eighty three. Your EFA extracted four aspects, which in turn landed Sixty seven.89% in the difference. Just about all things demonstrated adequate factor loadings, ranging from 2.

#Inhibitor Library#ATM/ATR inhibitor#Wnt-C59#CH-223191#Colforsin#Alisertib#Puromycin#Elexacaftor#Enasidenib#Dorsomorphin#Z-IETD-FMK#Dolutegravir#Docetaxel#GW4869#Tamoxifen#GSK J4#PLX5622#Blebbistatin#RepSox#Erdafitinib#compound 1#KWA 0711#DUP785#ICI-176334#MK-803#AV-951#PHA-848125#AP1903#Arg-Gly-Asp Peptides#2-MeOE2

1 note

·

View note

Text

1-[9-Ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl]ethanone 1-(O-acetyloxime) CAS#: 478556-66-0

IdentificationPhysical DataSpectraRoute of Synthesis (ROS)Safety and HazardsOther Data

Identification

Product Name1-ethanone 1-(O-acetyloxime)IUPAC Nameethylideneamino] acetateMolecular StructureCAS Registry Number 478556-66-0Synonyms478556-66-0Ethanone, 1--, 1-(O-acetyloxime)ethylideneamino] acetateSCHEMBL514041DTXSID50889185(e)-1-(((1-(9-ethyl-6-(2-methylbenzoyl)-9h-carbazol-3-yl)ethylidene)amino)oxy)ethan-1-oneDB-0158441-ethanone (O-acetyloxime)Molecular FormulaC26H24N2O3 Molecular Weight412.5InChIInChI=1S/C26H24N2O3/c1-5-28-24-12-10-19(17(3)27-31-18(4)29)14-22(24)23-15-20(11-13-25(23)28)26(30)21-9-7-6-8-16(21)2/h6-15H,5H2,1-4H3 InChI KeySEEVRZDUPHZSOX-UHFFFAOYSA-NIsomeric SMILESCCN1C2=C(C=C(C=C2)C(=NOC(=O)C)C)C3=C1C=CC(=C3)C(=O)C4=CC=CC=C4C

Patent InformationPatent IDTitlePublication DateTW2023/34322Infrared absorbing composition, film, optical filter, solid-state imaging element, image display device, infrared sensor, and camera module2023TW2022/48363Composition, film, optical filter, solid-state imaging element, image display device, infrared sensor, camera module, compound, and infrared absorbing agent2022TW2022/29465COLORED COMPOSITION, CURED MATERIAL, COLOR FILTER, SOLID-STATE IMAGE SENSOR, IMAGE DISPLAY DEVICE, AND COMPOUND2022TW2021/4456Photosensitive resin composition, cured film, color filter, solid-state imaging element and image display device2021

Physical Data

AppearanceWhite Powder

Melting Point, °C Solvent (Melting Point) 125.5 - 126.1ethanol

Spectra

Description (NMR Spectroscopy)Nucleus (NMR Spectroscopy)Solvents (NMR Spectroscopy)Frequency (NMR Spectroscopy), MHzChemical shifts1Hchloroform-d1400Chemical shifts13Cchloroform-d1100

Description (IR Spectroscopy)Solvent (IR Spectroscopy)Bandspotassium bromide

Description (UV/VIS Spectroscopy)Solvent (UV/VIS Spectroscopy)Absorption Maxima (UV/VIS), nmExt./Abs. Coefficient, l·mol-1cm-1Spectrumacetonitrilemethanol33723000Spectrumacetonitrile

Route of Synthesis (ROS)

Route of Synthesis (ROS) of 1-ethanone 1-(O-acetyloxime) CAS# 478556-66-0

ConditionsYieldWith boric acid In water; chlorobenzene Solvent; Reflux;Experimental ProcedureWith an electric stirrer,Thermometer, and water separator were charged with 500 ml of chlorobenzene and 85.4 g of water1- (6-o-methylbenzoyl-N-ethylcarbazol-3-yl) -ethanone oxime (0.23 mol)27.6 g of acetic acid(0.46 mol) and 21.3 gBoric acid (0.34 mol) was added, and the mixture was refluxed. After completion of the reaction, carbon was successively usedSodium hydride solution, washing to neutral, adding anhydrous sodium sulfate drying, filtration. The filtrate was evaporated to remove the solventThe semi-solid was crystallized by adding 150 ml of ethanol to give 76.0 g of 1- (6-o-methylbenzoyl-N-Ethylcarbazol-3-yl) -ethanone oxime-O-acetyl, HPLC purity 98.7%, yield 80%80%

Safety and Hazards

Pictogram(s)SignalWarningGHS Hazard StatementsH302 (100%): Harmful if swallowed H317 (100%): May cause an allergic skin reaction Precautionary Statement CodesP261, P264, P270, P272, P280, P301+P317, P302+P352, P321, P330, P333+P317, P362+P364, and P501(The corresponding statement to each P-code can be found at the GHS Classification page.)

Other Data

TransportationUnder room temperature,Sealed and away from lightHS CodeStorageUnder room temperature,Sealed and away from light.Shelf Life1 yearMarket Price

DruglikenessLipinski rules componentMolecular Weight412.488logP6.834HBA3HBD0Matching Lipinski Rules4Veber rules componentPolar Surface Area (PSA)60.66Rotatable Bond (RotB)6Matching Veber Rules2

Use Pattern1-ethanone 1-(O-acetyloxime) CAS 478556-66-0 is a very efficient solid photoinitiator, especially suitable for For applications requiring extremely high photosensitivity. It has higher photosensitivity but slightly less resistance to yellowing. It has an absorption band in the range of 300-400nm, the peak wavelength is 340nm, the absorption edge reaches 400nm, and is sensitive to light at or below the i-line (365nm). And 1-ethanone 1-(O-acetyloxime) has excellent curing performance in high-pigment photoresist formulations, often used in colored photoresists (RGB glue) and black photoresists (BM glue):In addition, it can also be used in photosensitive polyimide formulations , LCD isolation materials, microlens materials, outer coatings, dielectric layers and insulating layers.It is highly soluble in solvents such as propylene glycol monomethyl ether acetate (PGMEA) and cyclohexanone, which are commonly used in color filter photoresists.

Read the full article

0 notes

Text

Selecting Energy-Efficient Windows and Doors: A Comprehensive Guide

Are you prepared to upgrade your doors and windows to more energy-efficient options but find yourself uncertain about the associated terminology? If the fear of making the wrong decision is holding you back, worry no more.

This comprehensive guide is designed to enlighten you on the intricacies of selecting energy-efficient windows and doors. Beginning with the clarification of common terminology and accompanied by valuable tips, we present a systematic approach to help you make the ideal choice for your property.

To kick things off, let's start by clearly defining what constitutes energy-efficient windows and doors.

Grasping the Concepts of Energy-Efficient Windows and Doors

In the realm of doors and windows, the concept of 'energy efficiency' revolves around optimizing energy consumption to achieve greater output with fewer resources. This entails reducing the amount of energy needed to heat or cool your home, ultimately leading to savings on electricity bills and the potential elimination of additional costs associated with fans or electric heaters.

Opting for the finest energy-efficient windows and doors yields a multitude of enduring advantages, such as:

Lower Energy Costs:

By minimizing the energy required for temperature regulation, these windows and doors contribute to substantial reductions in overall energy expenditures.

UV Ray Reduction:

Energy-efficient windows act as a barrier against harmful UV rays, safeguarding the interior of your home and its occupants from potential health risks.

Higher ROI for Resale:

Investing in energy-efficient features enhances the market value of your property, attracting environmentally-conscious buyers and leading to a higher return on investment when you decide to sell.

Additional Discounts and Tax Benefits:

Many regions offer incentives for incorporating energy-efficient elements in homes, ranging from tax credits to rebates, providing additional financial perks.

Improved Interior Comfort:

These windows and doors create a more comfortable living environment by maintaining consistent indoor temperatures, reducing drafts, and enhancing overall insulation.

Choosing energy-efficient windows and doors is not just a cost-effective decision but a holistic investment that positively impacts both your immediate living conditions and the long-term value of your property.

Essential Insights on Energy-Efficient Windows and Doors

Before embarking on the quest for energy-efficient windows and doors, it's essential to familiarize yourself with key terminologies associated with energy efficiency.

Here are some prevalent terms and phrases to guide you:

Glazed Windows and Doors:

The term "glaze" in the context of windows and doors pertains to the number of panes within the frame. Single-glazed windows have one pane, while double-glazed windows feature two, and so forth. Single-glazed windows offer modest energy benefits and are not recommended for extreme temperature variations.

Double-Insulated Windows and Doors:

Specifically engineered to diminish energy expenses and reduce noise pollution, double-insulated windows and doors excel in less predictable environmental conditions.

Low-E Glass:

Low-E (Low Emissivity) glass coating serves to diminish UV rays and infrared light infiltrating your property. Research indicates that it can enhance energy efficiency, reducing energy loss by up to 50%.

Solar Heat Gain Coefficient (SHGC):

SHGC measures a window or door's resistance to solar heat. A low SHGC rating signifies that windows and doors reflect more heat, maintaining a cooler interior. Conversely, a higher SHGC rating suggests greater heat absorption, making it suitable for colder climates.

U Value:

U-value serves as an indicator of how effectively glass retains warmth. It gauges how rapidly heat moves through the glass from warm air (excluding sunlight). A lower U-value signifies superior insulation, making glass with a low U-value ideal for trapping indoor warmth, especially in colder climates or during nighttime.

Understanding both the U-value and Solar Heat Gain Coefficient (SHGC) is pivotal when evaluating windows and doors. While the U-value assesses the insulation against heat transfer, the SHGC evaluates a window's capability to resist solar heat. These factors collectively contribute to making informed decisions in your pursuit of energy-efficient windows and doors.

Choosing Optimal Energy-Efficient Windows and Doors: A Guide

Not all energy-efficient windows and doors are created equal. As you explore your choices and narrow down your selection, it's crucial to consider three specific factors: cost, location, and style.

Consider the Cost:

The level of energy efficiency in a glass pane is directly proportional to its cost. While more energy-efficient windows and doors may have a higher initial purchase price, they can result in savings of up to 12% on energy expenses annually.

Evaluate Your Location:

The choice of energy-efficient windows and doors should be influenced by your geographical location. For instance, if you reside in a colder region of Australia, opting for glass with a higher Solar Heat Gain Coefficient (SHGC) might be beneficial. Conversely, in warmer areas, a lower SHGC may suffice. Regardless of location, the advantages of low-E and double-glazed glass apply universally.

Situate Your Style:

Energy-efficient windows come in various styles, and your personal preferences play a key role in the selection process. Exploring different styles, such as awning windows, sliding doors, casement windows, and aluminium doors Adelaide, allows you to find the one that aligns with your aesthetic preferences.

Popular energy-efficient choices in South Australia include:

Awning Windows

Sliding Doors

Casement Windows

Aluminium Doors

If you find yourself unsure about the myriad options and where to begin, seeking guidance from professionals, such as Adelaide Designer Windows, can assist you in making an informed decision tailored to your specific needs and preferences.

Selecting Optimal Energy-Efficient Windows and Doors: Your Guide with Adelaide Designer Windows

We stand out as a forward-thinking company dedicated to the advancement of window and door solutions with a focus on contemporary architectural design. Our repertoire includes an extensive array of energy-efficient options tailored for the discerning Australian consumer. From cutting-edge double-glazed glass to meticulously crafted aluminium frames, our offerings are meticulously designed to not only reduce energy bills but also contribute to the creation of a more sustainable environment.

0 notes

Text

Do sound absorbing ceiling panels truly muffle sound?

If you are looking forward to muffle sound in your commercial or home space, you are possibly already aware of how sound absorbing ceiling panels can assist. But perhaps you are not sold on the advantages of sound muffling products such as ceiling panels. Keep reading and learn whether acoustic panels can truly muffle sound and you can use them in your space.

Absorption vs. Muffling vs. soundproofing

There are many terms that fly around when you are researching on sound proofing tiles. Noise reduction coefficients, absorption coefficients, ceiling attenuation class and so on. The jargon may start to sound like a physics lesson. But it is not truly that complicated when you reach down to it. You don’t have to understand precisely how sound reflection and waves work to realize that acoustic panels can be beneficial.

To muffle sound is just to prevent it from echoing, or bouncing back so it can be heard again. Muffling and absorption are similar concepts, and soundproofing is not truly all that different either. The difference among the term is how effective a substance is. For the things we are discussing, it doesn’t matter to a soundproofing company.

Do acoustic ceiling panels truly muffle sound?

Yes, absolutely! Think about the terms “absorb” and “Muffle” as synonyms and interchangeable words in respect to acoustic ceiling panels. The way acoustic ceiling panels work is not precisely rocket science.

Acoustic ceiling tiles from Noisemaster are beneficial in spaces where you don’t want a reverberation, so they are frequently installed in lobbies, offices and other places where people talk and have to hear each other clearly. Residentially, they are an excellent option for basements as they can conveniently cover wiring and pipes. Therefore, acoustic ceiling panels are just excellent for sound, and they are also aesthetically impressive.

0 notes

Text

Best Practices for Marine Engine Room Insulation

Marine engine rooms are the powerhouse of ships and vessels, housing crucial machinery and systems essential for propulsion and operation. However, the harsh conditions within these engine rooms pose significant challenges to personnel safety, comfort, and equipment reliability. To address these challenges, marine engine room insulation plays a pivotal role by mitigating factors such as excessive heat, noise pollution, and exposure to hazardous substances.

Factors to Consider in Marine Engine Room Insulation

Thermal Conductivity: Thermal conductivity refers to the ability of a material to conduct heat. In the confined space of an engine room, effective insulation with low thermal conductivity is essential to regulate temperature levels. By minimizing heat transfer, insulation helps maintain optimal operating conditions for machinery and creates a comfortable working environment for personnel.

Sound Absorption: Engine rooms are inherently noisy environments due to the operation of engines, pumps, and other machinery. Excessive noise not only contributes to worker discomfort but also poses risks to hearing health and overall safety. Insulation materials with high sound absorption coefficients are critical for attenuating noise levels, reducing reverberation, and creating a quieter work environment conducive to concentration and communication.

Fire Resistance: The potential for fire hazards in marine engine rooms is a significant concern, given the presence of flammable fuels, lubricants, and electrical equipment. Insulation materials with robust fire resistance properties are vital for containing fires and preventing their spread in the event of an ignition. Additionally, fire-resistant insulation contributes to compliance with maritime safety regulations and enhances the overall fire protection strategy on board.

Environmental Impact: With growing awareness of environmental sustainability, the choice of insulation materials must consider their environmental impact. Avoiding materials containing harmful substances such as asbestos and selecting eco-friendly alternatives promotes responsible stewardship of marine ecosystems and reduces the carbon footprint of vessel operations. Sustainable insulation solutions align with industry trends toward green shipping and demonstrate a commitment to environmental responsibility.

Common Insulation Materials

Mineral Wool: Mineral wool, derived from molten rock or slag, offers excellent thermal and acoustic insulation properties. Its fibrous structure traps air pockets, providing effective thermal resistance while absorbing sound waves. Mineral wool insulation is non-combustible, making it a preferred choice for fire safety in engine rooms. Furthermore, its versatility and affordability make it a popular option for marine applications where durability and performance are paramount.

Glass Wool: Glass wool insulation, manufactured from molten glass spun into fibers, shares similarities with mineral wool but offers enhanced thermal and acoustic performance. Its lightweight composition and flexibility facilitate ease of installation in tight spaces, while its high temperature resistance ensures long-term durability in marine environments. Despite being slightly more expensive than mineral wool, glass wool’s superior insulation properties justify its adoption in critical areas of engine room insulation.

Foam Insulation: Foam insulation encompasses a variety of materials, including polyurethane, polystyrene, and polyethylene, each offering unique advantages for marine applications. Polyurethane foam, known for its high thermal resistance and moisture resistance, is suitable for insulating pipes, ducts, and equipment components within engine rooms. Polystyrene foam, with its lightweight and cost-effective nature, provides effective thermal insulation in bulkheads and wall panels. Polyethylene foam, characterized by its closed-cell structure, offers superior moisture resistance and buoyancy, making it ideal for insulating marine vessels’ hulls and decks.

Elastomeric Insulation: Elastomeric insulation, composed of synthetic rubber compounds, exhibits remarkable flexibility, resilience, and resistance to oil and chemicals. These properties make it particularly well-suited for insulating pipes, valves, and machinery components in engine rooms exposed to corrosive substances. Elastomeric insulation’s ability to withstand extreme temperatures and environmental conditions ensures long-term performance and reliability, contributing to the overall efficiency and safety of marine propulsion systems.

Installation Guidelines

Proper installation practices are essential to maximize the effectiveness of marine engine room insulation:

Thoroughly clean and prepare surfaces before applying insulation to ensure adhesion and prevent contamination.

Seal joints, seams, and penetrations with compatible sealants or tapes to minimize air leakage and enhance insulation integrity.

Utilize mechanical fasteners, adhesives, or clamping systems suitable for marine environments to secure insulation in place and prevent displacement.

Follow manufacturer recommendations regarding installation techniques, including curing times, temperature ranges, and safety precautions to achieve optimal insulation performance and durability.

Maintenance and Inspection

Regular maintenance and inspection of marine insulation are critical to identifying potential issues and ensuring ongoing performance:

Conduct routine visual inspections to check for signs of damage, degradation, or wear, such as cracks, tears, or discoloration.

Perform thickness measurements and thermal imaging scans to assess insulation integrity and identify areas of insufficient coverage or deterioration.

Promptly repair or replace damaged insulation materials to maintain thermal efficiency, acoustic performance, and fire resistance in engine room environments.

Schedule periodic maintenance intervals to coincide with other routine servicing activities, such as machinery inspections or system checks, to minimize downtime and optimize operational efficiency.

Benefits of Marine Engine Room Insulation

The installation of high-quality insulation in marine engine rooms delivers a multitude of benefits:

Enhanced Safety: Effective insulation mitigates fire risks, reduces noise exposure, and protects personnel from hazardous substances, enhancing overall safety and well-being on board vessels.

Improved Comfort: By regulating temperature levels and reducing noise pollution, insulation creates a more comfortable and conducive working environment for crew members, improving morale and productivity.

Extended Equipment Lifespan: Insulation protects critical machinery and equipment from thermal stress, vibration, and corrosion, prolonging their operational lifespan and reducing maintenance costs.

Energy Efficiency: By minimizing heat loss or gain, insulation contributes to energy conservation and operational efficiency, resulting in reduced fuel consumption and lower emissions during vessel operation.

Conclusion

In summary, marine engine room insulation is an indispensable component of shipboard systems, providing thermal, acoustic, and fire protection benefits essential for safe and efficient vessel operation. By considering factors such as thermal conductivity, sound absorption, fire resistance, and environmental impact, alongside proper installation, maintenance, and inspection practices, shipowners and operators can optimize insulation performance and realize the full spectrum of advantages it offers. Investing in high-quality insulation solutions not only enhances operational reliability and crew comfort but also reinforces a commitment to safety, sustainability, and regulatory compliance in the maritime industry.

Original Source: https://oceanstar-me.com/best-practices-for-marine-engine-room-insulation/

0 notes

Photo

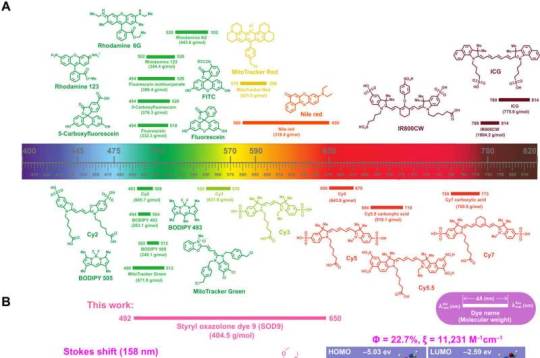

Bioinspired molecular dyes for biomedical fluorescent imaging

Fluorescence imaging can be conducted with long Stokes shift dyes that minimize crosstalk between the excitation source and fluorescent emission to improve the signal-to-background ratio. Regardless, researchers still form simple, small molecule dyes with large Stokes shift and near infrared emissions. In a new report now published in Science Advances, Hao Chen and a team of scientists developed a series of styrene oxazolone dyes (SODs) using simple synthetic methods inspired by the chromophore chemical structure of fluorescent proteins.

The dyes showed near-infrared emissions with long Stokes shift and small molecular weight. The most promising dyes also showed rapid renal excretion and blood-brain barrier passing properties. The bioengineers modified the compounds for tumor imaging, fluorescence image-guided surgery, neurosurgery and pathological analysis. The findings contribute an essential small molecular dye category to the classical dyes.

Developing long Stokes shift dyes

Fluorescence imaging is widespread in preclinical biomedical research, as well as clinical pathology and fluorescence image-guided surgery. The low cost, easy platform offers minor light damage to the biological specimen for high detection sensitivity. The biomedical application of fluorescent imaging depends on the dyes with critical features, including absorption/emission profiles, absorption coefficient, quantum yield, Stokes shift, and photochemical stability.

Read more.

28 notes

·

View notes

Text

Teflon Envelope Gaskets D&d Engineered Merchandise Inc

Often used as a seal for steam and scorching valves, taylor ring gaskets are minimize from quite a lot of sheet metals and shaped into corrugated concentric rings. Often found in sulfuric acid plants, Durlon® 9000 Step Ring Gaskets are capable of withstanding the thermal biking and aggressive chemical corrosion, making them the best gasket resolution. Gasket Resources Inc. improved the step ring gasket from its unique “glued” design by using a CNC machine to chop one strong piece to stop the potential of gasket separation. Filled PTFE – PTFE with graphite (carbon), glass and mineral – we source by buyer requirement if another fillers are required. Glass fibre is commonly added in several percentages and completely different fibre lengths, usually glass fibre will increase put on resistance with less deformation beneath load, creating a tougher material with lower thermal enlargement. The Federal Institute for Materials Research and Testing (BAM) tests the sealing material compatibility to be used in flanged connections with liquid and gaseous oxygen.

Gaskets can be found as standard DIN,ANSI, JIS size flanges and can be manufactured to suit any bespoke size or shape. Bronze Filled PTFE – Using Bronze powder as an additive from between 40% and 60% improves wear resistance. It does unfortunately reduce chemical inertness however then again it does tremendously improve hardness and compressive energy, and in addition provides higher dimensional stability and reduces creep and chilly circulate. Most TFCO products are made in the USA at our manufacturing facility in La Porte, IN, located about 50 miles southeast of Chicago. Various different fillers, such as ceramic, bronze, or polymeric materials, can be utilized further to tailor the properties of PTFE gaskets for specific applications. Available in varied types, such as sheet gaskets, spiral wound gaskets, and moulded gaskets, PTFE gaskets offer versatility and ease of installation, enabling seamless integration into complex sealing functions.

Expanded PTFE is much softer and extra flexible than regular PTFE gaskets and thus conforms simply to irregular and rough surfaces. PTFE sheetsVirgin PTFE sheet, incessantly misidentified as Teflon sheet, is a excessive efficiency thermoplastic with a very low moisture absorption price, an incredibly low coefficient of friction, and good dielectric energy. PTFE sheet is made from a fluoropolymer with low friction and exceptional chemical and weather resistance. PTFE sheets are obtainable in various sizes and thicknesses ranging from 6 to one hundred fifty mm. In sealing, PTFE gaskets are a beacon of excellence and dependability.

ptfe gasket sheets

In current years, advancements in PTFE gasket technology have led to revolutionary options that address common sealing challenges. One notable pattern is the development of modified PTFE gaskets, which incorporate specialized fillers or reinforcements to boost efficiency characteristics. These fillers, such as glass fibres or graphite, enhance the gasket's resilience, dimensional stability, and ability to resist larger pressures and temperatures. Solid PTFE gaskets without fillers offer excellent chemical resistance and low friction properties. Highly versatile and conformable gaskets with wonderful chemical resistance. The material features distinctive resistance to a variety of environments, which makes our product highly versatile.

Our mission is to be considered a thought leader and skilled manufacturer in hydraulic and pneumatic sealing merchandise. We are capable of present our prospects with technical expertise and innovation capabilities to ensure they obtain the highest quality sealing solutions, quick. Comprising preformed rings of chevron shaped layers of steel and filler material, spiral wound gaskets are often utilized in larger pressure functions. PTFE can be able to maintain it is useful properties in temperatures as little as -200°C and as high as 260°C. This ensures our gaskets provide constant efficiency, and a superior life expectancy compared to comparable gaskets. Gasket Resources Inc. supplies timely and accurate manufacturing facility fabricated minimize gaskets, welded gaskets, and sheet merchandise obtainable for quite so much of industries.

GORE GR Sheet Gasketing is a troublesome, dimensionally-stable and chemical-resistant gasket sheet for sealing steel pipe and tools flanges in a broad range of applications and course of situations. It reliably seals flanges with rough surfaces, and is good for flanges that require complicated gasketing shapes or larger gasketing sizes. Multi-directional ePTFE gasket material TEADIT® 24 SH TEADIT® 24 SH is a gasket sheet produced from pure, multidirectionally expanded PTFE. A particular production course of ensures equal tensile strength in all instructions. This makes gaskets cut from TEADIT ® 24 SH probably the greatest, most versatile and most reliable gasket supplies in the marketplace. Cold circulate and creep have been eliminated, gasket parameters have been drastically improved, whereas all the superb bodily properties of PTFE have been fully retained.

1 note

·

View note

Text

Factors Influencing the Production Benefits of Feed Pellet Machines

Due to challenges in process design and operational technology, the feed factory faced issues with the quality and output of its finished products. The particles exhibited uneven surfaces, high powder content, brittleness, and inconsistency. A comprehensive practical analysis revealed several critical factors influencing granulation efficiency:

Raw Materials:

Starch Content: High starch content facilitates gelatinization, which, when combined with proper conditioning, creates a conducive, viscous state for effective molding.

Crude Fiber: Elevated crude fiber increases friction in the ring die. The addition of a specific amount of grease aids material passage through the die hole and enhances the surface finish of the final product.

Crushing Diameter: Optimal crushing diameters vary based on raw materials. For instance, using a 2.5-3mm sieve plate is recommended for crushed corn in livestock and poultry feed.

Feed Control:

Comprehensive Monitoring: During periods of reduced production efficiency, addressing pelleting issues alone is insufficient. Comprehensive monitoring of incoming material control is crucial.

Production Operation:

Precise Adjustments: Fine-tuning each part of the poultry feed pellet machine, including the die and pressure roller (controlled at 0.05~0.30 mm), prevents issues such as excessive noise and ensures optimal material granulation.

Gap Control: Maintaining a controlled gap of 2-3 mm between the upper edge curve of the scraper and the die and die cover is critical for smooth pellet feed machine operation.

Start-Up Observations: Careful observation during start-up helps identify irregularities in particle discharge. Preventing the introduction of contaminants into the die contributes to a more efficient granulation process.

Ring Die:

Factors Influencing Material Ejection: Factors like the friction coefficient between the material and the die wall, moisture content, particle size, temperature, plasticity, and compressibility influence the smooth ejection of material.

Conditioning Factors:

Blade Wear Impact: Worn conditioner blades negatively impact material conditioning, affecting particle output and steam absorption.

Material Softening: Proper softening of conditioner material is crucial for achieving the desired pulverization rate and output.

Temperature Control: Specific temperature recommendations, like 70~88°C for livestock and poultry feed, optimize conditioning effects.

Steam Factor:

Steam Conveyance Challenges: Saturated steam entry during conveying results in energy loss and condensed water formation, negatively affecting conditioning.

Condensed Water Management: Discharging condensed water before conditioning and converting it into low-pressure dry hot steam through a pressure-reducing valve enhances conditioning effects.

Pressure and Temperature Control: Maintaining steam pressure above 0.2 MPa and a temperature not lower than 120 ℃ post-decompression ensures an optimized conditioning process.

By addressing these factors systematically, the feed factory can optimize the performance of the feed pellet machine, improving product quality and increasing overall output.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Phone/Whatsapp: 0086-18037508651

0 notes

Text

1-[4-(Phenylthio)phenyl]-1,2-octanedione 2-(O-benzoyloxime) CAS#: 253585-83-0

IdentificationPhysical DataSpectraRoute of Synthesis (ROS)Safety and HazardsOther Data

Identification

Product Name1--1,2-octanedione 2-(O-benzoyloxime)IUPAC Nameamino] benzoateMolecular StructureCAS Registry Number 253585-83-0MDL NumberMFCD12911795Synonyms253585-83-01,2-Octanedione, 1-(4-(phenylthio)phenyl)-, 2-(O-benzoyloxime)1,2-Octanedione, 1--, 2-(O-benzoyloxime)amino] benzoate1--1,2-octanedione 2-(O-benzoyloxime)amino] benzoateDTXSID1074969SB66345NS00077818(Z)-{1-OXO-1-OCTAN-2-YLIDENE}AMINO BENZOATEMolecular FormulaC27H27NO3S Molecular Weight445.6InChIInChI=1S/C27H27NO3S/c1-2-3-4-11-16-25(28-31-27(30)22-12-7-5-8-13-22)26(29)21-17-19-24(20-18-21)32-23-14-9-6-10-15-23/h5-10,12-15,17-20H,2-4,11,16H2,1H3InChI KeyLOCXTTRLSIDGPS-UHFFFAOYSA-NIsomeric SMILESCCCCCCC(=NOC(=O)C1=CC=CC=C1)C(=O)C2=CC=C(C=C2)SC3=CC=CC=C3

Patent InformationPatent IDTitlePublication DateTW2023/34322Infrared absorbing composition, film, optical filter, solid-state imaging element, image display device, infrared sensor, and camera module2023CN115260066Method for preparing oxime ester compound from supercritical carbon dioxide2022TW2022/48363Composition, film, optical filter, solid-state imaging element, image display device, infrared sensor, camera module, compound, and infrared absorbing agent2022TW2021/4456Photosensitive resin composition, cured film, color filter, solid-state imaging element and image display device2021US2020/392343COMPOSITION, CURED PRODUCT, COLOR FILTER, METHOD FOR PRODUCING COLOR FILTER, SOLID-STATE IMAGING ELEMENT, IMAGE DISPLAY DEVICE, AND COMPOUND2020

Physical Data

AppearanceOff-white or light yellow powder

Melting Point, °C 42

Spectra

Description (NMR Spectroscopy)Nucleus (NMR Spectroscopy)Solvents (NMR Spectroscopy)Chemical shifts1Hchloroform-d1

Description (UV/VIS Spectroscopy)Solvent (UV/VIS Spectroscopy)Absorption Maxima (UV/VIS), nmExt./Abs. Coefficient, l·mol-1cm-1Absorption maximaH2O, NaOHmethanol32629500326Absorption spectrum

Route of Synthesis (ROS)

Route of Synthesis (ROS) of 1--1,2-octanedione 2-(O-benzoyloxime) CAS# 253585-83-0

ConditionsYieldWith triethylamine In chloroform at 0℃; for 2h; Reagent/catalyst; Solvent;Experimental Procedure2.c c. Preparation of 1-diphenyl sulfide-1-cyclopentylacetone oxime benzyl esterA four-necked flask equipped with a motor-driven stirrer and a thermometer was charged with 102.4 g of diphenyl sulfide cyclopentylacetone oxime (0.30 mol)1200 ml of chloroform,39.5 g of triethylamine (0.39 mol),Stir well,After cooling to 0 ° C, a mixed solution of 50.6 g of benzoyl chloride (0.36 mol) and 50 g of chloroform was added dropwise.After completion of the addition, stirring was continued for 2 hours,1500 ml of cold water was added dropwise,Layered,Once with 500 ml of saturated sodium bicarbonate solution,500 ml of water,1000 ml of 0.5 N hydrochloric acid,500ml washing,Dried over 300 g of anhydrous magnesium sulfate,Filtration,The filtrate was evaporated to remove the solvent,A viscous liquid was obtained.To this was added an appropriate amount of ethanol,To precipitate white solid 1-diphenyl sulfide 1-cyclopentyl acetone oxime benzyl ester, filtration, drying product 104.2g, yield 78%, purity greater than 98%.78%With triethylamine at 20℃;Experimental ProcedureAdd the triethylamine of 121g,Control the reaction temperature within 10°C, Start stirring, continue to add the benzoyl chloride of 155g; After joining, Warming up to room temperature and continuing the reaction to the end; At room temperature, the reaction solution after the reaction was washed three times with 300 g of ice water;Atmospheric pressure reclaims dichloromethane to dry afterwards;Then add 1080g isopropanol for recrystallization,Filter, dry, finally obtain the OXE01 product of 346g,Has the structure shown in formula 1-1;Yield 78%,The purity is above 99%.78%

Safety and Hazards

Pictogram(s)SignalWarningGHS Hazard StatementsH317 (100%): May cause an allergic skin reaction Precautionary Statement CodesP261, P272, P280, P302+P352, P321, P333+P317, P362+P364, and P501(The corresponding statement to each P-code can be found at the GHS Classification page.)

Other Data

TransportationHS CodeStorageSealed and protected from light, store at 25°CShelf Life1 yearMarket Price

DruglikenessLipinski rules componentMolecular Weight445.582logP8.662HBA2HBD0Matching Lipinski Rules3Veber rules componentPolar Surface Area (PSA)81.03Rotatable Bond (RotB)12Matching Veber Rules1

Use Pattern1--1,2-octanedione 2-(O-benzoyloxime) CAS 253585-83-0 is a highly efficient photoinitiator, especially suitable for applications requiring high photosensitivity and low yellowing. It has an absorption band in the range of 300-400nm, the peak wavelength is 325nm, the absorption edge reaches 400nm, and it is sensitive to light at or below the i-line (365nm). Highly soluble in solvents such as propylene glycol monomethyl ether acetate (PGMEA) and cyclohexanone, which are commonly used in color filter photoresists.1--1,2-octanedione 2-(O-benzoyloxime) has excellent curing properties in highly pigmented photoresist formulations and is commonly used in color filter photoresists and black matrix photoresists. In resist (BM glue): In addition, it can be used in photosensitive polyimide formulations, LCD isolation materials, microlens materials, outer coatings, dielectric layers and insulating layers.

Read the full article

0 notes