Text

Relays in Automation: Electromechanical Solutions for Complex Control Tasks

In the realm of industrial and marine automation, reliability, precision, and efficiency are paramount. Complex control tasks demand sophisticated solutions, and one such crucial component that plays a pivotal role in achieving these goals is the relay. Relays have been a cornerstone of automation for decades, offering a dependable bridge between the digital and physical worlds. This blog post delves into the world of relays, their essential functions, applications, and why you should consider them for your automation needs.

The Heart of Automation

Relays are the essential building blocks of automation, serving as electromechanical switches that enable the control of high-power electrical circuits with low-power signals. These devices have been the cornerstone of industrial automation for decades, providing a reliable means of controlling complex systems with precision. They operate based on a simple yet ingenious principle: the conversion of an electrical signal into a mechanical action.

A relay consists of a coil and a set of contacts. When an electrical current flows through the coil, it generates a magnetic field that either attracts or repels a movable contact. This action opens or closes the circuit connected to the relay's contacts. In essence, a relay serves as an intermediary, allowing a small control signal to exert control over a much larger electrical load. This capability makes relays indispensable for applications where precision control and isolation of electrical circuits are critical.

The Role of Relays in Industrial Automation

Industrial automation encompasses a vast array of applications, from manufacturing and processing to robotics and quality control. In this context, relays play a pivotal role in ensuring the smooth operation of machinery and systems. One of their primary functions is to provide electrical isolation, safeguarding sensitive control circuits from high-voltage or high-current environments. This isolation helps prevent electrical interference and enhances the overall reliability of the system.

Moreover, relays offer precise control over the timing and sequencing of operations, making them ideal for applications that require synchronization. For instance, in a production line, relays can coordinate the activation of different components and ensure that they work together seamlessly. This level of control is crucial in achieving efficiency and consistency in industrial processes.

Types of Relays and Their Applications

Relays come in various types, each tailored to specific applications. Some of the most common types include:

Electromagnetic Relays: These relays use an electromagnetic coil to control the switching action. They are widely used in industrial automation for applications like motor control, lighting control, and safety interlocks.

Solid-State Relays: Unlike electromagnetic relays, solid-state relays use semiconductor components to switch electrical circuits. They are preferred for applications requiring fast switching, high reliability, and long service life.

Time Delay Relays: These relays introduce a time delay between the actuation of the coil and the switching action. They are indispensable for applications such as time-based control and motor soft-start circuits.

Latching Relays: Latching relays maintain their state even after the control signal is removed. They are suitable for applications where power consumption is a concern, as they don't require a continuous control signal.

The choice of relay type depends on the specific requirements of the automation task at hand. For instance, solid-state relays are often used in high-speed automation, while electromagnetic relays are preferred in applications requiring high current switching.

0 notes

Text

Remote Access and Monitoring: Taking Advantage of Networked PLCs

In today’s rapidly evolving industrial landscape, efficiency is key to staying competitive. Industrial automation has been a game-changer, and at the heart of this revolution are Programmable Logic Controllers (PLCs). These versatile devices have become indispensable in controlling machinery and processes, but their full potential is only realized when combined with remote access and monitoring…

View On WordPress

0 notes

Text

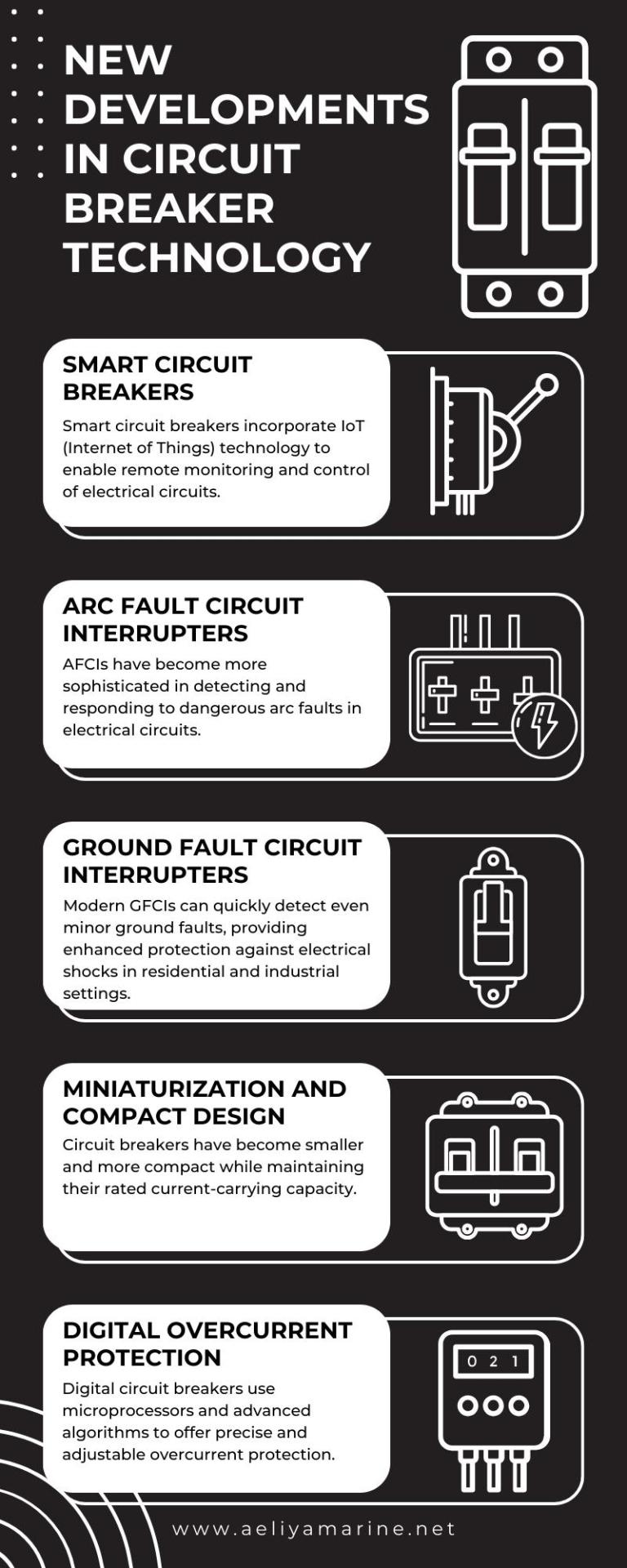

New developments in circuit breaker technology

Recent breakthroughs in circuit breaker technology have ushered in a new era of electrical safety and efficiency. Innovations include smart circuit breakers with remote control capabilities, advanced arc fault and ground fault protection, miniaturized designs for space-saving solutions, digital overcurrent protection for precision, and energy management features for improved efficiency. These developments enhance the reliability and intelligence of electrical systems, making them safer, more responsive, and better equipped for the demands of modern living and industry.

0 notes

Text

Getting the Most Out of Your Industrial Indicators

Explore the journey towards operational excellence through the informative infographic, 'Unlocking the Full Potential of Industrial Indicators.' This resource guides individuals in selecting, monitoring, and effectively utilizing industrial indicators. It empowers users to leverage data-driven insights, establish clear objectives, and continually refine processes for optimized performance and successful achievement of business objectives.

0 notes

Text

How Automation Increases Workplace Productivity and Safety

Fewer delays: Robots eliminate delays caused by human error or injury by performing many repetitive and strenuous jobs in material handling applications or on the production floor. Robots don't get bored or distracted while working, so consistent performance can be expected. This also means fewer wasted resources due to mistakes.

More data: With automated systems, it's easier for managers to calculate exactly how productive their facilities are. Rather than relying solely on what they see, managers can receive detailed metrics automatically from their equipment. This actionable information can be used to make adjustments and rework processes.

Enhanced management: Because robotic systems handle most tasks without intensive supervision, managers don't need to spend as much time micromanaging. This lets them focus on other aspects of their jobs, such as mentoring employees and guiding their professional development.

Accident prevention: Self-driving forklifts and other automated machinery deployed in manufacturing or material-handling applications prevent incidents caused by human operators' mistakes. They lessen the odds that injuries will occur due to mishandling or misuse of heavy equipment. Without having to do much heavy lifting on their own, workers also are at lower risk of being hurt or putting excess stress on their bodies.

0 notes

Text

The Fourth Industrial Revolution

The First Industrial Revolution was marked by the introduction of steam and water powered machines, which led to the mechanization of production. The Second Industrial Revolution was driven by electricity, gas, and oil, and it saw the introduction of new technologies such as cars, telephones, and telegraphs. The Third Industrial Revolution, also known as the Digital Revolution, was marked by the introduction of computers and robots, which transformed manufacturing.

The Fourth Industrial Revolution is still in its early stages, but it has the potential to revolutionize every aspect of our lives. It is already having a major impact on industries such as manufacturing, healthcare, and transportation. As these technologies continue to develop, they will likely have a profound impact on the global economy and society as a whole.

0 notes

Text

-300-0-490 Mmaq 4-20 Ma

-300-0-490 Mmaq 4-20 Ma

-300-0-490 Mmaq

4-20 Ma

Cat.: Iii.

600v

Weight : 850 Gm

Ref No : 82078

0 notes

Text

Argo Hytos Rpe3-043y11/02400e1k1 Directional Valve

Argo Hytos Rpe3-043y11/02400e1k1 Directional Valve

Argo Hytos

Rpe3-043y11/02400e1k1

486-0304

0712/01

Pmax P,a,b=320 Bar

Pmax T=210 Bar

24 Vdc 100%ed 1,16a

936-0026 0711/04

Xref: X200386560

Mat#: 552199

Part#: 2013340

Manf: Huisman Equipment Bv

Desc: Valve, Directional 4/3 Ng04

Made In Czech Republic

Weight : 1.300 Kg

Condition : New 2 Pcs

Ref No : 61163

0 notes

Text

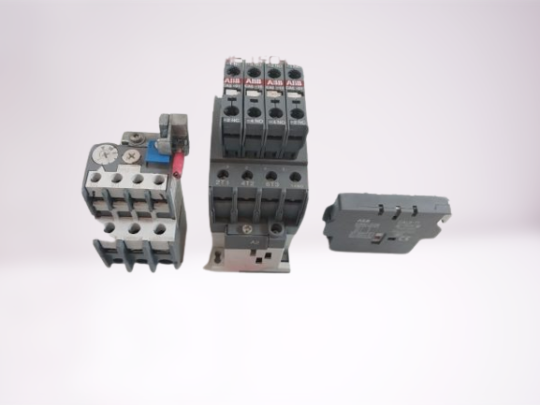

Abb A26 Contactor Auxiliary Contact Block Cal5-11 With Ta25 Du Thermal Overload Relay

Abb A26 Contactor Auxiliary Contact Block Cal5-11 With Ta25 Du Thermal Overload Relay Abb Stotz-kontakt Gmbh Ca5-01 Ca5-10 Cal5 Cal5-11 6-8,5 A Ui=690v~ Ith=16a Iec 60947-5-1 En 60947-5-1 A005135 A600 Q300 Awg 12-16 Cu Str/sol 60/75°c Torque 7-9lb.in-0,8-1 N.m A26 Ui=1000v~ Ith=45a Ieac-1=45a Iec 60947-4-1 En 60947-4-1 600vac Max. Breaking All Lines Continuous Current: 40a Awg 8-12 Cu Str75°c Torque 15 Lb.in-1.7nm Aux.cont. A600 P300 Use With Ta25 Series Overload Relays Ii (2)g Ptb 02 Atex 3045 Ta25 Du En/iec 60947-4-1/-5-1 Trip Class 10a/ui=690v Trip.curr.is 125% Of F.l.c. Iec 60947-4-1 600 Vac/class 10 A001546 Same Polarity Above 300v No C600 Nc B600 220-230v 50hz 230-240v 60hz R80 Made In France Made In Czech Republic Weight : 830 Gm Ref No : 76470

0 notes

Text

Kuramoto Pac-1d Converter

Kuramoto Pac-1d Converter

Kuramoto Instrument Mfg. Co., Ltd.

Converter

Pac-1d

No.: 877030

Dc 24v

Japan

Weight : 850 Gm

Ref No : 96801

0 notes

Text

Abb Sace Pr212/p Circuit Breaker - Aeliya Marine

Abb Sace Pr212/p Circuit Breaker Abb Sace Pr212/p In=~400a 25…400v Aux. 3a 400v A.c. Nr. Ag02064197 5h Made In Italy Weight : 6.400 Kg Condition : Used 1 Pcs Ref No : 61098

0 notes

Text

Abb Sace Pr212/p Circuit Breaker - Aeliya Marine

Abb Sace Pr212/p Circuit Breaker Abb Sace Pr212/p In=~800 A 15v Dc Aux 3a 400v A.c. Nr.: Af10125121 Made In Italy Weight : 11.500 Kg Condition : For Part 1 Pcs Ref No : 61430

1 note

·

View note

Text

Wireless Transmitters: Advancing Data Transmission in Industrial Settings

In the ever-evolving landscape of industrial automation and data management, wireless transmitters have emerged as a game-changing technology. These devices have revolutionized data transmission in industrial settings, offering greater flexibility, efficiency, and scalability than traditional wired systems. In this blog post, we will explore the key advantages of wireless transmitters and their impact on industrial operations.

The Rise of Wireless Transmitters

Traditionally, industrial environments relied heavily on wired systems for data transmission. While these systems were reliable, they came with their fair share of limitations. Cables were expensive to install and maintain, posed safety risks in hazardous environments, and constrained the flexibility of industrial processes.

Wireless transmitters have addressed these challenges head-on by eliminating the need for physical cables. Instead, they rely on radio waves, Wi-Fi, or other wireless communication protocols to transmit data between sensors, devices, and control systems. This shift from wired to wireless has opened up a world of possibilities for industrial applications.

Advantages of Wireless Transmitters in Industrial Settings

1. Enhanced Mobility and Flexibility

Wireless transmitters allow for easy reconfiguration and expansion of industrial systems. In a dynamic manufacturing environment, where equipment may need to be moved or added frequently, wireless solutions offer unmatched flexibility. This agility not only reduces installation and maintenance costs but also minimizes downtime and disruption to operations.

2. Cost Savings

The installation of wired systems can be labor-intensive and time-consuming. In contrast, wireless transmitters significantly reduce installation costs by eliminating the need to lay cables throughout a facility. Moreover, wireless systems are often more cost-effective in the long run due to reduced maintenance and repair expenses.

3. Scalability

As industrial processes evolve and grow, the demand for data transmission can increase substantially. Wireless transmitters are inherently scalable, making it easy to add new sensors or devices to the network as needed. This scalability ensures that data transmission remains efficient and reliable, even in expanding industrial operations.

4. Safety and Reliability

In hazardous industrial environments where the safety of workers is paramount, wireless transmitters offer a safer alternative to traditional wired systems. They eliminate the risk of cable damage, which can lead to electrical faults or accidents. Additionally, wireless technology is known for its reliability, ensuring that critical data is transmitted without interruption.

5. Real-time Data

Many industrial processes rely on real-time data for decision-making and control. Wireless transmitters excel in delivering real-time data, enabling operators to make immediate adjustments, identify issues, and optimize processes more effectively. This capability can lead to improved productivity and reduced downtime.

6. Remote Monitoring

One of the most significant advantages of wireless transmitters is the ability to monitor and control industrial processes remotely. Operators can access data and make adjustments from virtually anywhere, improving operational efficiency and reducing the need for on-site personnel.

Applications of Wireless Transmitters

Wireless transmitters find applications across various industrial sectors:

Manufacturing: In manufacturing plants, wireless transmitters help monitor equipment status, track inventory, and optimize production processes.

Oil and Gas: In remote and hazardous oil and gas facilities, wireless transmitters provide critical data on equipment health and environmental conditions.

Agriculture: In precision agriculture, wireless sensors are used to monitor soil conditions, crop health, and environmental factors to optimize farming operations.

Utilities: Wireless transmitters play a vital role in managing water treatment facilities, electrical grids, and other utility infrastructure.

Healthcare: In healthcare manufacturing, wireless transmitters ensure the quality and safety of pharmaceutical and medical device production.

Conclusion

Industrial Wireless transmitters have ushered in a new era of data transmission in industrial settings. Their mobility, cost-effectiveness, scalability, safety, and real-time capabilities have made them indispensable tools for enhancing operational efficiency and ensuring the reliability of critical industrial processes. As technology continues to advance, we can expect wireless transmitters to play an even more significant role in shaping the future of industrial automation and data management.

0 notes

Text

Abb Sace Pr212/p Circuit Breaker - Aeliya Marine

Abb Sace Pr212/p Circuit Breaker Abb 15v Dc 25...400 V ~220...250 V 50...60 Hz Aux. 3a 400v A.c. Nr.: Ag02092925 4h Made In Italy Weight : 4.900 Kg Condition : For Part 1 Pcs Ref No : 61050

0 notes

Text

Abb Sace Pr212/p Circuit Breaker - Aeliya Marine

Abb Sace Pr212/p Circuit Breaker Abb Sace In=~400a 15v Dc Aux. 3a 400v A.c. Nr.: Ag02064203 5h Made In Italy Weight : 6.500 Kg Condition : For Part 1 Pcs Ref No : 61049

0 notes

Text

Abb Sace Pr211 Circuit Breaker - Aeliya Marine

Abb Sace Pr211 Circuit Breaker Abb Sace Pr211 In= ~800a Inn= In/2 Yu ~220…250v 50…60 Hz Aux. 3a 400v A.c. Nr. Ag08027072 6s Made In Italy Weight : 11.700 Kg Condition : For Part 1 Pcs Ref No : 61431

0 notes

Text

Abb Sace Pr123/p-lsi Low-voltage Ac Power Circuit-breaker Trip Unit - Aeliya Marine

Abb Sace Pr123/p-lsi Low-voltage Ac Power Circuit-breaker Trip Unit Abb Abb Sace Sace Pr123/p-lsi Nr.: G0381q05a In=2500a Low-voltage Ac Power Circuit-breaker Trip Unit 63fa Sace Pr120/k Signalling Nr.: F 0108 W01a Sace Pr120/v Measuring Weight : 760 Gm Ref No : 76889

0 notes