#industrial automation

Text

Allen Bradley Kinetix 5500 Servo Drives (single-phase)

Delivering the performance and scalability you need to compete in today’s marketplace, our Kinetix 5500 Servo Drives help you achieve the most from your motion processes. With their innovative, compact design and EtherNet/IP communication, Kinetix 5500 Servo Drives help minimize machine footprint and simplify machine design, operation and maintenance. These versatile servo drives can help you deliver optimized operation in a wide range of single-axis or multi-axis applications from basic position moves to high-speed and coordinated motion solutions.

youtube

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#Kinetix#5500servo drive#industrial automation#industry4.0#business#networking#Youtube

2 notes

·

View notes

Text

"Safeguarding Lives and Property: The Vital Role of Gas Leak Detectors in Ensuring Safety and Peace

Gas leak detectors are indispensable safety tools that protect lives, property, and the environment from the devastating consequences of gas leaks. Whether in homes, commercial spaces, or industrial facilities, these devices serve as early warning systems, giving occupants crucial time to respond to potential hazards. Regular maintenance and periodic calibration ensure their optimal performance, offering peace of mind and fostering a safer living and working environment for everyone.

Gas leaks can be silent and odorless, making them particularly dangerous. Without a reliable gas leak detector, these leaks could go undetected until it's too late. These detectors utilize advanced sensing technologies to swiftly identify the presence of gas and trigger timely alerts. Their swift response enables people to evacuate, shut off gas supply, and call for help, mitigating potential disasters.

To uphold their efficiency, periodic maintenance is essential. Routine checks guarantee that the detectors remain in peak condition, minimizing false alarms and maximizing their accuracy. Additionally, regular calibration enhances sensitivity and ensures they meet safety standards. This diligence reinforces trust in these devices, encouraging individuals to embrace a safety-conscious mindset.

In conclusion, gas detectors are critical safety assets that protect lives and property. Through consistent maintenance and calibration, they function optimally, empowering people to respond effectively to gas leaks, promoting a secure and harmonious environment for all.

2 notes

·

View notes

Text

Industrial Automation: How it Works and its Benefits

What is Industrial Automation?

Industrial automation is the use of technology to automate industrial processes, such as manufacturing, packaging, and materials handling. It involves the use of different technologies including robotics, sensors, controllers, and AI. Industrial automation can also include the use of software systems to control and monitor industrial processes.

Types of Industrial Automation

There are different types of industrial automation, including:

a. Fixed Automation

Fixed automation is a type of automation that is used for high-volume production of standardized products. It uses specialized equipment, such as assembly lines, that are designed to perform specific tasks repeatedly.

b. Programmable Automation

Programmable automation involves the use of machines that can be re-programmed to perform various tasks. This type of automation is suitable for low-volume manufacturing of customized products.

c. Flexible Automation

Flexible automation is a type of automation that combines the benefits of fixed and programmable automation. It involves the use of machines that can be reconfigured to perform different tasks, allowing for both the high volume production of standardized products and the low volume production of customized products.

How does industrial automation work?

Industrial automation involves the use of different technologies to automate industrial processes. These strategies can include:

a. Robotics

Robots are machines that can perform tasks automatically, autonomously, or under human supervision. In industrial automation, robots are used for tasks like assembly, packaging, and material handling.

b. Sensor

Sensors are devices that can detect changes in the environment and supply data to a control system. In industrial automation, sensors are used to monitor various parameters such as temperature, pressure, and speed.

c. Controller

Controllers are devices that can control the operation of machines and processes. In industrial automation, controllers are used to control the speed, position, and other parameters of machines and robots.

d. Artificial Intelligence (AI)

AI involves the use of algorithms and models to enable machines to perform tasks that typically require human intelligence. In industrial automation, AI is used for tasks like quality control, predictive maintenance, and process optimization.

Advantages of Industrial Automation

Industrial automation has several benefits, including:

a. Increased Productivity

Industrial automation can significantly increase productivity by reducing cycle time, increasing output, and improving quality.

b. Improved Security

Industrial automation can improve safety by reducing the risk of accidents, such as those caused by human error, and by enabling machines to perform dangerous tasks.

c. Reduce Costs

Industrial automation can lower costs by reducing labor costs, increasing efficiency, and improving quality.

d. Increased Flexibility

Industrial automation can increase flexibility by allowing machines to be reconfigured quickly and easily.

e. Improved Quality

Industrial automation can improve quality by reducing errors, reducing variability, and ensuring consistency in production.

f. Improved Data Collection and Analysis

Industrial automation can deliver real-time data on industrial processes, enabling businesses to analyze and optimize their operations for better efficiency and productivity.

Industrial Automation Challenges

While industrial automation has many benefits, it also poses some challenges, including:

a. Initial Cost

The initial cost of implementing industrial automation can be high, as it requires significant investments in equipment, software, and training.

b. Maintenance and Upkeep

Industrial automation systems require regular maintenance and upkeep to ensure optimal performance, which can be costly and time consuming.

c. Job Displacement

Industrial automation can result in job displacement, as machines replace human workers in some tasks.

d. Cyber Security Risks

Industrial automation systems are vulnerable to cyber-attacks, which can pose a significant risk to businesses and their operations.

The Future of Industrial Automation

The future of industrial automation is exciting, with new technologies emerging that promise to revolutionize the way industries are operated. Some of the emerging trends of industrial automation include:

a. Collaborative Robot

Collaborative robots, also known as cobots, are robots that can work alongside humans, providing assistance in tasks that require strength, precision, or skill.

b. Augmented Reality

Augmented reality uses digital overlays in real-world environments, providing employees with real-time information and guidance on their tasks.

c. Predictive Maintenance

Predictive maintenance involves using data and AI to predict equipment failures before they happen, enabling businesses to perform maintenance before downtime occurs.

d. Digital Twins

A digital twin is a digital replica of a physical asset, enabling businesses to monitor and optimize their operations in real time.

Conclusion

Industrial automation is transforming various industries, providing businesses with many benefits, including productivity, improved safety, cost reduction, increased flexibility, improved quality, and better data collection and analysis. However, it also poses some challenges, including initial costs, maintenance and upkeep, job displacement, and cyber security risks. The future of industrial automation is exciting, with emerging technologies such as collaborative robots, augmented reality, predictive maintenance, and digital twins promising to revolutionize the way industries are operated.

3 notes

·

View notes

Text

Tri-Star Automation

653 MB-210, Saint Adolphe Manitoba MB R5A 1A1

(204) 883-2222

https://tristarautomation.ca/

Tristar Automation is a leading provider of industrial automation solutions for businesses in Manitoba, Canada. With over 20 years of business in the industry, Tristar Automation offers a range of services including PLC programming, robotic automation, and custom control panel design. They also specialize in retrofitting existing equipment with new automation technology to help businesses improve productivity and reduce downtime. Tristar Automation prides itself on delivering quality solutions that are tailored to the unique needs of each customer. Contact them today to learn how they can help your business achieve its automation goals.

#industrial automation#automation companies#automation solutions#Industrial Automation systems#automation controls#Automation robotics#robotics companies#industrial robotics companies#Precision Robotics#robotic integration

2 notes

·

View notes

Text

Compressor Parts Supplier in India | United Marine Services

Looking for a compressor parts supplier in India? At United Marine Services, we provide high-quality parts and components to suit a wide range of compressors. Our team is dedicated to ensuring that our customers receive the best service and products for their needs

2 notes

·

View notes

Text

Certificate IV in Instrumentation and Control - Meo Training

Certificate IV in Instrumentation and Control is a vocational education and training (VET) qualification in the field of industrial instrumentation and control that is designed if you want to work as an instrumentation and control technician in various industries such as manufacturing, mining, and utilities. The course covers topics such as electrical principles, process control, and instrumentation, and typically includes a combination of classroom instruction and hands-on training. Enrol for this course at Meo Training and get upskilled in the area of instrumentation.

#instrumentation#instrumentation and control#engineering courses brisbane#engineering#electrotechnology#education#higher education#training organisation#industrial automation#electrical engineering

1 note

·

View note

Text

Highlighting Industrial automation in India at www.engmag.in, Engineering Review offers accurate and latest industry insights to readers. It is a reliable digital magazine that offers exclusive updates on Industrial automation and other industries. The strong brand name is worth relying on for its accurate content. It features the latest advancement in industrial automation.

2 notes

·

View notes

Text

What is Industrial Automation & How it Evolved

What is industrial Automation

Industrial Automation is really a technique in which we make give over human control to machines. In https://idealprocessandautomation.com.au/ are designed to accomplish the tasks which human beings accustomed to achieve. Why it is done? Because of its advantages:

Through Industrial automation we are able to do mass production with less manpower

Quality in the product is increased

Safety of individual & tools are increased

More accurate process control

Since human intervention is less so reliability in the system is higher

Systems operate is low power supply, more electronic control so equipment every day life is higher

Changes in process logic becomes easier since logics are changed mostly through software

Principal Industrial Automation MNCs

L & T • ALSTOM

Schneider • FESTO

Siemens • Fuji Electric

Allen Bradley • Toshiba

Messung • TATA Honeywell

Modicon • Omron

Mitsubishi • Fanuc

Asia Automation • Delta

How industrial automation control system Evolved?

Initially automation was achieved through manual control, operators used to control the procedure at each step. Human intervention was there at each step. Drawbacks were substandard quality output, errors involved with human involvement affected compromised safety, wastage of raw material, and accuracy of human action.

Then came Pneumatic Control: Industrial automation with this era was achieved through invention of pneumatic controllers at the begining of 1920s. Automation was achieved by controlling air to pneumatic valves, which were actually switched on/off by relays and switches. They were very bulky and changing of the logic was very complex procedure since a great deal of rework was necessary to accomplish change in logic. So time come to complete task changes was very high

Hard wired logic control: contactors, relays (for switching), timers and counters (for timing and counting) were chosen for achieving desired industrial automation. But these systems also resulted into bulky panels. A lot of wiring was involved so time come to complete task was higher. Defect investigation & troubleshooting was complex.

Electronic Control using Logic Gates: In early 60s electronics dominated the procedure, electronic logic gates were utilised for achieving logical operations. they replaced switching devices like relays and contactors inside the control circuits. Electronic times & counters replaced mechanical timers & counters. Due to using electronics space and requirements reduced, maintenance requirement reduced & systems were more reliable.

#Industrial automation#Programmable controller#Programmable logic controller#Power supply modules#Siemens S7#Siemens s7 200#Siemens s7 1500#Modicon#Modicon m580#Modicon m340#mika schneider#Schneider m340

3 notes

·

View notes

Text

Fuse Essentials: Powering Up Your Industrial Automation System

In the realm of industrial automation, every component plays a crucial role in ensuring smooth operations. Among these components, fuses stand out as essential guardians of electrical systems. Fuses serve as the first line of defense against electrical faults, protecting equipment, personnel, and the overall integrity of the automation system. In this blog, we'll look into the fundamentals of fuses in industrial automation, exploring their importance, types, selection criteria, installation best practices, and maintenance tips. By understanding fuse essentials, you'll be empowered to optimize your industrial automation system for enhanced performance, safety, and reliability.

Understanding Fuses

Fuses are simple yet crucial components in electrical circuits. At their core, fuses are safety devices designed to interrupt the flow of current when it exceeds a specified threshold, thereby protecting the circuit and the connected equipment from damage. They consist of a metal wire or strip that melts when exposed to excessive current, breaking the circuit. In industrial automation, where machinery and processes rely heavily on electrical power, fuses play a critical role in safeguarding assets and preventing catastrophic failures.

Importance in Industrial Automation

In industrial automation, where machinery and equipment operate continuously, fuses act as the first line of defense against electrical faults. They safeguard expensive machinery, control systems, and sensitive electronics from damage caused by over currents, short circuits, and other electrical faults. Without proper fuse protection, industrial automation systems are vulnerable to downtime, costly repairs, and even catastrophic failures. The importance of fuses in industrial automation cannot be showy. These small yet mighty devices act as guardians, preventing electrical overloads, short circuits, and other faults from causing damage to expensive equipment and disrupting production processes. By interrupting the flow of excessive current, fuses mitigate the risk of fires, equipment damage, and costly downtime.

Types of Fuses for Industrial Automation

Several types of fuses are used in industrial automation systems, each customized to specific applications and operating conditions. These include cartridge fuses, blade fuses, resettable fuses (PTCs), and semiconductor fuses. Understanding the characteristics and limitations of each type is essential for selecting the right fuse for your automation system.

Selecting the Right Fuse for Your Automation System

Selecting the right fuse involves considering multiple factors, including circuit voltage, voltage rating, current rating, interrupting rating, operating environment, and system requirements. It's crucial to choose a fuse with the appropriate current rating and time-delay characteristics to ensure reliable protection without unnecessary nuisance trips. Additionally, proper fuse sizing helps optimize system performance and minimize downtime. By conducting a thorough assessment of your automation system's electrical needs and potential risks, you can choose fuses that provide optimal protection without compromising performance or safety. Consulting with electrical engineers or experienced professionals can help ensure proper fuse selection.

Best Practices for Fuse Installation and Maintenance

Proper installation and maintenance are essential for ensuring the effectiveness of fuses in industrial automation systems. This includes following manufacturer guidelines for installation, using quality fuse holders, regularly inspecting fuses for signs of wear or damage, and replacing them as needed. Fuses should be installed according to manufacturer specifications and industry standards, with attention to factors such as mounting orientation, enclosure type, and wire size. Additionally, regular inspections and maintenance checks can help identify issues such as loose connections or corrosion, ensuring continued reliability and safety. Implementing proactive maintenance practices can help prevent unexpected failures and prolong the lifespan of your equipment.

Maintaining and Troubleshooting Fuses

Regular maintenance is key to ensuring the reliability and effectiveness of fuses in industrial automation. Periodic inspections should be conducted to check for signs of wear, damage, or overheating. Additionally, troubleshooting techniques such as continuity testing can help identify faulty fuses and prevent potential failures before they occur. Prompt replacement of damaged or expired fuses is essential to maintain the integrity of the automation system.

Conclusion

In conclusion, fuse essentials are critical for powering up industrial automation systems, providing essential protection against electrical faults and ensuring the reliability and safety of your operations. By understanding the fundamentals of fuses, selecting the right type and size, and following best practices for installation and maintenance, you can optimize the performance of your automation systems and minimize downtime. Invest in quality fuses and prioritize safety to keep your operations running smoothly.

#industrial automation#industrial equipment#industrial spare parts#auto2mation#industrial and marine automation#industrial and marine automation equipment#industrial automation equipment#automation#industrial#fuses

0 notes

Text

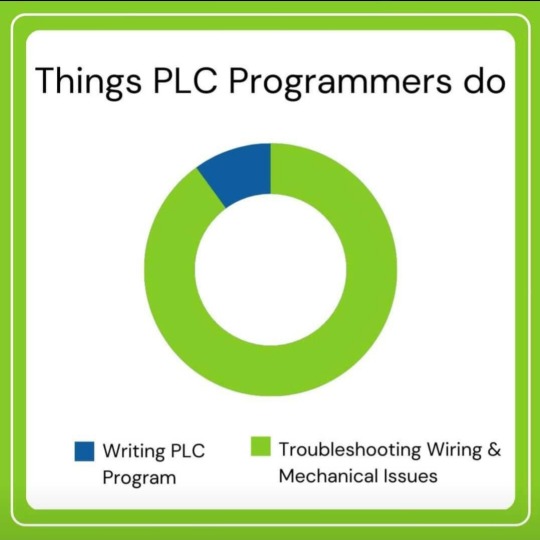

Things PLC Programmers do

A PLC programmer is a highly skilled IT professional who designs, maintains and troubleshoots machines and plants that use programmable logic controllers. Programmable logic controllers (PLC) are small computers that are connected to a machine and are programmed to control the machine's functions.

#How to use PLC#PLC#Allen Bradley#Rockwell Automation#Writing PLC Program#trending#automation#industrial automation

3 notes

·

View notes

Text

LabVIEW Data Acquisition System

Data acquisition is a critical aspect of various industries, from scientific research to industrial automation. LabVIEW, developed by National Instruments, offers a powerful platform for designing and implementing data acquisition systems efficiently. In this article, we'll delve into the intricacies of LabVIEW data acquisition systems, exploring their components, setup, programming, benefits, applications, case studies, challenges, and future trends.

Introduction to LabVIEW Data Acquisition System

Understanding Data Acquisition Systems

Data acquisition systems are instrumental in collecting and processing data from physical phenomena or systems. These systems typically consist of sensors, signal conditioning hardware, and software for data processing and analysis.

Importance of LabVIEW in Data Acquisition

LabVIEW stands out as a premier software tool for data acquisition due to its user-friendly graphical programming interface and extensive library of functions for signal processing, analysis, and visualization.

Components of a LabVIEW Data Acquisition System

Hardware Components

A LabVIEW data acquisition system comprises various hardware components, including sensors, signal conditioning modules, data acquisition devices (DAQ), and interfaces for connecting with external devices.

Software Components

LabVIEW software provides the programming environment for configuring, controlling, and monitoring data acquisition processes. It offers a wide range of built-in functions and libraries for seamless integration with hardware components.

Setting Up a LabVIEW Data Acquisition System

Installation Process

Setting up LabVIEW involves installing the software on a compatible computer system and configuring it to communicate with the hardware components of the data acquisition system.

Configuring Hardware

Once the software is installed, users need to configure the hardware components by selecting appropriate drivers and setting up communication protocols within the LabVIEW environment.

Programming in LabVIEW for Data Acquisition

Basics of LabVIEW Programming

LabVIEW programming involves creating virtual instruments (VIs) using a graphical programming language known as G, which utilizes a block diagram approach for visual representation of code.

Data Acquisition Techniques

LabVIEW offers various data acquisition techniques, including analog and digital input/output, voltage measurements, frequency measurements, and waveform generation, all of which can be implemented through intuitive programming constructs.

Benefits of Using LabVIEW for Data Acquisition

Versatility and Flexibility

LabVIEW provides a versatile and flexible platform for designing custom data acquisition systems tailored to specific application requirements.

Integration with Other Systems

LabVIEW seamlessly integrates with other systems and software tools, allowing for interoperability and compatibility with existing infrastructure.

Scalability and Customization

LabVIEW offers scalability, enabling users to expand their data acquisition systems as per evolving needs, along with extensive customization options for optimizing performance.

Applications of LabVIEW Data Acquisition System

Industrial Automation

LabVIEW data acquisition systems find extensive applications in industrial automation for monitoring and controlling processes in manufacturing, quality assurance, and product testing.

Scientific Research

In scientific research, LabVIEW facilitates data collection and analysis in diverse fields such as physics, chemistry, biology, and environmental science, enabling researchers to conduct experiments and gather insights efficiently.

Medical Monitoring

LabVIEW-based data acquisition systems play a crucial role in medical monitoring applications, including patient monitoring, diagnostic equipment, and biomedical research, aiding in the advancement of healthcare technologies.

Environmental Monitoring

LabVIEW is utilized for environmental monitoring tasks such as weather forecasting, pollution detection, and ecological research, contributing to the preservation and sustainability of natural resources.

Case Studies: Real-World Implementations

Case Study 1: Automotive Testing

LabVIEW data acquisition systems are employed in automotive testing facilities for evaluating vehicle performance, conducting crash tests, and analyzing vehicle dynamics under various conditions.

Case Study 2: Weather Monitoring

Meteorological agencies utilize LabVIEW-based data acquisition systems for collecting and analyzing weather data, including temperature, humidity, wind speed, and precipitation, to forecast weather patterns accurately.

Case Study 3: Biomedical Research

In biomedical research laboratories, LabVIEW facilitates the acquisition and analysis of physiological data, imaging data, and genetic data, supporting advancements in disease diagnosis, treatment, and drug development.

Challenges and Solutions in LabVIEW Data Acquisition

Compatibility Issues

One challenge in LabVIEW data acquisition is compatibility issues between hardware components and software versions, which can be mitigated through careful selection and configuration of compatible components.

Data Processing Challenges

Processing large volumes of data in real-time poses another challenge, requiring efficient algorithms and hardware optimization techniques to ensure timely and accurate data acquisition and analysis.

Calibration and Maintenance

Regular calibration and maintenance of hardware components are essential to maintain the accuracy and reliability of LabVIEW data acquisition systems, requiring adherence to best practices and standards.

Future Trends in LabVIEW Data Acquisition

Advancements in Hardware Technology

Future advancements in hardware technology, such as faster processors, higher-resolution sensors, and wireless connectivity, will enhance the performance and capabilities of LabVIEW data acquisition systems.

AI Integration

Integration of artificial intelligence (AI) algorithms into LabVIEW data acquisition systems will enable predictive analytics, anomaly detection, and autonomous decision-making, revolutionizing data acquisition processes.

IoT Integration

LabVIEW data acquisition systems will increasingly integrate with the Internet of Things (IoT) ecosystem, leveraging cloud computing, edge computing, and wireless sensor networks for enhanced connectivity, scalability, and interoperability.

Conclusion

LabVIEW data acquisition systems offer a comprehensive solution for collecting, processing, and analyzing data across various industries and applications. With its user-friendly interface, robust functionality, and versatility, LabVIEW continues to empower engineers, researchers, and scientists in their quest for innovation and discovery. If you want to read more blogs/articles so visit on PujaControls

#automation#labview#technology#software development#iot#iot integration#ai integration#automotive testing#industrial automation

0 notes

Text

Unveiling the Power of Epicyclic Gearboxes: From Basic Principles to Advanced Applications

Introduction:

The world of machines is driven by gears, and within this realm, the epicyclic gearbox, also known as a planetary gearset, stands out as a marvel of engineering ingenuity. This intricate system of interlocking gears offers a unique ability to achieve both speed reduction and torque multiplication, making it a cornerstone of various applications. Whether you’re fascinated by the…

View On WordPress

#automatic transmission#Compound Gear Train#Continuously Variable Transmission (CVT)#Differential Gears#Epicyclic Gearbox#Hybrid Vehicles#Industrial automation#Planetary Gearset#Robotics#Speed Reduction#Torque Multiplication

0 notes

Text

S5N-PA-5-C21-NN Datalogic Photoelectric Sensor Supplier in India

#industrial equipment#industrial sensors#switches#datalogic dealers#datalogic sensors#industrial automation#sensor

0 notes

Text

How to Choose the Right Electrical Automation Solutions for Your Needs

Imagine coming home to a house that adjusts its lighting based on the natural light available, manages the temperature to your comfort levels without you having to lift a finger, and ensures that all your devices work in the most energy-efficient way possible.

This isn't a glimpse into a far-off future; it's the reality that High-performance electrical automation solutions brings to us today.

In this blog, we'll dive into how you can choose the right Electrical Automation solutions tailored specifically to your needs, making your life more convenient, efficient, and even a bit more futuristic.

So, buckle up as we embark on this electrifying journey together!

Understanding Your Needs

Before diving into the vast ocean of Electrical Automation, it's crucial to take a step back and assess what you really need. Are you looking to automate your home, office, or perhaps a manufacturing process?

Your goals will significantly influence the type of solutions that are best suited for you. Remember, the right Electrical Automation system is the one that solves your problems, not adds to them.

Ease of Use and Compatibility

In the world of Electrical Automation, compatibility and ease of use are your best friends. Look for systems that can easily integrate with your existing devices and infrastructure.

The last thing you want is a solution that promises the world but requires a complete overhaul of your current setup. User-friendly interfaces and seamless integration not only make your life easier but also ensure that you get the most out of your automation solutions.

Future-Proofing Your Investment

Electrical Automation technology is rapidly evolving. Thus, opting for a system that is adaptable and scalable is paramount. Think long-term and choose solutions that can grow with your needs.

This might mean opting for open systems that are compatible with a wide range of products and technologies, ensuring that your investment is future-proof.

Safety and Security

When it comes to Electrical Automation, safety and security should never be an afterthought. Ensure that the solutions you're considering have robust security features to protect against unauthorised access and cyber threats.

Additionally, they should comply with local safety standards to safeguard against any electrical hazards.

Energy Efficiency and Sustainability

One of the most compelling reasons to adopt Electrical Automation is the potential for significant energy savings and sustainability benefits. Look for solutions that offer smart energy management features, allowing you to monitor and control energy usage in real time.

Not only does this help in reducing your carbon footprint, but it also leads to substantial savings on your energy bills.

Cost Considerations

While it's easy to get carried away with the latest and greatest Electrical Automation gadgets, it's important to keep your budget in mind. Evaluate the cost versus the benefit of each solution.

Remember, the most expensive option isn't always the best one for your needs. However, don't compromise on quality for the sake of cost, as this could end up being more expensive in the long run due to maintenance and replacements.

Expert Advice and Support

Last but not least, don't underestimate the value of expert advice and support.

Whether you're a DIY enthusiast or prefer a professional installation, having access to expert guidance can make all the difference in choosing and implementing the right Electrical Automation solutions.

Look for companies that offer comprehensive support, from initial consultation to after-sales service.

Wrapping Up

Choosing the right Electrical Automation solutions for your needs might seem daunting at first, but by understanding your needs, ensuring ease of use and compatibility, future-proofing your investment, prioritising safety and security, focusing on energy efficiency, considering costs, and seeking expert advice, you can make an informed decision that enhances your life in many ways.

Remember, the goal of Professional temperature calibration services is to make your life easier, more comfortable, and efficient.

So, take the plunge and transform your home or workplace into a smarter, more responsive environment that's ready for the future.

#Electrical Automation#Industrial Automation#Industrial Control System#Temperature Calibration#Thermometer Calibration

0 notes

Text

BLIIoT | BACnet gateway BA115 Support Multi-Protocol Conversion for Building Management Systems

Introduction

With the development of communication technology and control technology, in order to achieve efficient and intelligent management of buildings, centralised monitoring and management has become an inevitable trend in the development of intelligent management of buildings. In this context, high-performance building HVAC data transmission solutions - protocol conversion gateway came into being, widely used in building automation and HVAC system applications.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT Building Automation HVAC gateways, This series of products not only have excellent stability and anti-interference capabilities, but also have deep industry applications, aiming to bring users a new building automation data collection and conversion experience.

Product Description

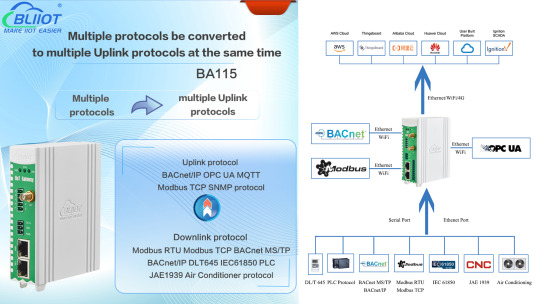

The multi-protocol to BACnet gateway BA115 is a protocol conversion gateway designed for converting various devices, power meters, and air-conditioning hosts into BACnet protocols for docking with BA systems.

The multi-protocol to BACnet gateway BA115 has powerful hardware interfaces, including 2/6 RS485/RS232 serial ports, 2 network ports and 1 4G/WiFi wireless transmission interface, providing users with flexible communication and connection solutions.

Multi-protocol to BACnet gateway BA115 uplinksupports BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

In the downlink, BA115 supports multiple protocols, such as Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC, air conditioning protocol and JAE1939, enabling it to communicate and communicate with various types of equipment. data collection.

By using BLIIoT patented guide rail buckle technology, the installation process is simplified and the practicality of the gateway is ensured.

Product features

Supported protocols:

Downlink protocol: Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC protocol, Air Conditioning protocol and JAE1939, etc.,

Uplink protocols: BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

Hardware interface:

6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.

2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.

4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need.

Data security:

Support data TSL/SSL, X.509 certificate, SNMP V1/V2, key encryption and other security gateway functions.

Remote Configuration Support:

Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

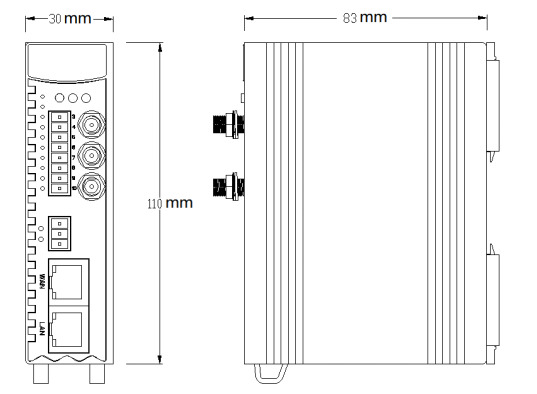

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

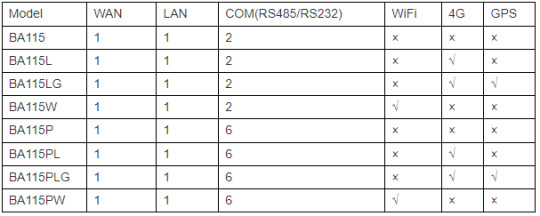

Model List

Application scenarios

Multi-protocol to BACnet gateway is widely used in building automation systems, energy management systems, air conditioning systems, smart factories, and BA systems protocol conversion.

More information about Multi-protocol to BACnet gateway BA115 : https://www.bliiot.com/industrial-iot-gateway-p00425p1.html

#IoT#IoT Solution#Industrial Automation#Smart Energy#BMS#BAS#HVAC#Modbus#BACnet#OPC UA#MQTT#IEC 104#DLT645#PLC#BLIIoT

0 notes