#refractoryfirebrick

Link

Refractory Fire Bricks Installation - Refmon Industries

Refractory Fire Bricks are used in various different industries, their primary goal is to withstand high temperatures and be somewhat chemically resistant. They have various applications like low and moderate heating zones of Boilers, Kilns and Furnaces, Chimney Ducts, and Preheaters and have low thermal conductivity and low water absorption.

#firebricks#firebrickmanufacturers#refractorybricks#firebricksinindia#refractoryfirebrick#firebrickmanufacturersinindia#refmon#refmonindustries

0 notes

Text

Advantages and disadvantages of fire clay brick

According to production process, fire clay brick is divided into machine made brick and handmade brick. According to structures, fire clay brick is divided into solid brick and hollow brick, and hollow brick can be divided into load-bearing brick and nonbearing brick. Fire clay brick is made at different shapes according to different using requirements.

Advantages of fire clay brick:

1.Fire clay brick is environmentally friendly and belongs to resource recycling bricks, so we can rest assured use fire clay brick. Fire clay bricks won’t be harmful to our health.

2.Fire clay brick has advantages of fireproof and heat insulation. Used clay brick can be used as concrete so that to save a lot of resources.

3.The price of fire clay brick is not as expensive as that of other fire bricks. Light weight brick is more expensive than fire clay brick. Besides, fire clay brick is very cheap and very durable

4. Fire clay brick has good moisture-proof function, it also has the advantages of fire insulation, heat insulation and moisture absorption.

Disadvantages of fire clay brick:

1.Clay brick is made of concrete and is much heavier than other masonry materials. It will make the whole building bear more weight, and it will increase the cost of the whole project.

2.Clay brick’s soundproof effect is poor. When outside sound spreads into clay brick, because it doesn't have a lot of air holes, it can't isolate the sound very well.

3.Clay brick’s main raw material is soil, and that will do harm to the environment. Clay brick manufacturing easily lead to the loss of soil and water. For this reason in China caly brick is being forbidden gradually.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory product for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Advantages and disadvantages of fire clay brick

Company name :Luoyang Wanhao New Material Co., Ltd.

More Refractory Products: http://www.wanhaorefractory.com/en/product.html

Website: http://www.wanhaorefractory.com/

0 notes

Text

The Belt and Road,Mutually beneficial Win-win with the world

The Belt And Road, refers to economic Belt "silk Road" and "Marine silk Road" of the 21st century. On September 7th, 2013, chairman Xi Jinping delivered an important speech at the university of Kazakhstan Nursultan Nazarbayev, the first time to put forward strengthen policy communication, road unicom, trade flow, currency, hearts are interlinked, work together for economic belt "silk road" of the strategic initiative; On October 3rd, 2013, the chairman Xi Jinping putted forward when delivered an important speech in Indonesia congress explicitly, China is committed to strengthening the construction of connectivity with ASEAN countries, and is willing to work with ASEAN countries develop Marine partnership, mutual construction "Marine silk road" of the 21st century. There have many kinds of refractory products in our factory. Such as fire brick for sale, refractory nozzle,refractory raw material, Magnesia Carbon Brick and other refractory.

Economic belt "silk road" and "Marine silk road economic belt" involving 65 countries and regions as follows.

Mongolia in east Asia, the 10 ASEAN countries: Singapore, Malaysia, Indonesia, Myanmar, Thailand, Laos, Cambodia, Vietnam, Brunei and the Philippines;

Josiah 18 countries: Iran, Iraq, Turkey, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Yemen, Oman, the united Arab emirates, Qatar, Kuwait, Bahrain, Greece, Cyprus and Egypt's Sinai Peninsula;

Eight South Asia countries: India, Pakistan, Bangladesh, Afghanistan, Sri Lanka, Maldives, Nepal and Bhutan;

The five central Asian countries, Kazakhstan, Uzbekistan, Turkmenistan, Tajikistan and Kyrgyzstan.

Commonwealth of independent states (CIS) 7 countries: Russia, Ukraine, Belarus, Georgia, Armenia, Azerbaijan, and Moldova.

16 countries in central and eastern Europe, Poland, Lithuania, Estonia, Latvia, the Czech republic, Slovakia, Hungary, Slovenia, Croatia, Bosnia and Herzegovina, Montenegro, Serbia, Romania, Bulgaria, Albania and Macedonia.

Under the policy support of “The Belt And Road”, China's refractory industry exports also has a great growth, Changxing company in the area all the way to continue under the policy of adhering to the good quality, excellent service tradition, and establish friendly cooperation relationship with many new customers, to make mutual benefit and win-win!

Article source: http://www.chinafirebrick.com/Company_News_123.html

0 notes

Photo

What is the Difference Between Refractory Fire Brick and Regular Brick

#brick#refractory#firebrick#refractorybricks#refractorymaterial#firebrickmanufacturers#castablerefractory#refractoryfirebrick#castable#refmonindustries

0 notes

Link

Difference Between Refractory Fire Brick And Regular Brick

Know the difference between refractory fire brick and generic bricks in detail, if you want to make the best choice, then you need to choose the best brick manufacturer. Refmon Industries will help you to choose the best bricks. You will learn more about the differences in this blog.

#brick#refractory#firebrick#refractorybricks#refractorymaterial#firebrickmanufacturers#castablerefractory#refractoryfirebrick#castable#refmonindustries

0 notes

Photo

Refractory Bricks: Pros, Cons, and Using Tips - Refmon Industries

#bricks#firebricks#refractory#refractorybricks#acidproofbricks#refractoryfirebrick#refractorybedmaterialsuppliers#castablerefractorycement#refmonindustries

0 notes

Link

Refractory Bricks: Pros, Cons, and Using Tips

You may have seen refractory brick laying around your neighborhood, but you don't know how efficient they are. In this article, you can know about the refractory fire bricks advantages, disadvantages, & applications.

#bricks#firebricks#refractory#refractorybricks#acidproofbricks#refractoryfirebrick#refractorybedmaterialsuppliers#castablerefractorycement#refmonindustries

0 notes

Text

The four most common damage mechanisms of magnesia carbon brick

1. Slag causes melting and dissolution of magnesia

2. The oxidation of carbon

(1) Direct oxidation

The carbon in the MgO-C brick is directly oxidized by oxygen in the environment, generally occurring below 1400℃.

(2) Indirect oxidation

Indirect oxidation generally occurs above 1400℃, and indirect oxidation is divided into intrinsic oxidation and external oxidation.

3. Corrosion caused by molten steel flow

(1) The slag layer formed on the working surface of the magnesium carbon material could be washed away by the flow of the molten steel, or the slag is insufficient.

(2) Repeated heating and cooling during the production process and the stirring force of the molten steel may cause the structure of the material to relax.

4. Hot peeling and mechanical peeling.

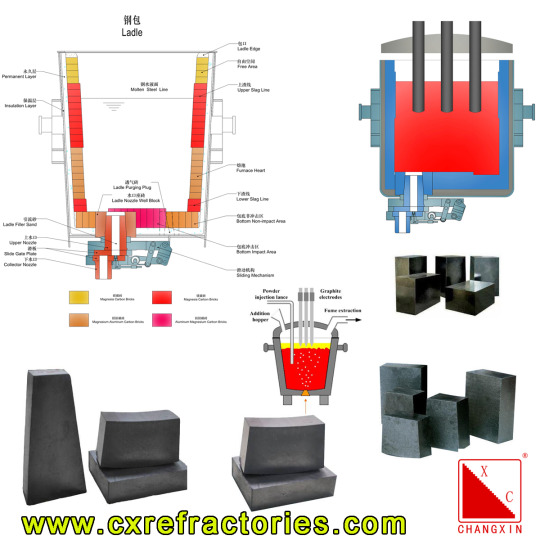

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality ladle magnesia carbon bricks are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Ladle Magnesia Carbon Brick:Magnesia carbon brick is made of fused magnesia and high carbon graphite, with antioxidant was added, and the phenolic resin was used as the binder for high pressure molding. MgO-C refractory bricks are widely used in steel industry.

Ladle Purging Plug:Ladle purging plug has been in the leading position in domestic and abroad over years. We have developed the series of corundum, chromium corundum, low silicon chromium corundum and corundum spinel one after another.

Ladle Slide Gate Plate:Slide gate plate is preferred products for big/medium ladle and continuous casting tundish. Alumina-carbon slide gate plates can meet the requirement of different steel grades.

Ladle Castable:Ladle castable has good workability, high strength, good volume stability, good abrasion resistance and thermal shock resistance, etc.

Article Source:The four most common damage mechanisms of magnesia carbon brick

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

4 solutions for serious damage to refractory materials used in ladle lining

Ladle turnover process: converter/electric furnace tapping once and twice refining process, continuous casting and pouring steel, ladle preparation work, and waiting for tapping. The normal turnaround time depends on the steel type and the continuous casting machine, and it takes 100 to 140 minutes. The tapping temperature of the ladle is 1680-1700℃, and the holding time is 100~120min. If the ultra-low carbon steel process such as silicon steel, bridge steel, automobile plate steel, etc must be vacuum treated, argon blowing and stirring at the bottom of the ladle and LF furnace are used at the same time. Arc heating, reducing atmosphere in the furnace, white slag refining, gas stirring, etc., strengthen the comprehensive refining effects of thermodynamics and kinetic conditions, desulfurization, alloying, and heating, so the slag alkalinity range is large, and the temperature of molten steel and slag is higher. The residence time of molten steel in the ladle is prolonged, the thermal shock is strong, the stirring force is large, and the damage to the inner lining of the ladle is aggravated.

The reasons for the damage of the ladle refractories are as follows:

First, the ladle is used to transport high-temperature molten steel. During transportation, high-temperature molten steel and molten slag at around 1680°C will erosively corrode it, especially at the slag line. The scouring erosion is more serious, which is an important factor in determining the service life of a tank.

Second, the refining treatment outside the furnace such as LF seriously damages the unburned bricks.

Third, the inner lining is subjected to severe temperature changes when the converter is tapped and molten steel flows out, which causes cracks and peeling of the inner lining material.

Fourth, when the ladle is filled with molten steel during the tapping of the converter, the high-temperature molten steel has strong mechanical erosion on the bottom of the ladle, which makes the lining material of this part prone to damage due to thermal shock. According to the above analysis, the ladle lining refractories should have the following characteristics: compact and uniform structure; high temperature micro-expansion, good volume stability; High strength, small ratio of medium temperature strength to high temperature strength.

In addition to the above-mentioned two chemical and physical reasons, there is another reason that cannot be ignored is man-made:

(1)Improper selection and collocation of refractory materials;

(2)Improper use of refractory materials, such as unreasonable masonry and baking methods;

(3)Too long ladle turnover period causes cold ladle;

(4)Improper unpacking will damage the permanent layer of the ladle;

(5)Failure to take repair measures in time. The method to reduce the structural spalling of refractory materials is to reduce the depth of slag penetration.

It is recommended to start from the following aspects:?

(1)Improve the slag penetration resistance of refractories;

(2)Reduce the porosity of?refractory materials?and reduce the erosion channel of slag;

(3)The slag reacts with the refractory material to form a high melting point compound retaining wall to prevent the penetration of the slag;

(4)Increase the viscosity of the slag. The greater the viscosity of the slag, the worse the corrosiveness to refractory materials;

(5)Understand the properties of the refractory materials used, and reasonably formulate the use conditions of the ladle;

(6)Speed up the use cycle of ladle as much as possible, and achieve "red envelope" work;

(7) The damaged parts of the lining refractories should be repaired or replaced in time.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality ladle magnesia carbon bricks are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Ladle Magnesia Carbon Brick:?Magnesia carbon brick is made of fused magnesia and high carbon graphite, with antioxidant was added, and the phenolic resin was used as the binder for high pressure molding. MgO-C refractory bricks are widely used in steel industry.

Ladle Purging Plug:Ladle purging plug has been in the leading position in domestic and abroad over years. We have developed the series of corundum, chromium corundum, low silicon chromium corundum and corundum spinel one after another.

Ladle Slide Gate Plate:Slide gate plate is preferred products for big/medium ladle and continuous casting tundish. Alumina-carbon slide gate plates can meet the requirement of different steel grades.

Ladle Castable:Ladle castable has good workability, high strength, good volume stability, good abrasion resistance and thermal shock resistance, etc.

Article Source:4 solutions for serious damage to refractory materials used in ladle lining

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Link

Changxing Refractory offer refractory products for u.Changxing Refractory focus on manufacturing all kinds of fire brick, refractory product, castable, refractory nozzle, cement, mortar, raw material, castable for Boilers & Furnace, etc.

0 notes