#Firebrick

Text

Fire Bricks VS Regular Bricks: Price, Benefits, Durability, Uses

Here, we will compare the fire bricks and the regular bricks – the two most common bricks available in the market. By comparing them, we can help you make an informed decision about your purchase.

#bricks#refractorybricks#firebrick#manufacturer#acidproofbricks#refractorymaterial#benefitsofrefractorybricks

1 note

·

View note

Text

What are the classifications of magnesia chrome bricks

Magnesia chrome brick is composed of MgO55%80%, Cr2O38%20% partial alkali refractory thermal insulation materials crafts, with magnesia, compound spinel and a small amount of silicate phase. Compound spinel contains solid solutions of MgAl2O4, MgFe2O4, MgCr2O4 and FeAl2O4.

Magnesia chrome bricks in the 20th century after the 60 era because of the purity of raw materials and firing temperature to improve the rapid development trend, the current magnesia chrome bricks according to the different production methods can be divided into general bricks, immediate fusion bricks, mutual sintering bricks, refusion bricks and fused bricks.

(1) General magnesia-chrome brick

It is a traditional commodity, with chromium ore as coarse particulate matter and magnesia as fine powder. Or the two raw materials are composed of graded particles, and the firing temperature is generally 1550-1600 ° C. The microstructure of this kind of brick mainly shows that there is little immediate fusion between chromium ore particles and cubic magnesite, and more silicate (CMS) fine sand or crack protection. There is little dissolved phase in the cubic magnesite, very little immediate fusion in the cultivation medium, and this kind of brick has poor physical properties and poor slag corrosion resistance.

(2) Immediately fuse magnesia-chrome brick

Immediate fusion magnesia-chrome brick is in the general magnesia-chrome brick basic development trend, its production characteristics are key to two points, one is the selection of more pure raw materials, the second is the selection of higher firing temperature. In plain words, immediate fusion refers to the chromium ore particles in the brick and the cubic magnesite in the middle of more immediate contact, due to the raw material SiO2 less (manipulation in 1%25% below), the silicate generation is less, according to the high temperature firing method to make the silicate extrusion molding to the corner of the solid particles. This improves immediate solid phase fusion.

Immediate fusion magnesium-chrome brick because of the high level of immediate fusion, so that the brick has a high temperature compressive strength, slag resistance, corrosion resistance, erosion resistance, corrosion resistance and high-quality thermal shock reliability and volume reliability at 1800℃.

(3) mutually calcined magnesia-chrome bricks

The characteristics of this kind of handicraft production process is to burn the mixture of magnesia and chromium ore fine powder according to a certain preparation at high temperature, maintain the conversion into secondary spinel and magnesia-chromium ore immediate fusion for the purpose of solid phase reaction, prepare mutual calcined materials, and use this material to produce burnt products or organic chemical fusion crafts.

The immediate fusion and microstructure uniformity of intercalcined magnesia-chrome bricks are stronger than those of immediate fusion bricks, and there is a large amount of brucite dedissolved phase and intergranular secondary spinel. The intercalcined magnesia-chrome bricks have a series of stronger characteristics than immediate fusion bricks, especially famous for high temperature compressive strength, temperature resistance and slag resistance.

Mutual sintered bricks can be divided into two types, one is all mutual sintered bricks, particulate matter and fine powder new mutual calciners, whether fired or organic chemical fusion of their microstructure is mostly similar; The second is a part of the mutual sintering bricks, a part of the raw materials, such as coarse particles with mutual calcining materials, and a part of the fine powder can be mixed with fine chromium ore and magnesia paper powder according to a certain proportion of the brick, so that the fired and organic chemical fusion crafts will have a certain difference in microstructure.

(4) Re-fusion magnesia-chrome brick

Magnesia-chromium mixture particles are melted by electromelting tube method, and according to the crystallization of the solution, a raw material with a very symmetrical microstructure and composed of magnesia-chromium spinel and cubic magnesite mixed crystals as the key phase is produced. Such electromelting magnesia-chromium material is broken into a certain particle size distribution, mixed and formed, and fired to produce refused bricks, or immediately used as organic chemical junction bricks.

The microstructure of the refused brick is characterized by the immediate fusion of the aspect ratio and the presence of a lot of spinel dissolubilized phase: the base crystal with a lot of dissolubilized phase substantially changes the physical properties of the brucite, such as reducing the coefficient of linear expansion, improving the heat resistance, and improving the resistance to acid-alkali slag corrosion. The refused brick has similar characteristics to the actual application of fused cast brick, but has stronger temperature snap resistance and more symmetrical microstructure than fused cast brick.

The refused magnesium-chrome brick has a well-proportioned sand and gravel culture medium, and has fine cracks, and is more sensitive to sudden temperature changes than the fusion casting. The high temperature characteristics of handicrafts are close to the middle of fused cast bricks and immediately fused bricks.

(5) Cast magnesia-chrome brick

Magnesia and chromium mineral compounds are thoroughly melted in an electric arc furnace, and then the solution is forged into a fireproof casting mold. In the whole process of condensation, it is transformed into a smooth brucite and spinel crystal phase, and a fine crystal mechanism is produced, so the fused cast magnesia-chromium brick has excellent high temperature compressive strength and slag corrosion resistance.

Molten magnesium-chromium brick and electromolten magnesium-chromium material, with the height to width ratio of immediate fusion and with a lot of spinel dissolved phase, this kind of crafts caused by high relative density, slag is not easy to penetrate, so the slag resistance to improve the immediate fusion brick is stronger, but the heat resistance is worse than the two crafts.

In terms of the principle of relative ash infiltration of fused magnesia-chrome bricks, it has the advantage of being different, because it is a high-density frit made by melting, pouring, and overall water cooling, the slag only has the effect of erosion on the surface of the brick, and it is unlikely to penetrate (which has been confirmed by the cross-sectional assessment of the fused magnesia-chrome bricks after application). Therefore, although the production of fused magnesium-chromium bricks is difficult and expensive, the key parts of the non-ferrous plate smelting furnace in technical capitalist countries still retain the advantages and influence that other refractory insulation materials can not replace.

0 notes

Photo

0 notes

Photo

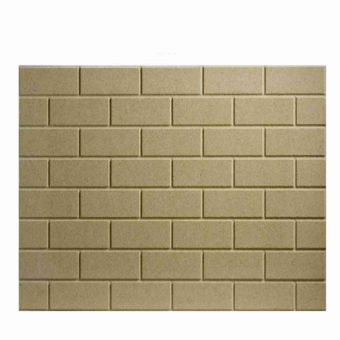

These Fire Brick are burnt at high temperatures for longer periods. It's made of natural fire clay and is corrosion and chemical resistant. The Firebrick can be cut and rearranged to fit specific unique spaces.

Buy now - https://www.woodstoves-fireplaces.com/firebrick/

0 notes

Text

Firebrick Seastar

#Firebrick Seastar#seastar#starfish#sea creatures#photography#naturecore#sea#ocean#underwater#pink#orange#purple#ocean floor#nature

515 notes

·

View notes

Text

finally. my webcomic ocs and one (1) self insert

each is based on a unique shape and color

#my art#my ocs#red triangle#sienna arch#orange hourglass#navajo white pentagon#yellow star#pale green oval#lime circle#dark green vertical rectangle#aqua raindrop#dodger blue cloud#blue square#indigo diamond#fuschia X#deep pink heart#slate gray crescent#black trapezoid#firebrick right triangle#coral octagon#dark goldenrod semicircle#olive drab four pointed star#teal hexagon#cornflower spiral#slate blue parallelogram#orchid arrow#medium violet red lighting bolt#sky blue ring#goldenrod pie#orange red dart

6 notes

·

View notes

Text

https://apocalypsesteelandpower.com/

#tmt bar supplier#tmt steel suppliers near me#Reinforcement Bar supplier#Ferro Alloys supplier#Ferro Silicon Manganese supplier#Silicon Manganese supplier#Pure Silicon supplier#Scrap Metal supplier#MS Billets supplier#Firebricks#Precast Prefired Blocks For Burners#Steel Grade Pig Iron supplier#ms angle

2 notes

·

View notes

Photo

Bedroom Master in New York

Large transitional master dark wood floor bedroom photo with white walls, a standard fireplace and a stone fireplace

0 notes

Video

Chimneys Explained #18 - Firebrick Joints

Firebrick joints are the spaces between firebricks that are filled with a special type of material to create a strong and stable structure that can withstand high temperatures. The refractory material used in the joints helps to distribute heat evenly and prevent hot spots from forming. Properly constructed firebrick joints are important for safety and efficiency.

0 notes

Photo

Buy High Quality Fire Bricks from Refmon Industries

If you want high alumina and high quality refractory bricks and looking for the best manufacturer then Refmon Industries in Alwar, India is the leading fire bricks manufacturer. Our bricks are made from high-grade clay and we can customize the shapes of bricks as per the client's requirement. To know more details or to buy these bricks from us then contact us.

0 notes

Text

marissa strip tease panty stuff then squirting pussy gush

Lala Ivey In Pink Lollipops And Black Pussy

Straight guys first time hardcore and of teen masturbating gay but in

lesbica lambendo a buceta da novinha de vibrador

Comendo a enteada novinha

Latina fucks some trump supporters

Fany golosa en el monte

Sweltering dilettante gives hot pov blowjob and gets screwed

Big ballsy guy has no mercy for cute girl as he bounds her taut

DANCING BEAR - Shy Girls Turn Into Horny Beasts When The Cocks Start Flyin'

#sprucier#prenoon#baroneted#afternoon#inkberries#soave#Deming#Ancalin#disassociable#greyhen#acquisita#altheine#Saharian#bessemerized#diaphysis#dim-lighted#firebricks#bituminized#broadcasted#hijabers

0 notes

Text

The use of magnesia chrome bricks

common magnesia-chrome bricks include ordinary magnesia-chrome bricks, electro-fused rebonded magnesia-chrome bricks, direct-bonded magnesia-chrome bricks and sintered magnesia-chrome bricks. The main components are magnesia and chromium trioxide, which are characterized by high temperature strength and alkali resistance. Slag erosion ability is strong. The main crystal phase of magnesia-chrome bricks is mainly periclase and magnesia-chrome spinel.

First, the use of magnesia chrome bricks:

Magnesia chrome bricks are mainly used in the metallurgical industry, such as building open hearth furnace roofs, electric furnace roofs, refining furnaces outside furnaces and various non-ferrous metal smelting furnaces. The high-temperature part of the high-power electric furnace wall adopts fused-cast magnesia-chrome bricks, the high-erosion area of the refining furnace outside the furnace adopts magnesia-chrome bricks made of synthetic materials, and the high-erosion area of the non-ferrous metal flash smelting furnace is used.

Second, the characteristics of magnesia chrome bricks:

(1) High refractory temperature.

(2) The temperature of the 0.2MPA load softening edge is high.

(3) Strong resistance to alkaline slag.

(4) High temperature strength.

(5) Excellent volume stability at high temperature.

(6) The standard size is accurate and the construction is convenient, and the size can be processed according to the drawing.

There. Detection rules for magnesia chrome bricks:

1. The weight of each batch of bricks shall not exceed 100t.

2. Sampling and acceptance of bricks shall be carried out in accordance with YB 367-75 "Rules for Sampling, Acceptance, Storage and Transportation of Refractory Products".

3. Packaging, transportation, storage and quality certificate

4. The packaging, transportation and storage of bricks shall be carried out according to YB 367-75.

5. When the brick is issued, it is accompanied by a quality certificate issued by the technical supervision department, the name of the supplier or the factory logo, the name of the buyer, the date of delivery, the contract number, the standard number, the product name, the grade, the brick number, the batch number, and the size , appearance, section and physical and chemical indicators and other results.

0 notes

Photo

Living Room Formal

#An illustration of a mid-sized transitional formal living room with a dark wood floor#white walls#a regular fireplace#a stone fireplace#and no television. limestone fireplace#sliding doors#ceiling detail#coffered ceiling#yellow firebrick

0 notes

Text

Years ago I built this firebrick barbecue and at night when the temperature begins to drop it serves also as my garden fireplace .To sit in front sipping my brandy listening to my favorite music.Words and pic by Sergio Guyman.

#my garden bbq#also serving as an outdoor fireplace.#firebrick SK32#firewood only#firebrick SK 45#my photography#words by sergioguyman

0 notes

Photo

These Fire Bricks are burnt at high temperatures for longer periods. It's made of natural fire clay and is corrosion and chemical resistant. The Firebrick can be cut and rearranged to fit specific unique spaces.

0 notes