#pneumatic blower fan

Text

Significant advantages of using a Pneumatic blower fan

High-quality blowers are essential to keeping a plant or production line running; more modest and negligible choices are likewise valuable in the average family home. These blowers guarantee that air can move persistently while keeping an energy-proficient degree of activity.

A pneumatic blower fan gives an expanded wind stream, which diminishes how many virus spots in the home and works on the exhibition of humidifiers and air purifiers. They likewise include almost quiet engines, so you may not hear the framework running.

Applications and Utilizations of Superior Execution Blowers

Blowers are regular in plants and production lines since they assist with combatting pressure ascending in pipes that highlight parts like channels, grates, valves, warmers, and condensers. In addition, they are frequently conveyed with genuinely restricted lines to advance a higher and more grounded stream; this can be particularly useful in situations where exhaust should be eliminated from an area.

Blowers are utilized to deliver enormous volumes of air at lower pressures when contrasted with packed air. As a result, an enormous number of modern applications can utilize either compacted air or air created by blowers, even though there are a few applications where packed air is vital (air chambers, pneumatic devices).

Blowers enjoy a few upper hands over packed air for applications where either compacted air or blowers will work.

Blowers are highly productive. The operating expense of a blower is a negligible part of the expense of involving compacted air for a given volume of air. Blowers likewise give clean air. There is no risk of oil beads or buildup in the blower air stream since blowers don't involve oil as oil. The exhaust is additionally liberated from condensation since pneumatic stresses are not exactly compacted air, and this is the explanation accordingly not as inclined to cooling because of air extension. Regularly found on compacted air frameworks, this disposes of the requirement for standard oil and water channels.

The organization of blowers is done freely. Because of the distance from the blower, there is no requirement for high-strain funneling, drop lines, or worries about pressure drops. Also, closing down one won't influence the activity of others since blowers are autonomous of one another.

Blowers succeed at creating enormous volumes of air required for some modern drying, cleaning, ventilation, and vacuum applications. Whether regenerative or diffusive while looking for a blower, search for these qualities

# blower ought to match the application necessities;

# it ought to be dependable; and

# It is not difficult to keep up with and administer.

Blowers are being utilized in many places, like regenerative blowers, additionally known as Ring blowers, Vortex Blowers, Side Channel blowers, and so on, give more prominent tension than fans. Utilizes regenerative blowers to incorporate air circulation, drying, blending, vacuum, material exchange, and ventilation.

More prominent strain is created by divergent blowers and volume than regenerative blowers. However, there are a few benefits of radial blowers: transport and sheet drying, bottle and can drying, transport flotsam and jetsam expulsion, plastic drying, stepped parts drying, modern vacuum applications, food handling, landfill gas evacuation, and parts conveying.

While planning a blower framework by a Pneumatic blower fan supplier in UAE, the following elements should be viewed as, for example, the separation from the air blade or spout to the objective, target piece and speed of development, and the distance between the blower and the air blades.

0 notes

Text

The Industrial dampers emerges as the silent main character amidst the intricate coordination of air movement within ducts, chimneys, and diverse air-handling systems. Have you ever contemplated the intricate variations in ventilation or the mechanisms by which your room sustains its optimal temperature in the face of external challenges? In pursuit of understanding their critical function in preserving stability and comfort, let’s delve into the realm of industrial dampers by removing their external sections.

Industrial Dampers

1. Understanding Dampers

Imagine oneself within a chamber, relishing in the finest convenience of temperature regulation. Unidentified to you, a damper is operating inconspicuously to regulate the airflow and preserve this comfortable environment. Therefore, what is a damper exactly? In essence, it comprises a valve or plate that is deliberately positioned within air-handling apparatus, ducts, chimneys, or ducts to regulate the airflow.

2. Types of Industrial Dampers

Dampers aren’t just simple valves; they’re adaptable tools, crafted to meet diverse requirements. Manual dampers offer a hands-on approach, allowing adjustments with a simple turn of a handle. However, the innovation doesn’t stop there. Enter automatic dampers, equipped with electric or pneumatic motors, ensuring continuous airflow regulation.

Automating Comfort: The Magic of Automatic Industrial Dampers

Imagine a world where your room’s temperature adjusts seamlessly, without any manual intervention. Automatic dampers make this a reality, effortlessly fine-tuning airflow to maintain ideal conditions. It’s a futuristic marvel that simplifies life and enhances comfort, showcasing the remarkable capabilities of modern technology in the realm of air control.

3. Applications of Industrial Dampers

Now, let’s talk applications. Ever noticed how chimneys have dampers to keep unwelcome guests like birds and pesky weather elements at bay? These dampers also play a crucial role in controlling the rate of combustion, ensuring your cozy fireplace experience doesn’t turn into a smoke-filled nightmare.

But it’s not just about fireplaces and chimneys. Dampers are the crucial part of centralized air conditioning systems too. They can isolate unused rooms to save energy or regulate airflow for room-by-room temperature control. It’s like having your own personal climate butler ensuring every corner of your space is just the way you like it.

Let’s Explore more types of Industrial dampers

Multi-Blade Control Dampers:

Multi-blade control dampers, also known as rectangular or multi-blade louver dampers, come in two varieties based on blade action.

-Parallel Blade Action: All blades open and close at the same angle and direction.

-Opposed Blade Action: Adjacent blades rotate in opposite directions.

Single Blade Dampers:

Single blade dampers, known as butterfly or wafer dampers, are versatile and can be round, square, or rectangular.

-They may feature single thickness blades or a double skin airfoil design.

-Often, they provide a cost-efficient alternative to pricier valves.

Commercial and Industrial Backdraft Dampers:

Also called gravity dampers, backdraft dampers are vital in light, medium, and heavy-duty industrial and HVAC applications.

-These Industrial dampers allow airflow in one direction while preventing reverse flow, crucial for maintaining system integrity.

-Commonly installed on fans to prevent backspin caused by back pressure.

Face and Bypass Dampers:

-Face and bypass dampers, also known as diverter or tee dampers, serve specialized functions.

-They redirect high-temperature gases, often from turbines, to recover heat efficiently.

-Typically part of a dual damper setup, these dampers are integral components in tee-pipe configurations.

Inlet Vane Dampers:

Inlet vane dampers, also referred to as inlet vane controls (IVC dampers) or variable inlet vanes (VIV dampers), control airflow and pressure from the inlet side of fans or blowers.

-Mounted directly to the fan inlet, they offer both shut-off and control capabilities by rotating to pre-spin the entering air.

-These round dampers ensure dependable operation and cost savings for fan or blower operations.

Bubble Tight and Guillotine Dampers:

Isolation dampers are categorized into bubble tight and guillotine dampers, purchasable for both round and rectangular duct systems.

-High-end bubble tight dampers provide the most reliable seals, preventing leakage when closed.

-Guillotine damper models, equipped with seal air fans, achieve zero leakage and minimal pressure drop, primarily used for ductwork isolation and shut-off during maintenance.

Industrial dampers, in their various forms, uphold system efficiency, reliability, and safety across a spectrum of applications, ensuring optimal performance and control in diverse industrial and HVAC environments.

Safety First

Safety is paramount and should never be taken lightly. Failing to open a damper before lighting a fireplace can lead to serious consequences, such as smoke-filled rooms or even a house fire. It’s crucial to always check the condition of dampers before starting any fire. Ensuring that dampers are properly open helps prevent potential hazards and ensures a safer environment for everyone. Always prioritize safety by double-checking the status of dampers before igniting flames, mitigating the risk of accidents or damage.

Conclusion

In the grand tapestry of HVAC systems and industrial setups, industrial dampers may seem like minor players, but their role is anything but insignificant. From maintaining comfort to ensuring safety, these unassuming valves silently orchestrate the airflow, making our lives a little more comfortable and a lot safer. So, the next time you adjust your room temperature or light up your fireplace, take a moment to appreciate the humble damper – the unsung hero of air control.

0 notes

Text

Which audio foam shape is the best?

Audio foam comes in different shapes and densities.

Each density absorbs sound waves at different frequencies and can help you if you are confused how to reduce noise from outside. The different shapes provide different kinds of aesthetic textures and qualities.

Sound cancelling panels are used in different spaces such as music venues, offices, bars and restaurants. They localize noise in particular areas, bettering the quality of the sound.

What is positive displacement blower?

A positive displacement blower is also used is some pneumatic conveying applications as these work better than the fans. These offer different kinds of volumetric airflow but at high pressures in respect to centrifugal fans, but lesser than the PD blowers.

The main problem is that these work at extreme design conditions and expect more depreciation in respect to the PD blowers.

The impeller blades that pass through the inlet port draw the air into the blower. After that, the impeller blades, along with centrifugal action, enhance the air forward and outward.

Here the regenerative principle starts working as the air is turned back by the annular shaped housing.

Regeneration imparts more pressure to the air. The vacuums or pressure are generated by a couple of spinning, oil-free and non-contacting impellers.

Positive displacement compressors

In some cases where high discharge pressures are needed, positive displacement compressors are used. These work on the same principle as PD blowers but work in multistage either screw or rotary compressors.

Vacuum pumps

However, specifically designed vacuum pumps are also used in vacuum conveying application to develop high vacuum where the rotating components or seals are cooled by water or air.

There are different aspects that make up positive displacement blowers. They are a vital element to pneumatic conveying systems and making sure the process flows as seamlessly as possible.

0 notes

Text

Welcome to Omega Seals: Your Trusted Partner for Pump Seals

Welcome to the official blog of Omega Seals, a leading manufacturer of high-quality pump seals serving clients across India, UAE, Egypt, and South Africa. At Omega Seals, we take pride in our commitment to excellence, innovation, and customer satisfaction. With decades of experience in the industry, we have established ourselves as a trusted partner for businesses seeking reliable sealing solutions.

Our Products

Omega Seals specializes in the design and production of a wide range of pump seals tailored to meet the diverse needs of our clients. Our product offerings include:

1. Mechanical Shaft Seals: Engineered to prevent leakage and contamination in rotating equipment, our mechanical shaft seals provide robust sealing solutions for pumps, mixers, and other machinery.

2. Carbon Seals: Known for their exceptional durability and resistance to harsh operating conditions, our carbon seals offer reliable performance in high-temperature and high-pressure applications.

3. Pump Seals: Our pump seals are meticulously crafted to maintain fluid containment and prevent leakage in centrifugal, rotary, and reciprocating pumps, enhancing operational efficiency and safety.

4. Agitator Seals: Ideal for applications involving agitation and mixing, our agitator seals are designed to withstand dynamic forces and ensure leak-free operation in industrial processes.

5. Reactor Seals: Engineered for use in chemical reactors and process vessels, our reactor seals provide effective sealing solutions for corrosive and hazardous environments, safeguarding equipment and personnel.

6. Metal Bellow Seals: With their flexible metal bellows design, our metal bellow seals offer superior performance and longevity, making them suitable for a wide range of applications, including refineries, petrochemical plants, and pharmaceutical facilities.

7. Labyrinth Seals: Designed to control fluid leakage and minimize frictional losses, our labyrinth seals are widely used in turbomachinery, compressors, and gas turbines, ensuring efficient operation and prolonged service life.

8. Teflon Bellow Seals: Offering exceptional chemical resistance and low friction characteristics, our Teflon bellow seals are an ideal choice for handling corrosive fluids and abrasive particles in chemical processing, food, and pharmaceutical industries.

9. Blower Seals: Engineered for sealing blowers and fans, our blower seals deliver reliable performance under varying operating conditions, helping to maintain equipment integrity and efficiency.

10. Compressor Seals: Designed to withstand high pressures and temperatures, our compressor seals ensure gas-tight sealing in compressors and pneumatic systems, contributing to enhanced productivity and reduced maintenance costs.

Serving Global Markets

With a strong presence in India, UAE, Egypt, and South Africa, Omega Seals is dedicated to serving clients across diverse industries, including manufacturing, petrochemical, water treatment, and more. Our strategically located facilities enable us to efficiently cater to the needs of our customers while ensuring timely delivery and support.

Commitment to Quality

At Omega Seals, quality is at the forefront of everything we do. We adhere to stringent quality standards throughout the manufacturing process to ensure that our products meet the highest industry standards. From material selection to final inspection, every step is meticulously executed to guarantee the reliability and performance of our seals.

Innovation and Technology

Continuous innovation drives our commitment to excellence at Omega Seals. We invest in the latest technology and manufacturing processes to enhance product performance, efficiency, and longevity. By staying at the forefront of technological advancements, we empower our clients with cutting-edge sealing solutions that deliver superior results.

Customer Satisfaction

At Omega Seals, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, integrity, and mutual respect. Our dedicated team of professionals is committed to providing exceptional service and support, ensuring that our clients receive personalized attention and solutions that exceed their expectations.

Stay Connected

Thank you for visiting the Omega Seals blog. We invite you to stay connected with us for the latest updates, industry insights, and news. Whether you’re looking for expert advice on pump sealing solutions or want to learn more about our products and services, we’re here to help. Contact us today to discover how Omega Seals can meet your sealing needs with precision and reliability.

Contact Us At: https://www.omegaseals.com/ | +91 9769499061 | [email protected]

#Mechanical Seal#Mechanical Shaft Seals#Carbon Seals#Pump Seals#Agitator Seals#Reactor Seals#Metal Bellow Seals#Labyrinth Seals#Teflon Bellow Seals#Mechanical Seals Manufacturers#Blower Seals#Compressor Seals

0 notes

Text

Navigating the Essentials: Equipment Used in this pneumatic conveying system.

Pneumatic conveying equipment governs the material transport area in industry and serves as the technology of picking up materials from a point over varied distances and then transferring them up to certain locations. A number of special equipment types are indispensable to the efficiency of the system which performs the main functions of providing the safety of both the materials and the workers via the smooth, clean and secured flow of materials. Pneumatic conveying is a prevalent industrial process employed to transport materials over long distances. This blog specifically focuses on the types of equipment which are vital in these pneumatic conveying system and how these equipment function, the benefits these equipment bring to the table and their areas of application.

Bag Dump / Unloading Station

Functionality

A manual dumping station is the name given to the unloading stations for bulk materials, and they can be considered as the gateway to the pneumatic conveying system. They have been engineered in a bid to help in emptying bags, sacks or other containers containing products of respiratory hazards or dust forms for the operator and for generation of dust.

Applications and Benefits

Suitable to use when entities move bulk items in the bagged form, these stations often come with a dust collection system as an additional feature to boost environmental compliance and ensure safe work. Their design can be altered to conquer different materials that can give them opportunity for the use in industries such as pharmaceuticals, food and chemicals.

Roots Blower / Centrifugal Fan

Functionality

Not only are the roots blowers and centrifugal fans, but also they are constructive in bringing the certain needed air volume for pneumatic conveying. A roots blower is an option in the industrial fields due to its ability to supply a consistent volume of air with variable pressures, while a centrifugal fan is mainly intended for those applications which require a lot of air at low pressures.

Applications and Benefits

Such air movers are then selected among those that are suitable to the particular requirements of the specific system of pneumatic transportation—high-velocity air-flow is the main thing to be taken into account for dilute phase systems (the centrifugal fans are preferable), and the ability to maintain consistent pressure over longer distances is the key for the dense phase systems (roots blowers are more preferable in this case).

RAL(Rotary AirLock Valve), / Venturi Feeder

Functionality

Conveyor systems employ RALs and Venturi feeders to introduce materials to the above lines. Different types of RALs have their own characteristics, enabling them to maintain air pressure and allowing bulk materials to get into the system. Meanwhile, Venturi feeders are distinct from RALs in that materials are pumped into the air stream via the Venturi effect without any mechanical parts.

Applications and Benefits

Flexibility of RALs is in their function than to handle an array of materials together with their working environments. First, Venturi feeders, being more keeping, have fewer failures and necessity of repairs than the others and that proves that they are quite suitable for abrasive materials and those principally composed of fine particulates. These systems, though different, are of equal importance since they guarantee a flow which is not jerky and always accurate.

Pressure Vessel & Control Instruments

Functionality

As temporary storage receptacles, pressure vessels in a pneumatic conveying system inject materials to which the pressure is applied and then fine convection occurs towards the removing point. Certain security instruments, such as pressure gauges, flow meters, and sensors ensure system parameters control and optimal performance by providing real-time monitoring and regulation.

Applications and Benefits

These are the most important matters for forming the "dense phase", which has a close relationship with a proper monitoring of material flow and system pressure. The complex controllers supported by this kind of workflows is a tool for automation which, in turn, optimizes the efficiency and lowers the demand for human supervision.

Product Separator / Vent Filter / Dust Collector

Functionality

Post transportation, the product separators, which are the vent filters, and dust collectors, are included in the systems. These accessories purify the conveyed air flow steam and reduce dust emissions to the minimum. The cyclone separators, the bag filters, and the cartridge filters are examples of the predominantly used types of the filters.

Applications and Benefits

These systems are broadly required for ensuring the best air condition and the recycling of the invaluable items around us. They are formulated to comply with the strict environmental regulations, this not only makes delivery to be smooth but are environmentally friendly and provide safe working conditions for people.

Expansion Sections

For each of the following components, you would expand similarly, covering their functions, applications, benefits, and any relevant technical considerations:For each of the following components, you would expand similarly, covering their functions, applications, benefits, and any relevant technical considerations:

Storage Silos/Hoppers: Talk on their tasks such as storing of materials in bulk prior to or after conveying them, various factors to be discovered and incorporated to suit distinct types of materials and methods of integrating them with the conveyor system.

Special Valves for Diverting the Flow/Metering: Investigate the variety of valves implemented in pneumatic setups consisting of diverters to steer flow and metering valves to adjust the rate of the material movement including analysis of their flexibility and efficiency.

Control Panel: Expound on the central nervous system of the system, revealing the control panels and the systems monitoring, controlling and safeguarding capability within the process.

Piping with Special Cross-Section Bends: Home in on the key to pipe design, that is, the durable material and the bends which reduce the wear and impact on the system while maintaining the optimal flow of materials.

Gas Cooling Heat Exchanger for Closed Loop Systems: Explore the function of heat exchangers as the primary temperature regulators in pneumatic systems, noting their relevance to materials that get easily affected when subjected to high temperatures or applications where the temperature of the materials determines the material properties.

Conclusion

Restating, now shows why knowing about each part within a pneumatic conveying system and what it does is essential. The rightness of the system's selecting and incorporation of the elements will affect its both efficiency and reliability and also environment. These concerns will be dealt with in the standards.

#pneumatic conveying#pneumatic conveyor system#pneumatic conveying system#pneumatic conveying systems#conveying system

0 notes

Text

Pneumatic conveyor system Manufacturers

Pneumatic conveyor system Manufacturers

A pneumatic conveyor is a system used to transport materials or objects within a facility or production environment using compressed air or gas as the conveying medium. Instead of using belts, chains, or other mechanical means, pneumatic conveyors rely on air pressure differentials to move materials through a pipeline or ductwork.

There are several types of pneumatic conveyors, including:

Pressure or Dense Phase Pneumatic Conveyors: In this type, materials are conveyed at higher pressures and lower velocities, typically in a batch-wise manner. The material is tightly packed and moves in a slug-like motion through the pipeline.

Vacuum or Dilute Phase Pneumatic Conveyors: These operate at lower pressures and higher velocities compared to dense phase conveyors. They use a vacuum created by a blower or fan to pull materials through the pipeline. Materials are usually conveyed in a dilute phase, meaning they are more spread out within the conveying airstream.

Combination Systems: Some systems combine elements of both pressure and vacuum conveyance, depending on the specific requirements of the application.

Pneumatic conveyors are commonly used in industries such as food processing, pharmaceuticals, chemicals, plastics, and manufacturing, where there is a need to transport materials efficiently and hygienically. They offer advantages such as gentle handling of materials, flexibility in routing, and the ability to convey materials over long distances and around obstacles.

However, pneumatic conveyors also have limitations, including higher energy consumption compared to mechanical conveyors and limitations on the types of materials that can be effectively conveyed. Additionally, proper system design and maintenance are crucial to ensure efficient operation and prevent issues such as material degradation or blockages within the pipeline.

Visit :

As one of the most sought-after pneumatic conveyor system manufacturers, we take great pride in our achievement and also remain humbled by the confidence our customers have bestowed upon us over the years

0 notes

Text

Dynemech Spring Isolators: Enhancing Vibration Control Across Industries

Extensive range of Visco Dampers, Spring Based Vibration Dampers, Open Spring Mounts

Introduction:

In the ever-evolving landscape of the manufacturing industry, precision machinery sector, and large-scale structures, the demand for effective vibration isolation solutions has witnessed significant growth. This surge is driven by the desire for structures to exhibit greater fatigue resistance and meet the escalating expectations for human comfort in both static and dynamic scenarios. Addressing these evolving standards necessitates the continuous advancement of vibration mitigation methods.

With an impressive 23-year history as a prominent global leader in anti-vibration solutions, Dynemech sets itself apart as a versatile engineering company specializing in vibration damping products and solutions. It specializes in crafting customized vibration mitigation solutions and manufactures an extensive array of vibration control systems, all under a single roof.

Their diverse product portfolio includes Pneumatic Isolators, High Accuracy Self Levelling Membrane Air Springs, Elastomeric Pads, Spring-based isolators, Springs with Viscous Damping, Inertial Mass solutions, as well as Anti-Vibration tables and platforms.

Our vibration damping solutions consists of stud mounts for very small machines/electrical panels to wedge mounts for precision machine tools, along with air springs for very low natural frequency vibration damping to spring isolators for heavy presses, hammers, gen sets etc.

Key Features of Dynemech Spring Isolators:

A spring isolator gives desired natural frequency to obtain phase difference in the frequencies for a rotating machine and impact generating machine. Viscous Damping is an important feature of an isolation system. In most cases viscous damping is required to limit excessive movement which could occur as a machine operates at a speed near to, or coinciding with the resonant frequencies of the system. Generally this problem arises during slow run up and run down of rotating machines and during impact at each stroke in presses and hammers.

Benefits of Spring Isolators:

1. High Vibration and Shock Isolation:

• Effective in mitigating both vibration and shock, ensuring operational stability.

2. Enhanced Structural Safety:

• Contributes to the structural integrity of machinery and surrounding infrastructure.

3. Health Protection and Operator Comfort:

• Reduces machine operator fatigue, creating a more congenial working environment.

4. Flexible Workshop Setup:

• Allows for the installation of sensitive equipment and heavy machinery in the same workshop.

5. Extended Equipment Life:

• Contributes to prolonged tool and machinery lifespan.

6. Reduced Foundation Requirements:

• No foundation is required for small and medium-weight machines.

• Reduced foundation depth for very heavy machines.

7. Ease of Installation:

• Simple to install, providing a reliable solution for various applications.

Applications:

1. Power Presses/Forging Hammers

2. Fans/Blowers/Centrifuges

3. Generating Sets

4. Test Beds

5. Textile Machines

6. Reducing Mills and Mixers

7. Coal and Stone Crushers

8. Refrigeration Units

9. Pumps and Boilers, etc.

Range of Spring Isolators :

1. Dynemech Restrained Spring Isolators

2. Dynemech Open Spring Mountings

3. Dynemech Spring Viscous Dampers with Shock Isolation

4. Dynemech Viscous Spring Isolators with multi-degree Restrainer.

5. Spring Isolators with Integrated Visco Dampers

6. Dynemech Spring isolators for forging hammers

7. DYNEMECH Vibration and Shock Control Solutions for FORGING PRESSES.

8. Spring Isolators for Hopper in Iron Ore Industry

9. Spring Support for Isolated Foundation of Centrifuges

10. Spring Support for Power Sector , Crushers, Turbines

Conclusion: Dynemech's Spring Isolators emerge as a pivotal solution in the realm of vibration control, offering a wide array of benefits across diverse industrial applications. With their proven track record and commitment to solving all vibration-related problems in all types of heavy industrial manufacturing setups, Dynemech continues to play a crucial role in enhancing the efficiency, safety, and reliability of machinery worldwide.

#Dynemech,#Spring Isolators,Vibration control,Anti-vibration solutions,#Precision machinery,#Viscous damping,#Natural frequency,#Equipment life,#Foundationrequirements,#Industrial applications.

Contact:

M:+91-9810760131

Website: www.vibrationmountsindia.com

#Dynemech#Spring Isolators#Vibration control#Anti-vibration solutions#Precision machinery#Viscous damping#Natural frequency#Equipment life#Foundationrequirements#Industrial applications.

0 notes

Text

Best Process Gas Blowers Manufacturer in India

Manufacturer of Rotary Piston Blower, Process Gas Blower, and centrifugal Fans offered by Swam Pneumatics Pvt.Ltd from Noida, Uttar Pradesh, India.Process Gas Blower. Get the Best Quote. Centrifugal Fans. Call us today +91-120469 6222

#condencer exhausters#Mechanical vacuum boosters#truck blowers#air blower exporter#vacuum pump manufacturer#bio gas blowers#Turbo Blower#bio gas compressors#Roots blower#Roots blower manufacturer#Positive displacement blowers#best process gas blowers manufacturer in india#Best Air Blowers Manufacturer in Delhi#best process gas blowers#Twin lobe blowers

0 notes

Text

Efficient Pneumatic Conveying System

Sodimate's pneumatic conveying systems use compressed air to transport powders, which allows them to be used in applications with complex paths. They can transport powders over long distances, from 0.2 kg / h up to 1000 kg / h, using fans or blowers depending on the product flow and the length of the piping. Contact us for top-notch powder conveying solutions.

#PneumaticConveying#MaterialHandling#BulkMaterialTransport#PneumaticTransportation#ConveyorSystems#IndustrialAutomation#PowderHandling#PneumaticConveyorTechnology#EfficientConveying#MaterialTransfer#ConveyorSolutions#MaterialHandlingEquipment#PneumaticConveyorSystem#ProcessAutomation#MaterialHandlingSolutions#PneumaticConveyorDesign#IndustrialConveying#PneumaticTransfer#MaterialTransportation#BulkHandling

1 note

·

View note

Text

Centrifugal Blower Manufacturer in Pune

We are Leading Exporter of Axial Flow Fans, Centrifugal Blower Manufacturer in Pune

Established in the year 1988 in Faridabad (Haryana, India), “Ventilair India Private Limited” is amongst the leading Manufacturer and Exporter of Axial Fan, Air Handling Unit, Dust Collector, Air Washer, AC Axial Fan, Ventilation Fan, Induced Draft Fan, Jet Fan, Axial Flow Fans, and Centrifugal Blower in Pune. Our product range includes Air Cooling System, Industrial Scrubber, Pneumatic Conveying System, Ventilation System Equipment, Metal Impeller, etc. The organization has come a long way from its modest beginning to its current market position. We have built a strong reputation in the market by manufacturing & supplying top grade products.

0 notes

Text

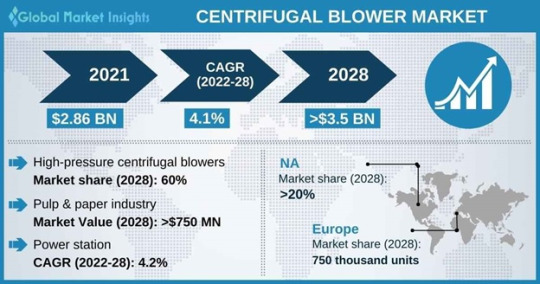

Centrifugal Blower Market Expansion Projected to Gain an Uptick During 2022-2028

The centrifugal blower market is estimated to grow significantly by 2028 primarily owing to rising product demand in cement production, petrochemicals, metal fabrication, and cryogenics.

Recently, burgeoning need for energy across virtually all industries globally has created an upsurge in the need for power producing units, such as nuclear power plants, coal power plants, thermal power plants, and hydro-power plants. These plants rely heavily on centrifugal fans and blowers to supply air for combustion and other types of heat transfers, which has been favorable for industry expansion.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/2602

Furthermore, centrifugal blowers have gained massive popularity in a number of industries, such as food and drinks, construction, and mining, particularly due to their efficiency and durability. In addition, escalating product requirement in regions with a high volume of air or gas has bolstered market uptake. Notably, industry players have increasingly been investing in product development and innovation in order to gain a competitive edge in the centrifugal blower market, thereby enhancing overall business dynamics.

For instance, in June 2021, Indian Space Research Organization (ISRO), the national space agency of India, introduced the Ventilation Assist Unit (VaU), an ICU grade positive pressure mechanical ventilator that has been designed to assist or replace spontaneous breathing in patients suffering from respiratory distress. The VaU has been designed based on a centrifugal blower that pulls in filtered ambient air, compresses it, and delivers it to the patient to provide ventilation, which allows it to function without a compressed pneumatic source.

The centrifugal blower market has been segmented on the basis of pressure, end-user, and region. In terms of end-user, the centrifugal market has been divided into cement plant, pulp & paper, chemical, steel plant, power station, mining, others. The cement plant end-user segment is foreseen to observe significant growth to garner a revenue share of more than 10% by 2028. The proliferating construction industry and mounting demand for cement and minerals are estimated to spur the growth of the segment.

The steel plant end-user segment is anticipated to witness substantial growth by 2028, registering approximately 3.6% CAGR by the forecast timeframe. Centrifugal blowers are used in steel plants to tackle problems like high temperatures and to cater to the need for a high output situation, which is likely to fuel segmental development in the upcoming years.

Request for customization @ https://www.gminsights.com/roc/2602

From the regional point of view, the Latin America centrifugal blower market is estimated to grow at a CAGR of over 3.7% through the forecast period. Meanwhile, the Middle East & Africa centrifugal blower industry held a volume share of around 7% in the overall market in 2021 and is projected to amass notable gains over 2022-2028.

Table of Contents (ToC) of the report:

Chapter 2 Executive Summary

2.1 Centrifugal blower industry 360° synopsis, 2018 – 2028

2.1.1 Business trends

2.1.2 Pressure by end-user trends

2.1.3 End-user trends

2.1.4 Regional trends

Chapter 3 Centrifugal Blowers Industry Insights

3.1 Industry segmentation

3.2 Industry size and forecast, 2018 – 2028

3.3 Industry ecosystem analysis

3.4 Innovation & sustainability

3.5 Industry impact forces

3.5.1 Growth drivers

3.5.1.1 Rapidly growing construction industry in the Asia Pacific

3.5.1.2 Strong product demand from power and mining industry in the U.S.

3.5.1.3 Growing food industry in the Asia Pacific

3.5.2 Industry pitfalls & challenges

3.5.2.1 High production and maintenance cost

3.6 Regulatory landscape

3.7 Growth potential analysis

3.8 Competitive landscape, 2020

3.9 Porter’s analysis

3.10 Regional price trends

3.11 PESTEL Analysis

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/centrifugal-blower-market

HVAC & Construction Research Reports

Asphalt Mixing Plants Market

Painting Tools Market

Building Thermal Centrifugal Blower Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Centrifugal Blower Market Analysis#Centrifugal Blower Market by Type#Centrifugal Blower Market Share#Centrifugal Blower Market Development#Centrifugal Blower Market Growth

0 notes

Text

Pneumatic Air blower fans

Cutting machines have been precious in the space of assembling. In any case, there are astonishing advantages clients can get by putting resources into air blowers on the web. With Pneumatic Air blower fans being utilized for current cycles, minimized and more modest choices are accessible for home use.

0 notes

Text

Centrifugal Blowers Manufacturers in Ahmedabad,Gujarat,India

Discription:

Features:

Capacity: 150 CFM to 85,000 CFM (200 CMH to 1,40,000 CMH)

Pressure: 50 mm WC to 1500 mm WC (2” WC to 60” WC)

Motor HP: 1 HP to 200 HP

Type: Induced Draught, Forced Draught

MOC: MS, SS 304, 316, 316L, FRP

Application:

Industrial furnace and Boiler, Chemical Processing Plant, Textile Plant, Cement Plant, Dairy Refrigeration Plant, Gas and Oil Firing Burner, Dust Collecting System, Ceramic Industries, Petro – Chemical Plant, Power Plant, Air Conditioning Plant, Ventilation System (in Hotels, Hospitals, Restaurant, Residents, Cinema Hall, Tunnel etc.), Pneumatic Conveying System of Powder and Granules.

Unique Features :

The SHIVAM Engineers Centrifugal Blowers Manufacturers in Ahmedabad,Gujarat are backed by computer software or design selection and detailed performance characteristics. It can offer low pressure ventilation fans with very high air volume and also makes very high pressure fan. It can offer various types of shaft seals to avoid leakages of gases. The SHIVAM blowers have careful design against noise pollution.

#Centrifugal Blowers Manufacturers in Ahmedabad#Centrifugal Blowers Manufacturers in Gujarat#Centrifugal Blowers Manufacturers in India#Centrifugal Blowers Manufacturers

0 notes

Text

Essential cleaning products in Singapore

Steam Cleaners

Steam cleaners are cleaning devices that use high-temperature steam to clean and sanitize various surfaces. They are a popular and effective alternative to traditional cleaning methods that rely on harsh chemicals and detergents.

Steam cleaners heat water to a high temperature, typically above 200 degrees Fahrenheit, and then release the resulting steam through a nozzle or brush attachment. The steam loosens and dissolves dirt and grime on surfaces, and the high temperature also kills bacteria, germs, and other microorganisms, making it a great option for sanitizing and disinfecting.

Steam cleaners can be used on a variety of surfaces, including floors, carpets, upholstery, tile, and grout. They can also be used to clean and sanitize kitchen appliances, bathrooms, and other areas where bacteria and germs can thrive.

There are several types of steam cleaners available on the market, including handheld steam cleaners, canister steam cleaners, and steam mops. Handheld steam cleaners are portable and versatile, making them ideal for spot cleaning and hard-to-reach areas. Canister steam cleaners are larger and more powerful, making them better suited for heavy-duty cleaning tasks. Steam mops are designed specifically for cleaning floors and typically come with a mop head and a water tank.

Overall, steam cleaners are an eco-friendly and effective way to clean and sanitize various surfaces without relying on harsh chemicals or detergents.

Air Blower

An air blower is a device that is designed to blow air at high speed in order to create a powerful stream of air. Air blowers come in a variety of sizes and styles, and can be used for a wide range of applications.

In industrial settings, air blowers are commonly used to move large volumes of air, such as in ventilation systems, pneumatic conveying systems, and drying processes. They can also be used to clean machinery and equipment, remove debris and dust from work areas, and provide air for combustion in furnaces and boilers.

In commercial and residential settings, air blowers can be used for tasks such as drying carpets and upholstery, inflating inflatable structures such as bounce houses, and blowing leaves and other debris off of outdoor surfaces.

Air blowers typically use electric motors or gas engines to power a fan or impeller, which creates a stream of air. The air is then directed through a nozzle or other attachment to provide the desired airflow.

It is important to note that air blowers can be quite loud and may produce high levels of noise, which can be a concern in certain settings. Additionally, when used to blow debris or dust, air blowers can create airborne particles that may be hazardous to breathe, so proper protective equipment should be worn.

Battery Powered Leaf Blowers

Battery-powered leaf blowers are a type of leaf blower that uses rechargeable batteries as a power source, rather than gasoline or electricity from an outlet. They are becoming increasingly popular as a more convenient and environmentally-friendly option for yard cleanup.

One of the main advantages of battery-powered leaf blowers is their portability and convenience. They are generally lightweight and easy to maneuver, making them ideal for use in smaller yards or for quick cleanups. They also do not require a power cord or gasoline, so there are no cords to trip over or fumes to inhale.

Battery-powered leaf blowers typically use lithium-ion batteries, which provide a longer run time and faster charging than other types of batteries. However, the run time and power output can vary depending on the size of the battery and the model of the leaf blower. Some models may only provide enough power for light-duty tasks, while others are capable of handling heavier debris and larger yards.

Another advantage of battery-powered leaf blowers is their low noise output. They are generally much quieter than gas-powered leaf blowers, making them a better choice for use in residential areas where noise restrictions may apply.

However, there are some potential drawbacks to consider when using a battery-powered leaf blower. The run time may not be sufficient for larger yards or heavy-duty tasks, and the batteries may take several hours to fully recharge. Additionally, some models may not provide as much power as gas-powered leaf blowers, so they may not be as effective at moving heavy debris or wet leaves.

Overall, battery-powered leaf blowers can be a convenient and effective option for smaller yards or light-duty tasks. However, it is important to choose a model with the right power output and battery size for your needs and to ensure that the battery is fully charged before use.

Disinfectant Sprayer

A disinfectant sprayer is a device that is designed to spray disinfectant solutions onto surfaces to kill germs and bacteria. These sprayers are commonly used in a variety of settings, including hospitals, schools, offices, and homes.

Disinfectant sprayers come in several different types, including handheld sprayers, backpack sprayers, and electrostatic sprayers. Handheld sprayers are portable and easy to use, but may not be suitable for larger areas. Backpack sprayers are worn like a backpack and are ideal for larger areas, but may be heavier and less maneuverable. Electrostatic sprayers use an electrostatic charge to ensure that the disinfectant solution is evenly distributed over surfaces, which can help to improve coverage and reduce waste.

Disinfectant sprayers typically use a disinfectant solution that is approved by the Environmental Protection Agency (EPA) for use against specific types of viruses and bacteria. These solutions may be either alcohol-based or water-based, depending on the type of surface being disinfected.

One of the main advantages of using a disinfectant sprayer is that it can help to quickly and effectively kill germs and bacteria on surfaces. This can be particularly important in settings where people may be at risk of exposure to infectious diseases.

However, it is important to use disinfectant sprayers properly in order to achieve the desired results. The solution must be allowed to sit on surfaces for a certain amount of time in order to effectively kill germs and bacteria, and the sprayer must be used in a way that ensures even coverage of all surfaces.

Additionally, it is important to follow all safety guidelines when using disinfectant sprayers. This may include wearing protective clothing, gloves, and masks, and ensuring that the area being sprayed is well-ventilated.

Entrance Matting

Entrance matting, also known as entryway matting or entry mats, is a type of flooring system that is designed to be used at the entrances of buildings. It is typically made up of a series of mats or tiles that are placed at the entryway to help remove dirt, moisture, and debris from the shoes of people entering the building.

Entrance matting serves several important functions. First, it helps keep floors clean and dry by trapping dirt and moisture before they can be tracked further into the building. This can help to prevent slips and falls, reduce maintenance costs, and extend the life of flooring surfaces.

In addition to their practical benefits, entrance mats can also be used to enhance the appearance of a building's entryway. They come in a wide range of materials, colors, and styles, and can be customized to feature logos or other branding elements.

There are several different types of entrance matting available, including carpet mats, rubber mats, and aluminum grates. Carpet mats are soft and absorbent, making them ideal for indoor use. Rubber mats are durable and slip-resistant, making them suitable for outdoor use. Aluminum grates are highly effective at removing dirt and moisture but can be more expensive than other types of matting.

When selecting entrance matting, it is important to consider factors such as the amount of foot traffic in the area, the types of shoes that will be worn, and the environmental conditions. Proper maintenance is also important in order to ensure that the mats remain effective at trapping dirt and moisture over time. This may include vacuuming or hosing off the mats on a regular basis, as well as replacing worn or damaged mats as needed.

Floor Polisher

A floor polisher, also known as a floor buffer or floor scrubber, is a machine that is used to clean and maintain the appearance of various types of hard floorings, such as tile, hardwood, and concrete. The machine typically consists of a motorized circular pad or brush that rotates at a high speed to scrub or polish the floor.

Floor polishers come in several different types and sizes, including handheld models, walk-behind models, and ride-on models. Handheld models are smaller and more portable, making them ideal for use in tight spaces or for spot cleaning. Walk-behind models are larger and can cover a wider area, making them suitable for larger commercial or industrial spaces. Ride-on models are even larger and are designed for use in very large spaces, such as warehouses or airports.

Floor polishers can be used for a variety of tasks, including stripping old wax or finish from a floor, applying new wax or finish, and buffing or polishing the floor to a high shine. The type of pad or brush used will depend on the type of flooring being cleaned and the specific task being performed.

Using a floor polisher can offer several benefits, including improved appearance and increased durability of the flooring. Regular cleaning and maintenance can help to extend the life of the flooring and reduce the need for costly repairs or replacements.

However, it is important to use a floor polisher properly in order to avoid damage to the flooring or the machine. This may include selecting the appropriate pad or brush for the task at hand, using the correct amount of cleaning solution, and avoiding excessive pressure or speed that could cause damage. Proper training and safety equipment should also be used when operating a floor polisher.

Industrial Vacuum Cleaners

Industrial vacuum cleaners, also known as commercial vacuum cleaners, are powerful and durable cleaning machines that are designed to handle heavy-duty cleaning tasks in commercial and industrial settings. They are typically larger and more robust than household vacuum cleaners and can pick up larger debris and clean more frequently.

Industrial vacuum cleaners come in a variety of sizes and types, ranging from handheld models to large, ride-on machines. They are typically powered by electricity, but can also be powered by gasoline or diesel engines for outdoor use.

One of the main advantages of industrial vacuum cleaners is their ability to clean large areas quickly and efficiently. They can also handle a wide range of surfaces and debris types, including dust, dirt, gravel, and metal shavings.

Industrial vacuum cleaners typically use a combination of suction and airflow to remove debris from surfaces and transport it into a collection bag or container. Some models also feature filters or separators to remove fine dust or other particles from the air before it is released back into the environment.

When selecting an industrial vacuum cleaner, it is important to consider factors such as the size of the space to be cleaned, the types of debris and surfaces, and the power source available. Some models also come with additional features, such as adjustable suction power, noise reduction technology, and easy-to-empty collection containers.

Proper maintenance and cleaning are also important to ensure the longevity and effectiveness of the machine. This may include regularly checking and replacing filters, emptying and cleaning the collection container, and inspecting the machine for signs of wear or damage.

Wet Vacuum Cleaning

Wet vacuum cleaning, also known as wet-dry vacuuming, is a cleaning process that involves using a specialized vacuum cleaner to clean up liquid spills or wet debris from floors, carpets, and other surfaces. Unlike traditional vacuum cleaners, wet vacuums are designed to handle liquids and are equipped with specialized components that prevent damage to the motor or other components.

Wet vacuum cleaners typically feature a larger capacity than traditional vacuum cleaners and are able to collect and hold liquids in a separate tank or chamber. They may also come with specialized tools, such as squeegees and brushes, that are designed to effectively clean up liquid spills and wet debris.

Wet vacuum cleaning can be particularly useful in commercial or industrial settings where spills and wet debris are common. It can help to prevent slip-and-fall accidents, reduce the risk of mold growth, and improve the overall cleanliness and safety of the space.

When using a wet vacuum cleaner, it is important to follow proper safety precautions, such as wearing appropriate personal protective equipment and ensuring that the machine is properly grounded. It is also important to properly maintain and clean the machine to prevent the buildup of mold or bacteria and to extend its life of the machine.

Overall, wet vacuum cleaning is an effective and efficient way to clean up liquid spills and wet debris, and is a valuable tool for commercial and industrial cleaning applications.

Baby changing Stations

Baby changing stations, also known as diaper changing stations, are specialized fixtures designed for changing the diapers of infants and toddlers. They are typically found in public restrooms, daycare centers, and other facilities that cater to young children and their caregivers.

Baby changing stations are available in several different types and styles, including wall-mounted units, countertop units, and freestanding units. They are typically made from durable materials, such as plastic or stainless steel, and feature a flat, padded surface for the baby to lie on while being changed.

Many baby changing stations also come equipped with additional features, such as safety straps to secure the baby during the changing process, built-in diaper storage compartments, and antimicrobial surfaces to help prevent the spread of germs.

When selecting a baby changing station, it is important to consider factors such as the size of the space available, the number of babies that will be using the station, and the level of traffic the facility receives. It is also important to choose a station that meets all relevant safety standards and regulations.

Proper maintenance and cleaning are also essential to ensure the safety and cleanliness of the baby changing station. This may include regular cleaning with a disinfectant solution, inspecting the unit for signs of wear or damage, and replacing any damaged or worn components as needed.

Overall, baby changing stations are an important fixture in facilities that cater to young children and their caregivers and can help to promote hygiene, safety, and convenience for all users.

0 notes

Text

ETP and Centrifugal Blowers Manufacturers in India

ETP (Effluent Treatment Plant) and centrifugal blowers are two different things, but they can be used together in the treatment of wastewater.

An ETP and Centrifugal Blowers is a plant used to treat industrial wastewater and remove pollutants from it before it is discharged into the environment. The process of treating the wastewater involves several stages such as primary treatment, secondary treatment, and tertiary treatment. Each stage involves different processes such as sedimentation, biological treatment, and filtration.

Centrifugal blowers are devices used to provide air or gas flow at high pressures. They are commonly used in ETPs to supply air to the biological treatment process. In the biological treatment process, microorganisms are used to break down the pollutants in the wastewater. These microorganisms require oxygen to survive, which is supplied by the air from the centrifugal blowers. The air is diffused into the wastewater, creating an aerobic environment that promotes the growth of the microorganisms.

Overall, the combination of ETP and Centrifugal Blowers is an effective way to treat wastewater and protect the environment from pollution.

ETP stands for Effluent Treatment Plant, which is a facility designed to treat and purify industrial wastewater before it is discharged into the environment. The process of treating wastewater involves various stages, such as physical, chemical, and biological treatment, and the use of ETPs helps to ensure that the wastewater meets the required environmental standards.

Centrifugal blowers, also known as centrifugal fans, are mechanical devices used to create a continuous flow of air or gas. They work by using centrifugal force to increase the velocity of the air or gas, which creates pressure and causes the air or gas to move through a system of ducts or pipes. Centrifugal blowers are commonly used in a variety of industrial applications, including ventilation, exhaust systems, and pneumatic conveying.

In the context of ETPs, centrifugal blowers are often used to provide the air or gas needed for the aeration process, which is a key step in the biological treatment of wastewater. Aeration is the process of adding air or oxygen to the wastewater to stimulate the growth of microorganisms that help to break down organic pollutants. Centrifugal blowers can provide the necessary air flow to create the right conditions for the microorganisms to thrive and efficiently treat the wastewater.

A chromic fume scrubber system is a type of air pollution control device used to remove harmful chromic acid fumes from industrial exhaust streams. Chromic acid fumes are commonly produced during metal plating and surface finishing operations, and can pose a significant health hazard if not properly controlled.

The scrubber system typically consists of a vessel filled with a liquid scrubbing solution, such as sodium hydroxide or calcium hydroxide, which is designed to react with the chromic acid fumes and neutralize them. The exhaust stream is directed into the scrubber vessel, where it passes through the scrubbing solution and the fumes are absorbed.

The system may also include various components, such as mist eliminators, pumps, and recirculation systems, to optimize the scrubbing process and remove any remaining pollutants from the exhaust stream.

Chromic fume scrubber systems are typically designed and installed in compliance with local air pollution control regulations, which may specify specific design requirements, operation parameters, and monitoring and reporting requirements. Proper maintenance and monitoring of the system are also essential to ensure its continued effectiveness in removing chromic acid fumes and protecting worker health and safety.

Call Now : +91 9822962750, 9881843815

More about information for ETP and Centrifugal Blowers then Visit our site - https://www.jaibhavaniengineering.com/etp-centrifugal-blower.html

#ETP and Centrifugal Blowers#Centrifugal Blowers#ETP and Centrifugal Blowers in Nashik#Centrifugal Blowers in Nashik

1 note

·

View note

Link

Using an industrial blower, impeller, and airfoils housed in a well sealed enclosure, an industrial blower effectively and efficiently improves airflow. Industrial blowers are used to improve airflow and eliminate pollutants including dust, dirt, and particle matter. They are extremely complex machines made to produce pressure greater than that of a fan at a ratio of 1.11 to 1.2, which puts them between a fan and a compressor.

Centrifugal, multistage centrifugal, axial, and positive displacement blowers are the several types of industrial blowers. Centrifugal blowers can be single-stage or multi-stage devices with a gear system. Positive displacement blowers feature a rotor geometry, whereas axial industrial blowers have a central shaft and attached blades similar to residential fans.

Industrial blowers are an essential part of any type of production or manufacturing operation to increase airflow and create positive air pressure. Present-day industrial blowers were developed in the middle of the first industrial revolution as air pumps for internal combustion engines. The simple design of these initial designs included a motor, shaft, and impeller blades.

Positive Displacement Industrial Blowers

Positive displacement industrial blowers, also referred to as lobe blowers, release air using a safety valve at a particular time, pressure, velocity, and direction. The two counterrotating propellers in the system give rise to the moniker "lobe blower." The blower's outlet and chamber are both filled with air. The blower can maintain constant airflow and pressure thanks to this design.

Centrifugal Industrial Blower

Due to their ability to continually transport gas and air while also blocking air contaminants, centrifugal industrial blowers are the most common type of industrial blower utilized in ventilation systems. The speed and volume of the air are gradually raised as it passes through a set of rotating impellers. As more air is drawn through it, the fan wheel changes its direction and quickens. The blower's kinetic energy rises as more air is introduced.

Multi-Stage Centrifugal Blowers

When a variable flow at constant pressure is necessary, multistage centrifugal blowers are used. They increase pressure by utilizing impellers to accelerate airflow and long-diameter, very effective diffusers to decrease it. A valve on the suction side controls the airflow while keeping the pressure steady and uniform.

Regenerative

High-flow low-pressure compressed air blowers are another name for regenerative industrial blowers. They create a vacuum or a quick flow of compressed air at low pressure. Compressed air is moving throughout the housing, creating pressure. The air circulates once in a single-stage blower and twice in a two-stage blower, depending on the type of blower. Higher pressure is produced by regenerative blowers with two stages.

High-Speed Industrial Blower

High pressure and quick airflow are produced when a high-speed industrial blower works. To maximize the amount of air being absorbed, impellers are positioned around the blower's shaft and are driven by an electric motor. A high-speed blower's architecture comprises of a valve for air release and a compression unit for blower speed control. Each of these elements can be simply changed to suit the operation's requirements.

Helical Screw Industrial Blower

A helical screw industrial blower features a second rotor in addition to a main rotor with two lobes. The second rotor's flute receives the main rotor. Industrial blowers with helical screws have a more complex design, but they are incredibly effective at delivering higher pressure. To prevent a collision, the two rotors rotate in a helical pattern that is precisely synchronized.

Axial Industrial Blower

Positive and negative pressure is created around the blades of axial industrial blowers, resulting in airflow. To account for variations in atmospheric pressure, the fan blades are positioned vertically and inclined. An axial blower forces the air to travel in a direction that is axially parallel to the shaft around which the rotating blades are mounted. The air pressure difference that leads to continuous airflow is produced by this design. The quantity and design of an axial fan's blades affect its performance.

Vapor Recovery Industrial Blower

Industrial centrifugal blowers known as vapor recovery blowers are used to gather gas and fuel vapors so they don't escape and enter the atmosphere. When there are poisonous, explosive, or flammable vapors present, a certain type of industrial blower may be mandated by law. As gasoline storage tanks are full, pressure increases. Vapor recovery industrial blowers remove the pressure-related vapors and send them to be converted to natural gas or burned off.

0 notes