#pavers set in sand

Photo

Mediterranean Wine Cellar

Medium-sized terra cotta tile wine cellar in Tuscany with racks for storage

#redwood racking#barrel vault#pavers set in sand#corking table#wine labels#countertop#herringbon tile pattern

0 notes

Photo

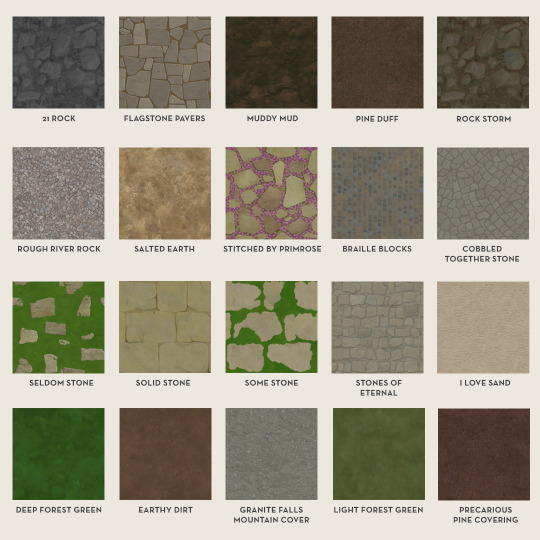

Advent Calendar 2023 — Day 1 — Ground Cover

An advent calendar in February? Why not! 🎄 From 6 February to 17 February, I'll be releasing a new gift set for your Sims 2 game every day! 🤍

Welcome to Day 1! We're starting off with Ground Cover, a set of 20 terrain paints converted from The Sims 4 to The Sims 2, to really help beautify your lots.

Be sure to visit tomorrow for your next gift! ˖˟ ⸜₍⁽ˊ꒳ˋ⁾₎⸝ ˟˖

Included in this set are:

BASE GAME

— 21 Rock

— Flagstone Pavers

— Muddy Mud

— Pine Duff

— Rock Storm

— Rough River Rock*

— Salted Earth

EXPANSION PACKS

— EP02 Get Together: Braille Blocks

— EP02 Get Together: Cobbled Together Stone

— EP02 Get Together: Seldom Stone

— EP02 Get Together: Solid Stone

— EP02 Get Together: Some Stone

— EP02 Get Together: Stones of Eternal

— EP11 Cottage Living: Stitched by Primrose*

GAME PACKS

— GP01 Outdoor Retreat: Deep Forest Green

— GP01 Outdoor Retreat: Earthy Dirt

— GP01 Outdoor Retreat: Granite Falls Mountain Cover

— GP01 Outdoor Retreat: Light Forest Green

— GP01 Outdoor Retreat: Precarious Pine Covering

— GP11 My Wedding Stories: I Love Sand*

---

DETAILS

— All terrain paints have a 512 x 512 pixels texture except those marked with an asterisk (*). These are newer terrain paints, which come with a higher resolution texture (1024 x 1024 pixels).

— All terrain paints can be found in the build catalogue under Build > Terrain > Ground Cover. They share the same price as all EA terrain paints: §1.

— Everything has been compressed.

---------

LINKS

— 📝 Terms of Use

— 🦋 Bug Reports (Google Form)

— 🎁 Commissions

— ☕ Patreon

— 📁 Download on Patreon (Free)

#s2cc#ts2cc#sims 2 download#dl: terrain paints#4t2 conversion#dl: build mode#dl: conversion#s2mm#s2 maxis match#s2 build

124 notes

·

View notes

Text

Day 12: Evitts Creek to Confluence, PA

Distance Covered: 66.56 miles

Total Time (including rests): 7:24 (7:27am-2:51pm)

Time spent riding: 5:29

Average Speed: 12.1 mph

Apples Eaten: 3 (fuji - 7.5/10, gala - 6.5/10, gala - 7.5/10)

Today's ride was a nice one (and rather short, too). Almost the entire ride was spent on the Great Allegheny Passage trail, a mostly flat rail trail that goes all the way to Pittsburgh. The roads are mostly light gravel/crushed limestone, but they're grainy enough that the ride isn't uncomfortable. The first 20 miles or so we're tiring and I felt rather lethargic, because they were slightly uphill. However, starting at around the 25 mile mark, it became a slight downhill, and stayed that way for the rest of the ride.

I stopped twice, once around 20 miles in, and a second time 25 miles later. During the second stop I had to fix a flat, and I grabbed lunch (a slice of pizza & 2 cheeseburgers) from a nearby gas station. Most of the ride was in the shade, making it so I never really got overheated. I arrived at the campsite rather early, but I just relaxed and did some fixes for a while before setting up my tent.

Also, as today is day 12, I have officially passed the halfway mark for this trip!

Notes from the Ride

Sleep issues - I woke up several times during the night, because I forgot to put earplugs in, and there were 2 large causes of noise disturbance. (1) the Evitts Creek campsite was right next to a train load-off station, and (2) the frogs in the nearby pond croaked very loudly.

Lunch was good - there was a small town gas station by my lunch stop, and I got lunch there at the recommendation of the lady at the trail information desk. At first, I bought a cheeseburger and slice of pizza, but the burger was really good and I was still hungry, so I got a second.

Another flat, luckily only a mile away from a bike station

Pavers - on part of the trail, I had to get off my bike and walk because there were trucks and machines paving over the trail. I say "paving", but I don't really know if that's what you call what they were doing: they were pouring down sand/dirt, and then rolling over it to pack it down.

"Morning" - I said the word "morning" today probably more than any other word, cause I said it to almost everyone I saw on the trail from when I started til it became afternoon

Other bikepackers - I was not the only bicyclist on the trail loaded up to be able to camp. I saw at least half-a-dozen other, though I'm pretty sure I was the youngest bikepacker I saw (not the youngest biker in general, though).

Power banks - I'm carrying 2 power banks on me to charge my phone. One is solar-powered, and I use it most of the time, and the other is a back-up. I started using the back-up yesterday, and I just realized it carries such a large amount of charge, I'm not even sure if I needed my solar power bank.

Design Notes

Short design notes today. This is because today's ride was heavily focused on just enjoying the scenery in the moment, so I didn't spend too much time thinking about things. Also, one of the topics I did think a lot about, Covencraft, is not one which I'm going to be discussing on this blog, because it's actually a project in development.

Time loop

I've been thinking about how player communication should work - I can think of several options:

No information sharing

Total information sharing

Only information sharing if in the same room (this would be much easier if the game was fully digital)

Information sharing able to be limited by events? For example, there's usually total information sharing, but there can be events that limit it to players in the same room as each other.

Example Events: I'm going to showcase a few examples of different possible events that can take place to show how the system might work.

Structure of an event: Event Name - Event Type - Event description

Chemical Spill - Round Event - Occurs in 1 or more rooms. In a room that it occurs in, a player may move in or out of that room but not through that room in a single turn. If a player ends their turn in this room, they take 1 damage. Can be cleaned up with janitorial items.

Meteor Warning - Round Event - notifies all players. In a few turns, if no player has done specific notes actions in the Navigation hub or Defense Control Room, an asteroid hits, which is a cause-and-effect event.

Time Lock - Time event - a random item in the current room becomes time-locked. It will not reset its position when a time loop occurs (this may cause more time paradoxes).

Escaped specimen - round event - a creature appears in a certain room. It can see into adjacent rooms. At the end of each room, it moves into an adjacent room, attempting to move away from players if it sees any. When it reaches certain rooms, it causes damage & temporal instability to occur in that room. There are ways to catch or kill it (undetermined as of yet).

That's all for today. Ride was good, food was good, etc. One flat, but that wasn't enough to put me down. Tomorrow's ride is supposed to be almost all downhill until I get to Pittsburgh, so I'm looking forward to that!

I'd like to possibly post more about what I do this evening, but there's no service at the campsite, and I'm currently eating dinner at a restaurant which is one of the only places with WiFi. Later! (I might or might not post pics tonight - I might just end up posting them all tomorrow)

Previous -- Next

3 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

Install interlocking pavers process:

To install interlocking pavers, you will need to prepare the area where they will be laid, and then set the pavers in place. Here is a general overview of the process:

Prepare the area: Clear the area of any grass, weeds, or other debris. Excavate the area to the desired depth (typically about 4 inches for a patio or walkway) and add a layer of crushed stone. Level the crushed stone and compact it to create a stable base for the pavers.

Install edge restraints: Edge restraints, such as plastic or metal edging, are used to keep the pavers in place and to create a clean edge around the patio or walkway. Install the edge restraints around the perimeter of the area to be paved, making sure they are level and securely in place.

Lay a screed layer: Spread a layer of fine crushed stone, called "screed" layer, over the base and level it out by using a long straight board.

Lay the pavers: Begin laying the pavers in the center of the area and work outward. Place them closely together, with a small amount of space between them for sand (joints).

Cut pavers to fit: As necessary, use a paver cutter or saw to cut pavers to fit around the edges or in tight spaces.

Compact pavers: Use a plate compactor to compact the pavers in place. This helps to ensure that the pavers will stay in place and will not shift over time.

Add Sand to joints and compact again: Once the pavers are in place, use a broom or blower to remove any debris from the joints, and spread sand over the surface of the pavers. Compact the pavers with a plate compactor once more

Clean and Seal: Clean the surface of the pavers with water and a mild detergent, then use a sealant to protect them from weathering and staining.

Note that this is a general process, depending on the scope of your project, you may require additional tools and steps. This is just an overview and its recommended to consult with professionals or read the manufacturer's instructions when you have the specific product on hand.

#paverstone#construction bayarea contractor newconstruction constructionlife constructionsite underconstruction generalcontractor sfbayarea stone instal#construction#paver stone#paving stone#paver company#paving#interlocking paver

2 notes

·

View notes

Text

The Ultimate Guide to Paver Pool Decks in Florida

Florida is synonymous with beautiful weather, and what better way to enjoy it than by lounging by your pool? A key component of an inviting pool area is the deck, and paver pool decks are becoming increasingly popular among homeowners in Florida. This blog will delve into the advantages of paver pool decks, their types, installation process, maintenance tips, and why they are the perfect choice for your Florida home.

Why Choose Paver Pool Decks?

Paver pool decks offer several benefits that make them an excellent choice for Florida’s unique climate and lifestyle:

1. Durability

Pavers are incredibly durable and can withstand heavy foot traffic, pool chemicals, and the elements. This durability ensures your pool deck will look great and function well for years.

2. Slip Resistance

Safety is paramount around pool areas. Pavers provide a textured surface that enhances traction, reducing the risk of slips and fall.

3. Heat Resistance

Florida can get extremely hot, but pavers stay cooler to the touch compared to other materials like concrete or wood. This feature makes them more comfortable for bare feet.

4. Aesthetic Appeal

Pavers come in various colors, shapes, and patterns, allowing for endless design possibilities. You can create a custom look that complements your home and landscaping.

5. Easy Repairs

If a paver gets damaged, it can be easily replaced without disrupting the entire deck. This convenience makes maintenance simpler and more cost-effective.

Types of Pavers for Pool Decks

There are several types of pavers you can choose from for your pool deck:

1. Concrete Pavers

Concrete pavers are popular due to their affordability and versatility. They can be molded into various shapes and sizes, and colored to match your aesthetic preferences.

2. Brick Pavers

Brick pavers offer a classic, timeless look. They are highly durable and can withstand extreme weather conditions, making them ideal for Florida’s climate.

3. Natural Stone Pavers

For a luxurious touch, natural stone pavers like travertine, slate, and granite are excellent choices. They offer a unique, high-end appearance and are naturally slip-resistant.

4. Travertine Pavers

Travertine is a type of limestone known for its elegance and cool surface. It is particularly popular for pool decks because it remains cool underfoot and provides excellent traction.

Installation Process

Installing a paver pool deck involves several steps to ensure a high-quality and long-lasting result:

1. Planning and Design

Start with a detailed plan and design. Consider the layout, paver type, pattern, and any additional features like seating areas or landscaping.

2. Excavation and Base Preparation

Excavate the area to the required depth and lay a compacted gravel base. This base provides a stable foundation and aids in drainage.

3. Sand Layer

A layer of sand is spread over the gravel base. This sand bed allows the pavers to be set evenly and helps lock them in place.

4. Laying the Pavers

Pavers are laid according to the chosen pattern. It’s important to start from a straight edge and work your way out, ensuring consistent spacing and alignment.

5. Edge Restraints

Install edge restraints to keep the pavers in place and prevent shifting over time.

6. Sand Filling

Once the pavers are laid, sweep sand into the joints to lock the pavers together and provide stability.

7. Compaction

Use a compactor to ensure the pavers are firmly set into the sand base, creating a solid, even surface.

Maintenance Tips

To keep your paver pool deck looking its best, follow these maintenance tips:

1. Regular Cleaning

Sweep the deck regularly to remove debris. Periodically wash it with water and mild detergent to prevent stains and mold growth.

2. Sealing

Sealing the pavers can enhance their color and provide additional protection against stains and weathering. Reapply the sealant as recommended by the manufacturer.

3. Weed Control

Keep an eye on the joints for weed growth. Remove any weeds promptly and consider using a joint stabilizing sealer to prevent weed seeds from taking root.

4. Repair and Replacement

Inspect the deck regularly for any damaged or loose pavers. Replace or repair them as needed to maintain a safe and attractive surface.

Why Paver Pool Decks Are Perfect for Florida

Florida’s climate, with its abundant sunshine and occasional heavy rains, demands a pool deck material that can withstand extreme conditions. Paver pool decks are well-suited for this environment due to their durability, heat resistance, and slip-resistant properties. Additionally, the ability to customize the look of your pool area with various paver styles and designs allows you to create a personal oasis that complements the natural beauty of Florida.

Conclusion

A paver pool deck is an excellent investment for any Florida homeowner. Its durability, aesthetic appeal, and safety features make it the ideal choice for creating a beautiful and functional outdoor space. Whether you prefer the classic look of brick, the elegance of natural stone, or the versatility of concrete, pavers offer endless possibilities for designing your dream pool deck. Embrace the benefits of paver pool decks and transform your pool area into a stunning retreat that you and your family will enjoy for years to come.

0 notes

Text

Revitalize Your Home's Entryway: The Ultimate Guide to Driveway Regeneration

Introduction:

Your driveway serves as the gateway to your home, setting the stage for the impression your property makes. Yet, over time, the wear and tear from vehicles and weather can diminish its appeal. Luckily, driveway regeneration offers an effective solution to refresh and enhance your home's entryway. In this comprehensive guide, we'll explore the benefits, process, and maintenance tips for driveway regeneration, empowering you to transform your driveway and elevate your home's curb appeal.

Understanding Driveway Regeneration:

Driveway regeneration involves restoring and enhancing the surface of your existing driveway to address issues like cracks, stains, and deterioration. Unlike a complete replacement, regeneration focuses on improving the appearance and functionality of your driveway without the need for extensive excavation. Whether you prefer asphalt, concrete, or pavers, regeneration offers a customizable approach to suit your style and budget, breathing new life into your driveway and creating a welcoming entrance to your home.

Benefits of Driveway Regeneration:

Enhanced Curb Appeal: A regenerated driveway instantly enhances the aesthetic appeal of your home, making a positive impression on guests and passersby. With a variety of materials and design options available, regeneration allows you to create a driveway that complements your home's architecture and landscaping, boosting its overall curb appeal.

Improved Functionality: Beyond aesthetics, driveway regeneration enhances the functionality and safety of your driveway. By repairing cracks, filling potholes, and creating a smooth, even surface, regeneration provides a stable foundation for vehicles and improves accessibility for pedestrians, ensuring a welcoming and safe entrance to your home.

Cost-Effectiveness: Driveway regeneration is a cost-effective alternative to complete replacement, minimizing material and labor costs while reducing disruption to your property. By leveraging the existing driveway as a base, regeneration allows you to refresh your driveway without exceeding your budget, making it a practical option for homeowners looking to enhance their home's exterior.

Durability and Longevity: Despite its affordability, driveway regeneration does not compromise on durability. Whether you choose asphalt, concrete, or pavers, regeneration materials are designed to withstand the rigors of daily use and harsh weather conditions, ensuring your driveway maintains its appearance and functionality for years to come.

The Driveway Regeneration Process:

Assessment and Preparation: The regeneration process begins with a thorough assessment of your existing driveway to identify any areas in need of repair. Cracks, stains, and surface imperfections are addressed, and the driveway is cleaned to remove debris and prepare the surface for regeneration.

Material Selection: Once the preparation work is complete, it's time to select the regeneration material that best suits your needs and preferences. Consider factors like durability, appearance, and maintenance requirements when choosing between asphalt, concrete, or pavers.

Application: Skilled professionals apply the chosen regeneration material to the driveway surface using specialized equipment and techniques. Whether it's applying a fresh layer of asphalt, resurfacing with concrete, or installing interlocking pavers, precision and attention to detail are crucial to achieving a smooth, uniform finish.

Finishing Touches: After the regeneration material is applied, finishing touches may be added to enhance durability and aesthetics. This could include sealcoating (for asphalt driveways), decorative staining or stamping (for concrete driveways), or joint sanding and sealing (for paver driveways), adding the final touches to your revitalized driveway.

Maintenance Tips for a Long-Lasting Driveway:

Regular Cleaning: Keep your regenerated driveway clean by removing debris, leaves, and dirt regularly. Use a broom, leaf blower, or pressure washer to maintain a clean surface and prevent stains or discoloration.

Prompt Repairs: Address any minor issues, such as cracks or surface damage, promptly to prevent them from worsening over time. Fill cracks, repair potholes, and maintain proper drainage to prolong the lifespan of your driveway.

Sealcoating and Sealant Application: Consider applying sealcoating (for asphalt driveways) or sealant (for concrete or paver driveways) every few years to protect the surface from water damage, UV exposure, and oil stains, enhancing its longevity and appearance.

Conclusion:

Driveway regeneration offers a practical and cost-effective solution for enhancing your home's entryway and curb appeal. By understanding the benefits, process, and maintenance considerations of driveway regeneration, you can transform your driveway and create an inviting first impression. Whether you're looking to repair minor imperfections or completely overhaul the look of your driveway, regeneration provides a durable, long-lasting solution that adds value and beauty to your home.

0 notes

Text

How to Clean Patio Pavers

How to Clean Patio Pavers: A Quick Guide

Maintaining the pristine look of your patio pavers is easier than you might think. Regular cleaning not only enhances their appearance but also extends their lifespan. Here’s a simple guide to keep your patio pavers looking their best.

Step 1: Clear the Area

Begin by removing all furniture, plants, and any other items from your patio. Sweep the surface to clear away loose dirt, leaves, and debris. This initial step ensures you have a clean slate to work on and prevents any scratches or damage during the cleaning process.

Step 2: Wet and Pre-Treat

Use a garden hose to wet the pavers thoroughly. This helps to loosen any dirt and grime. For stubborn stains, prepare a cleaning solution by mixing water with a mild detergent or a specialized paver cleaner. Apply this solution to the affected areas and let it sit for about 10-15 minutes.

Step 3: Scrub and Rinse

Using a stiff-bristled brush, scrub the pavers to remove dirt and stains. Pay special attention to areas with heavy buildup. After scrubbing, rinse the entire patio with a garden hose, ensuring all the soap and dirt are washed away. Avoid using a pressure washer, as it can damage the pavers and dislodge the joint sand.

Step 4: Re-Sand the Joints

Once the patio is clean and dry, inspect the joints between the pavers. If the sand has been washed away, refill the joints with polymeric sand to maintain stability and prevent weed growth. Sweep the sand into the joints, and lightly mist with water to set it.

Step 5: Seal the Pavers

To protect your patio from future stains and wear, consider applying a sealant. A good sealant enhances the color of the pavers and provides a protective layer against dirt, stains, and weather damage. Follow the manufacturer’s instructions for the best results, and allow the sealant to dry completely before using the patio.

Regular maintenance is key to preserving the beauty of your patio pavers. With these simple steps, you can keep your outdoor space looking clean and inviting year-round.

0 notes

Text

Enhance Your Poolside Oasis with Professional Pool Deck Sandblasting

Introduction

Creating an inviting and aesthetically pleasing pool area involves more than just crystal-clear water and comfortable lounge chairs. The pool deck plays a crucial role in enhancing the overall ambiance and functionality of your outdoor oasis. One effective way to revitalize your poolside space is through a process known as sablage de piscine, or pool deck sandblasting. This technique offers numerous benefits, from improving safety to rejuvenating the appearance of your pool deck.

Understanding Pool Deck Sandblasting

Sablage de piscine is a surface preparation method that involves using high-pressure air to propel abrasive materials onto the pool deck's surface. The abrasive particles, such as sand or grit, effectively remove dirt, grime, old coatings, and imperfections from the surface, leaving behind a clean and smooth substrate. This process can be tailored to suit various types of pool deck materials, including concrete, stone, and pavers.

Benefits of Pool Deck Sandblasting

Enhanced Safety: Over time, pool decks can become slippery due to the buildup of algae, mold, and other contaminants. Sablage de piscine removes these hazards, making the surface safer for barefoot enjoyment and reducing the risk of slips and falls.

Improved Aesthetics: Weathering, staining, and discoloration can detract from the visual appeal of your pool deck. Sandblasting effectively strips away years of accumulated grime, revealing the natural beauty of the underlying surface. Whether you prefer a clean, minimalist look or plan to apply a fresh coat of sealant or paint, a properly sandblasted pool deck provides the ideal canvas for customization.

Longer Lifespan: By removing surface imperfections and preparing the substrate for refinishing, pool deck sandblasting can extend the lifespan of your outdoor flooring. A well-maintained pool deck is less susceptible to cracking, spalling, and other forms of deterioration, helping you avoid costly repairs and replacements down the line.

Efficient Preparation: If you're planning to resurface or refinish your pool deck, sandblasting is an essential first step. Unlike traditional methods such as pressure washing or chemical cleaning, which may not fully remove stubborn stains or coatings, sandblasting offers thorough and uniform surface preparation, ensuring optimal adhesion for subsequent treatments.

The Sandblasting Process

Professional pool deck sandblasting involves several key steps:

Surface Inspection: A thorough assessment of the pool deck's condition helps determine the appropriate abrasives and pressure levels for the sandblasting process.

Preparation: Surrounding areas are carefully masked off to protect them from abrasive particles and debris.

Abrasive Application: Using specialized equipment, abrasive materials are propelled onto the pool deck's surface at high velocity, effectively removing contaminants and imperfections.

Cleanup: Once sandblasting is complete, the area is thoroughly cleaned to remove any remaining debris, ensuring a pristine finish.

Optional Finishing Touches: Depending on your preferences, additional treatments such as sealing or painting can be applied to enhance durability and aesthetics.

Conclusion

Investing in professional pool deck sandblasting is a worthwhile endeavor for homeowners looking to enhance the beauty, safety, and longevity of their outdoor living spaces. By removing surface contaminants and preparing the substrate for refinishing, sablage de piscine rejuvenates tired pool decks, transforming them into inviting retreats for relaxation and recreation. Whether you're planning a poolside gathering or simply enjoying a quiet afternoon by the water, a beautifully sandblasted pool deck sets the stage for unforgettable moments with family and friends.

0 notes

Text

10 Creative Stone Walkway Ideas to Enhance Your Outdoor Space

Stone walkways can serve as both functional paths and aesthetic focal points in outdoor areas. Here are ten inspiring stone walkway ideas to enhance your outdoor space:

Natural Stone Pavers

Utilize irregularly shaped natural stone pavers to create a rustic and organic pathway. Their varying sizes and colours add visual interest and blend seamlessly with the surrounding landscape.

Stepping Stones

Incorporate large, flat stepping stones into your walkway design for a charming and whimsical touch. Arrange them in a staggered pattern to create a sense of rhythm and flow.

Cobblestone Path

Opt for timeless elegance with a classic cobblestone path. The smooth, rounded stones provide a durable and traditional option that complements any outdoor setting.

Flagstone Walkway

Choose flagstone for a versatile and durable Stone Walkways solution. Its flat, irregularly shaped pieces can be laid in various patterns, such as herringbone or random ashlar, to suit your style.

Gravel and Stone Mix

Combine gravel with large stone pavers to create a visually dynamic walkway with a natural, textured look. This blend of materials offers both stability and visual interest.

Mosaic Stone Path

Get creative with a mosaic stone path featuring intricately arranged stones of different shapes and colours. This artistic approach adds a unique focal point to your outdoor space.

Japanese Zen Garden Walkway

Embrace tranquillity with a Japanese-inspired stone landscaping surrounded by lush greenery and carefully placed rocks. Incorporate raked gravel or sand for an authentic Zen garden experience.

Border with River Rocks

Frame your stone walkway with river rocks to define the edges and add a touch of contrast. The smooth, rounded stones create a visually pleasing border that complements the ruggedness of the pathway.

Inlaid Pebble Design

Enhance your stone walkway with intricate pebble inlays featuring geometric patterns or natural motifs. This artistic detailing adds texture and visual interest to an otherwise simple pathway.

Interlocking Stone Pavers

Opt for interlocking stone pavers for a modern and streamlined look. Their uniform shape and precise fit create a clean and polished pathway that complements contemporary outdoor spaces.

0 notes

Text

front yard landscape

We are one of the high-quality front yard landscape materials providers across Houston, TX. Customers can directly purchase from our store through phone calls or from our online store, we are open to the public. To cultivate a fertile foundation we need topsoil, compost, garden soil mix, rock, and gravel to enhance the aesthetics and drainage. We also have other landscaping materials like flagstone, fertilizer & chemicals, mulch, sand, etc. Sand is essential for paver settings and leveling. Flagstones are used for patios and pathways, and also they offer natural elegance, chemicals, and fertilizers used for nature growth and managing pests.

0 notes

Text

front yard landscape

We provide different front yard landscape materials to our customers they are sand, mulch, flagstone, rock & gravel etc. Flagstones used for patios, pathways it also offer a natural elegance. Sand is also an ideal material for paver setting and leveling, other main materials used for landscaping are rock and gravel which enhance the aesthetics and drainage. Compost and garden soil mix are used to create a fertile foundation; we also have fertilizers and chemicals that help for natural growth and manage pests. We also provide pavers and stepping stones they are perfect for creating unique paths and features.

0 notes

Text

Outdoor Porcelain Pavers

Outdoor porcelain pavers are a type of paving material made from porcelain, a durable and dense ceramic material. These pavers are specifically designed for outdoor use and are gaining popularity for various landscaping and outdoor flooring applications. Here are some key features and benefits of outdoor porcelain pavers:

Durability: Banas Porcelain provide pavers are highly durable and resistant to scratches, stains, fading, and extreme weather conditions, making them suitable for outdoor use in various climates.

Low Maintenance: They require minimal maintenance compared to other outdoor paving materials like natural stone or concrete. Porcelain pavers are easy to clean and typically only need occasional sweeping and washing with water.

Versatility: Porcelain pavers come in a wide range of colors, textures, and sizes, allowing for versatile design options to suit different outdoor spaces and aesthetic preferences.

Slip Resistance: Many porcelain pavers are designed with textured surfaces or anti-slip finishes, providing a safe and slip-resistant surface, especially in wet conditions.

Fade Resistance: The color and finish of porcelain pavers are baked into the material during the manufacturing process, making them highly resistant to fading from UV exposure over time.

Environmental Benefits: Porcelain pavers are often made from recycled materials and are fully recyclable themselves, making them an environmentally friendly choice for outdoor flooring.

Ease of Installation: Porcelain pavers can be installed using various methods, including traditional mortar setting, pedestal systems, or dry installation methods like sand or gravel beds, depending on the specific project requirements and site conditions.

Resistance to Stains and Chemicals: Porcelain is non-porous, which means it's resistant to stains from spills, oils, and other common outdoor contaminants. Additionally, it's resistant to chemicals such as fertilizers and pool chemicals, making it suitable for use around pools and in other outdoor settings where exposure to chemicals is likely.

Overall, outdoor porcelain pavers , Porcelain Tiles in Mississauga and other city offer a durable, low-maintenance, and aesthetically pleasing solution for outdoor flooring, suitable for residential, commercial, and public spaces alike.

0 notes

Text

Cobblestone Pavers Driveway Paving & Outside Flooring Australia's Least Expensive + Largest Range Of Outdoor Tiles & Stone Pavers

Reclaimed stone is on the market in many different shapes, sizes and colors, but the qualities that set it aside most are its weathering and wear. We actually just like the look of those weathered and worn stone surfaces—they are unique and distinctive with an old world feel. Almost all reclaimed stone reveals weathering or staining of some sort, relying on how and the place it was used. Many reclaimed stones also exhibit signs of put on and tear from a long time or centuries of use as pavers. Our Reclaimed Footworn Granite Plank Pavers from China, come to mind but there are different product types obtainable as well. We supply reclaimed basalt, porphyry and sandstone pavers, as nicely as other less common stones.

Cobbles are heavy and bulky, so appropriate lifting and dealing with tools must be used. The appropriate security gear and protective clothes must be worn at all times together with gloves, dust masks, and security boots. The cobblestone value can differ a bit as properly, particularly when you use sand or mortar in between the stones. Mortar can crack and have to be reapplied, whereas sand can erode away and must be replaced as properly. If you’re wondering how a lot is cobblestone when compared to other widespread supplies, it ranks among the most expensive.

Sometimes referred to as Belgian Blocks or setts, cobblestone pavers have been used for paving roads in European villages and cities since Roman occasions. The installation course of for a driveway produced from TRUEGRID permeable pavers can be much faster than cobblestone, with some installations being completed in as little as a single day. If you need a paving materials that’s more inexpensive, stylistically diverse, and sturdy than cobblestone, contact a pavement skilled at TRUEGRID at present for a quote. If you plan on building a granite cobblestone driveway on your own, the DIY price will run you one other $10 per square foot, on top of the supplies value.

Often cobblestones are used in new metropolis plazas, parks, public open areas, and malls as a stand-out design factor. That design influence has crossed over to residential driveways and patios. With this rising market, both salvaged and new cobblestone materials may be bought now with rising ease and decreasing expense. Thanks to Cobbles, you may give a country and strong appearance to the entryway out of your entrance door. They not only give a surprising look to your personal home but also add to the price of your property.

cobblestone paving

Cobblestone has been used throughout historical past as a paving material for walkways, driveways, patios, and extra. Granite cobblestones enhance the looks of your property while maintaining grass out and creating a clean garden border for pathways. The entryways have a country but exquisite look due to using granite cobblestones. Not solely at properties, however park walkways are also commonly accomplished with cobblestones. Cobblestones are easy to install since they are generally provided in mesh form. This mesh is simple to put in and covers a bigger surface space, saving males hours of set up time.

These stones are made to endure the load of heavy autos and the check of time as a result of they're produced from natural supplies like Granite or basalt. Despite publicity to high visitors and harsh weather, they retain their strength and visual appeal. Every customized driveway design includes a paver form and design sample. From the smallest sized cobblestone cubes to oversized irregular flagstone pavers, the form of the stone is a matter of non-public choice. Once a shape is set on, then contemplate the sample it goes to be laid in. Longer shaped planks are extremely popular nowadays and they make dramatic driveways and patios.

Their beautiful worn and weathered surfaces are simply a half of the story. They have been quarried from many various elements of New England so the granite grain and colours range as does the wear and tear and weathering. We reclaim bluestone, sandstone and porphyry cobblestones from Europe as well as colourful reclaimed Swedish granite cobblestones. These reclaimed cobblestones are available with their authentic worn surfaces or sawn flat if the design calls for. The sizes and shapes of reclaimed cobbles differ widely from small 4×4 surfaced cobbles to our 80-pound reclaimed road pavers.

But we’ve all seen big cobblestoned piazzas and courtyards, and they additionally work well. Your driveway design needs only to consider the scale of the pavers as it contributes to the general design. One thing to maintain in mind is that the bigger the floor space of each paver, the thicker it ought to be. It’s simple physics—a nine sq. foot paver, one inch thick, is way simpler to wreck than one that is three inches thick.

Combining a few of these products will allow you to create an attractive continuity round your property. Our vary of cobblestone pavers also have hand-split tough edges, highlighting their warm and welcoming European look. Though they are relatively small, our cobblestone driveway pavers have a excessive compressive power rating making them extremely tough and durable. This means that they're robust sufficient to support the burden and fixed vibration of automobiles getting into and exiting the driveway. Their darkish color and textured finish additionally helps mask stains, tyre marks and oil leaks, making our cobblestones ideal for use in high-traffic areas.

They additionally separate your lawn from the backyard mattress, permitting you to create a unique search for both areas of your yard. A border made of Cobblestones is sturdy and strong and permits simple mowing of grass without having to fret about the flora and flowerbeds. Cobblestone pavers are available in two ways-loose and on a mesh. The mesh choice with the again sawn is handy because it permits for simpler set up. Cobblestones are available stunning colours corresponding to grey, earthy brown, black and multi-chromatic shades. They add depth to outdoor areas and pair nicely with any architectural fashion.

#cobble stone#textured cobbles#cobblestone pavers#cobbles supplier#cobble stone paving#cobblestone paving#cobble paving bricks

1 note

·

View note

Text

Cement Block Making Machine in Telangana

Company Overview:

Robexo Industries is a manufacturer and supplier specializing in Cement Block Making Machine in Telangana, India.

Robexo Industries is a leading manufacturer of construction machinery established in 2015, based in Ahmedabad, Gujarat, India.

The company specializes in manufacturing a diverse range of machinery including fully automatic/fly ash brick, interlocking brick, paver block, concrete solid/hollow block making machines, vibrating table sets, concrete raw material supply automatic batching plants, and silos.

Robexo Industries is recognized as a prominent engineering consultant, service provider, and manufacturer of automatic, semi-automatic, and manual machines.

We offer the latest technology with distinguishing features of reliability, safety, and rugged construction at an affordable price, understanding the value of money for our customers.

Our focus is on providing multipurpose, low-maintenance, modern designs with new-generation features and complete project solutions, catering to diverse construction needs.

A cement block making machine is a specialized industrial equipment designed to efficiently produce concrete blocks.

These machines automate the process of mixing cement, sand, and other aggregates, compressing them into solid and durable blocks of various sizes and shapes.

Essential in the construction industry, these machines enable cost-effective and consistent manufacturing of building materials used in walls, foundations, and structures.

Key Features of Cement Block Making Machine:

Utilizes Hydro+Vibro German Base System for enhanced performance.

Features a low maintenance compact design for easy operation and upkeep.

Operates on an eco-friendly system, promoting sustainable manufacturing practices.

Geographical Coverage in Telangana:

Robexo Industries offers Cement Block Making Machine in Telangana Including Adilabad, Bhadradri-Kothagudem, Hyderabad,

Jagtial, Jangaon, Jayashankar, Bhoopalpally, Jogulamba-Gadwal, Kamareddy, Karimnagar, Khammam, Komaram Bheem Asifabad, Mahabubabad,

Mahabubnagar, Mancherial, Medchal, Medak, Nagarkurnool, Nalgonda. Nirmal, Nizamabad, Peddapalle, Rajanna Sircilla, Ranga Reddy, Sangareddy, Siddipet, Suryapet, Vikarabad, Wanaparthy, Warangal,Yadadri-Bhuvanagiri.

For detailed information and inquiries, please don't hesitate to contact us.

Read the full article

#Bhadradri-Kothagudem#Bhoopalpally#CementBlockMakingMachine#CementBlockMakingMachineinIndia#CementBlockMakingMachineinTelangana#dilabad#Exporter#Hyderabad#India#Jagtial#Jangaon#Jayashankar#Jogulamba-Gadwal#Kamareddy#Karimnagar#Khammam#KomaramBheemAsifabad#Mahabubabad#Mahabubnagar#Mancherial#Manufacturer#ManufacturerofCementBlockMakingMachine#Medak#Medchal#Nagarkurnool#Nalgonda.Nirmal#Nizamabad#Peddapalle#RajannaSircilla#RangaReddy

0 notes

Text

Know All About the Trending French Pattern Travertine

The French are well-known over the world for their delicious buttery croissants, the Eiffel Tower, and impeccable fashion sense. But there is another underrated but wonderful feature of the French that is alluring and aspirational: the way they design their houses.

French-style homes ooze casual elegance and are a great mix of historic and modern. These houses appear simple, despite having been thoroughly selected and created, and they have a customized appearance; it appears that the home was designed on a very personal scale.

You may now have the same architectural style in your home thanks to our French pattern tiles. They come in a variety of colors, textures, and finishes. Let's discuss the advantages of employing these tiles:

Advantages of French Pattern Travertine

Strong Durability

French pattern tiles are usually constructed from high-quality natural stone like travertine, marble, or limestone. These materials are noted for their strength, making French-style floor tiles resistant to wear, stains, and high foot traffic.

Distinctive Design

When these tiles are laid down in the French pattern, they produce a visually appealing and recognizable result. The floor area can be made beautiful and unique by using stones of varying sizes and colored grout. This style, inspired of classic European buildings, brings beauty and elegance to any room.

Versatile Usage

They can be utilized indoors and out. These tiles look fantastic in many different settings, including living rooms, bedrooms, patios, and swimming pools. Furthermore, the French design can be produced with both tiles and pavers, with tiles on the inside and pavers on the exterior.

Refined Hardscape

Once installed, French pattern tiles become the focal point of your hardscape. The pattern's precise design refines and details the region without requiring extra constraints. The French design is naturally attractive to the eye, resulting in a visually appealing focal point.

Cooling Effect:

As previously stated, French pattern floor tiles made of natural stone, such as Travertine, have the advantage of maintaining a cooler surface temperature than materials like concrete or ceramic tiles. This is especially handy in hot temperatures and outdoor settings.

Easy Maintenance:

French-style floor tiles are often easy to maintain. In most cases, regular sweeping and mopping with a little detergent would suffice to maintain them clean. Furthermore, their natural stone composition makes them stain and spill resistant.

What Natural Stones Can Be Used for French Pattern?

French pattern floor tile in natural stones such as travertine, limestone, sandstone, and others adds elegance and beauty to both indoor and outdoor spaces.

Travertine French Pattern Tiles

Travertine, a light-colored natural stone with surface cracks and streaks, has been utilized to create monuments and structures for millennia. The French pattern in Travertine offers a unique flooring option with its chiseled, tumbled, or straight edges, providing a charming contrast to the usual linear form. Travertine French pattern floor tile has the advantage of not requiring each piece to be carved into an exact design, saving contractors and homeowners both time and money.

Limestone French Pattern Tiles

Limestone is another excellent option for French pattern flooring due to its ease of installation and ability to enhance the appearance of a room with natural light. Limestone comes in a variety of tones, ranging from delicate to strong, and creates a smooth pattern with minimal color and texture variation.

Sandstone French Pattern Tiles

Sandstone, with its sand-like textures and inviting red and beige color scheme, is frequently used in interior design. It is easy to work with and can be cut to the right size, making installation more cost-effective. They bring indoor and outdoor surroundings to life, especially when paired with actual plants and complementary furnishings.

So here's what you should know about Australia's most popular tiling design. If you have any questions, please contact our stone professionals.

0 notes