#implantfailure

Photo

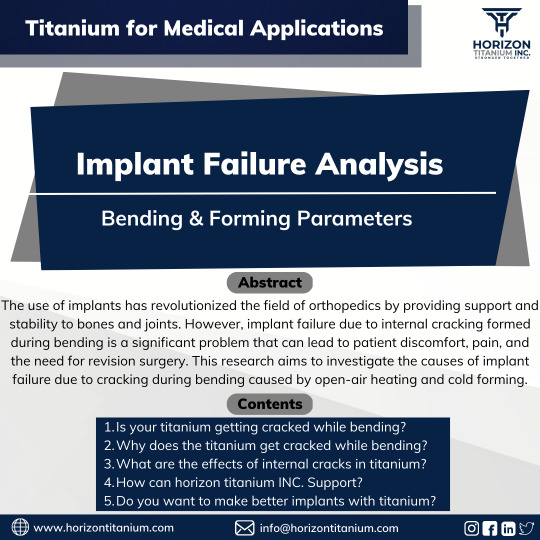

The study was carried out as a case study, concentrating on a specific type of implant and manufacturing process. The study used a combination of practical trials, failure analysis, and characterization of each implant to determine the fundamental cause of the problem and provide solutions to prevent future failures.

If you are having trouble bending Titanium materials, please contact us at [email protected]. We are fully prepared to share our research findings with you.

#KnowYourTitanium#TitaniumBending#TitaniumCracking#TitaniumImplant#ImplantFailure#FailureAnalysis#OrthopedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

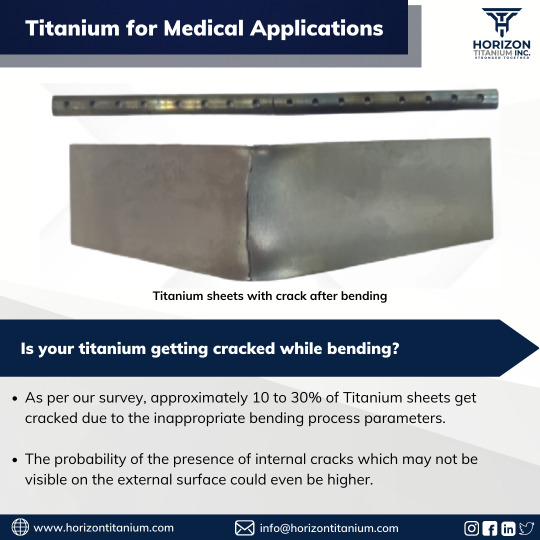

Although dental implants are highly successful, some people will encounter dental implant failure. Here's what you need to know about implant failure and other potential complications if you're considering dental implants or currently have one.

Learn more here: https://www.centurydental.org/signs-and-causes-of-dental-implant-failure/

1 note

·

View note

Text

Dental Implants

There was a time when you have to wait for a minimum of 6 months after removing the tooth to place an implant. And you have to wait another 6 months after placing the implant to get the crown on the top. Not anymore with Immediate Implants. Know more. https://dentakings.com/single-visit-dental-implants/

Denta Kings is the best dental hospital in Chennai which provides the best Dental Implants in Chennai.

Call Denta Kings at 9994009656 for fixing an appointment and to know more about the cost of dental implants in India.

Subscribe to Denta Kings's YouTube Channel at https://www.youtube.com/user/Dentakings

Email - [email protected]

0 notes

Photo

YOUR WORST CASE...WHAT IS IT? WHAT COULD BE THE REASON? It's always better to discuss the previous complications to avoid the future problems.. TTPHIL PHILOSOPHY: PROBLEM PREVENTION PROTOCOLS (PPP) I am Dr. P. Venkat Nag, Prosthodontist. I used to work with the best oral surgeons in a charity hospital, do only the prosthetic phase.. I might have seen maximum number of surgeries and restored maximum number of Implants, some successfull many failures.. There is lot of difference between IMPLANT SUCCESS AND IMPLANT FAILURES.. The whole concept is based on preventing and how to avoid complications and failures. TTPHIL ALL TILT PROTOCOL: ABC IMPLANTOLOGY A= ANATOMICAL B= BIOMECHANICAL C= CONCEPT ( EVIDENCE BASED) DRIVEN IMPLANTOLOGY.. It's a fusion of the best techniques for the immediate functional loading, moreover this is screw retained.. Let's discuss.. Jot down your bad experiences why your implant failed.. Let's find out the solutions for it.. Implant failures can be at 1. BONE TO IMPLANT INTERFACE 2. GINGIVAL TO ABUTMENT INTERFACE 3. IMPLANT TO ABUTMENT INTERFACE 4. ABUTMENT TO PROSTHESIS INTERFACE We will discuss these in detail.. Your comments will help us do better.. . . #TTPHIL #DRVENKATNAG #TTPHILTEXTBOOK #IMPLANTFAILURE #IMPLANTSUCCESS (at Ttphil ALL TILT Technique) https://www.instagram.com/p/CBdcKzOpkqT/?igshid=14g1du9mfhosh

0 notes

Photo

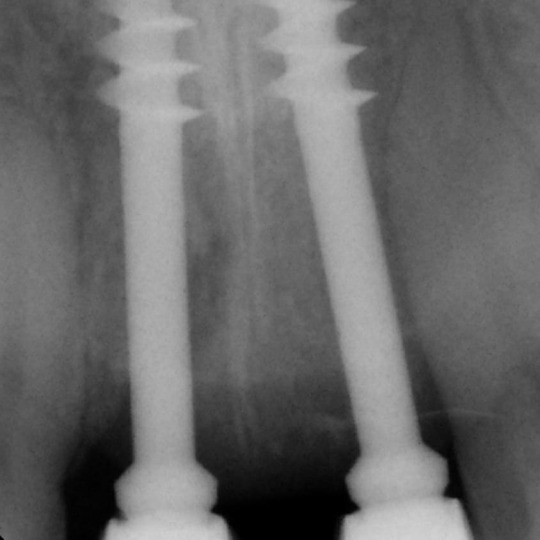

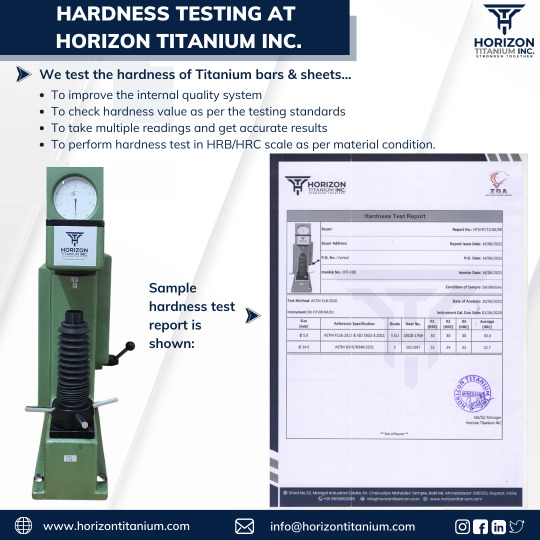

The hardness of Titanium is one of the factors in determining the longevity of an implant made using titanium raw materials.

- Low hardness may cause an implant to bend easily, which may cause a ductile failure.

- High hardness may lead to an implant breaking easily, which may cause a brittle fracture.

- Ideal hardness should be in a controlled range for the implant production process to be smooth.

There is no requirement for hardness mentioned in ASTM/ISO standards. So it is difficult to judge the Titanium raw material based on its hardness.

After discussing with a few skilled implant manufacturers, we could gauge and conclude about the ideal hardness range for Titanium raw materials.

To check the precise hardness values and improve our internal quality system, we now test the hardness of our Titanium bars and sheets at our in-house testing facility. We are even communicating with our manufacturing partners to deliver Titanium raw materials with controlled hardness.

It may take some time to achieve 100% ideal range as per implant manufacturing requirements, but we are sure to derive the best results for our customers in the long term.

#Titanium#Quality#Hardness#Ductility#Brittle#Implant#ImplantFailure#ImplantFracture#Mechanical#TitaniumImplants#MedicalImplants#OrthopaedicImplants#ValueAddition#testing

0 notes