#fishmeal plant

Text

How much does a complete set of fishmeal plant cost?

In fact, in response to this customer's problem, we must first understand one thing. The investment in fishmeal plant https://www.feedsmachinery.com depends more on your production capacity, technology, and the choice of equipment manufacturers. Let's talk about fishmeal equipment from these aspects and price difference.

1.Fish meal processing capacity

The production capacity of fishmeal processing depends on the processing volume of raw materials. Based on the 24h automatic processing of fishmeal processing equipment, we plan the amount of raw materials that need to be processed in one day to decide how large a production line to adopt. For example, the monthly output mentioned by the customer is 100 tons, then it is about 30 tons per day. The processing capacity of fish meal is determined, and then we have a rough plan for the construction of the plant, the investment of equipment, and the improvement of supporting facilities. Next, we will determine the equipment investment of the fishmeal production line according to the selection of the estimated processing technology.

2. Fish meal processing technology

The processing technology of fishmeal is mainly divided into two types, dry fishmeal processing and wet fishmeal processing. Of course, the fishmeal processing equipment required by different processing technologies is different. I will not introduce too much here. Interested friends can check《What's Include In Fish Meal Machine ? 》, introduces the detailed process and specific equipment.

3. Fish meal plant manufacturers

China's fishmeal processing industry started late, so the supporting fishmeal processing equipment is also later than other countries. However, with the rapid development of China's fishmeal processing industry, the supporting fishmeal processing equipment has also made a qualitative leap, and many fishmeal processing equipment manufacturers have also Impacting foreign markets, thanks to the quality and affordable prices of Chinese fishmeal machine, Chinese fishmeal machine is increasingly recognized by users in foreign markets. For fishmeal processing enterprises, more customers are willing to choose Chinese fishmeal plant.

4. The price of fish meal equipment

Finally, we talked about the most concerned question. How much does the whole set of fishmeal equipment cost? Different production lines need to be developed according to different needs of customers. If you are interested, please contact us.The above is the price reference of the whole set of fishmeal equipment production line. Of course, the specific price varies according to the process and equipment manufacturers. The data is for reference only. The core of fishmeal equipment is to solve productivity. As long as it can solve production problems for customers and generate benefits, that is Good fishmeal equipment.

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fishmeal and fish oil production lines machine, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fishmeal industry.

Based on years of R&D and production experience of fishmeal plant production lines , Feeds Machinery has launched the Fishmeal Process (FMP), a wet-process fishmeal production process, which is suitable for the production of fishmeal with a raw material capacity of up to 15 tons/hour and above. The produced fishmeal has better quality, high digestibility, low energy consumption and simple operation. If a complete fishmeal and fish oil production and processing system is adopted, the production capacity can be increased by 5% (the digestibility is increased by 3%), and the whole process can be achieved without pollution.

#fishmeal machine#fishmeal plant#fish protein#fish meal#fish oil#fishmeal equipment#fishmeal dryer#fishmeal cooker#fishmeal#fish oil separator

0 notes

Text

Mexican scientists ditch fishmeal for veggie-powered trout feed, aiming to curb overfishing and create a sustainable future for aquaculture. The plant-based diet shows promise in early trials, paving the way for a greener, tastier plate of fish.

#Mexican scientists#fishmeal#veggie-powered trout feed#trout feed#overfishing#sustainable future#aquaculture#plant-based diet

0 notes

Text

In August 1963, the Dutchveterinarian Dan (E.H.) Kampelmacher stepped on a plane to Lima, the capital of Peru. His destination: smelly factories in Lima’s port city which ground up tiny anchovy fish from the Pacific Ocean into huge amounts of animal feed. Peru exported one fifth of this ‘fishmeal’ to the Netherlands, where farmers used it to feed their quickly rising numbers of chickens and pigs in new intensive livestock or ‘factory’ farms. [...]

The ports of Lima and Rotterdam connected the ecosystems of Peruvian fishmeal plants and Dutch farms. [...] [H]ardly anyone showed any interest in what the stuff was made of. Although Dutch farmers had started to refer to their new industrial poultry and pig farms as ‘landless’ at this point in time, they did not intend this phrase to mean their growing dependence on oceans rather than land. Rather, it characterized a fundamental change in livestock farming: in the postwar era farmers could increase their numbers of animals independently of the area of land they had for growing feed. The phrase ‘landless’ erased from view that these farms in fact depended on places elsewhere on the planet. [...] [T]he fish, called “anchoveta” [were] from the Humboldt Current ecosystem [...].

Fishmeal was invisible, despite its crucial importance for two interrelated major changes in the Netherlands and the global north in general: the rise of intensive livestock farming, and the unprecedented increase in the consumption of meat and eggs. [...] How did fishmeal and its environmental impacts connect industrial livestock farming in the global north to its production places in the global south [...]? [...]

---

Shadow places are ‘all those places that produce or are affected by the commodities you consume, places consumers don’t know about, don’t want to know about, and in a commodity regime don’t ever need to know about or take responsibility for’. It is very similar to the ‘ghost acres’ concept used by environmental and global historians: the acres of land countries used elsewhere on the planet [...]. Cushman analyses the rise of the Peruvian fishmeal industry as another case of what he calls ‘neo-ecological imperialism’: the ‘Blue Revolution’ [...], to stress the connection between fishmeal production in the Pacific World and the rise of industrial livestock farming in the global north. [...]

Fishmeal fed the twentieth-century shift to industrial livestock farming – the Netherlands was among the top three fishmeal importers internationally from 1954 to 1972. [...] Animal proteins – and fishmeal in particular – played an essential role in this shift to industrial livestock farming [...]. But for poultry and pigs, animal proteins were an ‘indispensable ingredient’ [...]. Internationally, fishery landings tripled in the period 1950–1973 due to the rise in fishmeal production for animal feed. [...] During the Peruvian fishmeal boom from 1958 until 1970, [...] [t]he livestock sector started to refer to it explicitly as ‘Peru fishmeal’ [...]. The Netherlands was the second-largest importer after the USA in 1955 [...].

---

According to Cushman and Wintersteen, the spectacular rise of the Peruvian fishmeal industry was the result of [...] international interest in the Peruvian stocks of small fish suitable for fishmeal production, interest from the USA in particular.

After the collapse of the Californian fishmeal industry shortly after the Second World War, industrial fishmeal plants in Peru were realised with American marine expertise, investments by American industrialists, subsidiaries of American companies like Cargill and Ralston Purina, and second-hand American fishmeal equipment and technology. [...]

As a result, the Peruvian fishery industry changed radically during the 1950s. Rather than a being a by-product of fish canneries, fishmeal became its core focus. [...] [A]nd industrialists moved in entire fishmeal plants from the USA and Scandinavia. These plants could turn 5.4 tons of fish into a ton of fishmeal at the peak of the industry [...].

---

Angola exported fishmeal under Portuguese colonial rule (until 1975), and South Africa exported fishmeal during Apartheid (until 1994). In Chile the neoliberal dictatorship of general Augusto Pinochet (1973–1990) gave fishmeal industrialists free rein again from 1973 onwards, and Chile had replaced Peru as the major fishmeal exporter by 1980.

Social inequality was exacerbated [...]. Fishmeal industrialists made enormous amounts of money, and stock exchanges in the global north enabled speculation on fishmeal. Simultaneously, workers in the fishmeal plants were poorly paid and lived in slums with no paved roads, running water or electricity, unhealthy conditions and polluted air. Fishmeal’s volatile market resulted in labour unrest during the 1960s in Peru, and during the 1980s in Chile. [...] Many factories were moved to less-regulated places along the coast, taking the air pollution and resulting public health problems with them. One of these places was the city of Chimbote, which quickly grew into the largest fishmeal city of Peru, and became ‘one of the nation’s … most polluted cities’. [...] One place impacted by the feeding of fish to farm animals was in particular in shadows: the marine ecosystems from which the tiny fish were taken, like the Pacific Humboldt Current along the coast of Peru and Chile. [...]

The ocean ecosystems in the global south exploited to feed the industrial livestock sector in the north remained largely invisible. [...] The disappearance of the Peruvian anchoveta also made the ‘protein crisis’ move north. The Dutch livestock sector referred to the ‘true emergency situation’ of the Peruvian fishmeal crisis as the ‘protein crisis’ (‘de eiwit-crisis’). [...] But in 1972–1973 the Humboldt Current marine ecosystem created its own shadow places in both the north and the south. The extraordinary strong El Niño led to the sudden disappearance of the anchovy population [...].

---

All text above by: Floor Haalboom. “Oceans and Landless Farms: Linking Southern and Northern Shadow Places of Industrial Livestock (1954-1975).” Environment and History Volume 28 Number 4. November 2022. [Bold emphasis and some paragraph breaks/contractions added by me.]

162 notes

·

View notes

Note

Hi!

I was wondering if you were aware of the Plant-Based Treaty's campaign for octopuses, I think it's very important

https://www.drove.com/campaign/6202d5ca01cf365ea19492a3

i wasn't aware of the campaign. thank you for sharing!

for more context:

Previous attempts to breed octopuses for farming have faced high mortality rates among the animals, as well as cases of aggression, cannibalism and self-mutilation.

There's currently no recognised humane method to kill octopuses, and the current techniques used on wild octopuses are far from merciful to these cephalopods.

...

Growing demand for octopus is causing the overfishing of this animal, and subsequently the rise in its price on the global market. All of this is contributing to making the idea of farming octopuses increasingly more appealing.

...

In "The Case Against Octopus Farming" published on Issues in Science and Technology in 2019, researchers argue that "farming octopus is counterproductive from a perspective of environmental sustainability," as octopuses follow a carnivorous diet that will contain fishmeal.

According to the WWF, around a third of the global fish catch is used to feed other animals. Farming octopuses would just deepen the crisis experienced by depleted stocks.

With all that we know about the ongoing biodiversity crisis, animal welfare and the rise of vegan and vegetarian alternatives on the food market, choosing to farm octopuses seems, indeed, as scientists say, an unnecessary "disaster."

10 notes

·

View notes

Photo

On August 27th 1808 John West was born in Linlithgow.

John West canned fish products are known world wide, but how many people know that the founder of the company was born in Linlithgow?

That at least is the claim made by the company itself - and one echoed in many website entries.

His birthdate is given as the 27th August 1809 but actually tracking down his birth records is proving very difficult. An entry in the Daily Mail in October 2015 states, “The original John West was born in Linlithgow, Scotland, in 1809. After working in the fishing industry in Scotland, he emigrated to the USA where he pioneered the canning of fish.” The John West Company’s own website states that “he cut his teeth in the local Scottish fishing trade”.

So, if he was involved with fishing was he born in a coastal town in Linlithgowshire? Another entry in Wikipedia suggests that he had training as a millwright so was he born on a farm – perhaps, it has been suggested, in the vicinity of Ecclesmachan.

No school building existed in that village until the 1830s so did John attend a school in Linlithgow – perhaps the one which stood behind the Burgh Hall?

What is not in dispute is that, at the age of forty, he emigrated to Canada where he married Margaret and set up house near Quebec. He seems to have begun his working life working in a sawmill - perhaps using his mechanical expertise gained while employed in Scotland. The Californian Gold Rush of the late 1840s saw him trying his luck on the American goldfields where, perhaps having no luck with mineral exploration, he operated a sawmill and opened a general store and post office.

In 1853 he moved to the American state of Oregon and took up a 640- acre Land Claim on the Columbia River. He called the community which grew up there, ‘Westport’. Could that be a tribute to his birthplace in Linlithgow

He used his entrepreneurial skills to set up a sawmill from which he exported timber to Australia. As a side-line, he also began exporting salmon which migrated up the Columbia River in their thousands. Initially, the fish were salted, packed in barrels and shipped to California from where they were transported to Great Britain. In the late 1860s he set up his first canning plant – an operation which, by 1873, was producing 22,000 cases of salmon yearly. Using his technical expertise, he invented an automated can-filling machine and a process for turning salmon waste into oil and fishmeal. During the period when salmon were not so plentiful his machinery was used to can beef, mutton and brambles. By 1882, thirty-nine of his factories were in operation. Some 1700 fishing boats supplied the products he required.

In 1882, he commissioned a 118-foot propeller-driven steamer which he, rather egotistically, called the “John West”. Captain West, as he liked to be called, died in 1888 a very wealthy man. The company continued under the name “John West” but in the 1920s it was taken over by Unilever. In 1997 it was bought by Heinz who sold it to French-based MW Foods who in turn passed it on to the Thailand based Thai Foods Group. Further research may come up with more details of John West’s birth and upbringing in, or near, Linlithgow. Meanwhile we can but admire the story of a another Scot who became a household name across the world.

12 notes

·

View notes

Text

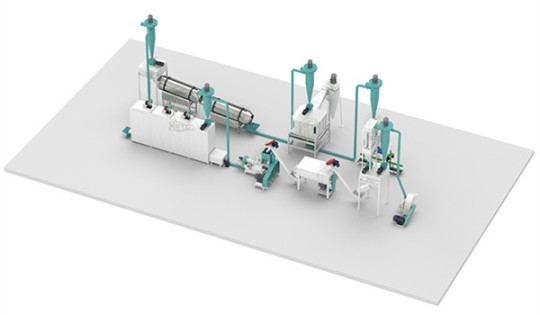

What's Include In Fish Meal Machine ?

Fishmeal is a very important animal protein feed. my country's fishmeal industry started late, but in recent years, with the increase in the output of high-yield and low-value fish and the development of animal husbandry, the demand for feed has surged, and the fishmeal processing industry has developed rapidly. The quality of fishmeal is closely related to the quality of feed products, and there are many factors that affect the quality of fishmeal. Among them, the processing technology of fishmeal and the selection of fishmeal equipment production lines are particularly important for the quality of fishmeal.

1.Process of fish meal processing

Fishmeal processing methods are mainly divided into two types: dry method and wet method. Among them, dry processing method is further divided into direct drying method and dry pressing method, and wet processing method is divided into pressing method, centrifugal method, extraction method and hydrolysis method.

Because the dry processing technology requires long-term high-temperature drying of the raw materials, the oxidation of the oil is more serious, the fish meal produced is dark in color, easy to produce peculiar smell, and the protein content is not high, which affects the digestibility of the feed. The advantage is that the equipment Simple, low investment in equipment, suitable for medium and low-fat fish.

The relative wet process is currently using a more common fish meal processing technology. The characteristics of this method are that the raw materials are precooked, squeezed, separated, and then dried. The fish meal produced has better quality and higher protein content. The cost is low, and the disadvantage is that the equipment investment cost is relatively high, and the threshold for small and medium-sized enterprises is relatively high.

2. What equipment is included in the fishmeal equipment production line

Since the currently commonly used fish meal processing is a wet process, here we mainly introduce all the equipment included in the fish meal plant production line in the wet process.

The wet processing technology mainly includes the following four methods:

wet pressing process

Centrifugal Process

extraction process

Hydrolysis process

Each process has its own characteristics and applicability, but the fishmeal equipment used is nothing more than the following

Cooking machine: The purpose of cooking is to rupture the fat cells in the fish body, coagulate the protein, and fully free the oil and water from the fish body to prepare for the subsequent pressing

Press: separate most of the oil and moisture of the cooked material and then dry it to reduce the load of the dryer and reduce the consumption of steam

Three-phase decanter centrifuge: By centrifuging the cooked material to separate oil, moisture and solid residue, it can replace the press to further reduce the moisture content, reduce the content of free fatty acids (FFA), reduce impurities in fish oil, and improve oil production. product to prolong the storage time of fish oil.

Fishmeal Dryer: The purpose of drying is to convert wet material into dry fishmeal. The moisture content of fish meal is generally below 12%. The use of the FM low-temperature vacuum dryer of Flytime Machinery can effectively avoid the high temperature oxidation of fish meal and obtain fish meal with higher protein content.

Fishmeal cooling equipment: The purpose is to cool the fishmeal to room temperature and prevent the fishmeal from burning fat due to high temperature. A good cooler that cools fishmeal efficiently and quickly.

Vacuum concentration equipment: By concentrating and recovering the protein solution produced in the production process, the cost of fish meal production can be reduced and benefits can be increased.

Fishmeal deodorization equipment: The purpose of deodorization is to solve the odor generated during the production of fishmeal and reduce the impact on the air and the environment.

The above is the main core production equipment in the fishmeal equipment production line. Of course, the fishmeal processing also includes other auxiliary production equipment such as other conveying equipment, grinding equipment, packaging equipment, etc.

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fishmeal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fishmeal industry.

Based on years of R&D and production experience of fishmeal equipment production lines, Feeds Machinery has launched the Fishmeal Process (FMP), a wet-process fishmeal production process, which is suitable for the production of fishmeal with a raw material capacity of up to 15 tons/hour and above. The produced fishmeal has better quality, high digestibility, low energy consumption and simple operation. If a complete fishmeal and fish oil production and processing system is adopted, the production capacity can be increased by 5% (the digestibility is increased by 3%), and the whole process can be achieved without pollution.

#fishmeal plant#fishmeal machine#fish meal#fish oil#fishmeal equipment#fishmeal dryer#fishmeal cooker#fish protein#fishmeal#fish oil separator

0 notes

Text

[T]he stink of the fishmeal plants in Iquique. [...] Local residents called it “the smell of money.”

Domestically produced fish flour had become the primary source for fish food in the new salmon farms that had begun to scar the [...] lakes and fiords in the Chilean south. It would also become dog food, and the “high protein cookies” on school lunch menus [...]. It would fatten pigs in Germany and chickens in California to satisfy the voracious appetites of a competing species now referred to simply as “the consumer.”

In her recent book, The Fishmeal Revolution, environmental historian Kristin A. Wintersteen follows the scent of the uniquely situated and environmentally sensitive biomass from the unusually cold and nutrient rich Humboldt Current that bathes the western coast of South America. [...] The sheer scale of biomass extraction for land-animal consumption constituted nothing less, in her view, than a colonizing expropriation of the world’s oceans. The masters of the land had claimed the vast wealth of the planet’s seas [...]. Moreover, like the British in India and the Spanish in Latin America, the colonizers did not understand the complexity of the space they had appropriated. [...] Wherein the abundant ocean life survives at all, that survival is a testament to species’ resilience and [...] the long [...] cycles [of the sea] [...].

---

During the late nineteenth and early twentieth centuries, from Norway to California, the ocean’s “trash fish” and offal from canneries had become the raw material for fertilizer and protein supplements in animal feed. As northern hemisphere fishing industries overfished their own waters, their gaze turned south. The magic of an apparently infinite supply of plankton-eating anchoveta off the western coast of Latin America depended on the frigid Humboldt Current that moved northward just off the west coast of the South America. But the abundance of anchoveta, and the prosperity of the complex ecosystem that depended on it, periodically gave way to an unpredictable cycle of warmer currents known as, El Niño. [...] [N]ineteenth and early twentieth-century agriculturalists created their own expanding niche in the maritime ecosystem by using fish parts [...]. [T]he golden anchoveta [...] became a special target [...].

Progress promised a bright future. [...] In the 1960s, the precariously built settlement of Chimbote, on the northern coast of Peru, became a boomtown. For a few short years, it was home to the world’s largest single-species fishery. That boom would bust in a spectacular way with the El Niño phenomenon of 1972. After 1980, [...] the Chilean ports of Iquique and Talcahuano began to harvest and process the anchoveta as its northern neighbor had done. [...]

---

In his study, La Frontera: Forests and Ecological Conflict in Chile’s Frontier Territory [...], historian Thomas Klubock observes how early twentieth century developmentalism treated the temperate forest of the Chilean south as if it were a non-renewable resource. The Chilean nation state had set about “mining the trees”, as it were, and leaving behind a charred wasteland, without regard to social or environmental impact. In Wintersteen’s account, a similar dynamic drove Pacific fisheries to self-destructive excess [...]. Producers assumed that “any fish not extracted from the sea had no value” (115). As the 1972 collapse unfolded in Chimbote, fishermen saw that two thirds of their catch consisted of juveniles, up from one fifth in normal times. And yet, they dutifully ground them all into fish meal, to meet their contracts with foreign hog and poultry farmers. [...]

[T]he modern state assumed that it could own the seas. Therein lies the rub. The Chilean national anthem triumphantly proclaims, the sea that peacefully washes your long coastline promises you a splendorous future.

Or, does it? [...]

---

Coastal communities had a word for the fluctuations of fortune, the vaivén, a contraction of the Spanish, va y viene - comings and goings.

The term reflects a[n] [...] acceptance of the unpredictable cycles of wind and wave to which humanity, like all other species, had to adapt. Neoliberal capitalism has no place for that kind of thinking. The linear growth charts of capitalized industry [...] presupposed an unlimited potential for growth. The Humboldt Current ecosystem has proven that the myth of unlimited growth is radically unsustainable. [...]

As any child in Iquique could tell you, what adults called the smell of money was simply the stink of dead fish.

---

All text above by: Nathan Stone. “Review of The Fishmeal Revolution: The Industrialization of the Humboldt Current Ecosystem by Kristin A. Wintersteen (2021).” Not Even Past. 22 September 2021. [Bold emphasis and some paragraph breaks/contractions added by me.]

145 notes

·

View notes

Text

Enhancing Health and Growth: A Comprehensive Guide to Ornamental Fish Feeding

Ornamental Fish Feed: Providing Optimal Nutrition for Your Tank Inhabitants

Fish Food Formulations

One of the most important factors to consider when feeding your ornamental fish is the specific food formulation. Fish foods come in a variety of formulas developed for different types of fish and their specific nutritional needs. For herbivores like goldfish and koi, an algae-based flake or pellet food is ideal. These foods contain more plant-based proteins and less fishmeal. Carnivorous fish are best fed foods higher in fishmeal and animal proteins like brine shrimp, krill, and feeder insects. Omnivorous fish can do well on balanced flake or pellet foods that provide a mix of plant and animal ingredients. No matter the fish type, it's crucial the food contains all the essential vitamins, minerals, proteins, and fats they need to thrive. High-quality ornamental fish foods undergo rigorous testing and analysis to ensure a nutritionally complete diet.

Feeding Schedule

In addition to choosing the right food formulation, establishing an appropriate feeding schedule is also important. Overfeeding ornamental fish leads to poor water quality and health issues, while underfeeding can cause stress and nutritional deficiencies. As a general rule, feed small amounts two to three times per day. The amount should be what your fish can consume within two to three minutes. Uneaten food will foul the water, so don't overfeed. Adjust portions based on your fish's appetites, life stage, water temperature, and activity levels. Growing juvenile fish or those in warmer water may need slightly more frequent feedings. Skip one scheduled feeding per week as a "fast day" to help keep waste buildup in check. Proper feeding schedules vary depending on tank conditions and fish types, so adjusting as needed is part of responsible fish keeping.

Food Variety

Just like humans, ornamental fish feed benefit from a balanced, varied diet. Rather than sticking to a single food type, incorporate multiple formulas and ingredients into their meals. Feeding different foods adds diversity of nutrients, flavors, and textures. You can vary between flake, pellet, freeze-dried, frozen, and live/frozen foods. Staple processed foods should make up the bulk of most ornamental fish diets, with occasional supplemental feeds. Freeze-dried tubifex worms, brine shrimp, bloodworms, and Daphnia provide natural nutrition while being a Welcome treat. Herbivores love algae wafers or spirulina-infused foods. You can also feed fresh vegetables like zucchini, peas, spinach, and courgette, which some omnivores readily take. By mixing up food types weekly, your fish get a nutritionally complete menu while avoiding boredom.

Feeding Equipment

The equipment used for ornamental fish feed also warrants consideration. For dry processed foods, small suspendedfish feeders work well. When lowered into the tank, these feeders allow foodto slowly disperse throughout the watercolumnover several minutes. This prevents uneaten pellets from sinkingto the bottom andpollutingthe substrate. For supplemental frozen or live foods, specialized feeders and tools aid in guiding portions around the tank. Tweezers, chopsticks or spoons are gentle ways to distribute these more fragile ingredients without harming delicate fins. Remember anything added to the aquarium should be rinsed beforehand to remove chemicals or dirt. Adjust feeder positions based on territories and behaviors to ensure all fish have access. With the right equipment, every fish can enjoy balanced, mess-free meals tailored to their needs.

0 notes

Text

The Green Revolution: Eco-Friendly Practices in Shrimp Farming

Shrimp, a beloved delicacy enjoyed by many around the world, has seen a surge in demand over the past few decades. The Asia-Pacific region, in particular, has been a hub for shrimp production and consumption, with countries like India, Indonesia, Thailand, Vietnam, and Bangladesh leading the market. However, with this growth comes the challenge of sustainability and environmental impact. In response to these concerns, the shrimp farming industry is undergoing a significant transformation towards more eco-friendly practices, heralding a new era: The Green Revolution in Shrimp Farming.

The Rise of Shrimp Farming in the Asia-Pacific

The Asia-Pacific region accounts for a substantial share of the global shrimp market, thanks to its favourable climate and ideal conditions for shrimp cultivation. This has led to rapid expansion, but traditional shrimp farming methods have often been criticised for their negative impacts on the environment. Issues such as mangrove destruction, water pollution, and disease outbreaks have raised alarms about the industry's sustainability.

Addressing Environmental Challenges

Recognizing the need for change, shrimp farmers and industry stakeholders have been actively implementing innovative and eco-friendly practices to mitigate these environmental challenges.

1. Sustainable Feed Practices

One significant area of improvement is in feed practices. Traditional shrimp feed often includes fishmeal, which contributes to overfishing and habitat destruction. However, there is a shift towards using alternative, more sustainable ingredients such as plant proteins and algae. This not only reduces the industry's reliance on wild-caught fish but also minimises waste and improves the nutritional value of the feed.

2. Water Management and Recycling

Water management is another critical aspect of sustainable shrimp farming. By implementing better pond designs, farmers can minimise water usage and reduce the risk of pollution. Additionally, the use of water treatment systems and the promotion of water recycling help maintain water quality and reduce the discharge of harmful effluents into surrounding ecosystems.

3. Mangrove Conservation

Mangroves play a crucial role in coastal ecosystems, providing habitats for diverse marine life and serving as natural buffers against storms and erosion. In the past, shrimp farming often led to the destruction of mangrove forests. However, there is now a growing emphasis on mangrove conservation and restoration within the industry. Some farms are incorporating mangrove areas into their operations, recognizing the benefits they provide in terms of biodiversity and sustainability.

4. Certification and Traceability

Certification programs such as the Aquaculture Stewardship Council (ASC) and the Best Aquaculture Practices (BAP) are gaining traction in the shrimp farming industry. These programs set standards for environmentally and socially responsible practices, providing consumers with assurance that the shrimp they purchase comes from farms that meet these criteria. Additionally, improved traceability systems allow consumers to track the origins of their shrimp, promoting transparency and accountability throughout the supply chain.

The Future of Eco-Friendly Shrimp Farming

The Green Revolution in shrimp farming is not just a passing trend; it is a necessary evolution towards a more sustainable future. As consumer awareness of environmental issues grows, there is a rising demand for responsibly sourced seafood products. Shrimp farmers in the Asia-Pacific region are adapting to these changing expectations, embracing innovation and sustainable practices to ensure the longevity of their industry.

Conclusion

The Asia-Pacific shrimp market is undergoing a profound transformation driven by the need for sustainability. The Green Revolution in shrimp farming is marked by a shift towards eco-friendly practices such as sustainable feed, efficient water management, mangrove conservation, and certification programs. These initiatives not only benefit the environment but also contribute to the long-term viability of the shrimp farming industry. As we continue to witness this evolution, consumers can enjoy their favourite crustaceans with the knowledge that they are supporting a more environmentally responsible seafood industry.

Keywords: Asia-Pacific Shrimp Market, Green Revolution, Shrimp Farming, Sustainable Practices, Environmental Impact, Aquaculture Stewardship Council, Certification, Water Management, Mangrove Conservation.

0 notes

Text

Dry Type Fish Feed Plant

What is The Dry Type Fish Feed Mill Plant?

Herm machinery high-quality fish feed pellet mill plant can produce various fish feed pellets, including grass carp feed, herring feed, carp feed, trout feed, tilapia feed, salmon feed, catfish feed, etc. The raw materials of the complete fish food plant production line include fishmeal, homemade fishmeal, alcohol masterbatch, soybean phosphatide,…

View On WordPress

0 notes

Text

How Black Soldier Fly Can Help Feed the World: A Sustainable Solution

Welcome to the future of sustainable food production. You might be wondering how we can possibly feed a growing population while also preserving our planet's resources. Well, you're in luck because black soldier fly just might hold the answer. Curious? Let's dive in and explore this innovative solution together.

Nutritional Profile of Black Soldier Fly Larvae

The nutritional composition of Black Soldier Fly larvae is amazing! Comparing it to traditional feedstocks like soybean meal, it's obvious these larvae can transform anything into protein and healthy fat. The protein content is a whopping 22-42%, fat 18-34%, fiber 4-12%, lauric acid-rich, high in zinc, magnesium, and calcium.

Plus, Black Soldier Fly larvae have lauric acid with antimicrobial and anti-inflammatory properties. All these make them great for animal feed production as an alternative to soybean meal because soybeans are responsible for a significant amount of deforestation. Beef and soy production are driving more than two-thirds of the recorded habitat loss.

Benefits of Black Soldier Fly Larvae as Livestock Feed

Black Soldier Fly Larvae (BSFL) as Livestock Feed boasts several advantages. These include reduced land, water, and resource usage. Plus, no antibiotics or pesticides are required. This alternative protein source is nutritious and produces fertilizer, too. It's perfect for poultry, pigs, and fish. BSFL needs minimal space and time to produce large amounts of protein.

Moreover, BSFL can efficiently consume all kinds of organic waste. This makes them a key part of sustainable waste management systems. Their high nutrient content adds to improved animal growth and health. Scientists at a renowned agricultural university compared conventional feed with feed supplemented with BSFL. Animals on the larvae-derived feed exhibited superior growth rates and overall health. This further highlights the potential of using BSFL as a sustainable solution for livestock feed production. Move over, Finding Nemo, the real stars of the sea are these black soldier flies, helping feed fish and fill our plates without taking the bait!

Aquaculture Harvesting the Fish

Role in Aquaculture

Black soldier fly larvae are incredibly important in aquaculture. Their nutritional content and special characteristics make them great for enhancing the health, growth, and cost efficiency of farmed fish, as feed often is the most significant expense.

Let's look at their contributions to aquaculture:

Black Soldier Fly Larvae Advantages in Aquaculture

Black soldier fly larvae also help the environment. They consume fish waste and provide a nutrient-rich food source. This is the right time for you to start an automated aquaponics system with this step-by-step guide.

Zhang et al. (2017) examined the larvae's suitability as a protein source for farmed fish. Their research showed they have a high nutritional value and positive effects on fish health and growth.

Why use traditional livestock feed when you can let black soldier flies do all the work?

Role in Livestock farming

The Black Soldier Fly holds a special significance in livestock farming! Its larvae promote sustainable practices and improve the efficiency of animal feed production. For example, they:

Work as chicken feed and help farmed eggs grow healthy.

Convert organic waste into protein-rich biomass.

Produce fertilizer, which plants can use to close the nutrient loop.

Process food scraps and manure that chickens can't consume.

Add taste and nutrients to eggs from poultry fed with them.

Reduce reliance on traditional feed sources like soybeans and fishmeal.

Black Soldier Fly larvae are an eco-friendly solution that improves resource utilization and productivity while minimizing waste. Who knew flies could be superheroes, helping us reduce waste and feed the world?

With the help of Black Soldier Fly Larvae, No Limited Organic Waste End in Landfills or Burned

Waste Management and Reduction

The larvae of the Black Soldier Fly can transform organic waste into biomass, cutting down on landfill usage and encouraging nutrient-rich compost production. A farm the size of a smart car can process 1 metric ton of organic waste in a year, which makes it perfect for apartments and households of smaller sizes.

By utilizing these methods, we can recycle organic waste and use it to produce food at the same place it was generated. This sustainable tactic helps to protect organic material and reduce environmental pollution. To manage waste successfully and lessen its effect on the environment, we must adopt innovative solutions like Black Soldier Fly larvae farming. This way, we can minimize contamination and increase food production by transforming waste into resources.

Pro Tip: Incorporate Black Soldier Fly farming systems on a small scale at home or community levels to maximize sustainability and self-sufficiency while minimizing environmental impact. Delight in the fact that flies can make such yummy compost and society's craving for sustainable choices just got even tastier!

In this guide you learn how to start your own black soldier fly farm.

Contribution to the Circular Economy

The Role of Black Soldier Fly Larvae in Advancing a Circular Economy:

Transforming Organic Waste into Nutrient-Rich Feed!

This innovative solution has the potential to revolutionize food production. Automated systems can be implemented in homes and businesses to convert organic waste into larvae feed. This could reshape how we interact with food and eliminate inefficiencies.

Contribution to the Circular Economy

Black Soldier Fly Larvae can:

Divert organic waste

Transform it into larvae

Create nutrient-rich feed

Decrease reliance on farming

Unique Details

Integrating black soldier fly larvae into food production could be hugely beneficial. We may soon be questioning how we once lived so inefficiently in the past. Minimizing waste is ever more critical, with organic material, fertilizer, and food increasing in price.

A True Fact

Studies show incorporating black soldier flies can lead to a 50-70% reduction in food waste! Let's make use of these eco-friendly insects and enjoy a sustainable world.

Environmental Sustainability

Achieving a Sustainable Environment.

Environmental sustainability is a must for keeping the balance between human activities and the natural world. To protect natural resources and biodiversity for future generations, sustainable practices must be adopted.

One such way is to grow black soldier fly larvae. Their nutrient-richness makes them an excellent feed for animals, meaning we can reduce reliance on traditional livestock farming. Also, black soldier fly larvae farming is 47 times lower in CO2 emissions than composting and takes up less space than the traditional method.

Furthermore, black soldier flies are amazing in transforming organic waste into a valuable source of protein. Their ability to eat a lot while producing little waste makes them perfect for sustainable food production.

Mayans and Aztecs used black soldier flies centuries ago for waste management and protein production. This shows that they have been known for their ecological advantages and potential contribution to global food security for a long time now.

It's time to start a fly revolution! These little soldiers have the potential to outperform any form of industrial farming.

Industrial Scaling of Black Soldier Fly Farming

Say goodbye to cows, 'cause the black soldier fly is here! It's ready to revolutionize global food security by transforming organic waste into nutrient-rich biomass. But, to achieve industrial scaling of Black Soldier Fly Farming, several factors must be addressed.

Mass production challenges are of high importance. Regulatory hurdles must also be taken into account. And, public perception towards consuming larvae must be managed.

It's essential to ensure transparency and honesty when presenting the larvae as an alternative food source. Even if some consumers decline, the larvae can still be effectively utilized in industrial production. For example, to feed pigs and chickens.

To make progress in scaling up production, innovation and collaboration between experts is needed. With great effort, a scalable farming model can be achieved, allowing the black soldier fly to save the day!

Let's explore further applications of Black Soldier Fly larvae in human consumption and food security, contributing to a more sustainable future. Time to discover the power of bugs!

If you have enough space maybe a small chicken farm is an option to feed black soldier fly larvae and harvest healthy organic eggs regularly.

Food Security Enhancement

Black Soldier Fly larvae can be used to tackle food shortages and global food security issues. They convert carbs from fruits, veggies and organic waste into essential protein and fat. In Africa, despite high malnutrition levels, there's heaps of food waste due to its perishability. Feeding this waste to BSF larvae saves calories and upgrades them while producing water and fertilizer.

This conversion process offers a sustainable solution for improving food security and reducing waste. Plus, the economic production of water and fertilizer adds value. A report from Food Tank shows that feeding organic waste to BSF larvae is effective in addressing food security issues and promoting sustainable practices.

1. How does the Black Soldier Fly help feed the world?

The Black Soldier Fly is a sustainable solution for feeding the world because its larvae can be used as a highly nutritious protein source for various animal feed, reducing the need for traditional protein sources like soy and fishmeal. In areas where food is rare direct consumption is also an option.

2. What makes the Black Soldier Fly larvae a sustainable protein source?

The Black Soldier Fly larvae are highly efficient at converting organic waste into protein, requiring significantly less resources and producing lower greenhouse gas emissions compared to traditional protein sources.

3. How can the Black Soldier Fly benefit the environment?

The use of Black Soldier Fly larvae as a protein source can reduce the amount of organic waste in landfills, as well as decrease the need for chemical fertilizers, antibiotics, and pesticides used in traditional animal feed production.

4. Is the Black Soldier Fly larvae safe for animals to consume?

Yes, Black Soldier Fly larvae are safe for animals to consume as they do not contain any harmful toxins or pathogens. In fact, they are a natural part of many animals' diets in the wild.

5. Can Black Soldier Fly be used as a human food source?

Yes, there has been research and development into using Black Soldier Fly larvae as a protein source for human consumption. However, the regulations and acceptance of this practice vary by country.

6. How does using Black Soldier Fly help with food insecurity?

By providing a sustainable and cost-effective source of protein, the use of Black Soldier Fly larvae can help alleviate food insecurity in areas where traditional protein sources are scarce or expensive.

Conclusion

The black soldier fly presents an innovative and sustainable solution to address global food insecurity and organic waste management. Their high protein content and nutritional value make them a valuable feed source for livestock and aquaculture. Additionally, black soldier fly larvae play a vital role in converting organic waste into nutrient-rich biomass, contributing to a circular economy.

As we face the challenges of a growing population and increasing environmental concerns, embracing the potential of black soldier fly farming can lead us towards a more sustainable and food-secure future. By promoting this eco-friendly solution, we can make a positive impact on both the environment and global food security.

Many inflammation-related diseases can be treated with black soldier fly fat. Start your own Black Soldier Fly Larvae Farm at home and produce healthy protein and fat for your pets or maybe even yourself.

#sustainability#environment#plasticfree#wastefree#trash#sustainable#viral#food waste#water#aquaponics

1 note

·

View note

Text

Floating Fish Feed Market Is Estimated To Witness High Growth Owing To Increasing Aquaculture Activities

The global Floating Fish Feed Market is estimated to be valued at US$ 9.95 Billion In 2023 and is expected to exhibit a CAGR Of 4.7% over the forecast period of 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Floating fish feed is a specialized product that is designed to float on the surface of water for a longer period of time, providing adequate nutrition to the fish. These feeds are highly efficient and cost-effective for aquaculture activities. The floating nature of the feed allows for easy feeding and minimizes feed wastage. Moreover, it offers several advantages such as enhanced nutrient utilization, better growth, and improved feed conversion ratio in fish. The increasing demand for fish as a protein-rich food source, coupled with the rising trend of aquaculture activities, is driving the growth of the floating fish feed market.

Market Key Trends:

One key trend in the Floating Fish Feed Market is the increasing adoption of alternative ingredients in fish feed. With the growing concerns over overfishing and the sustainability of fishmeal and fish oil, there is a rising demand for alternative protein and lipid sources in fish feed. Manufacturers are increasingly using plant-based ingredients, such as soybean meal, corn gluten meal, and canola meal, as substitutes for fishmeal and fish oil in floating fish feeds. These alternative ingredients not only help in reducing the dependency on marine resources but also offer economic benefits to farmers. The use of alternative ingredients is expected to continue to rise in the coming years, driven by the need for sustainable and environmentally friendly fish farming practices.

Key Takeaways:

The global floating fish feed market is expected to witness high growth, exhibiting a CAGR of 4.7% over the forecast period from 2023 to 2030. This growth can be attributed to the increasing demand for seafood and the rising aquaculture industry. The market size is projected to reach US$ 9.95 billion by 2023.

In terms of regional analysis, Asia Pacific is expected to be the fastest-growing and dominating region in the floating fish feed market. The increasing population, rising disposable incomes, and changing dietary patterns in countries like China and India are driving the demand for seafood and aquaculture, thereby boosting the market growth in the region.

Key players operating in the floating fish feed market include Cargill, Incorporated, Archer Daniels Midland Company, Skretting, Aller Aqua Group, BioMar Group, Ridley Corporation Limited, Purina Animal Nutrition, Nutriad International NV, BENEO GmbH, and Dibaq Aquaculture. These key players contribute to the growth of the market through product innovations, expansions, mergers and acquisitions, and strategic collaborations.

0 notes

Text

What is the best feed for catfish?

The best feed for catfish contains protein supplements. Most catfish feeds are plant-based and mostly contain soybean meal and cotton meal. However, it is possible to see fishmeal in feed for fingerlings.

How to feed catfish fingerlings

You can feed catfish fingerlings 2 or 3 times daily. The feed amount for the fingerlings should be 15%-20% of the fingerlings weight.

Can catfish eat…

View On WordPress

0 notes

Text

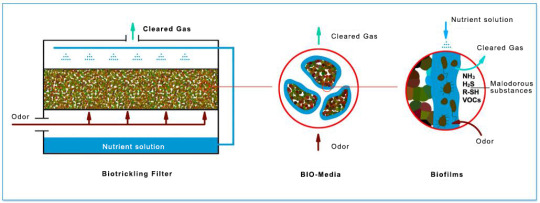

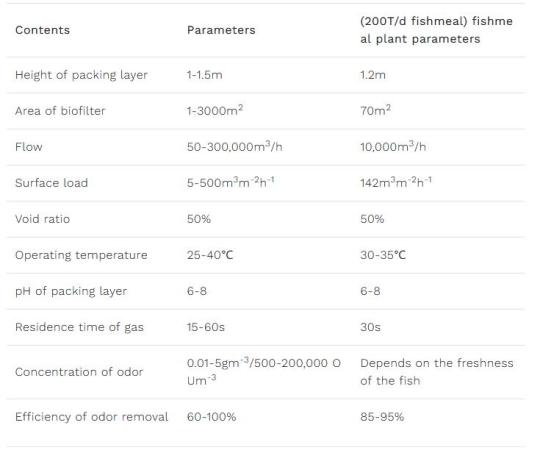

The Solutions of Odor Removal From Fish Meal Plant

The fish meal processing of the fish meal factory is to use the scraps of aquatic products and some small fish and shrimp to make fish meal for feed through high-temperature steam cooking, pressing, drying, crushing and other processes. Malodorous gas is produced in many links in production, and the odor causes serious air pollution. In particular, some fishmeal production enterprises are generally small in scale, with less investment, relatively backward equipment and technology, irregular operation and management, and more obvious odor pollution.

1.The source of odor from fish meal processing

Organized emission sources: high-temperature cooking exhaust gas of wet drying furnace, drying exhaust gas of dryer;

Unorganized emission sources: raw material storage yard, waste water, waste water treatment station, raw material transfer in production, etc.

Among them, high-temperature cooking, raw material storage yard, and raw material transfer are the main sources of odor.

The known components of fish meal odor are mainly acrolein, butyric acid and valeric acid, oil degradation products, hydrogen sulfide, ammonia, and trimethylamine. The concentration of trimethylamine in the waste gas discharged during the processing of fish meal can reach 600mg/m3, hydrogen sulfide can reach 30mg/m3, and the odor intensity is 4000~10000 (fresh fish processing). Up to more than 100,000.

2. Solutions for odor removal from fish meal processing

At present, the general fishmeal odor solution technology on the market can be roughly divided into the following points:

Combustion deodorization

adsorption deodorization

chemical deodorization

dissolution deodorization

biological deodorization

Today we mainly introduce the following biological trickle filter deodorization system launched by our company.

Biological trickling filtration is a type of biological filtration. The difference is that biological trickling filtration is equipped with a spray system. Compared with ordinary biological filters, biological trickling filtration can treat higher concentrations of pollutants with higher efficiency.

Through the biofilm absorption and metabolism on the filler, the pollutants in the gas are degraded into odorless and harmless small molecular substances. Moisture and other nutrients required by microorganisms are provided by a circulating trickling filter device. Through the circulation of nutrient solution, the growth environment of microorganisms is controlled. The tunability of the growth environment of microorganisms is the distinguishing feature of biological trickling filtration from other biological filtration technologies.

3. Practical application of biological trickling filtration in odor treatment of fishmeal factory

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fish meal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fish meal industry.

Based on years of R&D and production experience of fish meal plant www.feedsmachinery.com production lines, Feeds Machinery has launched the Fish Meal Process (FMP), a wet-process fish meal production process, which is suitable for the production of fish meal with a raw material capacity of up to 15 tons/hour and above. The produced fish meal has better quality, high digestibility, low energy consumption and simple operation. If a complete fish meal and fish oil production and treatment system is used, the production capacity can be increased by 5% (the digestibility is increased by 3%), and at the same time, the whole process can be made pollution-free with the biological deodorization solution.

#fishmeal machine#fishmeal plant#fish meal#fish protein#fish oil#fishmeal dryer#fishmeal cooker#fishmeal equipment#fishmeal#fish oil separator

0 notes

Text

Addressing Challenges in Sinking Fish Feed Market Supply Chain

The sinking fish feed market supply chain faces several challenges that require strategic solutions to ensure a smooth and efficient flow of products from manufacturers to end-users. Addressing these challenges is essential for meeting the increasing demand for high-quality feed while maintaining sustainability and reliability. One of the primary challenges in the supply chain is the sourcing of raw materials, especially alternative ingredients. As the industry moves away from traditional fishmeal and fish oil, securing a stable supply of sustainable ingredients like plant-based proteins, algae, and insect-based proteins becomes critical. Building strong supplier partnerships and exploring local sourcing options can help mitigate supply chain disruptions and ensure a consistent flow of raw materials. Quality control is another significant concern in the sinking fish feed market supply chain. Ensuring consistent feed quality is vital to support fish growth and overall health. Implementing rigorous quality assurance protocols and conducting regular testing can help maintain feed integrity and meet industry standards. Logistics and transportation present additional challenges. As the sinking fish feed market expands to serve global demand, optimizing transportation routes and ensuring timely deliveries become essential. Investing in efficient logistics infrastructure and adopting temperature-controlled shipping methods can help preserve feed freshness and shelf life during transit. Regulatory compliance is a critical aspect of the supply chain, as adherence to regional and international standards is essential to gain market access and build trust with consumers. Staying up-to-date with evolving regulations and maintaining transparent documentation can help feed manufacturers navigate the complexities of compliance seamlessly. Furthermore, addressing sustainability concerns throughout the supply chain is imperative. From ingredient sourcing to packaging and waste management, adopting eco-friendly practices and supporting circular economy initiatives can enhance the overall sustainability of the sinking fish feed market. In conclusion, addressing challenges in the sinking fish feed market supply chain requires collaboration and innovative approaches. By focusing on raw material sourcing, quality control, logistics, regulatory compliance, and sustainability, stakeholders can build a resilient supply chain that meets the industry's growing demand while minimizing environmental impact.

0 notes

Text

"Sourcing the Best Ingredients for High-Quality Aquafeed Formulations"

Aquafeed is a critical component in the sustainable production of seafood. As the global population continues to grow, demand for seafood is increasing rapidly, and aquaculture is becoming an increasingly important source of protein. However, in order to produce healthy and high-quality seafood, it is essential to use the best possible ingredients in aquafeed formulations.

The quality of the ingredients used in aquafeed can have a significant impact on the health and growth of farmed fish and shrimp. For example, high-quality proteins are essential for promoting muscle growth and supporting healthy immune function. Essential fatty acids, such as omega-3s, are important for maintaining heart health and promoting brain function. Vitamins and minerals are also important for overall health and wellbeing.

In order to ensure that aquafeed formulations are of the highest quality, it is essential to source the best possible ingredients. This involves a number of steps, including identifying the best sources of raw materials, assessing the quality and nutritional content of those materials, and ensuring that they are processed and stored properly to maintain their quality and freshness.

One of the key considerations in sourcing aquafeed ingredients is sustainability. Many of the most commonly used ingredients, such as fishmeal and fish oil, are derived from wild-caught fish. However, as demand for these ingredients has increased, concerns have been raised about the sustainability of the fisheries that supply them. In order to address these concerns, many aquafeed companies are turning to alternative sources of protein and fat, such as plant-based ingredients, to reduce their reliance on wild-caught fish.

Another important consideration in sourcing aquafeed ingredients is quality. In order to ensure that aquafeed is providing the best possible nutrition to farmed fish and shrimp, it is essential to use ingredients that are fresh, free from contaminants, and have a consistent nutritional profile. This requires careful selection of suppliers and rigorous quality control measures throughout the production process.

In addition to sourcing high-quality ingredients, aquafeed companies also need to ensure that those ingredients are processed and stored properly to maintain their quality and freshness. This can involve a variety of techniques, such as drying, grinding, and extrusion, as well as proper storage and handling to prevent spoilage and contamination.

One of the challenges in sourcing aquafeed ingredients is the wide range of raw materials that are used in aquafeed formulations. For example, different species of fish and shrimp may have different nutritional requirements, and different life stages may require different types of feed. This requires a deep understanding of the nutritional needs of the target species, as well as a broad knowledge of available raw materials and their nutritional profiles.

Despite these challenges, sourcing the best ingredients for high-quality aquafeed formulations is essential for sustainable seafood production. By using the best possible ingredients, aquafeed companies can help to ensure that farmed fish and shrimp are healthy and nutritious, and that they are produced in an environmentally responsible manner. This can help to meet the growing demand for seafood while protecting the health of our oceans and the communities that depend on them.

In conclusion, sourcing the best ingredients for high-quality aquafeed formulations is a critical component of sustainable seafood production. By prioritizing sustainability and quality in the selection and processing of raw materials, aquafeed companies can help to ensure that farmed fish and shrimp are healthy, nutritious, and environmentally responsible. This is essential for meeting the growing demand for seafood while protecting the health of our oceans and the communities that depend on them.

0 notes