#enterprise resource planning erp system

Text

#erp#erp system#enterprise resource management system#enterprise resource planning erp system#enterprise resource planning#software

0 notes

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

7 notes

·

View notes

Text

𝗥𝗲𝘃𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝗶𝘇𝗲 𝗬𝗼𝘂𝗿 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝗔𝗜-𝗱𝗿𝗶𝘃𝗲𝗻 𝗘𝗥𝗣 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀!

Discover how integrating Artificial Intelligence with Enterprise Resource Planning can transform your manufacturing operations. Check out our latest blog post to explore the future of smart manufacturing:

Read more about the next wave of intelligent ERP systems and stay ahead in the digital transformation race!

https://www.codetrade.io/blog/ai-driven-erp-solutions-for-the-manufacturing-industry/

#artificial intelligence#machine learning#erp solution#manufacturing industry#ERP in AI#enterprise resource planning#intelligent ERP system#AI ML#AI-driven ERP solutions

2 notes

·

View notes

Text

Spinning Efficiency: Maximizing Productivity with Textile ERP Solutions

In the intricate world of textile manufacturing, every thread counts. From the initial stages of yarn production to the final weaving of fabric, efficiency is paramount for success. Among the numerous tools at the disposal of textile manufacturers, the Enterprise Resource Planning (ERP) system stands out as a game-changer, particularly in optimizing spinning efficiency.

Source Link

#ERP#Enterprise resource planning#ERP solutions#ERP Services#ERP technology#ERP software#ERP systems

0 notes

Text

Exploring ERP Systems' Contribution to Business Development in Zambia

This infographic design illustrates the significance of ERP systems in driving business development in Zambia. It also showcases the benefits of ERP solutions and how they facilitate the transformation of enterprises.

#ERP system#ERP software#ERP system in zambia#ERP software in zambia#Enterprise resource planning Software

0 notes

Text

Exploring ERP Systems' Contribution to Business Development in Zambia

This infographic design illustrates the significance of ERP systems in driving business development in Zambia. It also showcases the benefits of ERP solutions and how they facilitate the transformation of enterprises.

#ERP system#ERP software#ERP system in zambia#ERP software in zambia#Enterprise resource planning Software

0 notes

Text

Retail Solutions for Streamlining Operations and Boosting Sales

Discover how our retail solutions enhance operations, improve customer experiences, and drive sales growth. Explore our retail solutions to optimize operations, elevate customer experiences, and accelerate sales growth in your business

#accnu#accnuerp#besterpsolutionprovider#erp solutions#erpservices#erp partner#erp service provider#erp solution provider#enterprise resource planning software#enterprise resource planning solutions#erp system

0 notes

Text

Enterprise resource planning(ERP System)

Unlock the power of Enterprise Resource Planning (ERP) systems to revolutionize your business operations. From managing finances, HR, supply chain, and beyond, ERP software offers comprehensive integration and optimization. Explore how ERP solutions streamline processes, enhance collaboration, and provide real-time insights for informed decision-making. Gain a competitive edge in today's dynamic market landscape with the right ERP strategy. Learn more about maximizing efficiency and productivity with ERP.

For more info: https://www.inventia.in/enterprise-resource-planning-erp

0 notes

Text

Introduction to Strategic Enterprise Resource Planning

In the past two decades, the software market has been significantly influenced by the strategic implementation of Enterprise Resource Planning (ERP). The transformative impact of Strategic Enterprise Resource Planning (SERP) on day-to-day business operations. SERP has emerged as a critical tool for organizations seeking to enhance their competitive edge, reduce costs, and prepare for the challenges of global competitiveness.

Evolution and Significance of Strategic Enterprise Resource Planning

SERP has evolved from a mere operational necessity to a strategic asset, enabling organizations to navigate the complexities of the global market. The integration of emerging technologies has become an inevitable step for organizations striving to sustain their competitive position. Despite the growth of SERP implementations, there is also a need to address concerns regarding expensive implementation costs, restricted functionality, and the complexities of configuration installations.

SERP: The Backbone of Business Processes

At its core, Strategic Enterprise Resource Planning determines the functionality of daily business processes. The successful implementation of a Customer Relationship Management (CRM) strategy hinges on a system where an organization’s back office and financial functions are seamlessly integrated with its front office customer-facing processes. This integration is crucial for the success of organizations, as it allows for the synchronization of product and service data, order management, customer service, and more.

The Integration Challenge: SCM, ERP, CRM, KMS, and Decision Making

SERP plays a vital role in integrating various organizational systems such as SCM, ERP, CRM, Knowledge Management Systems (KMS), and Corporate Decision Making Systems. The advancements in technology present both opportunities and challenges for organizations to systematically implement SERP and achieve synergy in building global supply chain competitiveness.

Literature Review: Insights into SERP Implementation

The literature on Strategic Enterprise Resource Planning implementation highlights the significant issues organizations face when embracing Knowledge Management Systems (KMS) and integrating SCM-CRM. The process of SCM-CRM integration has been revolutionized by technological advancements, offering vast possibilities for information and resource sharing. However, adopting an integrated approach throughout the supply chain requires a delicate balance between autonomy and control among supply partners.

SERP Philosophy and Change Management

SERP represents a philosophy of managing technology and processes in a manner that optimizes the delivery of goods, services, and information from supplier to customer. This philosophy necessitates change across the entire supply chain, including management practices, performance metrics, and business processes. Collaboration among organizations involved in the supply chain must be viewed as a strategic asset and operational priority to facilitate trust among trading partners.

The Role of Information Visibility in SERP

Information visibility across the supply chain is a critical component of SERP implementation. It serves as a replacement for inventory and must be managed with strict discipline policies and monitoring mechanisms. The total cycle time compression and inventory cost reduction can only be achieved when the entire supply chain is optimized, rather than focusing on individual enterprises.

Strategic Flexibility and Adaptability through SERP

Strategic Enterprise Resource Planning (SERP) provides organizations with significantly increased strategic options for achieving long-term flexibility and adaptability, which are essential for maintaining a competitive advantage. The level playing field created by SERP allows enterprises of any size to access global suppliers and customers, meeting the demands for faster turnaround and greater customization.

Creating Customer-Centric Businesses

In today’s market, customers demand quicker responses and more personalized services. Organizations must find innovative ways to become more customer-centric, improving relationships with customers and fostering loyalty. Information exchange is key to avoiding supply chain issues such as the bullwhip effect, and the Internet has enabled a shift towards dynamic communication and improved integration.

Knowledge Management Systems: The Foundation of Strategic Alliances

Knowledge Management is integral to the analysis of strategic alliances, providing insights into information-sharing aspects and the potential for learning. The structure of knowledge management offers novel pathways for exploring inter-firm information sharing and the characteristics of networks centered around continuous learning.

The Future of SERP, KMS, and Organizational Competitiveness

Looking ahead, the implementation of SERP and KMS is inevitable for organizations to survive and thrive in a competitive world. The study underscores the importance of SCM-CRM integration at each organizational level and the role of KMS in innovation and organizational restructuring to meet dynamic business conditions and customer preferences.

Conclusion: The Continuous Journey of SERP Implementation

In conclusion, Strategic Enterprise Resource Planning is not a static entity but a dynamic, ongoing process that demands continuous improvement and innovation. Organizations that fail to realize the importance of these mechanisms will struggle to keep up with competitors. The present research demonstrates that SERP is a challenge that requires organizations to examine and redesign processes, ensuring that they are aligned with advancements in communication and technology.

#enterprise resource planning#enterprise resource management#erp systems#enterprise resource planning systems#Strategic Enterprise Resource Planning

0 notes

Text

7 Tips to Choose the Right ERP Software for Your Business in 2024

Choosing the right ERP Software for your business in 2024 can be difficult. Because of this competitive market. If you wanna know what ERP Software can be the best for your business then visit our blog and know about the things that you need to know before choosing the right ERP Software for your business.

#erp system#ERP for your business#ERP for your business in 2024#ERP Software#Enterprise Resource Planning Software#Enterprise Resource Planning#What is ERP Software#Odoo ERP Software#Odoo for all industries#podcast#SoundCloud

0 notes

Text

Manufacturing ERP: The Top 10 ERP Systems for 2024

Introduction:

In the dynamic landscape of the manufacturing industry, the right technology can make all the difference in streamlining processes and enhancing overall efficiency. Manufacturing Enterprise Resource Planning (ERP) systems have become indispensable tools for businesses seeking to integrate various facets of their operations seamlessly. As we step into 2024, the demand for robust ERP solutions continues to grow. In this blog, we will explore the top 10 Manufacturing ERP systems that are poised to make a significant impact on the industry this year.

1. SAP S/4HANA: Pioneering Manufacturing Resource Planning System

One of the most trusted names in ERP, SAP S/4HANA stands out as a comprehensive Manufacturing Resource Planning System. Its real-time analytics, integrated modules, and intelligent automation make it an ideal choice for businesses aiming to optimize their manufacturing processes.

2. Oracle ERP Cloud: Empowering Manufacturing Enterprise Resource Planning

Oracle ERP Cloud offers a scalable and flexible solution for manufacturing enterprises. With its robust features, it caters to the diverse needs of businesses, ensuring a seamless integration of manufacturing operations. Its cloud-based architecture provides the agility required for modern manufacturing environments.

3. Microsoft Dynamics 365: A Versatile ERP Solution

Microsoft Dynamics 365 is gaining prominence as a Manufacturing Enterprise Resource Planning software that offers versatility and integration capabilities. Its user-friendly interface and interoperability with other Microsoft products make it an attractive choice for businesses, especially small enterprises.

4. Infor CloudSuite Industrial: Tailored Manufacturing ERP

Infor CloudSuite Industrial is designed with the unique needs of manufacturers in mind. It provides specialized functionalities, including supply chain management and shop floor control, making it a standout choice among ERP solution providers.

5. NetSuite ERP: Unifying Manufacturing Operations

NetSuite ERP is recognized for its ability to unify diverse manufacturing operations into a single, cohesive system. Its cloud-based platform allows for real-time collaboration and data accessibility, making it an efficient Manufacturing Enterprise Resource Planning Software.

6. Epicor ERP: Driving Growth for Small Businesses

Epicor ERP is particularly well-suited for small businesses in the manufacturing sector. With its focus on driving growth and improving efficiency, Epicor ERP offers a cost-effective solution without compromising on essential features.

7. IFS Applications: Comprehensive ERP Solution

IFS Applications is a comprehensive ERP solution that covers a wide range of manufacturing processes. Its modular structure allows businesses to tailor the system according to their specific requirements, making it a preferred choice for Manufacturing Enterprise Resource Planning.

8. IQMS Manufacturing ERP: Enhancing Shop Floor Control

IQMS Manufacturing ERP is distinguished by its emphasis on shop floor control and real-time monitoring. It empowers manufacturers with tools to optimize production processes and make informed decisions, positioning it as a top choice among ERP solution providers.

9. Acumatica Cloud ERP: Scalability for Growing Businesses

Acumatica Cloud ERP stands out for its scalability, making it an ideal choice for growing manufacturing businesses. With a flexible platform and advanced features, Acumatica supports businesses in adapting to changing demands and expanding their operations seamlessly.

10. SYSPRO ERP: Tailored for Manufacturing Success

SYSPRO ERP is tailored to meet the specific needs of manufacturing industries. Its focus on delivering a user-friendly experience and addressing industry challenges positions it as a reliable choice for Manufacturing Enterprise Resource Planning.

Conclusion:

As manufacturing industries evolve, the importance of robust ERP systems cannot be overstated. The top 10 ERP systems highlighted in this blog represent the cutting edge of technology, offering solutions that cater to the unique demands of the manufacturing sector. Whether it's SAP S/4HANA's real-time analytics, Oracle ERP Cloud's scalability, or Acumatica Cloud ERP's flexibility, each system brings its own strengths to the table.

For businesses in Madhya Pradesh seeking Manufacturing Software for Small Business, these ERP solutions provide a pathway to enhanced productivity and streamlined operations. Choosing the right Manufacturing ERP system is a critical decision that can impact a company's growth and competitiveness. Evaluate the features, scalability, and industry focus of each system to find the perfect fit for your manufacturing enterprise. Embrace the power of ERP in 2024 and position your business for success in the ever-evolving landscape of manufacturing technology.

#Manufacturing Software for Small Business#Manufacturing Enterprise Resource Planning Software#ERP Solution Providers in Madhya Pradesh#Manufacturing Enterprise Resource Planning#Manufacturing Resource Planning System#ERP Software#Chain Cycle Management#Business#Engineering#Manufacturing#India#Madhya Pradesh#Go-To-Market#GTM#ERP

7 notes

·

View notes

Text

Online Enterprise Resource Planning Software India

NYGGS Enterprise Resource Planning Software fits the bill if you are looking for the best ERP software in India. It aims to provide small businesses in the Indian market with a feature-rich, yet affordable, ERP platform. This cloud-based ERP solution is proudly 'Made in India' and has key features such as finance and accounting, inventory management, a project management module, an HR and payroll module and much more. You don't need to go anywhere when you can get a complete ERP solution in one place.

#best enterprise resource planning software#online enterprise resource planning software india#erp software#erp system

0 notes

Text

0 notes

Text

0 notes

Text

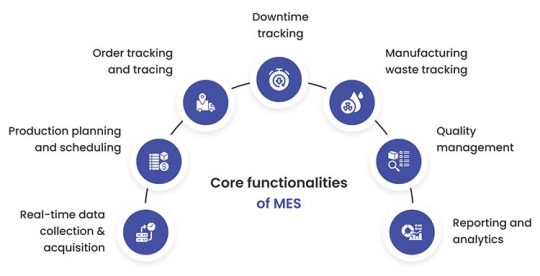

ERP vs. MES - Understanding Key Differences

MES and ERP - the two prominent data and operations management systems in the manufacturing industry are so interconnected that they are often interchangeable.

1 note

·

View note