#diaphragmairpump

Text

What Advantages Does a Customized Diaphragm Pump Offer?

Among many pump brands, Topsflo pumps are favored for their excellent performance and wide range of applications. The key behind this is the unique advantages brought by customized pumps. So what are the unique advantages of custom miniature diaphragm pumps?

Miniature diaphragm pumps have to deal with a series of stringent requirements when performing specific tasks. To meet these needs, Topsflo specializes in providing custom pump services, ensuring pump performance is precisely matched to the specific needs of each application. From material selection, design concept to setting of performance parameters, every aspect of the pump can be customized according to the specific needs of customers. This article analyzes in detail the unique advantages of deeply customized pumps compared to standard pump series, helping you gain a deeper understanding of the value and importance of customized diaphragm pumps.

1.Accurately match the working point:

Most application scenarios have specific requirements for flow, pressure or vacuum levels. Topsflo is committed to providing pump solutions that are highly tailored to customer needs by adjusting pump parameters such as speed, flow and pressure to more accurately meet customer needs. This not only helps to improve production efficiency, but also significantly reduces energy consumption, achieving a cost-effective and environmentally friendly win-win situation. In order to help customers find the most suitable custom diaphragm pump, Topsflo offers a variety of pump sizes and offers a variety of solutions to achieve the precise operating point, including the digital customization of the motor and the selection of carefully optimized eccentric, etc., to ensure that each pump can be precisely matched to the operating point, providing stable and reliable support for customers' production activities.

2. Excellent chemical compatibility:

In the face of challenging media unique to certain industries, such as corrosive, explosive, sensitive or environmentally hazardous substances, ensuring fluid integrity and safety is critical. To this end, Topsflo offers a range of highly screened, high-performance materials such as PP, PTFE, FKM, FFKM, EPDM and PPS for customising key components of miniature diaphragm pumps such as diaphragms, valves and pump heads. In harsh working environments, more corrosion-resistant and wear-resistant materials and structural designs can be used to reduce the failure rate and maintenance costs of the pump. Our goal is to provide you with custom diaphragm pump solutions with superior chemical compatibility to ensure the reliable operation of the entire system in a variety of complex environments.

3. Extend service life and optimize costs:

For some critical applications that rely on long-term continuous operation of the pump, Topsflo can provide high-quality brushless DC motors. Not only does this motor last long, but it also provides the custom pump with exceptional robustness and reliability, significantly extending the pump's service life. This means that, despite being a custom pump, it does not necessarily mean a higher cost. However, in some applications the pump may not need to be run for very long periods of time. For situations like these, we offer our customers the more economical and simpler option of brushed motors. Brushed motors have a relatively short service life due to brush wear, but they also offer excellent reliability.

Through this flexible customization strategy, Topsflo not only demonstrates the performance advantages of customized micro diaphragm pumps, but also highlights its great value in cost control. Through reasonable customization and selection, customers can optimize costs while meeting performance requirements and find the most cost-effective pump solution.

4. Lower maintenance costs:

Customized micro diaphragm pumps fully consider customer needs and usage scenarios during the design and manufacturing process, so their structure and material selection are more reasonable, which can reduce maintenance costs.

Imagine that many systems require adapters to connect when in use, which not only increases the complexity of installation and debugging, but may also cause leakage and resonance problems due to improper adaptation. However, custom micro diaphragm pumps are designed to fit perfectly into the customer's system without the need for additional adapters. This means the size, weight and installation are just right, avoiding potential performance issues and dramatically reducing the cost of repairs and replacement parts.

5. Enhance market competitiveness:

When customers choose Topsflo's customized pump services, they will receive the pumps that closely match their needs and enjoy strict confidentiality of specifications, which gives Topsflo customers a valuable advantage in the market competition. Competitors cannot easily imitate or understand the exact specifications of a custom pump, making it difficult to discover the core details of a customer's system. We are fully aware of the importance of business confidentiality and therefore solemnly promise not to disclose relevant details of customized pumps to any third party under any circumstances without the express written consent of the customer. Choosing Topsflo means choosing the most trustworthy partner.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Mini daiprahgm liquid pumps: https://www.topsflo.com/mini-diaphragm-pump/

Mini daiprahgm gas pumps: https://www.topsflo.com/mini-diaphragm-pump/

#diaphragmliquidpump#diaphragmairpump#microairpumps#micropump#microdiaphragmpump#minidiaphragmpump#dc air pump#12v air pump#12v vacuum pump#12v dc air pump#12v mini air pump#dc vacuum pump#mini air pump#micro air pump#mini vacuum pump#Micro diaphragm pump#Miniature Diaphragm Pump

0 notes

Text

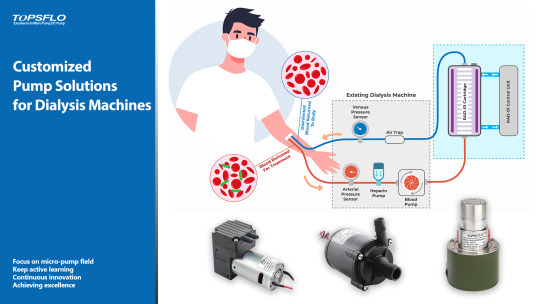

𝗠����𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

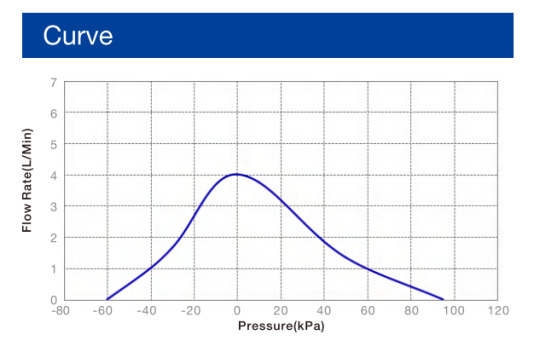

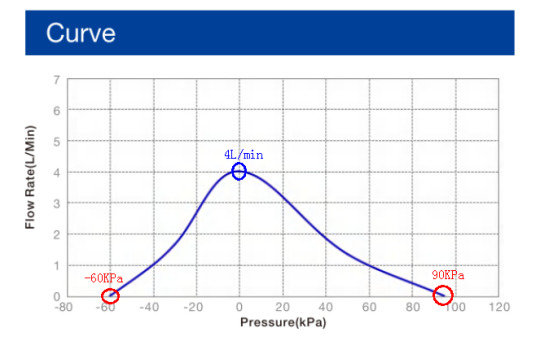

How to Read the Performance Curve of Miniature Diaphragm Pumps (Liquid & Gas)

Understanding the performance curve is crucial for deeper understanding of Miniature Diaphragm Pumps. The performance curve is a key tool that contains a series of key information to evaluate whether the pump can provide the required flow rate under specific pressure differential conditions, helping engineers and operators understand the performance of micro diaphragm pumps under different operating conditions.

What is a Performance Curve?

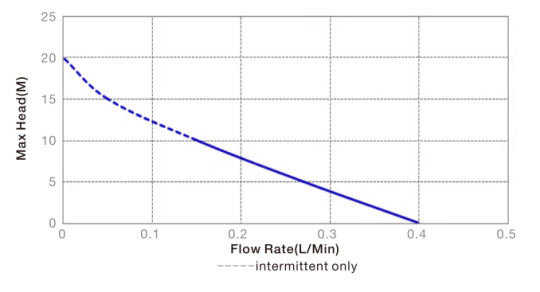

The performance curves graphically demonstrate the performance of miniature diaphragm pumps at different operating points.

The horizontal axis of the curve represents the pressure, which is usually measured in KPa, bar or MPa, while the vertical axis represents the flow rate, which is usually measured in L/min.

Micro Air pumps are divided into pressure pumps and vacuum pumps. Depending on the application, the performance curve may have a vertical split line that separates the curve into pressure applications and vacuum applications.The left side of the vertical line marks the vacuum application, and the pressure values on the horizontal axis represent the vacuum level at the inlet side of the pump in this application scenario, with the outlet pressure of the pump always maintained at a constant level of 1000 mbar (ambient pressure). The right side of the vertical line marks the pressure application, and the values on the horizontal axis represent the pressure at the outlet side of the pump, which indicates the relative pressure with the ambient pressure is maintained at 1000 mbar.

On the horizontal axis, the two furthest data points represent the two extremes that the pump can achieve, i.e. the ultimate vacuum (on the left) and the maximum pressure (on the right). On the vertical axis, the highest data point represents the maximum flow rate that the pump can achieve.

In addition to the flow rates, the performance curve of some models also indicates that it should be avoided to exceed certain pressure ranges during continuous operation. Although from a technical perspective, the TF30-A12-C01-W104 can achieve a head of over 20M, this range is not included in its performance curve because it exceeds its allowable working pressure range. It is allowed to have pressure exceeding the standard for a short period of time to impact the pump, but if it works for a long time beyond the standard pressure range, the service life of the pump will be greatly shortened.

How to Read the Performance Curve of Diaphragm Pumps

To use the pump performance curve:

Firstly, you need to clarify whether your application falls into the vacuum or pressure category, and identify the flow rate that meets the application requirements as well as the pressure differential between the pump inlet and outlet.

Then, find the point on the performance curve that corresponds to these values to ensure that the pump can operate efficiently.

During the pump selection process, you may also need to consider the power consumption of the pump at that point of operation and other factors that depend on the specific application.

Key Points of the Performance Curve

Limit Points: The two furthest points on the performance graph indicate the lowest vacuum (left) and the highest pressure (right) that miniature diaphragm pumps is capable of achieving. These points may not be shown in every graph as they depend on the type of pump and the permissible operating range.

Maximum Points: The highest intersection point of the curve represents the no-load flow rate of the pump, indicating that there is no restriction or pressure difference between the inlet and outlet of miniature diaphragm pumps. This is the maximum flow rate of the pump.

Application Matching: By identifying whether a specific application is vacuum or pressure and finding the point that corresponds to the required flow rate and differential pressure, ensure that the pump can operate effectively at that operating point.

The Importance of Performance Curves

The performance curve is a key tool in the selection and operation of micro diaphragm pumps, helping to optimize the efficiency and performance of the system. Different models of pumps have different performance curves due to their internal operating principles, so a proper understanding of these curves is critical to the effective selection and operation of diaphragm pump. You can avoid overloading or running the pump in inappropriate ranges, extending its life and saving costs.

Interpreting micro diaphragm pump performance curves can be challenging, but is critical to the proper selection and operation of your pump. As experts in diaphragm pumps, we understand the complexities of performance curves and are ready to provide you with professional assistance to ensure that the pump you select best meets your needs.

Whether you are looking for a diaphragm pump for a specific application or would like to gain a deeper understanding of what performance curves mean, we are always ready to provide you with professional advice and support.

TOPSFLO Official Website : www.topsflo.com

Email: [email protected]

Wechat/Whatsapp:+86-19376691419

Mini Vacuum Pumps:

youtube

Micro diaphragm liquid pump:

youtube

Key Words:

Micro diaphragm liquid pump, Micro diaphragm gas pump, dc air pump, 12v air pump, 12v vacuum pump, 12v dc air pump, 12v mini air pump, dc vacuum pump, mini air pump, micro air pump, mini vacuum pump, Micro diaphragm pump, Miniature Diaphragm Pump

#diaphragm pump#diaphragmliquidpump#diaphragm air pump#miniature diaphragm pump#diaphragmairpump#gaspumps#12v air pump#micro air pump#mini air pump#airpumps#mini vacuum pump#Youtube

0 notes

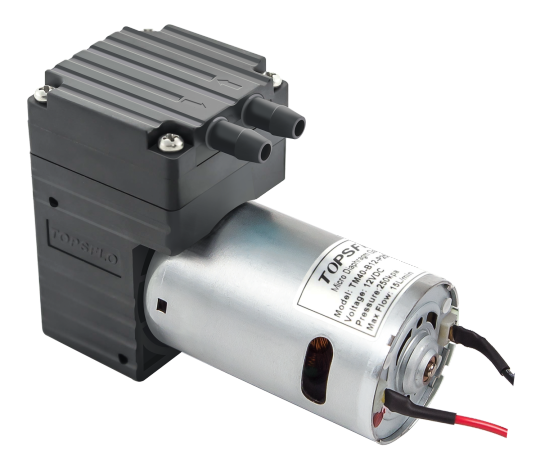

Photo

TOPSFLO continues to diaphragm pumps RD & production,

Self-designed TM40 series diaphragm air pumps ,

Solve real needs for the medical device industry,

Serve global high-end customers with high-quality products.

http://www.topsflo.com/mini-diaphragm-pump/tm40a-b-brush-air-pump.html

0 notes

Photo

What should be paid attention to when selecting miniature diaphragm pump?

1. Flow rate of diaphragm pump

2. Positive and negative pressure of diaphragm pump

3. Working voltage of diaphragm pump

4. Working mode and service life of diaphragm pump

5. Precautions for diaphragm pump use

All products of TOPSFLO are independent research and development design, with more than 20 years of industry experience of the R & D engineer team, has more than 10 years of experience in core customer customization development, can provide efficient professional customized solutions or new design and development solutions for global customers in various industries.

#diaphragmpumps #microairpump #miniairpump #diaphragmairpump

0 notes

Video

TOPSFLO TM40A-B Diaphragm Air Pump

Motor Type:Brush DC motor

Max flow rate:16L/min

Max pressure:280Kpa, Max vacuum: 80Kpa

Voltage:12V

Feature:

--Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM40A Series to push the performance envelope in a lightweight, compact size.

--Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

--Extreme chemical resistance

The use of chemically resistant materials optional such as FFPM, PTFE, FPM or other material combinations for the parts which allows the corrosive gas to be pumped.

More detial ,please contact us:

🔗http://www.topsflo.com/mini-diaphragm-pump/tm40-b-brush-nasal-aspirator-vacuum-pump.html

📞+86-731-82739266

📧[email protected]

0 notes