#centrifugal pumps

Text

The centrifugal pump happens to be one kind of automated system. It is made up of an electrical motor and a pump. The fluid used to be subjected to a centrifugal force. It goes through a fast-rotating impeller on an axis in centrifugal pumps. This force pushes the fluid through the pump’s casing. Impellers are more than any other component. The impeller’s curved vanes and shroud plates are made of cast iron. It has a strong corrosion resistance. Unless the pump system can do it on its own, priming a centrifugal impeller. Doing this while it is opserating usually necessitates immersing the entire apparatus in water.

Operation of a centrifugal pump

Self-priming centrifugal pumps require an additional component. This is not how centrifugal pumps are typically made. The liquid within can enter the pump housing through the impeller’s eye once the pump is started. Centrifugal force produced by the spinning impeller pushes your product into the discharge port and out of the pump. At the impeller’s eye, a low-pressure region is created by the fluid as it moves in the direction of the discharge outlet. In order to maintain the pumping cycle, this area of low pressure creates suction to suck fluid from the inlet port.

Centrifugal pump features

Centrifugal pumps are matchless. There are centrifugal pump solutions for all kinds of pumping applications. The self-priming has an electrical or magnetic drive. It handles sanitary fluids. It is large enough for large-scale industrial applications. They are available in a wide variety of size and shape possibilities. All these allow them to be tailored to suit a wide range of installations and requirements.

Pneumatically powered pumps are less efficient than centrifugal pumps, therefore if you require a pump for a high-flow application, consider the former.

0 notes

Text

Industrial Centrifugal Pumps Supplier & Exporter

MS Radix, a renowned Centrifugal Pump supplier and exporter, offers a comprehensive range of high-performance pumps for diverse industrial and agricultural applications. These versatile pumps utilize centrifugal force to efficiently transfer liquids, making them a popular choice for various fluid handling needs. The straightforward design with rotating impellers ensures smooth operation, efficient flow, and minimal maintenance requirements. These pumps can handle a wide range of liquids, including water, solvents, chemicals, and even oils with varying viscosities. Centrifugal pumps are capable of delivering high flow rates, ideal for applications requiring large volumes of liquid transfer. The efficient design and minimal moving parts contribute to lower operating costs compared to some alternative pump technologies.

For more details clicks here - https://www.msradix.com/centrifugal-pump.html

0 notes

Text

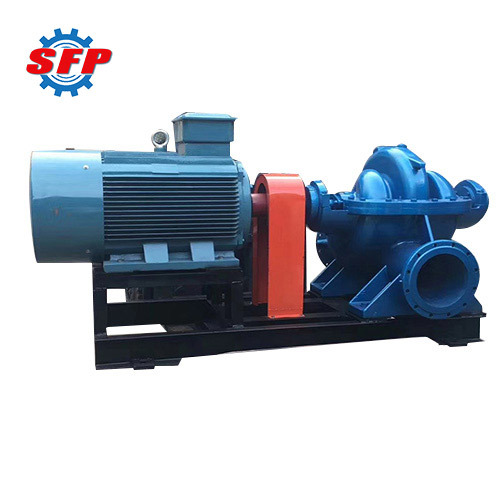

OEM ODM S/SH Single-Stage Double-Suction Centrifugal Pump has the advantages of beautiful appearance, compact structure, stable operation for improving working efficiency in your industry.

0 notes

Text

Are You Looking For Fire Fighting Pumps Manufacturer in India?

If you are Looking for Fire Fighting Pumps for you industries. Creative Engineers are the leading manufacturer from Ahmedabad, India. Our Fire Fighting Pump are available in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, Sri Lanka.

Fire fighting pump are essential equipment designed to combat fires efficiently. Typically powered by electricity, diesel, or gasoline, fire fighting pumps come in various sizes and configurations. A fire pump is a part of a fire sprinkler system’s water supply and can be powered by electricity, diesel or steam. The pump intake is either connected to the public underground water supply piping, or a static water source.

For ore Details

Click here : https://www.sspumpsindia.com

0 notes

Text

VND Plastico Pumps is a renowned manufacturer located in Vadodara, Gujarat. We specialize in producing centrifugal pumps that cater to various industries. Our pumps are designed to transfer water, chemicals, and light fuels with high efficiency and reliability. In addition, we have a wide range of pumps that are specifically designed for different industrial applications. We are committed to providing our customers with durable and high-quality products that meet their specific needs. Visit at https://www.vndplasticopumps.com

#Centrifugal Pumps#centrifugal pump manufacturers#air pump manufacturers#gujarat#Industrial Pumps#Leak-Proof Pumps#Chemical-resistant Pumps#Positive Displacement Pumps#Vacuum Pumps

0 notes

Text

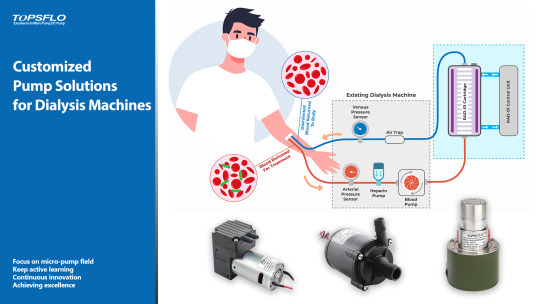

𝗠𝗶𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

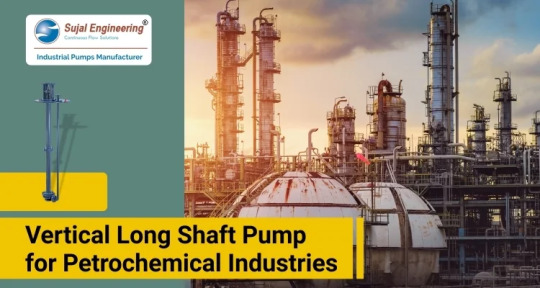

Vertical Long Shaft Pump for Petrochemical Industries

Introduction

Vertical Long Shaft Pump is one of the most popular and frequently used pumps in recent years. Robust design, long life, and high capacity make this pump an excellent choice for numerous industrial applications.

But is it the right choice for the Petrochemical Industry?

The petrochemical industry is one of the evolving industries which produces a remarkable range of valuable products that are important in almost all areas of modern society.

The petrochemical industry includes the transfer process of various abrasive and hazardous chemicals. To help transfer these chemicals from one point to another, a vertical shaft pump is required.

In this blog, we will take a comprehensive look at vertical long-shaft pumps and provide you with all the details you need to make an informed purchase.

Additionally, we will also discuss how vertical shaft pumps are used in petrochemical industries and highlight some of their key features and benefits.

Continue reading to get a clear understanding of vertical pumps and decide if it’s the right choice for you.

What Is A Vertical Long Shaft Pump?

The vertical long shaft sump pump is a single-stage industrial pump used for a diverse range of applications ranging from chemically aggressive fluids to automatic drainage of wastewater.

A vertical sump pump consists of a motor, discharge head, pipe columns, line and pump shaft, radial or channel impellers, and a suction bell.

Sujal Engineering is one of the leading vertical long-shaft pump manufacturers in India. Our vertical pump is designed for various high-pressure and high-head applications where vertical lift is required.

The vertical long-shaft sump pump also covers a wide range of hydraulic conditions to meet every pumping requirement in the industry with optimum efficiency.

To Read Full Blog : Vertical Long Shaft Pump

#centrifugal pumps#industrial pumps#centrifugal pump manufacturers#centrifugal pump manufacturer#centrifugal pump#centrifugalpump#industrial pump manufacturers#pump manufacturer

0 notes

Text

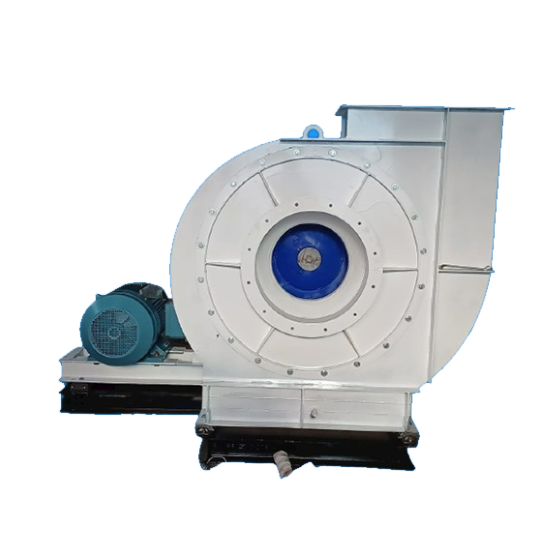

2024 - Top Quality Centrifugal Fans and Blowers Manufacturers in India

Centrifugal Fans and Blowers Manufacturers in India

Teral-Aerotech is a Top Centrifugal Fans and Blowers Manufacturers in India, offering a wide range of high-quality ventilation products. Their centrifugal blowers are engineered for high efficiency and low noise, making them suitable for various industrial and commercial applications. The company prides itself on its mission to develop, manufacture, and market top-notch ventilation products, with a focus on reliability, quality, and customer satisfaction.

Centrifugal Fans and Blowers

Centrifugal Fans and Blowers Manufacturers in India, Teral-Aerotech's centrifugal blower fans are precision designed to deliver efficient air movement and increase air or gas pressure. They offer a variety of fan types, including Double Inlet Double Width (DIDW) and Single Inlet fans, with features such as forward curved or backward curved impellers.

Teral

These fans are suitable for a wide range of applications, including general ventilation, pressurization, and various industrial processes, thanks to their high volume air displacement capabilities. The company's commitment to excellence is evident in its emphasis on trust, customer satisfaction, and continuous product development. They also prioritize timely delivery and aim to be the most reliable company for quality, availability, and delivery reliability.

Centrifugal Fans and Blowers

With a strong focus on customer relationships and community engagement, Teral-Aerotech is dedicated to providing the right products with the right performance characteristics, delivered at the right time. Their wide range of centrifugal blowers and fans, coupled with a commitment to quality and customer satisfaction, positions them as a leading manufacturer in the industry.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.blowers-fans.com/centrifugal-fan-blowers.html

Address : PLOT NO.188-89,ECOTECH EXTENSIONS-1, KASANA GREATER NOIDA-201301,(NEAR ASIAN PAINT) UTTAR PRADESH,INDIA

1 note

·

View note

Text

Centrifugal Pump Manufacturers, Suppliers, Dealers, Exporters in Chakan, Maharashtra

A centrifugal pump is a dynamic mechanical device that transports fluids by converting rotating kinetic energy to hydrodynamic energy. This type of pump is widely utilized in a variety of industries, including water delivery, wastewater treatment, and chemical processing.

To know more - https://www.flowtechpumps.co.in/centrifugal-pump.php

0 notes

Text

Centrifugal pumps are easy to use, long-lasting, and low-maintenance due to their few moving parts. Industrial, commercial, residential, scientific, and municipal operations use them. Centrifugal pumps have many benefits. This article discusses the main advantages of centrifugal pumps over reciprocating pumps. Why choose centrifugal pumps is the discussion of this article.

Resistance to corrosion

Centrifugal pumps are durable. Their ability to withstand high levels of corrosive chemical liquids is the key. Chemical distributors, manufacturers, and those handling highly corrosive fluids can perform many applications without worrying about wear and tear costs. Due to centrifugal pump’s reliability and extended service life, you can increase your ROI.

The Energy Efficiency

Energy costs are a major factor in any industrial pump system. Centrifugal pumps save energy better than other pump systems, according to industry trends. If the application involves multiple centrifugal pumps, energy efficiency would benefit the industry.

Smooth Flow

Flow is another Centrifugal Pump benefit. Pump impellers rotate smoothly to evenly distribute fluid pressure. The fluid discharge is more uniform than with a positive displacement pump’s pulsating and erratic motion. Uneven and pulsating fluid motion forces engineers to design pipes with special considerations to prevent cracks and other weaknesses. This may raise design, installation, and operational costs.

#centrifugal pump manufacturer#centrifugal pump manufacturer in india#Centrifugal Pump#centrifugal pumps

0 notes

Text

#shakti pump#Submersible Pumps#Vertical Multistage#Centrifugal Pumps#Monoblock End Suction Pumps#Solar Pumps

0 notes

Text

youtube

🚀 Immerse yourself in the world of engineering like never before with our groundbreaking VR experience! 🌐 Join us on a captivating journey inside the heart of Centrifugal Pumps, where theory comes to life and learning becomes an adventure.

🔍 Unlock the secrets of fluid dynamics and pump performance in stunning virtual reality. Our interactive VR module takes you deep into the intricate details of Centrifugal Pumps, offering a hands-on, 360-degree exploration that transcends traditional education methods.

0 notes

Text

Where is Centrifugal Generally Used?

Centrifugal pumps and displacement pumps are the two primary types of pumps. Centrifugal pumps are designed for transferring and pumping low viscosity liquids down and are typically specified for higher flow rates than reciprocating pumps.

Centrifugal Pumps are used for low pressure, high capacity pumping applications involving low viscosity fluids like water, solvents, chemicals, and light oils.

Centrifugal pump designed to provide straightforward, reasonably priced solutions.

Common uses in irrigation, petrochemical plant chemical transfer, and water supply and circulation. Applications requiring precise dosing, complicated feeds like emulsions, edibles, or biological fluids, and extremely viscous fluids like thick oils and slurries.

Creative Engineers are Manufacturer of Centrifugal Pump, S S Centrifugal Pump, Stainless Steel Centrifugal Pump, Stainless Steel Pump from Ahmedabad.

SS Centrifugal Pump

CF Series Stainless Steel Centrifugal Pump

CFS Series Stainless Steel Centrifugal Pumps

SS Self Priming Pump

Self Priming Centrifugal Pumps & Self Priming Cum Centrifugal Type Mud Pump

Special Products Stainless Steel Centrifugal Casting Pump

Vertical Inline Centrifugal Pumps (Multistage Pump)

Buy Best Centrifugal pumps for more details

Click here:- https://www.sspumpsindia.com

0 notes

Text

1 note

·

View note

Text

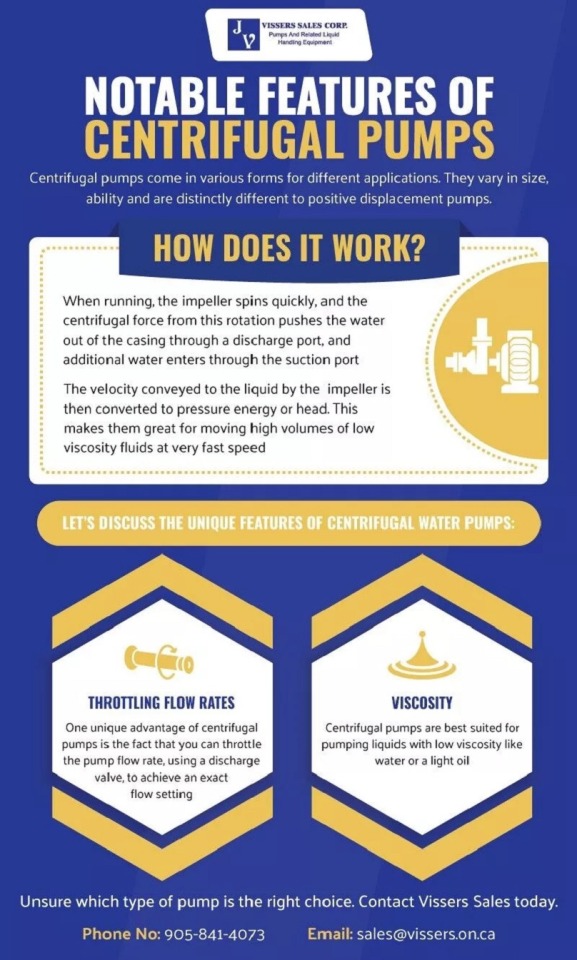

Centrifugal pumps are best suited for pumping liquids with low viscosity like water or a light oil Unsure which type of pump is the right choice. Contact Vissers Sales today.

0 notes