#black masterbatch

Text

Anti-static agent for plastics

Anti-static agent for plastics are used to reduce the static charge present in plastics.The accumulation of static charge can cause combustion and explosions as well as have an impact on how efficiently dust and electrostatic adsorption work . Therefore, it's important to get rid of static electricity buildup. Utilizing an antistatic agent can make a material's surface more resistive and decrease static electricity buildup.

Ammonium and phosphorus salts are the most common antistatic agents. Plastics frequently utilize this kind of antistatic substance. It performs well against static and has a strong affinity towards polar polymers. By reducing the material's resistance, anti-static chemicals are integrated into polymers to give static protection. Anti-static compounds are included into polymers to provide static protection by lowering the material's resistance. The majority of plastic materials are electrical insulators and can withstand significant static buildup.

Anti-static compounds help plastic surfaces resist the development of electrostatic charges. During the compounding phase of the manufacturing process, they are either applied directly to the surface or combined with additional materials. Leading supplier of anti-static materials for plastics is BS Masterbatches. Depending on your requirements, one can obtain a full list of additives that can be used on your product. To guarantee that the ideal solution is consistently supplied on time they have a R&D team that collaborates closely with clients. They are FDA-approved and their products adhere to a number of international standards for food contact and packaging.

For their clients, they are master producers of plastic masterbatches and experts in providing unique color matching solutions. They have a complete R&D department, allowing them to match every color masterbatch to the specifications of the client.

2 notes

·

View notes

Photo

we are going to highlight about an important subject for plastic-based industries, the masterbatch. Many relevant subjects will be covered throughout the blog

9 notes

·

View notes

Text

The Perfect Balance: Optimizing Friction with Targeted Slip Masterbatch Solutions

In the intricate world of manufacturing, achieving the perfect balance between functionality and performance is an ongoing pursuit. This is especially true when it comes to plastics, where friction plays a crucial role in various applications. Excessive friction can lead to inefficiencies, wear and tear, and even product failure, while insufficient friction can compromise grip and stability. This is where slip masterbatches emerge as a game-changer, offering a targeted solution to optimize friction and unlock the full potential of plastic products.

Delving Deeper into the Science of Friction:

Friction is not simply a force resisting movement; it's a complex phenomenon arising from the interaction of microscopic asperities on two contacting surfaces. These asperities interlock and resist relative motion, generating friction force. In the context of plastics, various factors influence the degree of friction:

Surface roughness: Smoother surfaces generally exhibit lower friction compared to rougher ones due to fewer interlocking asperities.

Material properties: The inherent properties of the plastic material, such as its stiffness and elasticity, can also influence friction behavior.

Normal force: The force pressing the two surfaces together directly affects the friction force. A higher normal force leads to greater friction.

Environmental factors: Temperature, humidity, and the presence of lubricants can all impact the coefficient of friction (COF) between plastic surfaces.

Understanding the Challenges of Uncontrolled Friction in Plastics:

Uncontrolled friction in plastics can pose several challenges throughout the product lifecycle:

Manufacturing inefficiencies: High friction during processing can lead to increased energy consumption, slower processing speeds, and potential machine wear. This can translate to higher production costs and reduced efficiency.

Premature wear and tear: Excessive friction between moving parts within a plastic assembly can accelerate wear, leading to shortened product lifespan and potential product failures. This necessitates earlier replacements and increased maintenance costs.

Compromised performance: In applications like packaging films or conveyor belts, excessive friction can hinder smooth operation and functionality. For instance, high friction in packaging films can make them difficult to handle and dispense, while in conveyor belts, it can impede smooth product flow and increase energy consumption.

Introducing Slip Masterbatches: A Tailored Approach to Friction Management:

Slip masterbatches are precisely formulated concentrates containing lubricating additives dispersed within a carrier resin. These pre-measured and meticulously engineered compounds are seamlessly integrated into the plastic manufacturing, offering a controlled and targeted approach to reduce friction on plastic surfaces.

How Slip Masterbatches Work: The Magic Behind the Reduction:

The lubricating agents present in slip masterbatches migrate to the surface of the plastic during processing. These agents form a thin, lubricating layer that reduces the interaction between asperities on contacting surfaces. This, in turn, lowers the COF and achieves the desired level of friction for the specific application.

Unlocking the Potential of Slip Masterbatches: A Multifaceted Approach to Benefits:

Incorporating slip masterbatches into your plastic manufacturing process can yield a multitude of benefits:

Enhanced processing efficiency: Reduced friction translates to lower energy consumption during extrusion, injection molding, or other processing methods. This can lead to faster processing speeds, improved production output, and potential cost savings.

Improved product performance: By optimizing friction, slip masterbatches can significantly enhance the functionality of plastic components in various applications. For instance, they can:

Improve the slideability of packaging films, facilitating easier handling and dispensing.

Reduce wear and tear in moving parts within plastic assemblies, extending product lifespan and reducing maintenance costs.

Enhance the grip of medical devices, ensuring secure handling and optimal functionality.

Extended product lifespan: Reduced friction minimizes wear and tear on plastic components, leading to longer-lasting products and potentially lower replacement costs. This translates to environmental benefits by reducing plastic waste generation.

Versatility: Slip masterbatches are available in a diverse range of formulations, catering to various plastic types and specific friction reduction requirements. This allows for tailored solutions to address the unique needs of different applications.

Choosing the Right Slip Masterbatch: A Matter of Compatibility and Performance:

Selecting the right slip masterbatch for your specific needs requires careful consideration of several factors:

Polymer compatibility: Ensure the chosen slip masterbatch is compatible with the specific type of plastic you are using. Different plastics exhibit varying degrees of compatibility with different lubricating agents.

Desired level of friction reduction: The optimal level of friction reduction varies depending on the application. Consider factors like the required level of grip, smoothness, and wear resistance to choose a masterbatch that delivers the appropriate friction reduction.

Processing conditions: Different processing methods (e.g., extrusion, and injection molding) have varying temperature and shear stress profiles. Choose a masterbatch formulated to withstand specific processing conditions without compromising its effectiveness or degrading the plastic material.

Regulatory compliance: If your products are subject to specific regulations (e.g., food contact applications, medical device requirements), choose a slip masterbatch that complies with relevant standards and certifications.

Beyond the Basics: Exploring Advanced Applications of Slip Masterbatches:

While reducing friction remains a core function, slip masterbatches offer additional functionalities that can further enhance the performance of plastic products:

Anti-blocking: Certain slip masterbatches incorporate additives that prevent plastic films from sticking together during storage or transportation. This is crucial for applications like packaging films and food wrappers, ensuring product integrity and maintaining visual appeal.

Improved aesthetics: By creating a smoother surface finish, slip masterbatches can enhance the visual appeal of plastic products, contributing to a more premium look and feel. This can be particularly beneficial for consumer goods and packaging applications.

UV protection: Some slip masterbatches can be formulated with UV stabilizers, offering additional protection against sun damage and degradation. This is especially valuable for outdoor applications where plastic products are exposed to prolonged sunlight.

Sustainability Considerations: A Responsible Approach to Manufacturing:

As environmental consciousness grows, manufacturers are increasingly seeking sustainable solutions. The good news is that slip masterbatches can contribute to sustainability efforts in several ways:

Reduced energy consumption: By enabling smoother processing and lowering friction, slip masterbatches can help reduce energy consumption during manufacturing, contributing to a smaller environmental footprint.

Extended product lifespan: By minimizing wear and tear, slip masterbatches can help extend the lifespan of plastic products, reducing waste generation and the need for frequent replacements. This translates to a lower environmental impact.

Bio-based alternatives: The development of slip masterbatches formulated with bio-based ingredients is an ongoing pursuit, offering a more sustainable alternative to traditional options. This aligns with the growing demand for eco-friendly solutions in the manufacturing industry.

Conclusion:

Slip masterbatches are not simply friction reducers; they are powerful tools for optimizing performance, enhancing functionality, and unlocking the full potential of plastic products. By carefully considering your specific needs and choosing the right slip masterbatch, you can achieve the perfect balance between friction and performance, paving the way for innovative and successful plastic solutions that are both functional and sustainable.

Ready to take your plastic products to the next level? Contact us today to discuss your specific requirements and explore the diverse range of slip masterbatches available. Our team of experts can help you select the perfect solution to optimize friction, enhance performance, and unlock the full potential of your plastic products.

Together, let's create a future where plastics are not only functional but also sustainable and contribute to a more responsible manufacturing landscape.

#anti block masterbatches#color masterbatches#additive masterbatches#black masterbatch#black masterbatches#polyester masterbatch#color masterbatch#additive masterbatch#kolokan masterbatch#calcium filler masterbatches

0 notes

Text

Types of Plastic and their Recyclability:

Understanding the different types of plastic and their recycling potential is crucial for making informed choices and reducing plastic waste. Here's a breakdown of some common plastics and their recyclability:

Highly Recyclable:

PET (Polyethylene Terephthalate): Often used in clear beverage bottles, food containers, and textiles. Widely recycled and readily accepted in most programs.

HDPE (High-Density Polyethylene): Found in milk jugs, detergent bottles, and some rigid containers. Highly recyclable and widely accepted.

PP (Polypropylene): Used in yogurt tubs, straws, bottle caps, and medical packaging. Increasingly recyclable, but check local programs for acceptance.

Moderately Recyclable:

LDPE (Low-Density Polyethylene): Present in grocery bags, bread bags, and shrink wrap. Sometimes recyclable, but check local programs and ensure clean, dry condition.

PVC (Polyvinyl Chloride): Used in pipes, flooring, and some food packaging. Limited recycling options due to contamination concerns.

PS (Polystyrene): Commonly known as Styrofoam, used in disposable cups and take-out containers. Rarely accepted in curb side recycling due to low density and difficulty processing.

Other Plastics:

Bioplastics: Made from renewable resources like corn starch, some are compostable but not necessarily recyclable. Check specific product labelling.

Mixed Plastics: Often used in composite materials and single-use items. Usually not recyclable due to difficulty separating components.

Remember: Even accepted plastics may have specific requirements for cleanliness, preparation, and local program limitations. Always check local guidelines before recycling.

2. Plastic Products: Examining the Impact

Plastic products permeate nearly every aspect of our lives, offering diverse applications from food packaging to medical devices. However, their extensive use raises concerns about environmental impact, resource depletion, and potential health risks. To comprehensively explore plastic products,

Benefits:

Durability and Versatility: Plastics offer superior strength, lightweight properties, and resistance to corrosion, making them ideal for numerous applications.

Hygiene and Food Safety: Plastic packaging helps preserve food, prevent contamination, and extend shelf life, reducing food waste.

Medical Applications: Sterile, single-use plastic tools and devices play a crucial role in maintaining hygiene and reducing infection risks in healthcare settings.

Affordability and Accessibility: The low cost of production and processing makes plastic products affordable for a wider range of consumers.

Drawbacks:

Environmental Impact: Plastic production relies on fossil fuels, contributing to greenhouse gas emissions and environmental pollution. Plastic waste, particularly single-use items, ends up in landfills, oceans, and natural environments, harming wildlife and ecosystems.

Micro plastics and Health Concerns: Plastic degradation leads to micro plastics, tiny fragments entering the food chain and potentially posing health risks, though research is ongoing.

Resource Depletion: Traditional plastic production relies on non-renewable resources like oil and gas, raising concerns about long-term sustainability.

Moving Forward:

Addressing the challenges of plastic products requires a multifaceted approach:

Reduce and Reuse: Minimize single-use plastics and choose reusable alternatives whenever possible.

Recycle Responsibly: Understand local recycling guidelines and actively participate in responsible waste management.

Support Sustainable Innovations: Advocate for and invest in bioplastics, biodegradable options, and closed-loop recycling systems.

Policy and Regulation: Implement policies that promote responsible plastic production, consumption, and waste management.

Conclusion:

The impact of plastic products goes beyond a simple word count. By acknowledging both their benefits and drawbacks, we can encourage responsible use, support sustainable innovations, and work towards a future where plastics contribute positively to society without compromising environmental well-being and human health. Remember, individual choices and collective action can make a significant difference.

This exploration merely scratches the surface of the complex issue of plastic products. Further research, individual responsibility, and collective action are crucial to navigating this challenge and shaping a more sustainable future.

#plastic exhibition#international plastic exhibition#bioplastic exhibition#plastic trade fair#plastic fair#black masterbatch#injection molding#pvc pipe price

0 notes

Text

Black masterbatches are essential components in the plastics industry, imparting a deep black color to various plastic products. Comprising high concentrations of carbon black, these masterbatches enhance UV resistance and provide superior opacity. Industries such as packaging, automotive, and construction benefit from their versatility. Black masterbatches not only deliver aesthetic appeal but also contribute to product longevity by shielding against harmful UV rays. With precise formulations, they offer consistent color dispersion, ensuring uniformity in the end product. Manufacturers appreciate their compatibility with different polymer resins, enabling seamless integration into diverse production processes. From agricultural films to consumer goods, black masterbatches play a pivotal role in achieving desired product aesthetics and performance. Their ability to improve processing characteristics, such as melt flow and dispersion, makes them a preferred choice in injection molding, extrusion, and blow molding applications. As sustainability gains prominence, the development of eco-friendly black masterbatches with recycled content further aligns with industry trends. The evolving landscape of polymer technology continues to witness innovations in black masterbatches, catering to the evolving demands of modern manufacturing.

Contact Us:-

C-65/1, Okhla Industrial Area, Phase-2, New Delhi - 110020. India

Phone no: +91-11-41612244/ 47, +91-11-41610333/ 34

Email: [email protected]

0 notes

Text

Leading Black Masterbatch Manufacturer in India - Explore our versatile solutions, applications, and advantages. Elevate your products with our high-quality black masterbatch formulations.

0 notes

Text

Colour Masterbatches

With a range of more than 25000 colors in our databank we're almost sure we have a match for the color you are looking for - not only for commodity polymers but for engineering plastics as well.

Besides our databank and standard colors, we can match a color according to your physical sample, LAB values or even a Pantone or RAL shade card number. Our team of color technicians can practically match any color that you can dream of.

#Colour masterbatch#Masterbatch#Plastic Products#White Masterbatch#Black Masterbatch#Additive Masterbatch

0 notes

Text

Black Masterbatch - Overview,advantage and uses :

Black masterbatch is a concentrate of pigments and additives that are used to color plastic materials. It is added in small amounts to polymers during the manufacturing process to achieve a uniform and consistent color. The advantage of using masterbatch is that it saves time, reduces cost and eliminates color variations compared to coloring the polymer directly. The black color is commonly used in products such as packaging, consumer goods, and automotive parts.

Black masterbatch is commonly used in the following industries and applications

Packaging: For making bags, films, containers, and other packaging materials.

Consumer goods: For producing black color in products such as toys, electronics, and appliances.

Automotive parts: For coloring parts such as bumpers, grilles, and interior trim.

Building and construction: For making pipes, window frames, and roofing materials.

Agricultural: For producing black mulch films and other agricultural products.

Textile: For coloring synthetic fibers, carpets, and other textiles.

Medical devices: For coloring medical equipment, implants, and disposables.

These are some of the most common applications, but black masterbatch can also be used in other industries where a uniform black color is desired.

Advantages of using black masterbatch in plastic processing

Cost savings: By using a small amount of masterbatch, it's more cost-effective compared to coloring the entire polymer directly.

Consistent color: Masterbatch ensures consistent coloring throughout the entire production process, resulting in uniform color in the final product.

Improved efficiency: By using masterbatch, the time required for coloring is reduced, leading to increased production efficiency.

Improved quality: Using masterbatch leads to improved color dispersion and improved overall product quality.

Easy to handle: Masterbatch is easy to handle and store, reducing the risk of contamination or color variation.

Wide availability: Black masterbatch is widely available and can be easily sourced from suppliers.

Environment-friendly: Masterbatch does not emit any harmful substances, making it an environmentally friendly option for coloring plastic materials.

Regenerate response

Visit : One of the leading Black masterbatch manufacturers and exporters in india now to knowmore !

0 notes

Text

Leading High-quality Black Masterbatch Manufacturer | SAMHWA CORPORATION

SAMHWA CORPORATION is the leading masterbatch supplier and exporter in Korea.

Over the past 36 years, Samhwa Corporation has been consistently supplying high-quality black and white masterbatch, color masterbatch, and functional masterbatch products not only to its Korean customers but also customers around the world with the brand name SAMTECH.

Samhwa Corporation Masterbatch products are widely used in the world by many plastic film injection and extrusion producers in many countries such as Korea, Japan, Kenya, China, Vietnam, Botswana, Congo, Peru, Bolivia, Colombia, Lebanon, Zimbabwe, Ghana, Uzbekistan, Tanzania, Ecuador, Russia, and other countries.

The most important feature of Samhwa Corporation masterbatch products is the quality and is assured through constant quality checks in all processes of production. Strict quality specifications are set and production samples are tested accordingly up to the requirements of ISO 9001 and ISO 14001.

Samhwa Corporation Black Masterbatch

Ø Black Masterbatch is one of the most widely used colorants in the plastics processing industry fit for the automotive, pipe, and agriculture area.

Ø Samhwa Corporation Black Masterbatch boasts its high quality with the characteristics of black carbon and the way it is produced.

Ø The Black Masterbatch is made from carbon black, and the grade is determined based on the requirements of a customer’s needs.

Ø Black Masterbatch has a homogeneous dispersion and concentration level, which determines the intensity of the blackness, the brightness, and other requirements.

Benefits of Samhwa Corporation Black Masterbatches:

Ø Acceptable for food contact

Ø High-performing, durable to even withstand extreme temperatures or weather conditions.

Ø They have better dispersion than the others.

Ø Electrostatic conductivity grades

If you are looking for a high-quality black masterbatch, you can find it at Samhwa Corporation.

Click here to contact SAMHWA CORPORATION.

View more:

Samhwa Corporation Leading High-quality Black Masterbatch Manufacturer

0 notes

Text

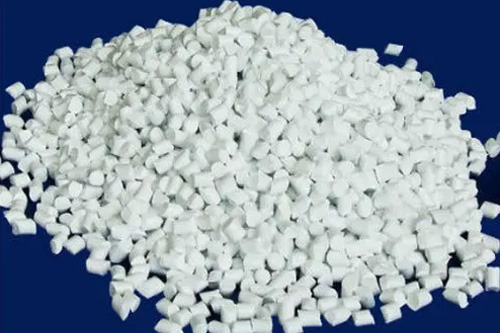

White Masterbatches - MG Polyblends

Our White Masterbatches are made with highest quality of Rutile Titanium Dioxide with Whiteness more than 97% which is sourced from global suppliers from Europe and United States. For More Infoemation:- https://www.mg-polyblends.com/

#White Masterbatch#Black Masterbatch#Polymer Masterbatch#Masterbatch#Oxy Bio Degradable Masterbatch#Additive Masterbatch

1 note

·

View note

Text

FC PLASTICS Masterbatches have continuous focus on delivering high efficiency products and services with advanced effect techniques at affordable prices in Delhi, India. Our innovative products play a key role in our customers’ manufacturing and treatment processes and add value to their end all type products

1 note

·

View note

Text

MASTERBATCHES

Masterbatches are the best in modern manufacturing, infusing life and color into various materials. BSmasterbatch, a pioneering force in this field, redefines the art of coloring materials by seamlessly integrating vibrant shades into plastics, fibers, and foams. Their mastery in crafting colors with precision, seamless integration for enhanced efficiency, and a colorful spectrum of offerings showcases their experience and expertise.

Additive masterbatches, a cornerstone of their offerings, enhance materials with properties like UV stability, anti-oxidation, flame resistance, and more. White masterbatches exude consistency and cleanliness, while black masterbatches create deep, uniformly black, gracing pipes, films, automotive parts, and electronics. Empowering performance is another critical aspect of BSmasterbatch's offerings. Filler masterbatches, enriched with mineral fillers, bolster mechanical properties, cut costs, and streamline processing. Their multi-layer packaging protects food freshness, while mono-layer films embrace lightweight packaging solutions.

BSmasterbatch's journey is driven by innovation and sustainability, combining quality with an eco-conscious approach, paving the way toward a future where color and creativity harmonize with responsible manufacturing practices. As we venture into a world where colors intertwine with sustainability, BSmasterbatch stands as a beacon, leading the way toward a more vibrant, efficient, and responsible future through its variety of masterbatches.

0 notes

Link

we are going to highlight about an important subject for plastic-based industries, the masterbatch. Many relevant subjects will be covered throughout the blog

9 notes

·

View notes

Text

Black Masterbatch: The Unsung Hero of Colored Plastics

The world of colorful plastics depends heavily on black masterbatch, which is frequently disregarded. It is a necessary component of many everyday items because of its capacity to facilitate production, enhance functioning, and deliver uniform color. Future research on eco-friendly substitutes for black masterbatch that preserve its essential qualities is necessary as worries about sustainability grow.

Black Masterbatch may be hidden, but its impact is undeniable. Let's appreciate its role and work towards a future where vibrant colors and sustainability go hand in hand.

0 notes

Text

Plastic Fantastic? Navigating the World of Trade Fairs in 2024

The world of plastics, once hailed as a revolutionary material, now finds itself at a crossroads. Sustainability concerns and environmental anxieties have cast a shadow on this ubiquitous material, prompting the industry to innovate and adapt. Amidst this transformation, plastic trade fairs remain crucial platforms for showcasing advancements, fostering collaboration, and navigating the future of this versatile material. In 2024, three key events stand out - Chinaplas, Plastprintpack Nigeria, and a generic bioplastic exhibition. Let's delve into each, exploring their significance and what they offer to the global plastics landscape.

1. Chinaplas 2024: The Titan of Trade Fairs

Hailed as the world's leading plastics and rubber exhibition, Chinaplas is a behemoth in the trade fair arena. Scheduled for April 23-26 in Shanghai, it promises a colossal gathering of over 4,000 exhibitors from 40 countries. With over 380,000 sqm of exhibition space, expect to be overwhelmed by the sheer diversity of machinery, chemicals, and technologies on display. From injection molding machines to bioplastics, Chinaplas 2024 offers a comprehensive snapshot of the industry's cutting edge.

But Chinaplas is more than just a showcase. It's a melting pot of ideas, innovations, and collaborations. Expect insightful conferences, technical seminars, and networking opportunities galore. For any player in the global plastics game, Chinaplas is an unmissable event to connect, learn, and stay ahead of the curve.

2. Plastprintpack Nigeria 2024: Africa's Rising Star

While Chinaplas dominates the global stage, Plastprintpack Nigeria 2024 brings focus to a rapidly growing market - Africa. Scheduled for June 11-13 in Lagos, this trade fair caters to the specific needs and challenges of the Nigerian and West African plastics and printing industries.

With a burgeoning population and increasing disposable income, Africa presents a fertile ground for plastic products. However, the continent also faces unique challenges – fragmented infrastructure, limited recycling facilities, and concerns about plastic pollution. Plastprintpack Nigeria 2024 aims to address these issues head-on, showcasing sustainable solutions and technologies tailored to the African market.

This trade fair offers a unique opportunity for businesses to tap into Africa's vast potential, while simultaneously contributing to responsible and sustainable growth.

3. Bioplastics Exhibition: A Glimpse into the Future

The third key event is, well, simply a "bioplastics exhibition." Bioplastics, derived from renewable resources like corn starch or cellulose, present a promising alternative to traditional plastics. Their biodegradability and lower carbon footprint make them a crucial piece of the puzzle in the quest for a more sustainable plastics industry.

While specific dates and locations for a dedicated bioplastics exhibition are still to be announced, expect dedicated sections within broader trade fairs like Chinaplas to focus on this burgeoning sector. Bioplastics exhibitions offer a platform for innovators, manufacturers, and end users to come together, explore the latest advancements, and pave the way for a greener future.

Connecting the Dots: Navigating the Future of Plastics

These three trade fairs, each unique in its scale, focus, and region, offer valuable insights into the evolving world of plastics. As environmental concerns mount, the industry is undergoing a seismic shift, with innovation and sustainability taking center stage. These trade fairs serve as vital conduits for knowledge sharing, fostering collaboration between diverse players, and shaping the future of this ubiquitous material.

Whether you're a seasoned industry veteran or a curious newcomer, attending a plastics trade fair in 2024 promises to be an enriching experience. From witnessing cutting-edge machinery to exploring sustainable solutions, you'll leave with a deeper understanding of the challenges and opportunities that lie ahead for the world of plastics. So, mark your calendars, choose your trade fair, and get ready to navigate the future of plastic – a future that, hopefully, will be both innovative and sustainable.

#Plastic exhibition#plastics industry#plastic fair#bioplastic exhibition#plastic trade fair#international plastic exhibition#black masterbatch

0 notes

Text

0 notes