#additive masterbatch

Text

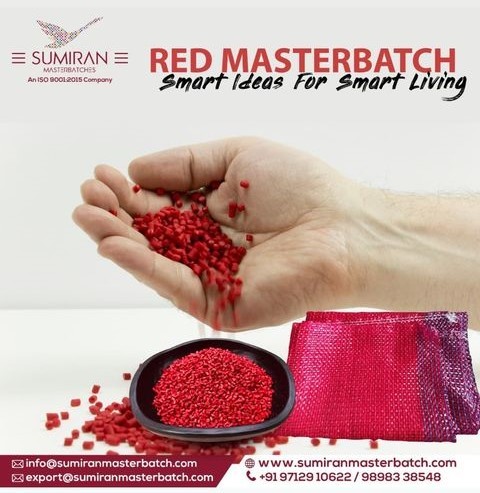

Sumiran Masterbatch: Innovating Colors, Transforming Industries

#masterbatch manufacturer#additive masterbatch#masterbatch manufacturer in ahmedabad#white masterbatch#black masterbatches manufacturer

0 notes

Text

The Perfect Balance: Optimizing Friction with Targeted Slip Masterbatch Solutions

In the intricate world of manufacturing, achieving the perfect balance between functionality and performance is an ongoing pursuit. This is especially true when it comes to plastics, where friction plays a crucial role in various applications. Excessive friction can lead to inefficiencies, wear and tear, and even product failure, while insufficient friction can compromise grip and stability. This is where slip masterbatches emerge as a game-changer, offering a targeted solution to optimize friction and unlock the full potential of plastic products.

Delving Deeper into the Science of Friction:

Friction is not simply a force resisting movement; it's a complex phenomenon arising from the interaction of microscopic asperities on two contacting surfaces. These asperities interlock and resist relative motion, generating friction force. In the context of plastics, various factors influence the degree of friction:

Surface roughness: Smoother surfaces generally exhibit lower friction compared to rougher ones due to fewer interlocking asperities.

Material properties: The inherent properties of the plastic material, such as its stiffness and elasticity, can also influence friction behavior.

Normal force: The force pressing the two surfaces together directly affects the friction force. A higher normal force leads to greater friction.

Environmental factors: Temperature, humidity, and the presence of lubricants can all impact the coefficient of friction (COF) between plastic surfaces.

Understanding the Challenges of Uncontrolled Friction in Plastics:

Uncontrolled friction in plastics can pose several challenges throughout the product lifecycle:

Manufacturing inefficiencies: High friction during processing can lead to increased energy consumption, slower processing speeds, and potential machine wear. This can translate to higher production costs and reduced efficiency.

Premature wear and tear: Excessive friction between moving parts within a plastic assembly can accelerate wear, leading to shortened product lifespan and potential product failures. This necessitates earlier replacements and increased maintenance costs.

Compromised performance: In applications like packaging films or conveyor belts, excessive friction can hinder smooth operation and functionality. For instance, high friction in packaging films can make them difficult to handle and dispense, while in conveyor belts, it can impede smooth product flow and increase energy consumption.

Introducing Slip Masterbatches: A Tailored Approach to Friction Management:

Slip masterbatches are precisely formulated concentrates containing lubricating additives dispersed within a carrier resin. These pre-measured and meticulously engineered compounds are seamlessly integrated into the plastic manufacturing, offering a controlled and targeted approach to reduce friction on plastic surfaces.

How Slip Masterbatches Work: The Magic Behind the Reduction:

The lubricating agents present in slip masterbatches migrate to the surface of the plastic during processing. These agents form a thin, lubricating layer that reduces the interaction between asperities on contacting surfaces. This, in turn, lowers the COF and achieves the desired level of friction for the specific application.

Unlocking the Potential of Slip Masterbatches: A Multifaceted Approach to Benefits:

Incorporating slip masterbatches into your plastic manufacturing process can yield a multitude of benefits:

Enhanced processing efficiency: Reduced friction translates to lower energy consumption during extrusion, injection molding, or other processing methods. This can lead to faster processing speeds, improved production output, and potential cost savings.

Improved product performance: By optimizing friction, slip masterbatches can significantly enhance the functionality of plastic components in various applications. For instance, they can:

Improve the slideability of packaging films, facilitating easier handling and dispensing.

Reduce wear and tear in moving parts within plastic assemblies, extending product lifespan and reducing maintenance costs.

Enhance the grip of medical devices, ensuring secure handling and optimal functionality.

Extended product lifespan: Reduced friction minimizes wear and tear on plastic components, leading to longer-lasting products and potentially lower replacement costs. This translates to environmental benefits by reducing plastic waste generation.

Versatility: Slip masterbatches are available in a diverse range of formulations, catering to various plastic types and specific friction reduction requirements. This allows for tailored solutions to address the unique needs of different applications.

Choosing the Right Slip Masterbatch: A Matter of Compatibility and Performance:

Selecting the right slip masterbatch for your specific needs requires careful consideration of several factors:

Polymer compatibility: Ensure the chosen slip masterbatch is compatible with the specific type of plastic you are using. Different plastics exhibit varying degrees of compatibility with different lubricating agents.

Desired level of friction reduction: The optimal level of friction reduction varies depending on the application. Consider factors like the required level of grip, smoothness, and wear resistance to choose a masterbatch that delivers the appropriate friction reduction.

Processing conditions: Different processing methods (e.g., extrusion, and injection molding) have varying temperature and shear stress profiles. Choose a masterbatch formulated to withstand specific processing conditions without compromising its effectiveness or degrading the plastic material.

Regulatory compliance: If your products are subject to specific regulations (e.g., food contact applications, medical device requirements), choose a slip masterbatch that complies with relevant standards and certifications.

Beyond the Basics: Exploring Advanced Applications of Slip Masterbatches:

While reducing friction remains a core function, slip masterbatches offer additional functionalities that can further enhance the performance of plastic products:

Anti-blocking: Certain slip masterbatches incorporate additives that prevent plastic films from sticking together during storage or transportation. This is crucial for applications like packaging films and food wrappers, ensuring product integrity and maintaining visual appeal.

Improved aesthetics: By creating a smoother surface finish, slip masterbatches can enhance the visual appeal of plastic products, contributing to a more premium look and feel. This can be particularly beneficial for consumer goods and packaging applications.

UV protection: Some slip masterbatches can be formulated with UV stabilizers, offering additional protection against sun damage and degradation. This is especially valuable for outdoor applications where plastic products are exposed to prolonged sunlight.

Sustainability Considerations: A Responsible Approach to Manufacturing:

As environmental consciousness grows, manufacturers are increasingly seeking sustainable solutions. The good news is that slip masterbatches can contribute to sustainability efforts in several ways:

Reduced energy consumption: By enabling smoother processing and lowering friction, slip masterbatches can help reduce energy consumption during manufacturing, contributing to a smaller environmental footprint.

Extended product lifespan: By minimizing wear and tear, slip masterbatches can help extend the lifespan of plastic products, reducing waste generation and the need for frequent replacements. This translates to a lower environmental impact.

Bio-based alternatives: The development of slip masterbatches formulated with bio-based ingredients is an ongoing pursuit, offering a more sustainable alternative to traditional options. This aligns with the growing demand for eco-friendly solutions in the manufacturing industry.

Conclusion:

Slip masterbatches are not simply friction reducers; they are powerful tools for optimizing performance, enhancing functionality, and unlocking the full potential of plastic products. By carefully considering your specific needs and choosing the right slip masterbatch, you can achieve the perfect balance between friction and performance, paving the way for innovative and successful plastic solutions that are both functional and sustainable.

Ready to take your plastic products to the next level? Contact us today to discuss your specific requirements and explore the diverse range of slip masterbatches available. Our team of experts can help you select the perfect solution to optimize friction, enhance performance, and unlock the full potential of your plastic products.

Together, let's create a future where plastics are not only functional but also sustainable and contribute to a more responsible manufacturing landscape.

#anti block masterbatches#color masterbatches#additive masterbatches#black masterbatch#black masterbatches#polyester masterbatch#color masterbatch#additive masterbatch#kolokan masterbatch#calcium filler masterbatches

0 notes

Text

Lifeline Technologies is the market-leading Anti Microbial Additive Masterbatch manufacturer offering high-quality Anti Fungal Additive Masterbatch. Visit our website where you will find full information about the company and our products.

"anti fungal additive"

"anti microbial additive"

"anti bacterial additive"

"anti bacterial masterbatch"

0 notes

Text

1 note

·

View note

Text

With a range of more than 25000 colors in our databank we're almost sure we have a match for the color you are looking for - not only for commodity polymers but for engineering plastics as well.

Besides our databank and standard colors, we can match a color according to your physical sample, LAB values or even a Pantone or RAL shade card number. Our team of color technicians can practically match any color that you can dream of.

0 notes

Text

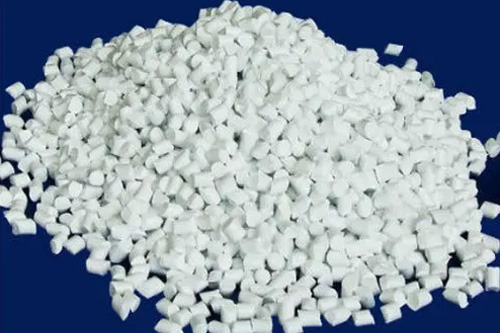

White Masterbatches - MG Polyblends

Our White Masterbatches are made with highest quality of Rutile Titanium Dioxide with Whiteness more than 97% which is sourced from global suppliers from Europe and United States. For More Infoemation:- https://www.mg-polyblends.com/

#White Masterbatch#Black Masterbatch#Polymer Masterbatch#Masterbatch#Oxy Bio Degradable Masterbatch#Additive Masterbatch

1 note

·

View note

Link

A newly found business entity of strong business values is Delhi, India settled by Tephra Polymers Plastic granules manufacturers in India. We are serving at the right prices, an impressive line of Color Masterbatch manufacturers in India, Additive Masterbatch, Virgin material polypropylene plastic raw material, Plastic Masterbatch manufacturers in Delhi

Tephra Polymers Masterbatch manufacturerS in India years of expertise and accumulating countless client service experiences enable our customers to get the best degree of opacity, with very low quantities of Tephra Polymers masterbatches. Our products are backed by our extensive, responsive, all-time around technical support network of Plastic raw material suppliers in India.

#Masterbatch manufacturers in India#Plastic granules manufacturers in India#color masterbatch#Additive Masterbatch#masterbatch manufacture#Polymers granules manufacturers in India

0 notes

Text

Choose The Best Additive Masterbatches From Our Leading Exporters in India

Kandui is one of the leading manufacturers of masterbatches for various purposes, including engineering polymers. We consider the polymer, additive masterbatch, and pigment selections while designing, and we ensure the best dispersion for the best fit. Finally, in-house, the color masterbatch will be tested on our Blown Film, Injection Moulding, and Spinning Lines. Visit our website for more details.

0 notes

Text

Masterbatchin - Black & white Masterbatches

Masterbatchin's black & white masterbatches are the ideal choice for achieving vibrant and durable colors in your plastic goods. With a focus on quality and performance, our masterbatches are designed to enhance the appearance and functionality of your products. Experience the difference with Masterbatchin.

Click Here: https://www.masterbatchin.com/

#additives masterbatches#colour masterbatch manufacturers#black & white masterbatches#eva compound manufacturers for footwear#light weight pvc compound for footwear#phthalate free pvc compound for footwear#phthalate free colour masterbatch#eva masterbatches manufacturers#pvc compound manufacturers

0 notes

Text

India additive masterbatch market size was valued at USD 128.7 million in FY2023, which is expected to grow to USD 231.2 million in FY2031, with a CAGR of 7.6% during the forecast period between FY2024 and FY2031.

0 notes

Text

PP functional masterbatch

PP functional masterbatch elevates polypropylene's (PP) performance by integrating specialized additives, enhancing strength, durability, and color stability. Ideal for diverse industries like automotive and packaging, it optimizes production efficiency, addressing thermal stability and impact strength. This cost-effective solution ensures seamless integration with PP resin, offering manufacturers a reliable means to achieve desired specifications, be it vibrant colors or superior mechanical properties.

0 notes

Text

What Is The Importance Of Additive Masterbatch In Plastic Industry?

Considering the properties and features of additive masterbatch, plastic industries cutting across domains and locations are using it on a large scale.

Do you know – what is an additive masterbatch?

In simple language, it concentrates on granule form for adding specific features and modifying thermoplastics. As far as its composition is concerned, it comprises one or more additives and a polymer-specific carrier resin.

Let’s understand this further. Additive masterbatches may contain one or more than one additive in its composition, including UV stabilizers, antioxidants, lubricants and demolding agents, foaming agents, antistatic agents, nucleating agents, anti-blocking agents, diffusers, laser-marking additives, IR absorbers for laser welding of plastics and metal and copper deactivators.

The product is also famous in industry circles as a functional masterbatch which is developed to improve the performance of a variety of plastic-made products.

Properties of additive masterbatch

Here are the major properties of this specialized kind of masterbatch:

Mechanical properties

Thermal resistance

Light resistance

Ozone resistance

Flame resistance and self-extinguishing properties

Rheology

Thermal and electrical conductivity

Specific gravity

Resistance to fungi and bacteria

Traceability

Applications of additive masterbatch in the plastic industry

The product has plenty of applications in plastic-based industries, including food films, drawer rails, technical film profiles, gardening products, films for mulching, cables, O-ring, Tube and hose, etc.

Industrial use

Plenty of industries are drawing benefits from this brilliant product, including agriculture, electronics, automobiles, and food processing.

Quality counts in this age of tough competition. Buy products from a prominent additive masterbatch manufacturer only!

0 notes

Text

Lifeline Technologies manufactures high-quality Insect Repellent Additive Masterbatch for applications like Packaging film, Banana skirting bags, Crate liners, Plastic table drawers and much more.

"Anti Insect Additive"

0 notes

Text

Discover the Advantages of Black Masterbatch: Specifications, Features, and Beyond. Elevate your products with this versatile solution for enhanced performance and aesthetics.

#filler masterbatch manufacturer in india#additive masterbatch manufacturer in india#jet black masterbatch#mould release spray manufacturer in india#pigments powder manufacturer in india

0 notes

Text

Colour Masterbatches

With a range of more than 25000 colors in our databank we're almost sure we have a match for the color you are looking for - not only for commodity polymers but for engineering plastics as well.

Besides our databank and standard colors, we can match a color according to your physical sample, LAB values or even a Pantone or RAL shade card number. Our team of color technicians can practically match any color that you can dream of.

#Colour masterbatch#Masterbatch#Plastic Products#White Masterbatch#Black Masterbatch#Additive Masterbatch

0 notes