#anodised aluminum sheets

Text

Gooding aluminium

acp seven

Gooding Aluminium instructions What You Will need to Know

Throughout this article, we will talk about Spectra Bond coating, 5000 alloy louvre energy, and Anodised in addition to Satin-brushed effects. You are going to also discover how to get free samples of Gooding aluminium products. To get going, browse the company's website plus request a quotation. Alternatively, contact these people directly to request about their custom-design service. Whatever your requirements, Gooding Aluminum is certain to have the solution for you.

Spectra Bond coating

Some sort of Spectra Bond finish for aluminium is definitely a composite panel which is applied to the surface associated with aluminium. This finish makes the surface different from bare lightweight alloy. Its color modifications slowly over a period of moment. In addition, this adds a range effect to the particular surface, giving that an unique plus distinctive appearance. As being an aluminium-based panel, this is a durable and durable option.

It is definitely important to make the surface associated with the aluminium base before applying typically the polymeric coating. In such a case, a prehydroxylated aluminum alloy was used. Then, a polymer bonded called methyl methacrylate was applied in order to the surface. This process promotes polymerization from the alloy. The effect is a layer that is not necessarily only durable yet also corrosion-resistant. That also reduces the organization of biofilms and bacteria and stops them from adhering to the surface.

Typically the spectral data regarding an ultrathin PMMA overlayer on aluminum oxide are displayed in Figure a few. The results demonstrate that the layered sample shows a new fragment characteristic together with a mass range of 59u. Typically the fragment characteristic is definitely attributed to the C-2H-3O-2+, probably while a result regarding the dissociation involving the PMMA efficient groups. An identical style can be seen for a thin PMMA overlayer on aluminium.

Performance Series five thousand alloy louvre panels

The performance of Gooding Aluminium's Efficiency Series 5000 combination louvre panels is usually tested to the health standard set by the Royal Society of Medicine. Installed on a school's roof terrace, typically the panels screen surroundings flow to ducting and provide an aesthetically pleasing visual appeal. These panels are available throughout different sizes plus surface finishes. Merely select the preferred image, follow typically the guidelines make an order.

Anodised finishes

The Pimlico School, a Visual and even Performing Arts University in Westminster, taken advantage of from the PS152million BSF Programme. While part of this particular scheme, Westminster Council funded the building of any new sports hall, gym, most weather floodlight message, education centre, in addition to community library. Gooding Aluminium clad the sports auditorium's walls with lightweight cut aluminium panels in GA Ano-Sil Anodised finishes.

Anodised coatings are achieved by electrochemical processes. Shiny dipping takes an unique dip solution regarding hot phosphoric and even nitric acids. Typically the process essentially thickens the metal's corrosion-resistant oxide layer, allowing it to accept vibrant colourants. Anodising is possible on any type of aluminum metal. This process makes Gooding aluminium a perfect choice with regard to high-end architectural projects.

Satin-brushed outcomes

Presently there are many techniques to acquire a satin-brushed finish, but generally there are only some sort of few steps in addition to tools you should include. First, it is advisable to wipe down the fresh aluminium sheet. And then, utilize a sanding disk to smooth out any defects, delivering it back towards the base product's surface finish. Finally, use a great Aluminium Foil Tape to shield the surface area from distortion.

Shuffle Glazing and Shuffle-Less Glazing users

Whether you're replacing existing windows, replacing typically the entire glazing method, or installing a brand new window, Gooding Lightweight alloy can help an individual. With their pre-finished glazing channels, they may have the perfect option for almost any window assembly. Using a two-part floors channel, there's no need to raise the glass top to bottom, which means minimum framing and quick fixing. The profile's peelable film safety ensures first-class ornamental looks. In addition , Gooding Aluminium also makes translucent pvc glazing wedges that go with both finishes.

Gooding Aluminium manufactures a new complete range regarding bespoke glazing channels and frames regarding both commercial and residential use. Typically the GA "shuffle-less" plus "complete" glazed devices feature pre-drilled slots and countersunk equipment for easier assembly. They are delivered pre-finished. Vernacare System is usually a healthcare-grade hygienic toileting system that eliminates the advantages of chemical substance disinfection processes and clinical waste. Nurses can take more time upon caring for people, and this technique is also environmentally-friendly.

Suitable for sa a variety regarding window styles, Gooding aluminium Shuffle Double glazed and 'Shuffle-Less' Glazing profiles feature a changeable wedge to match 10mm, 11mm, or 12mm glass. Additionally , broad glazing channel packages include plastic setting blocks, ensuring free from danger, damage-free installation. Gooding aluminium Shuffle Glazing and Shuffle-Less Double glazed profiles can be found together with an one-stop-supply mounting system. These information can be finished in a number of finishes, which includes powder-coating, satin anodised, with a peelable film to supply excellent surface defense.

Aluminium glazing stations

If you happen to be looking for the supplier of gooding aluminium glazing stations, you might have come in order to the right location. Gooding Aluminium specialises in a wide range of aluminum products and services. From sheets plus profiles to extrusions, stair nosing, louvres, and board in addition to panel fixings, Gooding Aluminium will help you get the right double glazed channel for your current needs. However, when you have any questions in regards to the company or would want to find out even more about their products, contact Gooding Lightweight alloy today.

Gooding Aluminium is definitely an aluminium user profile and sheet dealer and contains recently introduced an array of aluminium double glazed channels. These are really known as GA "complete" and GA "shuffle-less glazing systems". They frame 10mm-thick glass and contain pre-drilled holes. These products are provided pre-finished with glazing wedges and setting up blocks. You can get hold of them delivered using a branded installation set up, which is a great added benefit.

Alspec(r) Aluminium Glazing Stations are available in recessed and regular perimeter applications. Their very own array of profiles ranges from 25mm in order to 44mm. Alspec's Aluminium Glazing Channels will be available in numerous sizes and may accept 4mm in order to 12mm glass with regard to single glazed double glazed, and 24mm to be able to 28mm for double-glazed windows. The aluminium lightweight glazing channels will be also suitable for silicone glazing. They could be utilized on walls plus ceilings.

#acp seven#harga acp per lembar#harga acp seven#harga alucopan seven#harga acp seven per lembar#harga acp per m2

1 note

·

View note

Text

The Many Uses of Aluminum 1050

You may be surprised to learn that aluminum 1050 has various applications in the industry. This versatile metal is used in everything from aircraft construction to electrical wiring. Let's take a closer look at some of the most common uses for aluminum 1050.

Aircraft Construction

Aluminum 1050 is frequently used in the construction of aircraft. Its lightweight and high strength-to-weight ratio make it an ideal choice for this application. In addition, aluminum 1050 is resistant to corrosion, which is important in preventing structural damage to aircraft.

Automotive Applications

Aluminum 1050 is also used in many automotive applications. Its light weight makes it ideal for use in car bodies and wheels. In addition, aluminum 1050 can be used in engine components such as pistons and cylinder heads. Its corrosion resistance is also essential in preventing damage to automotive parts exposed to the elements.

Electrical Wiring

Another everyday use for aluminum 1050 is electrical wiring. This metal is an excellent conductor of electricity and is often used in household wiring and automotive electrical systems. Aluminum 1050 is also used in the construction of electrical transmission lines.

Beverage industry

Another industry that commonly uses aluminum 1050 is the food and beverage industry. This alloy is often used in the construction of food processing and storage facilities because it is non-toxic and does not rust.

Is 1050 Aluminium flexible?

1050 H14 aluminum is very ductile, so it is often used by fabricators and sheet metal workers who need to bend or shape the material into a specific form.

Can 1050 aluminum be anodized?

Yes, 1050 can be anodized. For example, Grade 1050A has excellent properties for decorative and technical requirements regarding anodizing. Additionally, it works well with chemical and electrolytic brightening.

Can you Anodise aluminium twice?

If you want to restore the coating performance of your aluminum item with a good cosmetic finish, then you can re-anodize it. Since anodizing requires electrical contact, any existing coating on the item must be removed before it can be anodized again.

What removes anodizing from aluminum?

Acid Etching: This process involves a mixture of chromic acid and phosphoric acid. The end result will look similar to the aluminum before it was anodized.

Potassium hydroxide is a strong base (alkali) that reacts well with acids. It’s commonly found in drain cleaners and sodium hydroxide and sulfuric acid.

Sodium Hydroxide, also called caustic soda or lye, is the most classic way to remove the anodized coating.

De-oxidizing: You can also use a strong de-oxidizer to strip the aluminum surface.

Conclusion:

As you can see, aluminum 1050 has various applications in the industry. Its lightweight, high strength-to-weight ratio, and corrosion resistance make it an ideal choice for use in aircraft construction, automotive applications, and electrical wiring. If you are looking for a versatile metal for your next project, consider using aluminum 1050.

Who are we?

We are an aluminum enthusiast and an aluminum metals supplier in Canada and the USA.

We offer premium, different Aluminum Coil sheets, raw Aluminum sheets, & assorted colour aluminum wire for sale and black Aluminum Foil in our warehouse, ready to ship today.

Call us today, Toll-Free: 866–860–0652, if you need further information.

1 note

·

View note

Text

How to Choose the Best Cantaport Awnings for Your Home

When looking for the best Cantaport awnings for your home, you need to know what features you should look for. You should choose a model that is durable and easy to use. You can choose from manual or motorized awnings. Manual models are more affordable than motorized options. However, you should remember that motorized models require a longer installation cord. For this reason, you should have extension cords handy, or consult with an electrician for help.

Retractable awnings

Retractable awnings offer a stylish solution for protecting outdoor furniture, reducing outdoor temperatures, and cutting down on energy bills. Compared to traditional Cantaport awnings , which are left exposed to the elements all day, retractable awnings roll up and away when the weather changes. This can increase the longevity of the awning and save the homeowner money in the long run.

When purchasing a retractable awning, be sure to choose a model that is built to last. Make sure that the frame is made of a durable, yet lightweight material, such as aluminum or stainless steel. Both of these materials are sturdy and durable and can withstand a variety of weather conditions. Be sure to have an electrician nearby to assist with installation if the unit requires additional wiring.

Cantaport awnings

A great way to enjoy your outdoor space year-round is by installing Cantaport awnings . These shade systems are extremely durable and are made from anodised aluminium. They are designed to resist winds of up to 125 km per hour and are certified to Australian Standards. Moreover, they can be easily installed by DIY enthusiasts.

Cantaport shading solutions are a perfect alternative to traditional patio cover, carport, and shading systems. Made in Japan from high quality materials, these awnings and covers are highly durable, stylish, and weatherproof. In addition, they have patented polycarbonate sheeting that protects against UV rays. You can choose from a wide variety of colours and designs to suit your home and garden.

Cantaport awnings has a range of residential cantilever awnings that outperform conventional ones. They are constructed using state-of-the-art technology and are more flexible than other awnings. The aluminium framework and polycarbonate sheeting offer excellent UV protection and are rust-free. Cantaport awnings are available at local awning distributors throughout Australia.

Fabric options

Cantaport awnings can be covered with a variety of fabrics to add aesthetic value to your outdoor space. Some fabrics are made of canvas, while others are made of acrylic. Canvas is an inexpensive material that is both durable and resistant to fading. Those who want a professional appearance can choose acrylic, which will cost as much as ten times as much as canvas, but is more durable.

These cantilever awnings are easy to install and can be set up in as little as one day. They're also great for poolside shade and patio protection. Once you've made your payment, you can expect your kit to arrive in 10 days or less. The Cantaport is made of quality materials that are durable enough to withstand the elements. They're also designed to be easy to assemble with special connection kits. Freight to the local depot is included in the price.

Durability

Cantaport awnings are made of high-quality materials that are built to last for many years. Some models include a 3-year warranty and come with stainless steel brackets and arms. Some models also have drop-forged aluminium brackets for maximum strength. Awnings made of this material are incredibly sturdy and come in a wide range of colors.

Cantaport awnings are wind and snow-rated. This means that they can withstand strong winds and even heavy snowfall. They also come with a seven-year warranty.

Cost

Cantaport awnings are a modern and stylish shade solution for your patio, pool or other outdoor spaces. The canopy is made of high-grade anodised aluminium and has built-in rainwater-down piping and gutters for added protection and performance. These awnings are a solid investment for your home, and are available in a variety of colours, including black, urban grey, and silver.

The Cantaport shade structure is built with high-quality, anodised aluminium and is 100% corrosion free. Its patented polycarbonate sheeting blocks up to 99% of the sun's harmful UV rays and reduces the risk of fading paintwork and furniture. A Cantaport awning can be installed by a local professional, such as Shady Places.

1 note

·

View note

Text

What is an Epoxy Primers? & Why You Should Use An Epoxy Primers?

Choosing whether to utilize an Epoxy Primers preliminary is a subject that is much of the time ignored by numerous organizations that are putting resources into a top notch floor covering. As a matter of fact, many individuals don't know that floor groundworks exist or that they aren't required and are an extra expense.

The establishment of another floor requires a ton of painstakingly thought about processes. Floor planning, being the first, is principal and a story groundwork is similarly as significant, saving you time and exertion as well as cash.

What Does Epoxy Primers Mean?

Epoxy Primers groundwork alludes to a sealer that has a non-permeable completion. It is principally suggested as the a respectable starting point coat over uncovered steel. These base covers or Epoxy Primers preliminaries can be utilized over fiberglass, plastic or the dark iron phosphate covering too.

Epoxy Primers preliminaries are utilized for a wide assortment of materials because of their solid grip, great mechanical capacity, and sturdy compound obstruction in wet and high-moistness conditions. The capacity of an Epoxy Primers groundwork to oppose consumption is connected with its thickness; the thicker the Epoxy Primers preliminary layer, the better the assurance.

This groundwork can likewise be utilized on breaks and gouges. Its holding limit is incredible and it creates a decent surface completion. Epoxy Primers groundworks offer great grip to metals as well as act as a legitimate base for additional undercoat items and top coats. Epoxy Primers groundworks are likewise generally used to cover metal jars and compartments, particularly those used to hold acidic food, like tomatoes.

Benefits of Epoxy Primers

There are numerous benefits in applying an Epoxy Paints prior to coating your flooring:

Epoxy Primers preliminaries are slender, giving a superior grip as it infiltrated into the substantial substrate permitting a superior security.

Preliminaries give a superior compound bond while utilizing thicker Epoxy Primers base coats. This outcomes in a more drawn out enduring and a more tough substantial floor covering.

Disposal of air pockets and pinhole that are framed because of the outgassing of the concrete*

Capacity to accomplish a higher dry film thickness and covering consistency as it isn't splashing into the substantial.

Powerful in giving a dampness protection from substantial ground surface that has dampness issues.

Groundworks structure a tireless waterproof obstruction for substantial deck that is without a powerful Damp Proof Membrane (DPM) which as a rule brings about essentially any paint lifting and stripping off the surface.

Most Epoxy Primers preliminaries are dampness lenient and function admirably while being applied on substantial that has not completely dried from being cleaned or corrosive scratched.

A few preliminaries are explicitly fabricated as oil impeding groundworks. These dissolvable based groundworks are intended to cover substantial that has been sullied by oil and can't be totally cleaned.

Features

Fantastic bond and security - Product won't run and will forestalls consumption

Fast drying time - Overpaintable following 12-15 minutes (@ 20 degree)

Great stream - Smooth completion

Viable with driving paint frameworks - No rebounds

Wet-on-wet application conceivable - Time saving

10 years time span of usability (at 10-25 degree, max 60% mugginess) - Long capacity life

Application

Epoxy Primers is a 1-K preliminary that gives fantastic bond and safeguards from erosion.

Because of its speedy drying time it is great for spot fixes and revamping parts. It is additionally weldable and you can apply clay on the groundwork.

This preliminary is drying quick with a decent stream and can be applied wet-on-wet.

It gives a decent insualtion against dampness and it is viable with water-based and dissolvable based items.

Appropriate on aluminum, anodised aluminum, sheet steel, zinc covered steel, clear metal, glass fiber and plastic substrates (plastic preliminary suggested!).

Zigma Paints Pvt. Ltd. makes many modern groundworks that are great for applications in steel creation, fundamental gear makers (OEMs), fabricated steel items, modern support, beautiful iron, business propane, defensive coatings on electrical products, electrostatic and bath refining. With our space skill, we are taken part in offering a great many modern preliminary coatings and paints made utilizing quality fixings.

The groundwork, otherwise called the undercoat, is a pre-covering applied to the material before painting. The preparing guarantees great bond of the paint to the surface, builds the sturdiness of the paint and gives extra fundamental assurance to the painted material. An Epoxy Primers groundworks is a kind of uncompromising modern preliminary that gives great security to the steel utilized and created in a typical modern climate. This Primers item is a high strong preliminary.

More about information for Epoxy Primers Suppliers & Manufacturers then Visit our site -

https://www.zigmapaints.com/epoxy-primer-paints.php

0 notes

Text

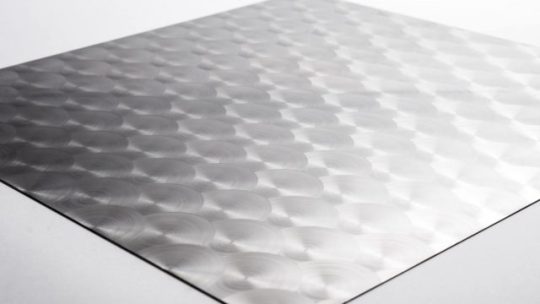

The Application of Anodized Aluminum Sheet

The Application of Anodized Aluminum Sheet

The anodized aluminum sheet is of higher harness, wear resistance, heat resistance and excellent insulation. The melting point of the hard anodized film is up to 2320K and the breakdown voltage resistance is up to 2000V. It has no corrosion in ω=0.03NaCl salt mist after thousands of hours.

The thin layer of the oxide film has a large number of micropores, which can absorb various lubricants,…

View On WordPress

0 notes

Photo

Why The Aluminum Wire Is Chosen Over Other Metals

Physically, chemically and mechanically, aluminum is a metal like steel, metal, copper, zinc, lead, or titanium. It tends to be softened, projected, framed, and machined likewise to these metals and conveys electric flows. Indeed, regularly similar hardware and manufacturing strategies are utilized concerning steel. Bullion pipes are one of the leading suppliers of aluminum wires.

Light Weight

Aluminum is an extremely light metal with a particular load of 2.7 g/cm3, about 33% of that of steel. This reduces the expenses of assembling with aluminum. Once more, its utilization in vehicles decreases dead-weight and energy utilization while expanding the load limit. This likewise lessens commotion and improves comfort levels.

Its solidarity can be adjusted to the application needed by changing the organization of its composites. Aluminum-magnesium-manganese composites are an ideal blend of formability with strength, while aluminum-magnesium-silicon combinations are ideal for auto body sheets, which show great age-solidifying when exposed to the heat on artwork.

Erosion Resistance

Aluminum normally creates a defensive meager oxide covering which holds the metal back from connecting with the climate. It is especially valuable for applications where it is presented to eroding specialists, as in kitchen cupboards and in vehicles. All in all, aluminum amalgams are less erosion safe than unadulterated aluminum, with the exception of marine magnesium-aluminum composites. Various sorts of surface treatment, for example, anodising, painting or lacquering can additionally improve this property.

Electrical and Thermal Conductivity

Aluminum is an incredible warmth and power conveyor and corresponding to its weight is twice as great a channel as copper. This has settled on aluminum as the best option for significant force transmission lines. It is additionally a sublime warmth sink for some applications that expect warmth to be depleted away quickly, for example, in PC motherboards and LED lights.

On the off chance that aluminum is utilized as a conveyor material, its lower conductivity requires a wire size that is around 33% bigger than that of a copper wire. Eventually, be that as it may, the protecting material utilized with the wire assumes a pivotal part in presentation; an aluminum wire can have a similar current conveying limit as an H07RN-F copper wire. Aluminum’s bigger wire size would just be a hindrance in applications requiring tight separating, for example, when introduced in thickly stuffed control cupboards. Current realities for aluminum represent themselves with regards to the issue of weight. As a crude material, aluminum is around 70% lighter in weight than copper. This can be useful in the endeavors of various application fields hoping to lessen the heaviness, everything being equal. Normally, when utilized in electrical links, the lower weight makes them simpler to introduce. High-voltage links have for some time been produced using aluminum; the lighter weight decreases the malleable power put on wire and poles essentially. However, even enterprises, for example, auto-intention producing and the avionic business is changing to aluminum wires. All the link bridles in the Airbus A380 are as of now made of aluminum. Aluminum wires can be up to 60% lighter than copper wire with a similar current-conveying limit. In any event, for applications that require adaptable link associations, copper should not generally be the best option.

Reflectivity

Aluminum is a decent reflector of obvious light just as warmth, and that along with its low weight, makes it an ideal material for reflectors in, for instance, light fittings or salvage covers. Cool rooftops made of covered aluminum are important in decreasing inner sun oriented warmth inside a house, by reflecting up to 95% of daylight.

Pliability

Aluminum is flexible and has a low dissolving point and thickness. It tends to be prepared in a few different ways in a liquid condition. Its malleability permits aluminum items to be shaped near the finish of the item’s plan. Regardless of whether sheets, foil, mathematical setups, cylinders, bars or wires, aluminum is up to them all.

Strength at Low Temperatures

As opposed to steel, which quickly gets fragile at low temperatures, aluminum shows expanded elasticity as temperatures drop.

Impermeable and Odorless

Aluminum foil is just 0.007 mm in thickness, yet is as yet solid and totally impermeable, keeping any food enclosed by it liberated from outer tastes or scents. It keeps out bright beams also.

Also, the actual metal is non-harmful and scentless, which makes it ideal for bundling touchy items like food or drugs. The way that reused aluminum can be utilized lessens the carbon impression for this phase of food and refreshment producers too.

Non-attractive

Aluminum is non-attractive, making it valuable for electrical shieldings as in PC plates, dish recieving wires, busbars or magnet lodgings.

Non-harmful

Aluminum is non-poisonous and is utilized to make woks, pressure cookers, and numerous other cooking tools unafraid. It is handily cleaned and doesn’t taint the food at any stage.

Sound and Shock Absorption

Aluminum is a brilliant sound safeguard and is utilized for developing roofs. It is additionally utilized in auto guards because of its stun retaining properties.

Non-sparking

Aluminum delivers no sparkles when it comes into contact with itself or non-ferrous metals.

Recyclability

Aluminum is 100% recyclable and reused aluminum is indistinguishable from the virgin item. This makes it a substantially more financially savvy source material for creation runs. The re-liquefying of aluminum requires little energy: just about 5% of the energy needed to deliver the essential metal at first is required in the reusing interaction.

https://bullionpipe.com/

#Hydraulic Pressure Test Pump & Pressure Gauge#Thermowell Fittings#SAE Flanges#Condensate Pot & Air Header#Swivel Fittings#Stainless Steel Flanges#Special Products#Stainless Steel Seamless Pipes & Tubes#Stainless Steel Butt Weld Fittings#Instrumentation Tube Fittings#High Pressure Fittings#Manifold Valves#Hydraulic Tube Clamps & Accessories#Hydraulic Fittings#Hydraulic SAE Flanges#Instrumentation Valves & Tube Fittings#Quick Release Coupling#Single Ferrule Fittings#Hydraulic Pipe Clamps#Double Ferrule Fittings#Ball Valves#NEEDLE VALVES

2 notes

·

View notes

Text

Introduction to anodised aluminum sheets

Anodised aluminum sheet is to place the aluminum sheet in corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode for electrolysis under specific conditions with externally applied current. Thealuminum sheet of the anode is oxidized and has an aluminum oxide film formed on the surface; the film is 5-20μm thick, and a hard anodic oxidation film can be up to 60-200μm thick. After anodization, the aluminum sheet achieves greater hardness, better abrasive resistance (up to 250-500 kg/mm2), and good resistance to heat; the hard anodic oxidation film also features a melting point of up to 2320 K, excellent insulativity, high breakdown voltage (up to 2000V), and enhanced resistance to corrosion (it may stand salt spray under ω=0.03NaCl for thousands of hours without being corroded). Additionally, the oxide film is distributed with numerous pores that can absorb various lubricants, thus making the anodised aluminum sheet suitable for manufacturing engine cylinder or other wear-resistant parts; the strong absorbability of the film can also be well utilized to form various bright colors.

II. Anodization process of aluminum sheets

1. General principle of aluminum sheet anodization generating aluminum oxide film

2. Selection of electrolyte for anodization of aluminum sheets

3. Types of anodization of aluminum sheet

4. Structure and properties of the oxide film formed during aluminum sheetanodization

III. Applicable scope of the anodised aluminum sheets

The anodised aluminum sheets are widely used in such fields as mechanical parts, airplane and automobile parts, precise instruments, wireless electrical appliances, building decorations, mechanical housing, illumination lamps, electronic consumables, art wares, household appliances, indoor decorations, sign boards, furniture automobile decorations, etc.

IV. Advantages of the anodised aluminum sheet

(1) Good processability: the anodised aluminum sheet is strongly decorative, featuring moderate hardness and easy bending and shaping; it can be processed by continuous pressing at high speeds, and directly made into products without requiring complex surface treatment, thus having greatly reduced the production period and the production cost of products.

(2) Good weatherability: an anodised aluminum sheet with oxide film of standard thickness (3μm) stands colorfast for a long time when it is used indoors, with no corrosion, oxidation or rusting; a thickened anodised aluminum sheet (thickness of 10μm) can be used outdoors with colorfastness under long-time exposure to sunlight.

(3) Prominent metallic features: anodised aluminum sheets may have their hardness on a par with gems and are well resistant to scratches; they have no paint coating on the surface and thus have retained the metallic gloss of aluminum sheets, protruding the modern metallic features and promoting the class and added value of the products.

(4) Good resistance to fire: as the anodised aluminum sheet is purely made of metal without any paint or chemical substance, it neither combusts at a temperature as high as 600 degrees, nor generates any poisonous gas, and thus satisfies the requirements for environmental protection.

(5) Good resistance to dirt: the anodised aluminum sheet retains no finger print, and thus no stains will be left; it can also be easily cleaned, without producing any corroded spot.

(6) Wide applicability: the anodised aluminum sheet is widely used, and applicable to metal aluminum ceiling, curtain wall plate, aluminum composite panel, fireproof board, honeycomb aluminum panel, single aluminum sheet, electric appliance panel, cabinet panel, furniture panel, etc.

VII. Basic processing procedures of surface treatment are as follows:

Procedures for anodization of aluminum sheets: racking – degreasing – rinsing – alkaline corrosion – rinsing – neutralizing – rinsing – anodizing – rinsing – pore sealing – rinsing – off rack – testing – packing.

Among the procedures, degreasing, alkaline corrosion, neutralizing, anodizing and pore sealing are key to ensure the oxidation quality.

Mirror anodized aluminum sheet/reflective aluminum sheet

The most advantage for mirror/reflective aluminum sheet for wall material, such as the building exterior curtain walls/renovations for old building, the mirror/reflective aluminum sheet for shop door decorations, advertisement board display platforms and signboards, or wallboards and ceiling for tunnels, or industrial materials.

0 notes

Text

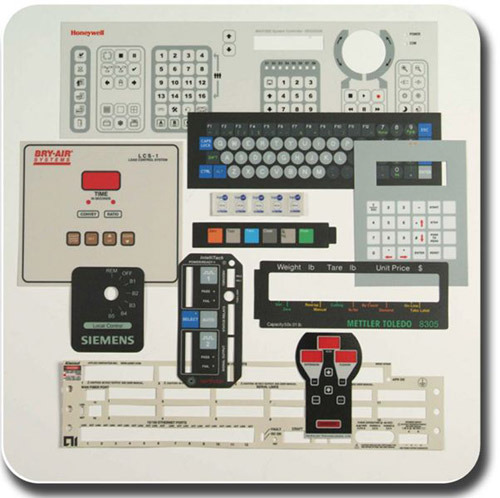

Prozessleittechnik gmbh berlin

What's a mosaic mimic panel. Panels have led status indicators, control switches, and will embody din mount meters or different panel devices as required. Kayali mixed cycle power plant venture - osmaniye logstrup withdrawable mcc panels (form4b) have been accomplished successfully. Manufacture of: engraved mosaic mimic panels, photograph anodised aluminium face plates, silk screening, engraved gravoply labels, control desks and consoles, enclosures, customized electrical and electronic systems.

Acrastyle can provide standard 19” rack sort control panels or customized-sized panels tailor-made to particular person calls for. Sibalt mc is a producer of graphic display panels (or mosaic mimic panel — mmc); utilizing a canadian mosaic high quality polycarbonate (makrolon) tile system, russian aluminum frame structure, totally different gauges and switches.

As each tiles and grid are produced from polycarbonate (makrolon), which is a steady heat-resistant material, they've matching growth traits. Our specifically developed all-goal mosaic techniques are installed in quite a few management rooms all over the world. Business profile : mfr: lt control panels, db mimic panels, mcc and allied merchandise. Supervisory management and back mosaic Mosaic mimic panels control desks, selector switches and control cables.

These mosaic matrix panels are widely utilized in distant control panel in power crops, hearth & fuel panels and emergency shutdown system in oil & gas applications.The present display simulated mosaic display (the industry as "White flake") are single-layer construction. Flat floor alignment of tiles is ensured within a tolerance of lower than zero.1mm (.004") in height, and with out imposing any limitation on the positioning of control and indication gadgets or instrumentation.

The pliability of design permits straightforward integration of buyer tools corresponding to pcs, switsches, power supplies, monitor holders or even mosaic panels. Or engraving on the tiles of the mosaic. If the elements are reduce or eliminated to suit instruments, the mosaic grid might be changed in small modules (2x4 tiles). Adobe steel products have immensely taken half in the means of sheet metal fabrication in india as well as crp panel producers in india.

1 note

·

View note

Text

Everything You Need to Know About Nameplates Printing

If you are in search for nameplates printing, you have come to the right place. In this post, we discuss everything you need to know about this process. We will talk about the different types of nameplates that are available, as well as the materials that they can be made from. We will also discuss how to choose the right type of nameplate for your business, and how to order them from a printing company.

Different Types of Nameplates and their Materials

Nameplates come in many different shapes, sizes, and colors. They can be made from a variety of materials, including plastic, metal, wood, or even glass.

The most common type of nameplate is the rectangular one that is placed on the front of a door or on the side of a desk. These nameplates usually have the person's name and title printed on them.

Another popular type of nameplate is the square nameplate. These are often used for office doors or cubicles. They typically have the person's initials or company logo printed on them.

Nameplates can also be made in the shape of a business card. These nameplates are often used to identify conference rooms or other meeting spaces.

The material that you choose for your nameplate will depend on where you plan to use it. For example, if you need a nameplate for an outdoor sign, you will want to choose a material that can withstand the elements.

There are also the anodised aluminum nameplates which are used for both indoor and outdoor purposes. These nameplates can be printed with either one or two colors. Anodised aluminum nameplates are made from a sheet of aluminum that is passed through an electrolytic process. This process gives the nameplate a durable, corrosion-resistant finish.

The steel powder-Coated Finishes that can be printed with a range of colours using epoxy inks. The inks are cured at high temperatures, which gives the nameplate a tough, durable finish.

How to Choose the Right Type of Nameplate for Your Business

When choosing a nameplate for your business, you will need to consider a few factors. First, you need to decide where you will be using the nameplate. If it is for an outdoor sign, you will need to choose a material that can withstand the elements. If it is for an indoor office space, you can choose any material that you like.

You also need to decide what size and shape of nameplate you need. Rectangular nameplates are the most common type, but if you have a specific space in mind, you may want to choose a different shape.

If you plan on using the nameplate for branding purposes, you will need to choose a material that can be printed with your company logo. Anodised aluminum or steel are both good choices for this.

Finally, you need to decide how many colors you want to use for your nameplate. If you only need one color, any material will work. If you want to use two colors, anodized aluminum or steel are both good choices.

Nameplates Printing

Once you have chosen the type of nameplate that you need, you will need to choose a printing company to print it for you. When choosing a printing company, you should always ask for samples of their work. You should also inquire about their turnaround time and pricing.

When you are ready to place your order, simply send the printing company your artwork and specifications. The printing company will then create a proof for you to approve before they begin printing your nameplates.

Nameplates are a great way to identify your business and brand your office space. By following these tips, you can be sure to choose the right type of nameplate for your needs.

0 notes

Text

Standard Titanium Co | Airplane and also Aerospace Light Weight titanium tube

Pure aluminum and pure magnesium are totally unsuitable as structural products for airframes, because they have extremely low toughness. However, when alloyed (chemically mixed) with each other or with various other metals, their stamina is greatly enhanced, as well as they form the most utilized group of airframe products. Alloying steels consist of zinc, copper, manganese, silicon and lithium, as well as might be made use of singly or in mix.

There are much various variations, each having various residential or commercial properties and so fit to various uses. Magnesium alloys are extremely prone to assault by sea water, and their use in carrier-based aircraft is normally avoided. Aluminum alloys, although denser than magnesium alloys, are much less prone to chemical assault, and are less expensive, so are extra commonly used. 2024 alloy, referred to as duralumin, contains 93.5 percent aluminum, 4.4 percent copper, 1.5 percent manganese and 0.6 per cent magnesium, and is one of the most commonly used of all materials in aircraft structures. Light weight aluminum alloys are a lot more susceptible to rust than pure aluminum, so pure light weight aluminum is typically rolled onto the surfaces of its alloys to form a safety layer. The procedure is called cladding, as well as sheets of alloy dealt with similar to this are referred to as clad sheets or Al-clad. Another usual means of shielding light weight aluminum alloys is anodising - conversion of the surface layer to a type which is a lot more corrosion-resistant by an electro-chemical process. Aluminum-lithium alloys are superior to aluminum-zinc and aluminum-copper alloys in stamina and also rigidity, so can be utilized to save weight. Their use is limited since they are around three times as pricey.

titanium tube

An intriguing residential or commercial property which specific light weight aluminum alloys share with titanium is that they can be super-plastically created (SPF). When the material is warmed to a particular temperature, much below its melting point, it can being stretched by several times its very own size without tearing or neighborhood thinning. It can after that be flawed, using an inert gas such as argon, to load a mould as well as take its shape exactly, without spring-back when the pressure is launched. There are various strategies based on this residential or commercial property, which can be utilized to make exceptionally difficult shapes accurately and with minimum weight. The high first price of tooling indicates SPF is limited to specific high-cost products, and it is not yet suited to automation. Products such as pressure vessels, little storage tanks as well as storage tanks might be used this method.

Advantages of aluminum and also magnesium alloys1. High strength-to-weight ratios2. A wide range of various alloys, to fit a variety of various usages3. Low density, so better mass for same weight suggests they can be used in a greater thickness than denser products, as well as therefore are much less susceptible to regional buckling; this puts on magnesium alloys even more than light weight aluminum alloys4. Readily available in lots of basic forms - sheet, plate, tube, bar, extrusions5. Aluminum alloys are simple to work after easy heat treatment6. Can be super-plastically developed (particular aluminum alloys just).

Drawbacks.

1. Prone to rust, so need protective coatings, especially magnesium alloys.2. Lots of alloys have restricted stamina, specifically at elevated temperature levels.3. Magnesium alloys have reduced stamina (but high strength-to-weight ratio).4. No exhaustion limit (see section on exhaustion later on in this chapter).

0 notes

Text

Overview of aluminum alloy mechanical properties during and after fires

Aluminum alloys are increasingly being used in a broad spectrum of load-bearing applications such as lightweight structures, light rail, bridge decks, marine crafts, and off-shore platforms. A major concern in the design of land-based and marine aluminum structures is fire safety, at least in part due to mechanical property reduction at temperatures significantly lower than that for steel. A substantial concern also exists regarding the integrity and stability of an aluminum structure following a fire; however, little research has been reported on this topic. This paper provides a broad overview of the mechanical behavior of aluminum plates both during and following fire. The two aluminum alloys discussed in this work, 5083-H116 and 6061-T651, were selected due to their prevalence as lightweight structural alloys and their differing strengthening mechanisms (5083 – strain hardened, 6061 – precipitation hardened). The high temperature quasi-static mechanical and creep behavior are discussed. A creep model is presented to predict the secondary and tertiary creep strains followed by creep rupture. The residual mechanical behavior following fire (with and without applied stress) is elucidated in terms of the governing kinetically-dependent microstructural mechanisms. A review is provided on modeling techniques for residual mechanical behavior following fire including empirical relations, physically-based constitutive models, and finite element implementations. The principal objective is to provide a comprehensive description of select aluminum alloys, 5083-H116 and 6061-T651, to aid design and analysis of aluminum structures during and after fire.

The materials included in this study are 5083-H116 and 6061-T651. These alloys were investigated due to their prevalence as common structural alloys, especially in lightweight transportation and structural applications, and their different strengthening mechanisms. 5083 is strengthened by strain hardening (cold work). It is a weldable, moderate strength alloy which exhibits good corrosion resistance in the H116 condition. 6061 is strengthened by precipitation hardening (heat treatment). It is a weldable, high strength alloy which also exhibits good corrosion resistance. The chemical composition of the alloys are shown in Table 1.

A review of the literature devoted to the problem of efficiency of the use of aluminum alloys in automotive structures is presented. Requirements are formulated on the structure and properties of alloys for cold rolling of car parts. The results of a study of sheets from AV alloy with a fine-grained recrystallized structure and adaptability to manufacture, which makes the sheets suitable for automotive panels, and mechanical properties at the level of steel sheets after aging in the process of drying of the lacquer coating, are presented.

Aluminum is a very light metal with a specific weight of 2.7 g/cm3, about a third of that of steel. This cuts the costs of manufacturing with aluminum. Again, its use in vehicles reduces dead-weight and energy consumption while increasing load capacity. This also reduces noise and improves comfort levels.

Its strength can be adapted to the application required by modifying the composition of its alloys. Aluminum-magnesium-manganese alloys are an optimum mix of formability with strength, while aluminum-magnesium-silicon alloys are ideal for automobile body sheets, which show good age-hardening when subjected to the bake-on painting process.

Aluminum naturally generates a protective thin oxide coating which keeps the metal from making further contact with the environment. It is particularly useful for applications where it is exposed to corroding agents, as in kitchen cabinets and in vehicles. In general, aluminum alloys are less corrosion-resistant than pure aluminum, except for marine magnesium-aluminum alloys. Different types of surface treatment such as anodising, painting or lacquering can further improve this property.

Aluminum is an excellent heat and electricity conductor and in relation to its weight is almost twice as good a conductor as copper. This has made aluminum the first choice for major power transmission lines. It is also a superb heat sink for many applications that require heat to be drained away rapidly, such as in computer motherboards and LED lights.

Aluminum is ductile and has a low melting point and density. It can be processed in several ways in a molten condition. Its ductility allows aluminum material to be formed close to the end of the product’s design. Whether sheets, foil, geometrical configurations, tubes, rods or wires, aluminum is up to them all.

Aluminum foil is only 0.007 mm in thickness, but is still durable and completely impermeable, keeping any food wrapped in it free of external tastes or smells. It keeps out ultraviolet rays as well.

Moreover, the metal itself is non-toxic and odorless, which makes it ideal for packaging sensitive products such as food or pharmaceuticals. The fact that recycled aluminum can be used reduces the carbon footprint for this stage of food and beverage manufacturers as well.

Aluminum is 100% recyclable and recycled aluminum is identical to the virgin product. This makes it a much more cost-effective source material for production runs. The re-melting of aluminum requires little energy: only about 5% of the energy required to produce the primary metal initially is needed in the recycling process.

Since the last decades of the 20th century, aluminum sheet has proven to be one of the most versatile metallic materials in those applications where weight reduction plays a fundamental role. The possibility of recycling aluminum alloys an indefinite number of times is another of its great attractions. Currently, the development of new alloys that improve mechanical properties and corrosion resistance while maintaining a light weight is one of the important lines of research and development work. At the same time, new processes are being developed to manufacture better-performing aluminum-based components, overcoming difficulties in casting, the poor ductility of aluminum alloys at room temperature, and its challenging weldability. Among these processes, solid phase processing, semi-solid processing, the liquid die forging process, powder metallurgy, sheet hydroforming, incremental forming, additive manufacturing and friction stir welding and its variants allow for dissimilar joints.

Many of the advances produced in the design and processing of alloys have been obtained thanks to modeling and simulation techniques. These techniques make it possible to describe everything from phase diagrams of new compositions based on thermodynamic calculations to the flow of material during the deformation and forming processes. To face the future challenges in the aluminum bar, it is necessary to improve knowledge of the micro- and mesoscopic mechanisms that explain the mechanical behavior of aluminum alloys. A deeper understanding of these mechanisms is necessary both in components in real use, and during the manufacturing processes. Additionally, the correlation between aluminum alloy properties and their microstructure must be considered in a unified way to explain the mechanical behavior in volume and surface and against corrosion.

In this Special Issue, we openly invite contributions from researchers working on all the different aspects of this ever-challenging material.

The present article demonstrates the procedure for fabrication of aluminum alloy 2014 based metal matrix composites having particulates of silicon carbide as reinforcement. Using the stir casting route, three different compositions of aluminum alloy metal matrix composites were fabricated. Microstructure of as-cast composites revealed a homogeneous distribution of silicon carbide particles along with few agglomeration and casting defects. Friction stir processing was performed to avoid such agglomeration and casting defects present in as-cast composites. The influence of friction stir processing parameters, that is, rotational speed and transverse speed on metallurgical properties, was investigated. Two combinations of rotational speed and transverse speed were considered: (i) 270 rpm and 78 mm/min and (ii) 190 rpm and 50 mm/min, respectively. As a result of friction stir processing, the microstructure of processed composites revealed the presence of fine silicon carbide particles along with the magnificent reduction in grain size. Composites processed with a rotational speed of 270 rpm and transverse speed of 78 mm/min were found to have higher grain refinement and as a result of this, the enhancement in microhardness was also observed. Except for a few cases, the average microhardness of all processed composites under both processed conditions was still lower than that of as–cast composites.

If you’re like many people, when you hear the word “aluminum”, you think of everyday convenience items that, while incredibly useful, don’t exactly convey a high-strength image. And it’s true – aluminum is a highly versatile metal – meaning it can be processed to be thin, lightweight, bendable and even crushable by human hands.

What’s less well-understood is that aluminum tube can also be some of the toughest stuff on earth. Often, the metal is used in applications where high-strength and durability are the most important considerations – from cars and trucks to building material to military vehicles. You likely trust aluminum to keep you safe and secure dozens of times a day without even knowing it.

Aluminum is about one-third the weight of steel, meaning parts can be made thicker and stronger while still reducing weight in vehicles and other applications. Depending on the alloy and processing technique used, pound for pound aluminum can be forged to be just as strong if not stronger than some steel.

Aluminum is already the second-most-used material by automakers, so your car or truck likely has a lot of aluminum in it right now, protecting you from hazards on the road. Engineers know how to work with aluminum to make parts that perform as well or better than steel parts – all while reducing vehicle weight. Aluminum is highly effective at absorbing crash energy, protecting passengers in the event of an accident. And lighter aluminum vehicles improve performance. Better handling and shorter stopping distances help drivers avoid accidents to begin with.

Aluminum is used for window frames and curtain wall in some of the world’s tallest skyscrapers – maybe even the office building you’re sitting in right now. This versatile metal is used to make planes, trains, buses, trucks – even ocean liners!

In short, every day, people around the world trust the strength of aluminum – whether they know it or not.

0 notes

Text

Laser Engraved Versatile Multipurpose Aluminum Plaques Sydney

Aluminium plaques have been around since quite a long time. You can see them in gardens, on pet memorials, in cemeteries, on vehicles and on equipment. The traditional way of preparing anodised aluminium plaques or labels is the use of photosensitive layer followed by etching and then finishing. This is messy, time-consuming and expensive too. Today, you can get even better results with laser engraving. Laser engravers are so cheap that you could even buy one to use at home or in your office if you plan business of aluminium plaques Sydney based. However, you may find it is simpler and easier to get these plaques made by a manufacturer with better equipment and capabilities. After all, there is more to plaques than just laser engraving. One has to buy aluminium sheets, cut them to the right size and anodize the cut pieces. Apart from conventional uses, there are a few unique ideas for using aluminium plaques.

Create a nameplate for your house

If aluminium is good enough and you do not insist on brass or bronze then you can easily order a nameplate in the size of your choice with font style to suit your taste. You can include a line drawing too if you like to give a unique look to your front door.

Visiting card/service card

Business executives may not like the idea of using aluminium plaques Sydney manufacturer offers as a visiting card but it is not a bad thing for those engaged in providing service and maintenance of equipment, domestic or otherwise. You can order custom aluminium plaque that carries your name, phone number and address along with blank spaces to write the date and other details. The plaque can be glued to the equipment you service and it works as a reference as well as an ad.

Card to go with a gift

Your gift wraps something nicely and then stick a paper card on the box. Use a laser engraved plaque instead. It looks classier and definitely stylish. The recipient throws away the wrapping and the box. The item is used and put away but your plaque is stored and cherished.

Labels inside your house

Think of all the things that need labelling inside your house. You would normally think of writing with an indelible marker or make use of stickers. Now think of using laser engraved plaques that serve as labels on your fridge, on various containers, in your hobby workshop, in your home office, in your garden and so on. aluminium plaques last longer than stickers or cards. Keep a blank space that can be filled with a permanent marker.

Dog tags

It is comforting to know that custom aluminium plaque carrying your dog’s name and your name and address sit comfortably around the neck of your dog. Should he be lost there is the plaque that can come to the rescue and reunite your dog with you.

Warning signs are another use for aluminium plaques Sydney manufacturer offers. Whatever the use just get them from Stickers n Things in the size you want with the design you require.

0 notes

Text

Aluminum Anodizing Method

Aluminium is an exceptional, current product. It is light-weight, does not struggle with destructive deterioration and can be completely and repetitively reused. It is swiftly replacing even more standard materials such as steel and stainless-steel across a whole array of sectors.

Anodising is simply the most effective method to protect aluminium-- enabling the all-natural metal aspect of aluminium to be protected against the results of pollution as well as corrosion for the life time of the task or product.

Anodising is the makeover of the surface of the aluminium right into an organized oxide layer. Anodised aluminium remains pure aluminium, enabling it to be totally and also consistently recycled with easy re-melting.

Anodising brings substantial added value to the material, giving it exceptional homes such as resistance to deterioration, resistance to abrasion and sturdiness.

Anodising boosts the esthetic quality of aluminium over the really lengthy term-- the genuine metallic lustre of the steel is totally maintained in a perfectly identical surface area, which can coloured to achieve the called for surface finish.

Anodising is a technology which has already existed for 80 years as well as its extraordinary performance has actually been confirmed in the most aggressive and aggressive environments. Typically based on the batch procedure, level rolled aluminium can likewise anodised in coil form before improvement, allowing lighter gauge metal to be treated as well as guaranteeing optimum and economy with excellent homogeneity of element.

The Batch Anodising Process

A batch anodising line includes a series of upright therapy baths. For architectural applications, bathrooms will certainly be generally some 7-- 8 meters long (to allow the cost-effective therapy of accounts), 1.25 -2.0 metres vast (to permit the treatment of sheets) and 500 mm depth to permit the therapy of pre-fabricated areas.

Extruded, cast or sheet aluminium, in semi-finished or completed kind, is connected to a conductive rack with clamps. The aluminium is then submersed in the different therapy baths to undergo a collection of chemical as well as electrochemical processes. After the final treatment stage, the anodised parts are eliminated from the rack and packed for delivery to the client.

It is rapidly replacing more conventional products such as steel and also stainless steel across a whole range of industries.

Extruded, cast or sheet aluminium, in semi-finished or completed kind, is attached to a conductive shelf with clamps. The aluminium is after that immersed in the different treatment baths to undertake a collection of chemical as well as electrochemical processes.

Meface produces anodised aluminium panels based upon your style using your drawing documents with the guaranteed ideal on the market sub-surface printing top quality. Durable aluminium front panels for a variety of gadgets, equipment as well as control systems. Personalized Anodised Aluminium panels made in the UK as well as reduced making use of CNC milling equipment precisely to your requirements and assumptions. Every Front Panel is scratch proof, can withstand heat or cool as well as immune to severe solvents. Order prototypes, Low Volume or thousands of panels less costly.Find out more about it on website www.meface.co.uk

0 notes

Text

aluminum tread plate manufacturers and suppliers near me

aluminum tread plate manufacturers and suppliers near me

Huawei aluminum is 18 years aluminum tread plate manufacturers and suppliers.

Huawei aluminum tread plate is durable and corrosion-resistant. Available in 3003 Tread-Brite as well as 5086 and 6061 alloys, our extensive inventory includes both bright and mill-finished plate, in both embossed and diamond tread forms.

Our plate processing services deliver custom-sized aluminum tread plate to your specifications. With in-house processing centers in multiple markets and an extensive North American distribution network, Huawei has the inventory and processing capabilities to deliver the aluminum tread plate you need, when you need it.

As a China-based aluminum tread plate manufacturer and supplier, we also provide aluminium slit coil, aluminum strip, coated aluminum coil, aluminum sheet, anodising aluminum coil, embossed aluminum sheet, etc. For more detailed information, please feel free to contact us at Huawei. We look forward to working with you.

0 notes

Text

Roofing Company In Corpus Christi Publishes Informative Blog Post On Metal Roof Coatings

Texas based Galvan Builders, a trusted roofing contractor in Corpus Christi and the surrounding areas, has recently published an informative blog post on their website highlighting a number of coating options that can help to extend a metal roof’s lifespan.

“Metal roofs, no matter the brand, product type, or color, are only a good one if it is coated properly. Roof coatings serve as a barrier between the elements and the topmost layer of your roofing materials. Choosing the proper coating repels water more effectively, whilst guarding your roof from excessive moisture and corrosion. Roof coatings also prevent UV damage and reflect the heat away from the roof’s surface,” says David Galvan, owner of Galvan Builders.

A metal roofing system is preferred by many because of its durability, cost-efficiency, and versatility. However, a metal roof is prone to moisture and corrosion, so choosing the correct protective layer is crucial to ensure its optimal performance. There are three good options for protecting a metal roofing, and they include painting, powder coating, and anodizing.

As noted on the blog post titled, “Should I Have My Roof Powder Coated For Extended Lifespan and Durability?,” one of the most common surface protection for metal roofs is in the form of industrial grade powder coatings. Powder coating uses a process of electrostatically charged, or liquidized application of a dry powder. Once applied, the coating is baked in an oven to set, bond, and cure the coat. This process has been used for decades in both commercial and residential applications. For metal roofs, powder coating is used to extend the metal’s lifespan by protecting it from moisture, corrosion, weathering, and other external factors. Powder coating is an incredibly durable finishing technique that creates a customized look and protects surfaces for years with little to no upkeep.

Meanwhile, anodizing is another preferred coating technique for metal roofings. Anodized aluminum roofing has a protective surface coating of aluminum oxide that is applied via an electrochemical process. Because it is durable and weather-resistant, anodizing is a common, effective, and long-lasting protection for applications like standing seam metal roofing. Generally, the thicker the anodic coating, the longer it lasts. Anodic coatings create a hard and wear-resistant layer that effectively protects the underlying metal. Anodisation is not purely for protection though, because certain pre-treatments can also be applied so that the coating can take on various colors. Most importantly, the oxide layer is fully integrated in the material and forms a strong molecular compound that fully protects the metal surface from any elements that can cause corrosion.

Lastly, painting can be used to protect metal roof surfaces. Galvan Builders recommends choosing factory-painted metal roof sheets rather than doing a DIY application. He points out that polyvinylidene fluoride (PVDF) works exceptionally well on metal roofing even in harsh weather environments. PVDF coatings are based on resin and exhibit outstanding weathering, color retention, and durability. They are not only resistant to extreme weather, but also to chemicals, UV light, flaking, and chalking. In addition, there are also water based PVDF alternatives that can be used to recoat any exposed metal roof surfaces. Instead of replacing the roof with a new one, recoating can be done because it is cheaper and more economical. “The use of PVDF coating is becoming more and more popular not only because of its durability, but also its limitless range of color possibilities. Furthermore, some PVDF formulations can have less than 100 grams per liter VOC, which makes them more environmentally friendly when compared to other solvent systems,” Galvan said.

Those who are looking for a professional Corpus Christi metal roofing company, may connect with Galvan Builders by calling their office hotline. They are one of the most trusted metal roofing contractors in the area, with more than 36 years of experience in the construction industry. They specialize in both residential and commercial roof installation and replacement. Their services include roof repair, roof installation, gutter repair, door and window repair, and more. They also help their clients when it comes to insurance claims.

April Ocanas, in a 5 star Google review, said, “I had the best experience with Galvan Builders. My home was in need of a new roof, and the thought of finding an honest construction company was unheard of. We interviewed many companies and didn’t feel comfortable with any of them, that is until we met with David and Dina Galvan. They were honest and humble, and went out of their way to help us, and meet our needs and price point. Their work is top notch and done in a timely manner. I highly recommend them and will use them again for any of our future construction needs.”

More information can be found on the contractor’s website. Alternatively, customers may send an email or call their office hotline to request a free quote. Lastly, interested parties may connect with Galvan Builders through their official social media pages to be updated with their latest announcements.

{ "@context": "http://www.schema.org", "@type": "RoofingContractor", "name": "Galvan Builders", "url": "https://galvanbuilders.com", "logo": "https://galvanbuilders.com/wp-content/uploads/2019/02/Galvan-Builders-Construction-logo.png", "priceRange": "$$", "description": "Galvan Building is a local roofing contractor in Corpus Christi, TX specializing roof replacement, roof repairs, insurance claims with thirty-six years of roofing experience. ", "address": { "@type": "PostalAddress", "streetAddress": "4938 Williams Drive ", "addressLocality": "Corpus Christi", "addressRegion": "TX", "postalCode": "78411", "addressCountry": "United States" }, "geo": { "@type": "GeoCoordinates", "latitude": "27.7101129", "longitude": "-97.3848788" }, "hasMap": "https://goo.gl/maps/x7BnC35Zieu6VAGD9", "openingHours": "Mo 09:00-17:00 Tu 09:00-17:00 We 09:00-17:00 Th 09:00-17:00 Fr 09:00-17:00", "telephone": "(361) 857-4341" }

0 notes

Text

Do China suppliers have super anodized aluminum sheet

An anodized aluminum sheet falls on the category of high-tech semi-processing aluminum products, and the word “high-tech” is usually associated with developed countries in America and Europe. However, such an idea is mistaken in the field of anodizing. China suppliers are capable enough to supply anodized aluminium plates of super quality. There are even excellent blue anodized aluminum sheet manufacturers like Haomei.

Some purchasers, including those in China, might frown upon this statement. Why, then, they might ask, is it so difficult to obtain high-end anodising sheets in China? When an aluminum alloy sheet is anodized, a thin layer of aluminum oxide is formed on the surface. The thickness of the oxide is 5-30 microns, and the hard anodized film can reach 25-150 microns. Under normal circumstances, the thickness of the oxide film on the anodized surface of domestic aluminum is 7um-15um, that is, 0.07mm-0.15mm. Thickness of those for non-special uses rarely exceeds 12um, because thicker oxide film means higher cost and price eventually. It is not that China cannot make thicker and better anodized aluminum sheet pieces, but that our current consumption level and demand cannot afford this price. The oxide film is a very uniform, delicate and precise aluminum oxide protective layer. The use effect can be fully achieved as long as it is more than 7um in use in China.

Anodizing aluminium plates from China suppliers have the following features.

(1) Good processing ability: the anodized aluminum plate is highly decorative, moderate in hardness, and can be easily bent and formed for continuous high-speed stamping, which is convenient for direct processing it into products without further surface treatment, and greatly shortens the production cycle and reduce product production costs.

(2) Good weather resistance: Anodized aluminum plate with standard thickness oxide film (3μm) will not change color for a long time in the room. It will not corrode, oxidize or rust. An anodized aluminum plate, like a red anodized aluminum sheet with thick oxide film (10μm), can be used outdoors without changing colors under long-term exposure to sunlight.

(3) Strong metal feeling: An anodized aluminium plate has high surface hardness, good scratch resistance, paint-free surface and modern metal feeling, which improve its product grade and added value. If the sheet is anodized, it’s more popular, for a reflective aluminum mirror sheet has an extra advantage in decoration.

(4) High fire resistance: As pure metal products, the sheets have no paint or any chemical substances on the surface, no combustion at 600 ° C, no toxic gas, and meet the requirements of fire protection and environmental protection

(5) Strong anti-fouling property: No fingerprints or stain marks will be left on the surface. Even though there are stains, they are easy to clean, and no corrosion spots would be left on the surface.

Haomei anodized aluminium sheet products cover a wide range of application, made into metal aluminum ceiling, curtain wall aluminum plates, aluminum plastic panels, fireproof panels, honeycomb aluminum plates, aluminum veneer, electrical panels, cabinet panels, furniture panels and so on.

Reprinted from https://www.aluminum-coil.net/do-china-suppliers-have-super-anodized-aluminum-sheet.html

0 notes