#Surface Slitter Rewinder

Link

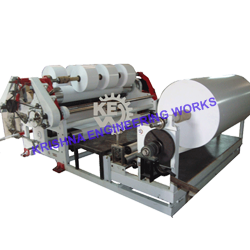

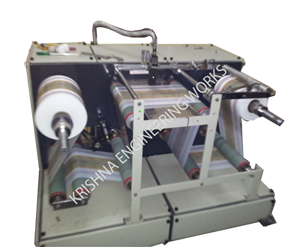

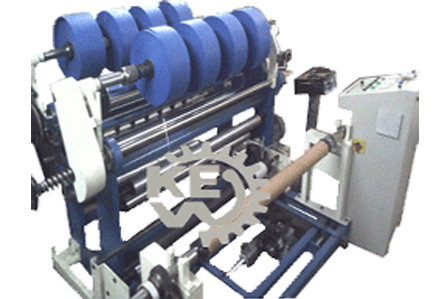

We have been successfully Manufacturing, Exporting & Supplying all types of Doctoring Slitting Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing. Our Doctoring Slitting Rewinding Machine is featuring on spending less power. Also, majorly used for Doctoring Slitting all types of Laminates like Foil, Paper, LDPE, HDPE, PVC. Doctoring Rewinding Machine, Doctoring Machine, Slitting Rewinding Machine, Doctoring Slitting Rewinding Machine, Slitter Rewinder Machine Manufacturer, Slitting and Rewinding Machine, Paper Rewinder Machine, Paper Slitting Machine for Sale, Surface Slitter Rewinder, Paper Slitting and Rewinding Machine, Paper Rewinder Machine Manufacturers, Slitting and Rewinding, Slitting Rewinding, BOPP Tape Slitting Rewinding Machine, Aluminium Foil Slitting Machine, Thermal Paper Slitter Rewinder, Roll Slitter Rewinder, Paper Slitting Rewinding Machine, Aluminium Slitting Machine, Paper Roll Slitter Rewinder, Paper Rewinder for Sale

#Doctoring Rewinding Machine#Doctoring Machine#Slitting Rewinding Machine#Doctoring Slitting Rewinding Machine#Slitter Rewinder Machine Manufacturer#Slitting and Rewinding Machine#Paper Rewinder Machine#Paper Slitting Machine for Sale#Surface Slitter Rewinder#Paper Slitting and Rewinding Machine#Paper Rewinder Machine Manufacturers#Slitting and Rewinding#Slitting Rewinding#BOPP Tape Slitting Rewinding Machine#Aluminium Foil Slitting Machine#Thermal Paper Slitter Rewinder#Roll Slitter Rewinder#Paper Slitting Rewinding Machine#Aluminium Slitting Machine#Paper Roll Slitter Rewinder#Paper Rewinder for Sale

1 note

·

View note

Link

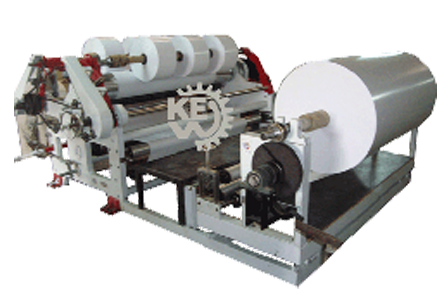

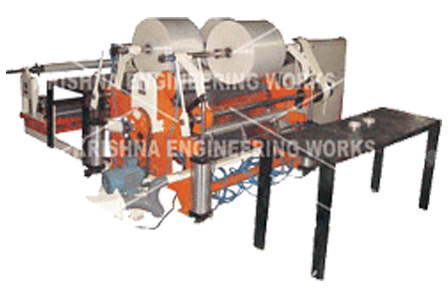

We are the manufacturer of High-Performance Slitter Rewinder Machine for every type of material like Fabric, Paper, Film, Jumbo Slitting Rewinding Machine, Heavy Duty Slitter Rewinder Machine. We are engaged in Slitter Rewinder Machine with hi-speed features. For Slitting Machine, we have processed all types of material like LD, PVC, Paper, Film, Cloth, Nylon, etc. We have more than 5000 installations of Slitter Rewinding Machine all over the world. For Doctoring Rewinding Machine, we have more than 4000 installations all over India & overseas. slitter rewinder machine, slitter rewinder, slitter rewinder machine manufacturer, slitter rewinder for sale, used slitter rewinder, paper slitter rewinder machine, slitter rewinder manufacturers, film slitting machine, surface slitter rewinder, slitting and rewinding machine, used slitting machine for sale, duplex slitter rewinder, used paper slitting machine for sale, turret slitter rewinder, foil slitting machine, thermal paper slitting rewinding machine, used slitter rewinder for sale, center slitter rewinder, center surface slitter rewinder, kraft paper slitting machine, mini Bopp tape slitting rewinding machine, paper slitting machine for sale, slitter rewinder used, paper slitter rewinder, thermal paper slitter rewinder, roll slitter rewinder, jumbo roll slitter rewinder, aluminum foil slitting machine, second-hand slitter rewinder machine, paper slitting and rewinding machine, slitter and rewinder, slitter rewinder machine price, roll slitting machine for sale

#slitter rewinder machine#slitter rewinder#slitter rewinder machine manufacturer#slitter rewinder for sale#used slitter rewinder#paper slitter rewinder machine#slitter rewinder manufacturers#film slitting machine#surface slitter rewinder#slitting and rewinding machine#used slitting machine for sale#duplex slitter rewinder#used paper slitting machine for sale#turret slitter rewinder#foil slitting machine#thermal paper slitting rewinding machine#used slitter rewinder for sale#center slitter rewinder#center surface slitter rewinder#kraft paper slitting machine#mini Bopp tape slitting rewinding machine#paper slitting machine for sale#slitter rewinder used#paper slitter rewinder#thermal paper slitter rewinder#roll slitter rewinder#jumbo roll slitter rewinder#aluminum foil slitting machine#second-hand slitter rewinder machine#paper slitting and rewinding machine

0 notes

Link

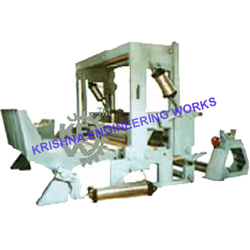

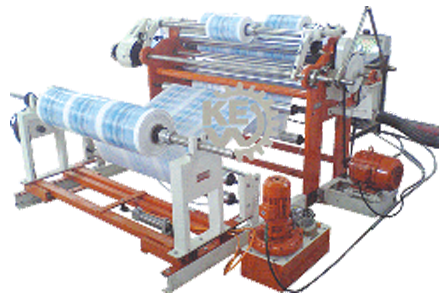

Krishna Engineering Works is one of the best Manufacturer, Exporter, and Supplier of Rewinding Machine, Roll to Roll Processing Machines for various types of process like Rewinding Machine, Slitting, Doctoring Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Rewinding Machine, Folding, Fold Open, Converting, Corona Treatment, Inspection, Trim Rewinding Machine, Printing, Coating, Laminating, Flexo Printing, Batch Printing, Flexible Packaging, Slitter Rewinder Machinery, Core Cutter, all types of Industrial Rollers, Printing machinery.

All our Rewinding Machine and Roll to Roll Converting Machines technically designed with heavy-duty and accurate features for different materials like Paper, Film, Nylon, Textile / Fabric, Non-Woven, Foil, Flexible Packaging, Tyre Cord, Technical Textile.

Our range of Different types of Rewinding Machine, Roll to Roll Processing Machines is capable to process all types of Laminates like Film, Paper, Aluminium, Foil, PVC, Plastic, LD, LDPE, PP, BOPP, Cloth, Fabric, and many more. Rubber Roller Manufacturer, Slitter Rewinder Machine, Roll to Roll Processing Machines, Roll to Roll Coating, Industrial Rubber Rollers, Slitter Rewinder Machine Manufacturer, Slitter Rewinder for Sale, Slitter Rewinder Manufacturers, Paper Slitter Rewinder Machine, Rubber Rollers Suppliers, Film Slitting Machine, Surface Slitter Rewinder, Slitting and Rewinding Machine, PU Roller Manufacturer, Roll to Roll Sputtering, Thermal Paper Slitting Rewinding Machine, Industrial Rollers Manufacturers, Mini BOPP Tape Slitting Rewinding Machine, Slitter Rewinder Machine Price

#Rubber Roller Manufacturer#Slitter Rewinder Machine#Roll to Roll Processing Machines#Roll to Roll Coating#Industrial Rubber Rollers#Slitter Rewinder Machine Manufacturer#Slitter Rewinder for Sale#Slitter Rewinder Manufacturers#Paper Slitter Rewinder Machine#Rubber Rollers Suppliers#Film Slitting Machine#Surface Slitter Rewinder#Slitting and Rewinding Machine#PU Roller Manufacturer#Roll to Roll Sputtering#Thermal Paper Slitting Rewinding Machine#Industrial Rollers Manufacturers#Mini BOPP Tape Slitting Rewinding Machine#Slitter Rewinder Machine Price

0 notes

Link

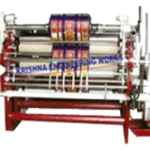

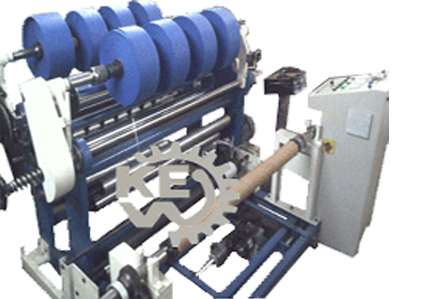

We have been successfully Manufacturing, Exporting & Supplying all the types of Slitting Rewinding Machine, Surface Slitting Rewinding Machine is the most commonly used machine type. All different types of Films & Paper Materials can be processed in our Surface Winding Slitting Machine. Slitter Rewinder Machine with heavy duty Rubber Roller Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Automatic Slitting Rewinding Machine.

#Surface Slitting Rewinding Machine#Surface Slitting Rewinding#Slitting Rewinding Machine#Slitting Rewinding#Slitter Rewinder Machine#Slitter Rewinder#Slitter Rewinder Machine Manufacturer#High Speed Slitting Rewinding#High Speed Slitting Rewinding Machine#Slitter Rewinding Machine

0 notes

Link

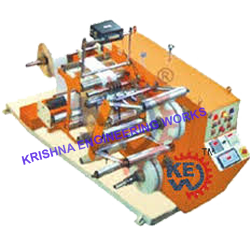

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of Metalizable Sandwich Lamination film rewinder machine. Metallised films are produced by the process of coating of Aluminium metal on the film’s surface under high vacuum Metallised films use vacuum sputtering techniques to coat a dielectric film with a metal composition. For more information about product or any types of query please visit our website: kew.net.in for contact us: [email protected]

#Slitter Rewinder Machine Manufacturer#Film Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine at best price#Lamination Film Slitter Rewinder Machine

4 notes

·

View notes

Text

Elite Cameron

Elite Cameron manufactures slitting, rewinding, coating and laminating machines which are incredibly versatile and capable of processing a broad range of materials such as delicate non-wovens, flexible packaging, self-adhesive tapes, laminates, papers, foils, rubber, and plastics. We offer a complete line of slitter rewinders including turret rewinders, surface winders, duplex slitters, center winders along with other converting equipment such as hot melt coaters, core cutters, laminators and specialty converting equipment. Our machines are available worldwide. For more information contact our sales & engineering teams in the UK or USA offices.

http://www.elitecameron.com

Facebook

Twitter

Youtube

Linkedin

Google Maps

Google Maps

1 note

·

View note

Link

We are focus on quality of Slitter Rewinder Machine Manufacturer for Film and Paper Slitting Rewinding Machine, Hi-Speed Slitting Rewinding Machine on custom requirements applications from India. Different types of shaft type Slitter Rewinder Machine such as Surface Slitting Machine, Thermal Paper Slitter Rewinder Machine, Rewinding Machine for label etc. Slitter Rewinder Machine Materials, Plastic Slitter Rewinder, Paper Slitter Rewinder, PVC Slitter Rewinder, Bopp Film Slitter Rewinder Machine.

#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitting rewindier machine#Slitter rewinding machine#Rewinding Machine#Slitting Rewinding#Slitter Rewinder Machine Manufacturer#Slitting Rewinding Machine manufacturer

3 notes

·

View notes

Link

The Slitter Rewinder Machine Market business report gives holistic view of the market and allows benchmarking all the companies in the industry, not just the ones that are focused. The research report is a significant repository for customers that contain the latest market intelligence which supports the strategic investment decisions. This business report includes both qualitative and quantitative aspects of the industry in each region and country mentioned in the market research study.

Few of the leading organizations’ names are listed here- Atlas Converting Equipment, Kampf, ASHE Controls Limited, Merchant logo, GOEBEL IMS, Parkinson Technologies Inc, Pasquato cutting machines, Universal Converting Equipment, Parkland International, Soma Engineering, Varga-Flexo Co, Grafotronic Sp. z o. o., Human–computer interaction, Revomac Industries, Furi Precision Machinery, Comexi, HAGIHARA INDUSTRIES INC., Deacro Industries and Temac among other domestic and global players.

>>>>To know How COVID-19 Pandemic Will Impact This Slitter Rewinder Machine Market| Download PDF Sample copy of the Report https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-slitter-rewinder-machine-market

Let’s know why the report is worth considering-

Slitter rewinder machine market is expected to be growing at a growth rate of 3.90% in the forecast period of 2020 to 2027. Slitter rewinder machine market report analyses the growth, which is currently being growing due to the rising demand for slitter rewinder machines for converting paper.

Machines include paper machines, plastic films, aluminium foil and flexible laminates. These slitting rewinding machines are generally categorized as converting machines and are utilized by manufacturers of flexible packaging material in conjunction with rotogravure/ flexographic printing and lamination equipment for the production of laminated reels and pouches.

The growing demand for converted paper products, higher productivity attained with the high operating speed of the slitter rewinder machines, integration of two operations into one machine are some of the factors expected to drive the growth of the slitter rewinder machine market in the forecast period of 2020-2027. On the other hand, the growing demand for conversion of technical films will create several opportunities that will lead to the growth of the slitter rewinder machine market in the above mentioned period.

The high price of the center-surface winder slitter rewinder machines will act as restraints and may hamper the growth of the slitter rewinder machine market in the above mentioned period.

Performs Competitive Analysis: The Slitter Rewinder Machine Market report incorporates the detailed analysis of the leading organizations and their thought process and what are the methodologies they are adopting to maintain their brand image in this market. The report aides the new bees to understand the level of competition that they need to fight for to strengthen their roots in this competitive market.

0 notes

Link

We have been manufacturing, exporting and supplying Film Ribbon Slitter Rewinder Machine since last 25 years from India, heavy duty Coating Machine Supplier. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminum Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Non-Woven Fabric, Paper Board, Adhesive Tape, Film Ribbon, Textile Cloth, Nylon Fabric, Micro Tape, Coated Paper, Ice Cream Cup Paper, Fax Roll, Laminated Film, Cling Film, Duct Tape, Mask Tape, Rubber, Tarpaulin, Tube, etc. makes us most experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. Our machine is an ultimate Slitter and Rewinding Machine for its accurate slitting and rewinding qualities. Slitter Rewinder Manufacturer. It ensures perfect slitting of rolls with consistent, flawless results and constant line speed. It is available in the adaptable model to suit your requirement. Our Slitter Rewinder Machine is available in Rewinder, Duplex surface slitter and Rewinder and Cantilever differential slitter and Rewinder.

#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitter Machine#Rewinder Machine#Film Ribbon Slitter#OPA Film Slitter#Film Slitter#Nylon Fabric#MICRO TAPE#Coated Paper#Slitter#Slitters#Rewinder Unwinder System#Plastic#Paper#Flexible Packaging#Flexo Machine#Unwinder System#Coating Machine

0 notes

Text

Hengxin non-woven fabric wet towel machinery

[Hengxin non-woven fabric wet towel machinery] Lianyungang Hengxin non-woven fabric wet towel Machinery Co., Ltd. is a professional manufacturer engaged in the manufacturing of printing and packaging machinery and equipment for more than ten years, and produces a series of computer slitting machines, rewinding slitting machines, etc. with the continuous exploration, innovation and development. Our factory also provides customers with a series of non-standard equipment: all kinds of coating machine transformation, production line equipped with automatic winding machine and other projects. The products sell well in more than 30 provinces and cities in China and Southeast countries, deeply best folding Utility knife favored and trusted by users at home and abroad. The main defect of slitting machine is that the speed can not be high. When it runs at high speed, it is easy to form high-speed tape dispenser blade friction of magnetic powder and generate high temperature to form magnetic powder clutch heating, thus shortening its service life. We all need to understand the characteristics of the slitter, as for its defects, which we all need to avoid as far as possible, but also difficult to avoid. The slitting machine is commonly used in paper-making machinery, wire and cable mica tape and printing and packaging machinery. The slitting machine is mainly used to cut the large reel mother coil into different width products. When we use the slitter, do you know what features it has? The main features of the slitter are as follows: unwinding photoelectric correction, high precision; control mode is divided into two levels: manual and automatic. The slitting machine can have two winding modes: surface coiling and central coiling; automatic safety cutter knife factory tension control is adopted for coiling and unwinding tension; tension feedback control and taper control are adopted for control modes. Round knife cutting and air knife cuttingThe cutting tool is reliable in quality and convenient in adjustment. It adopts surface center coiling. In fact, the efficiency of the slitter is related to the following factors: slitting speed, finished product rate, non operating occupation time, stability, etc. Slitting speed is an important indicator of the efficiency of slitting machine, but if the yield is low, it will not only result in low efficiency of the whole machine, but also cause the rise of cost. Similarly, if the non operation takes a long time, such as adjusting machine, setting cutter, changing tool, changing material, connecting joint, changing coil and handling problems, it is meaningless to simply increase the speed of slitter. The stability of the slitting machine, not to mention, will not only affect the efficiency of the slitter, but also affect the quality of the product, and will cause trouble and unnecessary waste to the next process. So the efficiency of slitting machine is a comprehensive concept. In the process of slitting, stable tension system is an important index to ensure the quality of products. It controls the mutual tension among unwinding, traction, slitting, winding, etc. Slitting machine is a kind of mechanical equipment which can cut the wide width paper or multi narrow width materials. It is commonly used in paper-making machinery, printing and packaging machinery. The speed of the front slitting electromagnetic clutch can not be high, because it is easy to cause friction magnetic powder and high temperature during operation, which shortens its service life. When it is seriously locked up, the machine operation is blocked, so as to produce very serious consequences. It has a serious impact on productivity. The traditional control scheme of slitting machine is to use a large motor to drive the winding shaft, and magnetic powder is added to the retractable reelBy adjusting the current of the magnetic powder clutch to control the resistance and control the surface tension of the material. Magnetic powder clutch and brake is a kind of special automatic actuator. It transfers torque through magnetic powder filled in working gap. Changing magnetic current can change magnetic state of magnetic powder and adjust torque transmission. In addition, the production process is also a weak link. In addition, the production equipment, in addition to some general machine tools, also needs some special equipment for making slitting machine. Automatic control part: at present, the automation level of domestic slitting machine is still at the middle and lower level. Although the domestic control original equipment has been widely used and the price is relatively low, the domestic Slitter manufacturers are far behind the level of foreign developed countries in the depth of use, especially in the control system and the structure of the slitter, and the materials cut by the lack of organic The combination of. Frame structure: domestic Slitter manufacturers should put their energy into the research of slitting machine on the frame structure, and plan more reasonable slitting machine from the perspective of slitter manufacturer, so as to get rid of the plagiarism phenomenon of slitter produced, discuss and plan personalized slitting machine, so as to make different materials of scoring machine more detailed in structure To chemical. It can be used for stepless speed regulation from zero to synchronous speed, for fine-tuning, low-power speed regulation system sections. It is also used in uncoiling or tension control system to adjust torque by adjusting current to ensure constant tension in winding process. Slitter mainThe main advantage of the magnetic powder clutch is that it is a passive equipment, and its tension can be controlled small. The change of cutting speed affects the change of tension: when the speed is increased or decelerated, the speed of main motor changes. First of all, it causes the instantaneous change of material tension from the unwinding traction to the winding section, and it must take a period of time for the material to vibrate slightly to make the tension stable gradually. The transmission mechanism of the slitting machine is unbalanced and the air pressure is unstable.

0 notes

Text

Field Service Mechanic - Paper Converting Equipment - Paterson, NJ

Perform installation, maintenance, and repair work on one or more of the following equipment: Turret Slitter Rewinders; Surface Slitter Rewinders; Duplex Slitter Rewinders; Single Shaft Slitter Rewinders; Salvage Rewinders; Continuous Winders; Surface Winders; Turret Winders; Cantilevered Winders; and similar. Additionally: Schedule and perform Preventative Maintenance. Maintain service logs and internal service records. Resolve delivery issues. Ensure proper calibration of tools and test equipment. Train and guide junior service technicians. Order and manage repair parts. Ideal candidate should be familiar with one or more of the following subcomponents: TENSION CONTROLS: Manual Tension Controls Diameter Sensors Dancer-roll Controls Closed Loop Transducer Roll Controls BRAKES & DRIVES: Pneumatic Puck Style Brakes Magnetic Particle Brakes Low Tension AC Vector Drives Servo Motor Drives DRIVES & MOTORS: Stepper Drives Servo Drive Brushless Servos Linear Motors Rotary Motors POSITION REQUIRES TRAVEL THROUGHOUT THE UNITED STATES AND CANADA Excellent compensation, earning potential to $80,000 to start with generous hourly rate and overtime potential. Company paid medical, health, dental, and vision benefits. Ability to advance within the company. Holiday bonuses, paid time off, 401(k) with match, vacations, and more! For complete details contact Nicholas Occhipinti at: (609) 584-9000 ext 240 Or submit resume online at: dmc9.com/nao/app.asp Or email to: 1000045837_10007368 AT najbcareers302.com Please reference #41386165 when responding. Education Requirements: High School Minimum Experience Requirements: 2-5 years Job City Location: Paterson Job State Location: NJ Job Country Location: USA Salary Range: $80,000to $120,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Field Engineer Maintenance Field Service Technician Specialist Paper Converting Machinery Mechanic Coating Laminating Equipment Winding Unwinding Bags Envelopes Packaging Perforators Cutters PLCs Allen Bradley #DiedreMoire #FieldServiceJobs #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499.

Reference : Field Service Mechanic - Paper Converting Equipment - Paterson, NJ jobs

from Latest listings added - JobsAggregation http://jobsaggregation.com/jobs/technology/field-service-mechanic-paper-converting-equipment-paterson-nj_i10296

0 notes

Link

We are experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. High speed and heavy duty Automatic Slitting Rewinding Machine Manufacturer on demand of client’s requirement and machine specific application and material. Slitting of all types of Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Surface Slitting Rewinding Machine, Label Slitting Rewinding Machine, Cantilever Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine.

#Automatic Slitting Rewinding Machine#Automatic Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Mini Cantilever Slitter Rewinder Machine#Rubber Slitter Rewinder Machine#Cantilever Slitter Rewinder Machine#Label Slitting Rewinding Machine#Surface Slitting Rewinding Machine#High Speed Slitting Rewinding Machine#Woven Sack Slitting Rewinding Machine#Plastic Slitting Rewinding Machine

2 notes

·

View notes

Text

Field Service Mechanic - Paper Converting Equipment - Paterson, NJ

Perform installation, maintenance, and repair work on one or more of the following equipment: Turret Slitter Rewinders; Surface Slitter Rewinders; Duplex Slitter Rewinders; Single Shaft Slitter Rewinders; Salvage Rewinders; Continuous Winders; Surface Winders; Turret Winders; Cantilevered Winders; and similar. Additionally: Schedule and perform Preventative Maintenance. Maintain service logs and internal service records. Resolve delivery issues. Ensure proper calibration of tools and test equipment. Train and guide junior service technicians. Order and manage repair parts. Ideal candidate should be familiar with one or more of the following subcomponents: TENSION CONTROLS: Manual Tension Controls Diameter Sensors Dancer-roll Controls Closed Loop Transducer Roll Controls BRAKES & DRIVES: Pneumatic Puck Style Brakes Magnetic Particle Brakes Low Tension AC Vector Drives Servo Motor Drives DRIVES & MOTORS: Stepper Drives Servo Drive Brushless Servos Linear Motors Rotary Motors POSITION REQUIRES TRAVEL THROUGHOUT THE UNITED STATES AND CANADA Excellent compensation, earning potential to $80,000 to start with generous hourly rate and overtime potential. Company paid medical, health, dental, and vision benefits. Ability to advance within the company. Holiday bonuses, paid time off, 401(k) with match, vacations, and more! For complete details contact Nicholas Occhipinti at: (609) 584-9000 ext 240 Or submit resume online at: dmc9.com/nao/app.asp Or email to: 1000045837_10007368 AT najbcareers302.com Please reference #41386165 when responding. Education Requirements: High School Minimum Experience Requirements: 2-5 years Job City Location: Paterson Job State Location: NJ Job Country Location: USA Salary Range: $80,000to $120,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Field Engineer Maintenance Field Service Technician Specialist Paper Converting Machinery Mechanic Coating Laminating Equipment Winding Unwinding Bags Envelopes Packaging Perforators Cutters PLCs Allen Bradley #DiedreMoire #FieldServiceJobs #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499.

Reference : Field Service Mechanic - Paper Converting Equipment - Paterson, NJ jobs

Source: http://jobrealtime.com/jobs/technology/field-service-mechanic-paper-converting-equipment-paterson-nj_i11010

0 notes

Link

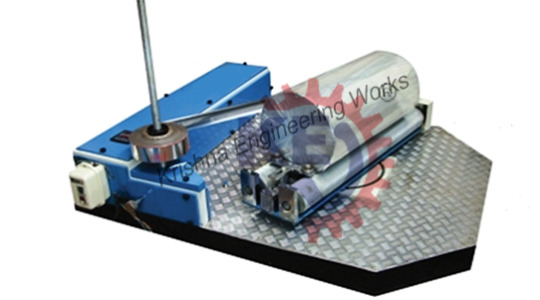

Slitter rewinder machines are designed for EVA Films with high quality and heavy duty equipment from last 25 years, India. EVA 1800 matte cast medical-grade EVA film with different types of Film Thickness (mm) 0.15, 0.19, 0.25, 0.33. Our Film slitter rewinder machines are used for EVA copolymers, also, used in many applications including. Most versatile, model providing combination of Duplex Center cum Surface Rewind System. Constantly flawless slit rolls by providing center driver drum to maintain. Fixed minimum distance between slitting and rewind point. Constant Line Speed causes constant tension rolls. Two Rewinding Shafts carried on swinging arms are center driven through adjustable slipping clutch. Counter Balance System to adjust the pressure between rewind reels and center drum. Suitable for off caliper / slippery / stretchy material. In special case, rewinding shaft can be supplied with provision of individual different slip assembly for each slit reels. Slitting methods as per customer requirement like: Scissor cut/crush cut (Circular knives) / Razor blade slitting system. https://youtu.be/dzoyR9rKV58

0 notes

Link

Heavy Duty and Light Duty Metallized Polyester Film Slitter Rewinder Machine We are award winning company of Slitting Machine Manufacturer, Exporter. Different types of films like, Chemical Metallized Polyester Film, Metallized Polyester Film Slitter Rewinder Machine, Metalized Polyester Film, Synthetic Metallized Polyester Film, and Corona Metalized Polyester Film. All our slitter Rewinder machines designed with heavy duty and high quality equipment for different types of applications in various applications. Our machine is an ultimate Slitter and Rewinder Machine for its accurate slitting and rewinding qualities. It ensures perfect slitting of rolls with consistent, flawless results and constant line speed. It is available in adaptable model to suit your requirement. Our Slitter Rewinder Machine is available in Rewinder, Duplex surface slitter and Rewinder and Canti lever differential slitter and Rewinder. Our Slitting Rewinding Machine is renowned for its accurate slitting at a higher speed and vibration less working.

#Film Slitter Rewinder Machine#Slitting Machine#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitter Rewinder#Slitter Machine#Slitters#Metallized Polyester Film Slitter#Slitter#BOPP Film#Paper Slitter Machine#Roll Slitting Rewinding Machines#Fabric Slitter Rewinder Machines#Winder Rewinder#Winding Rewinding Machine#Rewinder Unwinder Machine#Film Slitter Rewinder Machine Manufacturer#Film Slitter Machine Supplier

1 note

·

View note

Text

Field Service Mechanic - Paper Converting Equipment - Paterson, NJ

Perform installation, maintenance, and repair work on one or more of the following equipment: Turret Slitter Rewinders; Surface Slitter Rewinders; Duplex Slitter Rewinders; Single Shaft Slitter Rewinders; Salvage Rewinders; Continuous Winders; Surface Winders; Turret Winders; Cantilevered Winders; and similar. Additionally: Schedule and perform Preventative Maintenance. Maintain service logs and internal service records. Resolve delivery issues. Ensure proper calibration of tools and test equipment. Train and guide junior service technicians. Order and manage repair parts. Ideal candidate should be familiar with one or more of the following subcomponents: TENSION CONTROLS: Manual Tension Controls Diameter Sensors Dancer-roll Controls Closed Loop Transducer Roll Controls BRAKES & DRIVES: Pneumatic Puck Style Brakes Magnetic Particle Brakes Low Tension AC Vector Drives Servo Motor Drives DRIVES & MOTORS: Stepper Drives Servo Drive Brushless Servos Linear Motors Rotary Motors POSITION REQUIRES TRAVEL THROUGHOUT THE UNITED STATES AND CANADA Excellent compensation, earning potential to $80,000 to start with generous hourly rate and overtime potential. Company paid medical, health, dental, and vision benefits. Ability to advance within the company. Holiday bonuses, paid time off, 401(k) with match, vacations, and more! For complete details contact Nicholas Occhipinti at: (609) 584-9000 ext 240 Or submit resume online at: dmc9.com/nao/app.asp Or email to: 1000045837_10007368 AT najbcareers302.com Please reference #41386165 when responding. Education Requirements: High School Minimum Experience Requirements: 2-5 years Job City Location: Paterson Job State Location: NJ Job Country Location: USA Salary Range: $80,000to $120,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Field Engineer Maintenance Field Service Technician Specialist Paper Converting Machinery Mechanic Coating Laminating Equipment Winding Unwinding Bags Envelopes Packaging Perforators Cutters PLCs Allen Bradley #DiedreMoire #FieldServiceJobs #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499.

Reference : Field Service Mechanic - Paper Converting Equipment - Paterson, NJ jobs

from Latest listings added - cvwing http://cvwing.com/jobs/technology/field-service-mechanic-paper-converting-equipment-paterson-nj_i14036

0 notes