#Sandwich panel Manufacturers UAE

Text

NMSS METAL - Roofing Sheet Manufacturers Dubai

Since 2009, NMSS has dealt in Corrugated Roof & Wall Cladding Sheets, Roof & Wall Sandwich Panels, Z & C Purlin, GI Metal Decking Sheets, Fencing Panels, Dry Wall partition systems, and other valuable steel products. NMSS making its footsteps and expanding its product portfolio to lure its customers while understanding the market demands. https://www.nmss.ae

#Fencing Panel Manufacturers UAE#Insulated Panel Suppliers UAE#Corrugated Sheet Suppliers Dubai#Fencing Panel Suppliers UAE#Insulated Panel Manufacturers UAE#Cable trunking Suppliers UAE#Sandwich panel Manufacturers UAE

0 notes

Link

In this modern era, multiple options are available before the customers when it comes to the selection of the building material. Earlier, there were just a few selected materials such as stone and wood but today insulated panel manufacturers UAE can give your options. Click here. https://www.nmss.ae/blog-the-key-benefits-of-using-insulated-panels.aspx

#Cable ladder Suppliers UAE#Insulated Panel Manufacturers Dubai#Sandwich panel Manufacturers UAE#Fencing Panel Suppliers Dubai

0 notes

Text

Skylight Sheet Suppliers UAE:-

Do you want to renovate or build designer or trendy walls and roofs? We at NMSS Specialise in the field of interior, roof and wall cladding market by providing cost-effective and high-standard services to our customers to ensure the level of satisfaction of our precious clients. To know more: https://www.nmss.ae/Products/grp-translucent-sheet/single-layer-translucent-sheet/25

0 notes

Link

The majority of studies on structural behavior primarily concentrate on chilly steel sections themselves, whereas most work on chilly steel sections only takes into account the purlins operating under bending moment or pure compression. Contact Z and C purlin manufacturers Dubai. for more info visit us: https://www.nmss.ae/blog-a-cold-formed-steel-sections-definition.aspx

#Corrugated Sheet Suppliers UAE#Sandwich panel Manufacturers Dubai#Insulated Panel Suppliers UAE#Cable ladder Suppliers Dubai

0 notes

Text

Proudly Manufacturing Quality PUF Panels: MAK Prefab Steel Contracting LLC

MAK Prefab Steel Contracting LLC is one of the leading PUF panel manufacturers in the UAE. PUF (Polyurethane Foam) panels are a popular choice for building construction due to their excellent insulation properties and durability. These panels consist of an insulating foam core sandwiched between two metal sheets, providing superior thermal insulation and reducing energy consumption.

At MAK Prefab Steel Contracting LLC, we take pride in producing high-quality PUF panels that meet our clients’ exact requirements. Our PUF panels are versatile, lightweight, and easy to install, making them an ideal choice for various applications in construction, including roofing, wall cladding, cold rooms, and more.

We use advanced technology and high-grade materials to manufacture our PUF panels, ensuring their longevity and reliability. We are committed to providing our clients with customized solutions that meet their specific needs while ensuring the highest quality standards.

In addition to PUF panels, we also offer a wide range of other steel products, including steel structures, portable cabins, and prefabricated buildings. With our expertise and experience in the industry, we can provide our clients with innovative and cost-effective solutions for their construction needs.

If you’re looking for reliable PUF panel manufacturers in the UAE, look no further than MAK Prefab Steel Contracting LLC. Contact us today to discuss your project requirements and find out how we can help you with your construction needs.

0 notes

Text

Significance of Advanced Prefab Modular Housing Solutions for Your Commercial Needs

When you work in the construction industry, you must keep an eye on the newest design tools and techniques. The prevalence of prefab modular homes in Saudi Arabia has modified the construction process. They are an advanced form of construction consisting of a factory-like setting. Today, many small and large-scale businesses prefer prefab modular homes for dynamic, quick, and cost-effective solutions. Today, modular homes are widely popular due to their enormous benefits. Whether revamping existing property or getting affordable housing solutions, prefab modular homes have everything. Furthermore, prefab modular homes are perfect for designing holiday homes and even permanent residences. Read further to know the advantages of prefab modular home they provide.

Energy-Efficient Structures- Need Less Maintenance Costs

When you are considering prefab modular homes in Saudi Arabia for your construction practice, you save valuable money and time. Prefab modular homes are extremely compact and made from quality-assured sandwich panels. Made from high-quality polyurethane foam, sandwich panels consist of monolithic structures that minimize excess heat dissipation.

Besides, they are brilliant weather-resistant panels that do not undergo cracking, discoloration, and rusting. You can blindly go for prefab modular homes without having to spend huge maintenance costs.

Good Fireproof Structures-Prevent Fire Accidents

Before you decide to invest in prefab modular homes, make sure they are 100% fire-resistant. Prefab modular homes consist of a standard Class-A fire-grade feature that resists uncertain fire breakouts. Besides, prefab modular homes are full-fledged construction models that help you cater to your specific design needs. Such advanced structures mainly comprise cabinet styles, solid surface countertops, plumbing fixtures, and ceramic fixtures.

Less Installation Time

One key factor that makes prefab modular homes special is their hassle-free installation time. Integrated with durable steel framed construction, they are easy to install and maintain. They can be easily assembled and disassembled in less time. Moreover, no extra material or labor costs take place.

If you plan to install high-graded prefab modular homes for your commercial needs, rely upon TSSC today. We are one of the premium manufacturers of prefab modular homes in the UAE. TSSC's prefab modular homes are designed to perfect accuracy and functionality.

Trust TSSC today for Investing in High-Graded Prefab Modular Homes

Welcome to TSSC. We are one of the trustworthy and eminent manufacturers of prefab modular homes in Saudi Arabia. TSSC has a certified team of professionals having years of knowledge and skills in designing prefab modular homes. Established in 1975, TSSC leaves no stone unturned in providing you with the best-in-class building and construction materials. Some of the materials include- engineered refrigeration systems, roofing and cladding solutions, cold store solutions, kitchen equipment, Celsius coolers, and much more.

At TSSC, you also get lightweight, durable, and energy-efficient insulated panels. You can customize TSSC insulated panels according to specific needs and requirements. You can also book your consultation and discuss your paneling needs with the experts. Visit our website for more information.

0 notes

Text

Precast Detailing Engineering Services in the Kerak

SECD Technical Services LLC provides high-quality Precast Detailing Engineering Services in UAE major cities including Saudi Arabia, Jeddah, Riyadh, Jordan, Bahrain, Qatar, Doha. Precast Panel Detailing Services, often known as precast concrete, is an important element of the construction industry's history. We specialise in turning 2D drawings into a coordinated and clash-free 3D model data that can be used to better comprehend overall construction, comply to building codes, reduce waste, and speed up construction. Contractors, engineering consultants, precast manufacturers, structural engineers, and other stakeholders use Structural Precast Detailing Services to create comprehensive models and coordinate layouts. Contact Us for your next Precast Detailing Engineering CAD Services.

Precast Panel Derailing Services:

- Precast Concrete Detailing

- Concrete Panel Details

- Precast Detailing Services

- Precast Sandwich Panel Details

Click Here:

https://www.silicongcc.com/cad-services-dubai-uae/precast-panel-details.html

Contact Us:

[email protected]

#PrecastPanelDetailingCompany#PrecastPanelDetailingCADServices#PrecastPanelDetailingFirm#PrecastConceretePanelsDetailing#PrecastPanelShopDrawings#WallPanelDetailingServices#CAD#CADD#Silicongcc#Dubai

1 note

·

View note

Photo

DCD-Approved Sandwich Panels in the UAE

Our sandwich panels are made with different foam cores based on customer choice – Polyurethane (PU) and Polyisocyanurate (PIR). We manufacture both flat & corrugated panels with huge design flexibilities. The length, thickness, surface coating, & RAL colours can be personalised according to the needs of the client. It is available in mill-finish/pre-painted form. Also, we are one of the very few suppliers in the UAE manufacturing the thinnest sandwich panel dimensions (25mm & 26mm).

The United Arab Emirates is our local market. For the ultimate customer satisfaction, we provide doorstep delivery services. Presently, we supply all over the UAE, Oman (Nizwa, Sohar, Ibri, Salalah, Muscat, and Barka), Saudi, Kuwait, Qatar, Iraq, Bahrain, Sri Lanka, and Yemen.

Mail us at [email protected] to get a valid price quotation. Kindly mention the specifications and order quantity while mailing us.

https://ghoshgroups.com/sandwich-panel-supplier-manufacturer-uae-oman-saudi-iraq-kuwait/

#PolymerCoated#PU#PIR#CorrugatedSheet#SandwichPanels#MetalSheets#InsulatedPanels#DCDApproved#PVDFCoatedPanels#PolyesterCoatedPanels#GalvanizedSteelCoil

1 note

·

View note

Link

Metal and Machine is one of the Leading fencing suppliers UAE. we offers wide variety of Fencing panels, sandwich panel, purlins, c purlins, z purlins, steel sheet, aluminium sheet, that suit all your needs at affordable price.

we provides different types of fence and barricades solutions for construction, special events, and emergency response industries.

1 note

·

View note

Text

Enhance Your Interiors & Exteriors With Gypsum Works

Gypsum works enhance the beauty and utility wherever they are made. Gypsum also increases the fertility of clay soils, especially those that are weathered heavily for crop production. Gypsum decoration works can be used to create false ceilings, drywall, and gypsum plasterboard in offices, hotels, shops, industrial spaces, and other places like factories.

Ceilings are no longer a fifth wall of a room. Contemporary false ceilings are a natural choice because modern homes are more focused on aesthetics. Ceilings can be decorated with Gypsum or other materials to enhance their beauty.

Before you decide on the perfect faux ceiling, there are some things that you should consider. Gypsum is the most common and practical ceiling materials.

What Are The benefits Of Gypsum Décor?

With the help of professionals, it is easy to install ceilings with gypsum decoration.

Ceiling decoration with Gypsum provides a smooth surface that enhances the overall appearance.

Partitioning and wall decoration with Gypsum can be done cheaply and in a flexible way.

False ceilings conceal pipes, ducts, and electrical wires. They give the ceiling the appearance that it is finished and neat.

It's great for sound absorption and acoustic.

It's easy to replace or move the Gypsum board panels.

Gypsum works with a moisture resistance board is often referred to as for green-coloured boards. You can stay tension free as these are moisture resistant with green cover. The gypsum contractors suggest to use them in bathrooms, balconies kitchens, and other damp areas.

Gypsum decor when done with boards also absorbs sound within the space. This is constructed from laminated layers of polymers, wood fibres and Gypsum.

Gypsum decoration works are available when gypsum is sandwiched between two sheets of thick. These are less bulky and constructed from frames made of metal. Also you can trust them since these are quite durable. Gypsum boards are manufactured in factories where the designs are uniform to make them ideal for creating false ceilings.

Find the Gypsum Products Here:

All of these features can be found in top designs for Gypsum Ceilings from the gypsum contractors listed on Etisalat Yellow pages UAE. They sell a wide range of gypsum decoration works products including ceilings, false grid ceilings and gypsum boards to create false ceilings. Etisalat Yellow Pages UAE includes verified producers of Gypsum decorations, including the latest designs for Gypsum ceilings, gypsum decor, gypsum partitions, and all types of Gypsum board.

The gypsum decoration companies & contractors of gypsum decorations are authorized. You can trust their products and services.

0 notes

Text

Cable Trunking Suppliers Dubai - NMSS METAL

Looking for wall cladding services so that you can avoid negative effects on the building? Wall cladding is the process of layering one material on top of another material. We provide multiple services like cable ladders, tile profiling, sandwich panels, fencing, etc. Contact us for the services. https://www.nmss.ae/Products/cable-management-system/cable-trunking/28

#Fencing Panel Suppliers UAE#Insulated Panel Manufacturers UAE#Cable trunking Suppliers UAE#Sandwich panel Manufacturers UAE#Sandwich panel Manufacturers Dubai#Sandwich panel Suppliers Dubai#Cable trunking Manufacturers Dubai#Insulated Panel Manufacturers Dubai#Cable ladder Suppliers Dubai#Cable ladder Manufacturers Dubai

0 notes

Link

A corrugated panel features a wavy or rippling pattern that repeats over its design. In the United States, this was the first surplus metallic panel design. These panels are suitable for use as roofing, siding, and flooring. Corrugated panels are joined together by overlaying the sheets and attaching them using exposed fasteners. Trapezoidal ribbed panels are frequently misidentified as corrugated roofing. For more info visit us: https://www.nmss.ae/Products/gi-metal-decking-sheet/decking-sheet-75-305-profile/14

#sandwich panel Suppliers UAE#Fencing Panel Suppliers UAE#Profile Sheet Manufacturers Dubai#Corrugated Sheet Manufacturers UAE

0 notes

Text

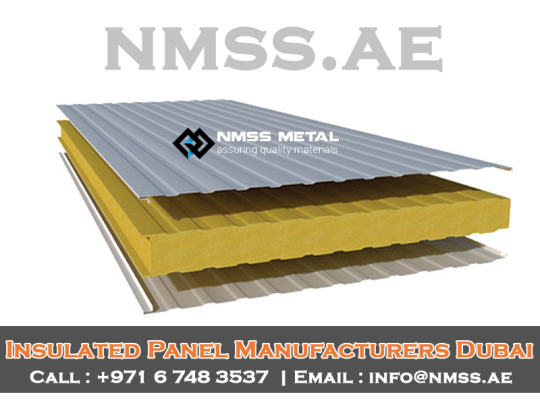

Insulated Panel Manufacturers UAE:-

Comprising of Corrugated Roof & Wall Cladding Sheet, Roof & Wall Sandwich Panel, Z & C Purlin, GI Metal Decking Sheet, Fencing Panel, Dry Wall partition system, and other valuable steel products since 2009. Aggressively expanding its product horizon, by closely understanding the existing market demand and needs of its consumers in the competitive market conditions. To view more visit: https://www.nmss.ae

0 notes

Link

There were just a few selected materials such as stone and wood but today insulated panel manufacturers UAE can give your options. It is now easy to construct walls, ceilings and floors in a proper manner. for more info visit us: https://www.nmss.ae/blog-the-key-benefits-of-using-insulated-panels.aspx

0 notes

Text

Rockwool Continuous Sandwich Panel

https://www.jinggongmachine.com/products/rockwool-continuous-sandwich-panel-production-line.html

The rockwool sandwich panel production line is one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system and polyurethane chemical reaction technology. The rock wool sandwich panel production machinery adopts advanced international roll forming technology, digital servo technology, frequency conversion vector technology and hydraulic controlling technology, automatic stacking technology.

The advantages of this rock wool sandwich panel machine are the following:

1) High automatization. The whole rockwool production line adopts one full computer integration controlling system of digital servo technology, frequency conversion vector technology and hydraulic controlling technology, which realizes whole connection, collecting control and collecting management. Adopt the cutting style of cut to length without machine stop, so that realize full automatically.

2) High efficiency. The production speed of rockwool sandwich panel machine is 3~8m/min(adjustable according to product forming requirement). The annual product capacity of this line can reach to 800000 M2 (count on the base of 250work days per year and 10 work hours per day)

3) Easy operation. Adopt collecting controlling system, using man-machine conversation. After preparing for the raw material and finishing other production requirements, input required parameters, then the machine can make the product automatically.

4) Low production cost. Developing the machine's automatization, the whole line only needs 5-8 operators to operate the machine fully, which saves much labor cost and production management cost for enterprises.

Video of Mineral/Rock wool Continuous Sandwich Panel Production Line

Zhejiang Jinggong Science and Technology Co., LTD., independently research, develop, and manufacture the PU/Rockwool sandwich panel continuous production line, which reaches the world's advanced technology, fills the blank of domestic PU/Rockwool production line manufacturing. It marks the coming of the era of localization of the PU/rock wool sandwich panel continuous production line. The PU/rock wool sandwich panel continuous production line manufactured by Zhejiang Jinggong Science and Technology Co., LTD. consists of the coiler system, filming, cutting, and slitting device, roll forming system, pre-heating device, rockwool system, rockwool upper and lower adhesive spraying system, pu side seal foaming machine, double belt system, double belt heating system, bandsaw system, stacker system, packing system, etc. It truly realized all the automatic integration production functions from pre-painted steel sheet decoiling to product's packaging. The maximum speed of this production line reaches 8 meters per minute, annual production of PU panel 1 million square meters.The whole production line is exported to Jordan, Kuwait, Tonicia, Russia, Brazil, Argentina, UAE, India, and other countries. The performance of the production line got unanimous approval and favorable comments from the customers. With the development of the construction industry, PU side seal rock wool sandwich panel will be more widely used in construction field. Jinggong Science and Technology will provide the best products and top quality service to the general customers by using most sophisticated manufacturing and technology, also make our own contribution for national and even global environmental protection, energy conservation.

Main Parameters of Rockwool Continuous Sandwich Panel Production Line

Sandwich panel specification:

Length: Min cutting length is 2.5 m

Max cutting length is 12m

Width: (see profile drawing)

Thickness: (see profile drawing)

Raw material specification:

coil thickness: 0.4~0.6 mm (steel be flat without ups and downs, deformation and bending)

sheet yield stress: ≤235MPa

coil max width: 1250 mm (tolerance±2mm)

coil max weight: 5T

coil ID: Φ500 and Φ600 mm

coil OD: Φ1000 mm

Rock wool material: fiber length is >100mm, and the fiber should be arranged vertically, volume density is ≥70kg/m3, one-piece length is ≥3m.

EPS material: volume density is ≥18kg/m3, each edge nonstraightness is ≤1mm/m, radian is ≤3mm/m, the panel surface should be flat, roughness is <1.5mm/m, EPS panel one-piece length is ≥3m.

EPS material width: min width is 1/2mm of the sandwich panel width.

Machine rockwool specification:

Work line speed: 4000m/min (adjustable)

Machine length: about 70 m

Working height: 1050 mm(panel output height)

Laminating effective length: 7.5m

Control way: adopt industrial computer PLC

Total power: about 45 kw

Power: 380V/3phase/50 Hz

control voltage: 24 V/110 V/220 V

pneumatic: 0.7 Mpa (self-prepared by the factory)

best working temperature: around 25℃

Component List of Rock Wool Sandwich Panel Production Line

No.

Component

Qty

Remarks

1

5T passive decoiler (upper forming system)

1set

Loading capacity is ≤5t

2

Upper roll forming machine

1set

With slitting and waste edge winder

Lower roll forming machine

1set

Connecting roller of upper & lower forming system

Each 1set

Platform, stair and rail of upper roll forming machine

1set

3

Rock wool transfer device

1set

Rock wool edge cutting device

1set

Dust collector

1set

4

Rock wool clamp device

Each 1 set

5

Laminator host

1set

Effective length 7.5m

6

Saw cutting system

1set

Upper & lower saw

7

Support frame

3sets

8

Electric control system

1set

0 notes

Text

Honeycomb Sandwich Material Market Analysis, Key Company Profiles, Types, Applications and Forecast to 2028

Honeycomb Sandwich Material Market is expected to show magnificent CAGR according to latest study Published by Profshare Market Research. The percentage splits, market shares, growth rate and breakdowns of the product markets are determined through using secondary sources and verified through the primary sources. The study also provides key market indicators affecting the growth of the market.

Research report includes in depth competitive analysis with shares of each player inside market, growth rate and market attractiveness in different end users/regions. Study used very precise top-down and bottom-up approach in order to validate market revenue, volume, manufacturers, regional analysis, product segments and end users/applications.

Major players in the market are identified through secondary research and their market revenues determined through primary and secondary research. Secondary research included the research of the annual and financial reports of the top manufacturers; whereas, primary research included key opinion of leaders and industry experts.

Access sample report @ https://www.profsharemarketresearch.com/inquiry/honeycomb-sandwich-material-market-report-inquiry/

Seamless product delivery to consumer has become more important than it ever were, proper value chain analysis exactly delivers the same. Supplier analysis delivers very clear picture supply- demand scenario in the market. Opportunities and threat analysis has gain significant importance in recent years primarily due to dynamic nature of industry. Analytical tools used while developing research studies includes SWOT analysis, market sizing, Porter's 5 Forces model, PESTAL analysis.

Access Full Report @ https://www.profsharemarketresearch.com/honeycomb-sandwich-material-market/

In order to completely understand market analysis, study is segmented into below categories:

Honeycomb Sandwich Material Market: Product Type

Aluminum

Steel

Titanium

Incoel

Global Honeycomb Sandwich Material Market: Competitive Analysis

Pacific Panels

Foshan Liming

Encocam Ltd

Benecor Inc.

Samia

Gill Corporation

Schweiter Technologies

Honeycomb Sandwich Material Market : Application

Aerospace

Automative

Locomotive

Marine

Regional analysis

North America : USA, Mexico, Canada

Europe: UK, Germany, France, Spain, Italy, Netherlands & Rest of Europe

Asia Pacific : China, India, Japan, Singapore, South Korea & Oceania

Latin America : Brazil & Argentina

Middle East : UAE, Qatar, Israel.

Rest of the World.

Research report includes below primary reasons that makes it very useful as one stop information point for various market scenarios.

Market estimation

Forecast 2020-28

Growth drivers

Raw material & Supply analysis

End User & Application insight

Key player’s analysis

Import & Export scenario

Challenges & Opportunities

Current & emerging market trends.

Tenders & Pricing scenario.

About Profshare:

Profshare Market Research is a full service market research company that delivers in depth market research globally. We operate within consumer and business to business markets offering both qualitative and quantitative research services. We work for private sector clients, along with public sector and voluntary organizations. Profshare Market Research publishes high quality, in-depth market research studies, to help clients obtain granular level clarity on current business trends and expected future developments. We are committed to our client’s needs, providing custom solutions best fit for strategy development and implementation to extract tangible results.

Contact :

Kalyani D

Profshare Market Research

0 notes