#Sandwich panel Manufacturers Dubai

Text

Cable Trunking Suppliers Dubai - NMSS METAL

Looking for wall cladding services so that you can avoid negative effects on the building? Wall cladding is the process of layering one material on top of another material. We provide multiple services like cable ladders, tile profiling, sandwich panels, fencing, etc. Contact us for the services. https://www.nmss.ae/Products/cable-management-system/cable-trunking/28

#Fencing Panel Suppliers UAE#Insulated Panel Manufacturers UAE#Cable trunking Suppliers UAE#Sandwich panel Manufacturers UAE#Sandwich panel Manufacturers Dubai#Sandwich panel Suppliers Dubai#Cable trunking Manufacturers Dubai#Insulated Panel Manufacturers Dubai#Cable ladder Suppliers Dubai#Cable ladder Manufacturers Dubai

0 notes

Link

The majority of studies on structural behavior primarily concentrate on chilly steel sections themselves, whereas most work on chilly steel sections only takes into account the purlins operating under bending moment or pure compression. Contact Z and C purlin manufacturers Dubai. for more info visit us: https://www.nmss.ae/blog-a-cold-formed-steel-sections-definition.aspx

#Corrugated Sheet Suppliers UAE#Sandwich panel Manufacturers Dubai#Insulated Panel Suppliers UAE#Cable ladder Suppliers Dubai

0 notes

Text

Skylight Sheet Suppliers UAE:-

Do you want to renovate or build designer or trendy walls and roofs? We at NMSS Specialise in the field of interior, roof and wall cladding market by providing cost-effective and high-standard services to our customers to ensure the level of satisfaction of our precious clients. To know more: https://www.nmss.ae/Products/grp-translucent-sheet/single-layer-translucent-sheet/25

0 notes

Link

In this modern era, multiple options are available before the customers when it comes to the selection of the building material. Earlier, there were just a few selected materials such as stone and wood but today insulated panel manufacturers UAE can give your options. Click here. https://www.nmss.ae/blog-the-key-benefits-of-using-insulated-panels.aspx

#Cable ladder Suppliers UAE#Insulated Panel Manufacturers Dubai#Sandwich panel Manufacturers UAE#Fencing Panel Suppliers Dubai

0 notes

Text

Building Excellence: TSSC Prefab Redefines Pre-Engineered Steel Structures in India

When it comes to innovation and trustworthiness, TSSC Prefab stands out in the building industry. Their influence is great because they are one of India's top producers of structures made of steel.

Did you know that TSSC Prefab's advanced manufacturing procedures have improved the nation's building efficiency by 20%? They have raised the standard for pre-engineered steel structure manufacturers India with their commitment to quality and cutting-edge technologies.

Let's go on a journey as we examine how TSSC Prefab is using unmatched quality and creativity to transform the building industry.

TSSC Prefab's Manufacturing Capabilities

TSSC Prefab's manufacturing facilities, located in the center of Sharjah, Dubai, and Abu Dhabi, are examples of industrial excellence in the building sector. Redefining the benchmarks for pre-engineered steel structures in India, TSSC Prefab offers a wide choice of products due to its decades of experience and state-of-the-art technology.

TSSC Prefab's production capability is unrestricted, along with insulated panels, rotating systems, glass systems, and prefabricated shelters. every product is made with extremely good care and attention to detail, making certain its efficiency, durability, and visible attractiveness.

Quality is paramount at TSSC Prefab. every product undergoes rigorous trying out to meet stringent fire ratings and achieve individual product certifications. With a dedication to excellence ingrained in every component of their production technique, TSSC Prefab sets the benchmark for steel structure manufacturers in India.

Advanced Manufacturing Technologies

At the forefront of steel structure manufacturing in India, TSSC Prefab introduces advanced technologies that redefine construction standards. Robor, their automated plant for continuous sandwich panel production, epitomizes innovation. Utilizing PIR and Mineral Wool applications, Robor ensures unparalleled quality in roofing and wall cladding solutions.

Robor's capabilities are unmatched, offering seamless integration of cutting, cooling, stacking, and packing stations, all fully CNC-controlled. This automated process optimizes productivity while minimizing manpower and costs.

Additionally, TSSC Prefab's Samesor® Prefab Superior technology revolutionises steel frame manufacturing for multi-storey buildings. With a combination of 3D modeling software and fully automated production machinery, Samesor® Prefab Superior produces C, U, Z, and Sigma profiles with precision and efficiency.

These superior manufacturing technologies characterise TSSC Prefab's commitment to innovation and excellence inside the production industry, cementing its role as a leader in steel structure manufacturing in India.

State-of-the-Art Aluminum and Glazing Fabrication

TSSC Prefab, an innovative steel structure manufacturer india, exhibits unprecedented expertise in aluminium and glazing fabrication. Their cutting-edge CNC machinery in their contemporary factories ensures both precision and efficiency in every product.

From curtain walls to doors, windows, and glass partitions, TSSC Prefab delivers a complete range of high-quality products. Equipped with automated CNC Cladding machines, their factories have a capacity of 200+ sqm routing per day, guaranteeing swift production without compromising on quality.

Moreover, TSSC Prefab's glass cutting line delivers precise cuts with a capacity of 400+ sqm per day. With capabilities ranging from 3mm to 16mm thickness, their glass cutting processes ensure superior accuracy and consistency.

Impact on the Construction Industry in India

With its innovative approaches, TSSC Prefab, a top steel structure manufacturer in India, has completely transformed the building sector. With its unrivalled efficiency and sustainability, TSSC Prefab has completely changed the construction industry in India by introducing pre-engineered steel structures.

Their efforts go beyond simple structures; they raise the bar for quality, sustainability, and efficiency in the industry. TSSC Prefab guarantees long-lasting and eco-friendly solutions through the use of cutting-edge production technology and maintaining stringent quality control procedures.

Future possibilities for TSSC Prefab in the Indian building industry appear bright. As the market for affordable, environmentally friendly building materials keeps growing, TSSC Prefab is expected to experience substantial growth. Their steadfast commitment to creativity and quality places them in a leading position to influence how Indian construction will develop going forward.

FAQs

1. What types of products does TSSC Prefab offer, and are they suitable for different construction needs?

TSSC Prefab offers an enormous selection of products, including glass systems, roofing systems, insulated panels, and prefabricated shelters. The above choices are quite adaptable and suit a variety of building specifications, including those for commercial and industrial structures.

2. How does TSSC Prefab ensure quality and safety in its manufacturing processes?

To guarantee the highest level of quality and safety in its manufacturing operations, TSSC Prefab follows strict quality control techniques and international standards. To fulfil industry requirements, all items also go through thorough testing and certification.

3. What role does TSSC Prefab play in promoting sustainability in the construction industry?

TSSC Prefab is dedicated to both environmental responsibility and preservation. Its products are made with the least amount of trash, energy consumption, and environmentally friendly building techniques in mind. Also, to improve the sustainability of its production processes, TSSC Prefab continually makes investments in research and development.

Want to partner up and create excellence hand in hand?

TSSC Prefab shines as a symbol of innovation in India's steel structure manufacturing sector. Their revolutionary technologies and unwavering quest for perfection have raised the bar for pre-engineered metal buildings.

Being the largest steel structure manufacturer India, TSSC Prefab constantly breaks down limitations and transforms the construction industry with its notable merchandise and innovative solutions. Partner with TSSC Prefab to elevate your construction endeavors and witness unparalleled success. Explore the distinctive edge that TSSC Prefab brings to your projects today.

#steel structure manufacturer India#steel structure manufacturer#steel structure#manufacturer#manufacturing#tssc group

0 notes

Text

Why Are ACP Sheets Considered A Modern Day Material?

ACP, an abbreviated form of aluminium composite panels, has caught the limelight of modern-day architecture and the construction sector. Ever since the dawn of civilization, humans have been in a constant search for durable and visually appealing architecture. Every civilization in history has built monuments, some for the display of power and some to carry forward the hierarchy.To achieve such monumental accomplishments, we have transformed our ways of construction several times. Starting from bricks to slabs and now to the future of construction and architecture, ACP sheets. Aluminium composite panel sheets are a layering of two thin coated aluminium sheets that are nowadays used for interiors, facades (front elevation), modular kitchens, etc.

What Are ACP Sheets And Their Modern-Day Aspect? Aluminum Composite Panel sheets are also referred to as sandwich sheets because they comprise aluminium sheets that layer close to a polyethylene care/sheet. Aluminium is a metal and polyethylene is a plastic, thus an ACP panel provides the architecture best of both worlds. The 2 core materials used in the manufacturing of ACP sheets are sandwiched together to give exceptional durability paired with beautiful aesthetics. Due to its features, they have taken the market by storm.Architects have started incorporating ACP sheets because of their long-lasting nature and versatility. ACP manufacturers offer a plethora of choices for aluminium composite panels that attract the architecture to leverage these choices and create magnificently facades in IT parks and shopping centres. For commercial places, ACP proves to be one of the biggest boons as they offer state-of-the-art performance with no compromise in customization and aesthetics.The chronology of ACP panel manufacturers started in Dubai which then commuted to Singapore and now India embarks on leveraging the same potential. Indian ACP manufacturers observe a surge in demand as commercial projects increase in number. One such example is

Areca ACP sheets manufacturers

, we have seized the opportunity and become the top ACP sheet manufacturer in India.To know More About the ACP sheet in detail, check our blog:

Why Are ACP Sheets Considered A Modern Day Material?

0 notes

Text

Precast Detailing Engineering Services in the Kerak

SECD Technical Services LLC provides high-quality Precast Detailing Engineering Services in UAE major cities including Saudi Arabia, Jeddah, Riyadh, Jordan, Bahrain, Qatar, Doha. Precast Panel Detailing Services, often known as precast concrete, is an important element of the construction industry's history. We specialise in turning 2D drawings into a coordinated and clash-free 3D model data that can be used to better comprehend overall construction, comply to building codes, reduce waste, and speed up construction. Contractors, engineering consultants, precast manufacturers, structural engineers, and other stakeholders use Structural Precast Detailing Services to create comprehensive models and coordinate layouts. Contact Us for your next Precast Detailing Engineering CAD Services.

Precast Panel Derailing Services:

- Precast Concrete Detailing

- Concrete Panel Details

- Precast Detailing Services

- Precast Sandwich Panel Details

Click Here:

https://www.silicongcc.com/cad-services-dubai-uae/precast-panel-details.html

Contact Us:

[email protected]

#PrecastPanelDetailingCompany#PrecastPanelDetailingCADServices#PrecastPanelDetailingFirm#PrecastConceretePanelsDetailing#PrecastPanelShopDrawings#WallPanelDetailingServices#CAD#CADD#Silicongcc#Dubai

1 note

·

View note

Text

TSSC is a Well Known Name in Sandwich Panel Manufacturers of UAE

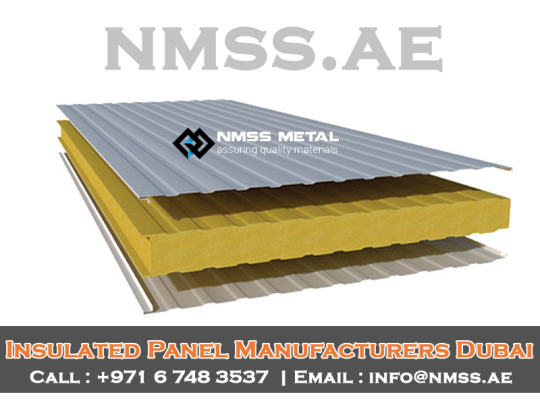

Since there are three layers in the insulated panel, thin sheets as the two covers and core in the middle, this is also known as sandwich panels. We are one of the largest manufacturers of the sandwich panel in Dubai, and our layered panel has much longer durability than ordinary ones. The layers are firmly connected to the adjacent one, that’s the reason why you can also call it a composite panel.

The outer shell of the panel is generally made out of a galvanised sheet of stainless steel or glass fibre reinforced plastic. The insulating material remains in the middle part. Polyurethane, rock wool, PIR or PUR is used as the insulating material. The covering layers are strong enough to protect the spongy core from the external environment. TSSC is famous for brand EASYWALL. Apart from this sandwich panel, there are roof panels, cold room panels, Eco room panels and more.

TSSC has become famous among the sandwich panel manufacturers in UAE because the panels are being used in diverse industries, such as construction, aerospace, automotive etc. They are lightweight, cost-effective and easy to install. They are ready to use and need no additional treatment before installing. They can be fixed on a stable structure such as a roof or walls with high insulation. Furthermore, sandwich panels of TSSC, UAE are a preferred choice for hall construction. The core material is fire resistant. Thus this brand of sandwich panel roof UAE is safe too.

The outer layer of the panel is anti-corrosive and prevents the damages caused due to UV radiation. Choose the right kind of panel from different variations based on the environmental condition where you will be installing it. The thicker materials are durable and sturdy. You can even walk on it without the fear of breakage.

But the thinner ones are not steady enough, and the thickness of this layer varies. So, it is protected by an aluminium or steel sheet to prevent damage. And both the interior and exterior layers of the panels are coated with polyester.

We, the TSSC team, deliver our orders directly from the manufacturing unit packed nicely so that no hamper causes due to transportation. If you want to invest in EASYWALL, place your order without worry. The responsibility of delivering to your destination without any damage is our responsibility.

If you need to rest the panels for some days because of logistics, remember not to lay it on the floor directly, instead use timbers or polystyrene spacers, then lie the panel on them. Make sure they are wider than the panels so that they don’t touch the floors anyhow. Don’t keep them idle for more than six months, and choose damp free, airy, clean rooms for resting. Good air circulation is needed to keep them in good condition before installation.

TSSC is an ISO 9001 certified manufacturing company based in UAE (Dubai) and follows international standards. We are known for quality products, specialised in a wide range of building materials for the construction industry.

For more details, visit our website. Have a look at the range of products we manufacture and our customers’ feedback. Contact for any information through our website. Our expert sales engineers will help you to resolve all your queries.

1 note

·

View note

Video

Largest Manufacturer of Sandwich PUF Panels with Continuous line Production..

All about Acetech Exhibition held on Oct 22nd to 24th at Palace #Ground Bengaluru..

Contact us for more info +91 9848005002

Whatsapp https://wa.me/919848005002

Mail id- [email protected]

To know more visit www.viraatindustries.com..

#roofingsheetmanufacturersindia #roofs #reelsinstagram #roofingsheetmanufacturer #pebstructure #structralengineering #structures #Continuous #constructionindustry #fabrication #fabrications #acetech #acetechexhibition #acetech2021 #pebengineeringsbuildingmanufacturesinindia #reelkarofeelkaro #reelsinstagram #reelsinsta #reelsinstagramreels #reelsinstagram #reelkarofeelkaro #insulatedpufpanels #insulatedpanels #puf #sandwichpufpanel #roofingsheetmanufacturer #pebstructure #peb #commercialgodowns #commercialpeb #godown #reelsinsta #bestresorts #buildingmaterials #prestige #sobha #viraatroofing #viratkohli #kerala #dubai #hyderabad #metalroof #metalroofing

0 notes

Text

5 Tips For Tackling Your First Big Car Repair - ServiceMyCar.ae

You're a capable weekend automobile mechanic. you've basic tools and skills. you have down oil changes and tire rotations. however once a giant repair comes on, it's call time. Take it on yourself, or decision during a pro?

That's the alternative I visaged at the tip of last summer once my 1990 Mazda Miata suffered a rotating shaft failure. Expecting a fast repair, I before long discovered the automobile required a fully new engine—and I discovered this simply once I might disassemble it to the purpose that it could not be swap along.

Instead of paying a mechanic to fix my Miata, i decided to do exchange the engine myself. I did it—eventually—though I created lots of novice mistakes on the manner. Here's what I learned.

Do Your analysis

Aftermarket search manuals are nice for learning the tools and components you'll have, however, they generally scan sort of a general summary (step one: take away the radiator, front bumper, and windscreen washer reservoir). web forums can give elaborated directions and tricks specific to your automobile, typically with piecemeal photos. Unless you drive one thing extremely bizarre, there is most likely a web site like VWvortex or JeepsUnlimited to assist you. however do not forget that net forums, whereas useful, ar simply net forums. Get an industrial plant service manual from your manufacturer if you are diving deep into a giant repair.

Set Up Your space

I started my teardown within the corner of my parents' two-car garage. I got equipped to drag the engine once I discovered I had no space to maneuver my engine hoist. Even with 2 muscular brothers, moving a half-disassembled automobile was a masochist's game of Tetris. thus do not build my mistake: Clear lots of areas before you begin the task, and position your automobile for max way. I found the simplest spot was right within the center of the garage, although not everybody in my family shared this read.

Expect It to require Time

The first time repairing perpetually takes the longest. Tinkering on nights and weekends, my journey lasted nearly a month, way on the far side what I might anticipate. there have been scores of visits for components, tools, and advice, and times once sheer frustration halted my progress. build different transportation plans before taking your automobile out of commission thus you do not get discharged once your Saturday project continues to be in items on Mon morning.

Take photos, Make Notes, Label Everything

When you are on step 2 of a giant job, it's tempting to assume you will bear in mind that bolt goes wherever, however by step fourteen you'll need a superfluity of fasteners, washers, and clips lying around that provide no indication wherever they came from. Save yourself a thousand headaches by being organized from the beginning. Use sandwich luggage, empty egg crates, and many labels. A phone camera and a dry-erase board are indispensable for noting the layout of wires, cables, and brackets, and neither one can blow away behind the work table after you open the garage door.

Use a white paint pen on metal components to point wherever components came from or their orientation. opt for a universal point of reference, like "front of the automobile," "passenger facet," or "driver facet," and label things with arrows and sides. Label supported scenario too. do not be afraid to write down notes directly on the half, or leave yourself notes concerning however things return along, like the orientation of the distributor relative to the block. masking paper is additionally an excellent tool similarly. Loop it around a hose, wire, or connexion and shut a pleasant 2-inch flap on the opposite facet that you just will use to label what it will or wherever it goes.

Make a Final list

There's a natural excitement to putting everything back along. you will be tempted to hustle through the ultimate touches. Don't. The last little bit of wire routing, bolt modification, or body-panel positioning is what separates a pro-quality repair from Associate in Nursing embarrassing hack job, and if you slap it along for a check drive, you would possibly ne'er get around to correcting it. (Nobody's affected by a bloke during a Miata with no hood, front fenders, or bumper—in case there was any doubt.)

So build yourself a thoroughgoing final list, as well as everything you would like to examine, control, torque, and check before you set that machine back on the road. think again it at your table or the eating table—not within the garage, wherever you will be anxious to induce happening your 1st drive.

Recommended Service Center

We recommend the Best - cheap and reliable car repair center. It is the No.1 Car Repair and Maintenance Service Center in Dubai, It operates all over the UAE. It is the largest car servicing network, capable of handling one thousand cars in a day.

0 notes

Text

Cable Tray Manufacturers UAE

Looking for wall cladding services so that you can avoid negative effects on the building? Wall cladding is the process of layering one material on top of another material. We provide multiple services like cable ladders, tile profiling, sandwich panels, fencing, etc. https://www.nmss.ae/Products/cable-management-system/cable-tray/26

#Profile Sheet Suppliers UAE#Fencing Panel Manufacturers UAE#Tile Profile Suppliers Dubai#Insulated Panel Suppliers Dubai#Cable trunking Suppliers Dubai#Sandwich panel Manufacturers Dubai#Fencing Panel Suppliers UAE

0 notes

Link

There were just a few selected materials such as stone and wood but today insulated panel manufacturers UAE can give your options. It is now easy to construct walls, ceilings and floors in a proper manner. for more info visit us: https://www.nmss.ae/blog-the-key-benefits-of-using-insulated-panels.aspx

0 notes

Text

Get Customized Made To Measure Vinyl Skirting Services Dubai In Your Access

https://shanky315.tumblr.com/post/182934876080/get-customized-made-to-measure-vinyl-striking

Vinyl skirting Services Dubai – galvanized by Perfection. The vinyl skirting system is that the excellent resolution to supply a clean, skilled crowning glory on homes' porches and enclosures. ... The system structure has integral flexibility to accommodate for flowing that will be needed to a lower place the house.

Best vinyl skirting system is that the good resolution to produce a clean, skilled completion on homes’ porches and enclosures.Create a fantastically clean shop around your deck, area and stairs, adding instant curb charm. Easy maintenance can alter you to stay it clean and recent with an easy hose spray.

The system structure has constitutional flexibility to accommodate for flow which will be needed below the house. Merely intersperse solid panels with ventilated panels and therefore the necessary air exchange is well achieved

How to buy mobile home skirting

In your house vinyl skirting service makes it look higher. Covering the layer from the underside of your factory-made housing to the bottom offers it a lot of stable look, prevents animals from seeking shelter underneath your home, and easily makes your house a lot of appealing. shopping for mobilehomeskirting will be a touch confusing, however, therefore we've got explained it below to assist you create the most effective call for your budget and family. If you're able to purchase, buy vinyl skirtingservices Abu Dhabi packages for individual more skirting panels and that we can have the mandatory provides headed your manner as shortly as doable.

Installing Mobile Home Skirting

Installing skirting on your mobile home can be done easily by hiring a professional. Purchase all the vinyl skirting services you need here at Complete MH to get the best value on supplies. A quality professional installer can completely "trim out" a manufactured home with skirting in half a day. Following the simple instructions below you could save on installation cost by doing it yourself - just be careful you are not getting in over your head!

Put up the top back to the base of the house with the 1" hex-head screws included in the trim kit.

Using a plumb line or level to ensure a straight drop, secure the bottomtrack to the ground using the 7" spikes provided.

Cut your skirting panels to size. Place lower edge of panels in bottom track, resting top edge on the top back. Interlock each panel side by side as you add the panels around your mobile home.

Add the top front, interlocking with the top back as shown in the picture, sandwiching the top edge of the skirting panel in between.

The vinyl skirting services Dubai system is that the right technique to supply a straightforward, knowledgeable final bit on homes’ porches and enclosures. Create a perfectly straightforward go searching your deck, area and stairs, adding instant slash attraction. simple maintenance can enable you to stay it clean and recent with a straightforward field hose spray.The device structure has integrated flexibility to cope with for flowing which will be needed to a lower place the house. Truly intersperse stable panels with ventilated panels and also the necessary air alternate is well finished. A small detail therefore on whole the planning of your house.

· Sanitary and clean to straightforward

· Insect and vermin resistant

· Smooth to place in; best for the do-it-yourselfer.

· Durations vinyl technology guarantees sturdiness and long lasting overall performance.

https://parquetflooring.ae

parquetflooring.ae

Phone: 056-600-9626, 04-2959449

Reach from map :

https://goo.gl/maps/wua4udPq4Ay

Follow us on :

https://twitter.com/ParquetFloorin1

https://www.facebook.com/Parquet-Flooring-1119843138047808/

https://in.pinterest.com/parquetflooringae/

Email: [email protected]

Read More :- https://shanky315.tumblr.com/post/182934876080/get-customized-made-to-measure-vinyl-striking

0 notes

Link

A corrugated panel features a wavy or rippling pattern that repeats over its design. In the United States, this was the first surplus metallic panel design. These panels are suitable for use as roofing, siding, and flooring. Corrugated panels are joined together by overlaying the sheets and attaching them using exposed fasteners. Trapezoidal ribbed panels are frequently misidentified as corrugated roofing. For more info visit us: https://www.nmss.ae/Products/gi-metal-decking-sheet/decking-sheet-75-305-profile/14

#sandwich panel Suppliers UAE#Fencing Panel Suppliers UAE#Profile Sheet Manufacturers Dubai#Corrugated Sheet Manufacturers UAE

0 notes

Text

Construct Your House Online With This New Hampshire Startup

The Farmhouse by Profile Homes.Profile ResidencesThe Brewers' very first house was a typical small ranch in York, Maine, purchased

under a very first time property buyer's program."The market's been respectable,"Maker stated. "We were able to build up some equity and made a little revenue.

"That revenue went into Maker's existing house in York, which is now under contract.©"The marketplace's still respectable,"Maker said."We were fortunate to get

what we wanted out of this house and roll that into developing a brand-new home, our forever home."Maker's "forever home"from Profile Homes will be a custom, prefabricated, net zero house. Net absolutely no indicates no utility expenses,

explains Matt Silva. "A net no house means the home produces as much energy as it uses on an annual basis," Silva said. Profile Homes are configured

to generate more solar energy than they use in the summertime, spring and fall, which results in energy credits from the power company. In the winter season, when your house is using more power than it creates, homeowners fall back on those credits to cover their energy expenses. Coastal Cape interior from Profile Homes.Profile Residences Net zero utilized to be out of reach for the common home, Silva states, however no longer, thanks to dropping rates for planetary systems and energy effective technology like LED lighting."The typical expense of planetary systems has gone down considerably, "Silva said. "Ten years ago LED lighting

was a hard number to take a look at.Now the cost is most likely 20 percent of what you paid

then. And the way I build houses the energy business will provide me those light bulbs."That brings us to another unique aspect of Profile Houses

-- prefabrication. However do not consider trailer parks. Silva uses what are called structurally insulated panels, or SIPs. They are made from plywood sandwiching a core of polyurethane foam, achieving a very high

insulation value. They're likewise extremely efficient in regards to timeline."Any house panel can be produced rapidly,"Silva stated." I provide my panel manufacturer the style and all doors and windows are

eliminated. "Silva says he can frame a house in a week, and build a whole home in 20 weeks with preselected bundles for everything from floor covering to

appliances. Silva has actually forged alliances with national companies and manufacturers of cabinets, windows, siding,

pipes and electrical fixtures.

Converted Barn interior from Profile Homes.Profile Houses"I can construct throughout New England with this system,"Silva said."It permits

me to control labor and product costs. It does not matter if it's metro Boston or Burlington, Vermont, my costs are reasonably close because on the makers'side I have fixed expenses.

I worked everything out. "Shane Brewer is putting a deal on eight acres in York where he and his wife wish to develop their Profile House. They selected the 1,890-square-foot Barn Conversion design with three bed rooms and 2 and a half baths, which will cost them about$430,000, consisting of the land, if their offer is accepted. "In speaking with family and friends entering into this procedure some individuals think you're insane,"Brewer said.

"People's sensations around building in general is that it's a headache. We do not feel that way with Matt." For his part, Silva is advised that as forward-thinking and modern as the modular method of Profile Houses is

, it's in fact absolutely nothing brand-new."While I like modular and I think it's underutilized, it goes back to the late 1800s," Silva said."

You could purchase a house from Sears. It would reveal up by train. That's how old modular is."'> Shane Maker is a 29-year-old branch manager for Bangor Cost savings Bank in Maine who is about to build his dream home with his spouse using a startup company called Profile Homes

. It will be the Makers'3rd house and, they hope, their last.But for Profile Residences founder Matt Silva, 40, the Brewers'home will mark the beginning of what he hopes is a new era in customized homebuilding.Matt Silva, Stefan Vittori and Jen Ramsey(delegated right ), the group behind Profile Houses. © 2018www. truslowphoto.com"

We started in from the ground up,"Silva stated. "What would the procedure appear like from start to end up using the innovation we have today, both in the structure and the preparation procedure?"What Silva and his partners came up with is an online homebuying procedure that resembles building the vehicle you desire online, just

for homes." I want individuals to enter and actually tour our houses like they can an existing property, "Silva said."Walk in and see the home, similar to you could go to Audi.com, alter the color and your tire bundles and know how you're affecting the cost. I desire people to do that with our homes."To accomplish his vision, Silva employed the aid of architect Jen Ramsey and 3D animator Stefan

Vittori, who owns Tangram 3DS in Kittery, Maine. Profile Residences is based in Portsmouth, New Hampshire."Stefan does international work throughout the world, doing virtual truth from high-rise buildings built

in

Dubai to superyachts to affordable metro-constructed homes, "Silva stated." I pertained to him with my concept. I stated no homebuilder of my size is concerning a company like yours but if there's chance for a partnership we might turn this market on its head. Stefan might see it."The Farmhouse by Profile Homes.Profile Houses The Brewers'very first house was a normal little cattle ranch in York, Maine, acquired under a first time property buyer's program."

The marketplace's been pretty excellent, "Brewer stated."We had the ability to develop some equity and made a little revenue."That earnings entered into Brewer's current house in York, which is now under contract."The market's still respectable,"Brewer stated."We were fortunate to get what we desired out of this home and roll that into building a brand-new home, our forever home."Brewer's"forever home"from Profile Residences will be

a custom-made, prefabricated, net no home. Net zero means no energy costs, discusses Matt Silva."A net absolutely no home indicates the house produces as much energy as it uses on a yearly basis,"

Silva said.Profile Residences are set up to produce more solar energy than they utilize in the summer, spring and fall, which leads to energy credits from the power business.

In the winter season, when your home is using more power than it produces, property owners fall back on those credits to cover their utility bills.Coastal Cape interior from Profile Homes.Profile Houses Net no utilized to be out of reach for the common house, Silva states, however no longer, thanks to dropping prices for solar systems and energy effective innovation like LED lighting."The typical cost of planetary systems has actually gone down drastically,"Silva stated." 10 years ago LED lighting was a hard number to take a look at. Now the expense is most likely 20 percent of what you paid then. And the method I develop homes the utility company will provide me those light bulbs."That brings us to another distinct aspect of Profile Homes-- prefabrication. But don't consider trailer parks.Silva uses what are called structurally insulated panels, or SIPs. They are made from plywood sandwiching a core of polyurethane foam, attaining an extremely high insulation value. They're also really effective in terms of timeline. "Any home panel can be produced quickly,"Silva said."I provide

my panel manufacturer the design andall windows and

doors are cut out."Silva says he can frame a house in a week, and develop an entire home in 20 weeks with preselected

plans for whatever from floor covering to appliances. Silva has forged alliances with nationwide companies and manufacturers of

kitchen cabinetry, windows, siding, plumbing and electrical fixtures.Converted Barn interior from Profile Homes.Profile Houses"I can construct throughout New England with this system, "Silva stated."It permits me to control labor and material expenses. It does not matter if it's city Boston or Burlington, Vermont, my expenses are reasonably close because on the makers 'side I have repaired costs. I worked everything out. "Shane Brewer is putting a deal on 8 acres in York where

he and his wife wish to develop their Profile Home. They chose the 1,890-square-foot Barn Conversion design with three

bedrooms and two and a half baths, which will cost them about $430,000, consisting of the land, if their offer is accepted."In talking with loved ones going into this procedure some people believe you're insane,"Brewer said."Individuals's sensations around structure in general is that it's a headache. We don't feel that way with Matt.

"For his part, Silva is reminded that as forward-thinking and modern as the modular technique of Profile Houses

is, it's actually nothing brand-new."While I enjoy modular and I think it's underutilized, it goes back to the late 1800s,"Silva stated."You could purchase a home from Sears. It would show up by train.

That's how old modular is."

0 notes

Text

Sales Executive Required for Bin Ghurair Trading LLC in Dubai

Sales Executive Required for Bin Ghurair Trading LLC in Dubai Responsibilities and General Position Summary: Leading manufacturing Company requires a Sales Executive with 3+yr experience from Fire rated steel door/Construction/Contracting/Manufacturing company background As a Sales Executive, you'll need to: Required Professional Sales Executive for immediate joining, familiar with Building Material / Construction & Cladding Background experience (Required), Min 3-5 years UAE Experience, holding a Valid UAE Driving License mandatory, Engineer or diploma holder preferred. Main Task & Duties - Increase sales volume - Activate marketing system - Strong and aggressive customer focused approach is mandatory - Possess knowledge of Cladding Industry – PUR/PIR/Rockwool sandwich composite panels - Should have min 2 years of relevant industry experience in UAE. - Identifies Business opportunities by researching and analyzing sales both locally and in the GCC region. - Prepare and deliver presentations on diverse products and services - Market share expansion - Develop key Accounts Customer service - Follow up inventory records - To follow up all enquiries, preparing proposals where necessary - Identifies business opportunities by identifying prospects and evaluating sales options. - Managing relationships with new & existing clients Qualifications (Eligibility Criteria): Bachelor's Degree in Engineering, Business & Marketing Essential Knowledge and Skills To be considered for this opportunity, you must have the following skills and attributes: You should have experience in Steel Fabrication, Manufacturing and Construction industry Knowledge/Experience in fire rated and non-fire rated steel doors manufacturing will be on priority. At least 3+ year(s) of working experience is required for this position in UAE & GCC. Strong leadership. Innovative management skills. Proficient with MS Office software, and any other related system Superior team work skills. Possess strong negotiation and presentation skills Must have valid UAE driving license. (PLEASE NOTE: The above statements are intended to describe the general nature and level of work being performed by people assigned to this job. They are not intended to be an exhaustive list of all responsibilities, duties and skills required.) Interested Candidates are requested to send copy of resume in Ms Word or PDF format to [email protected] Job Type: Full-time

0 notes