#Polyethylene Terephthalate

Text

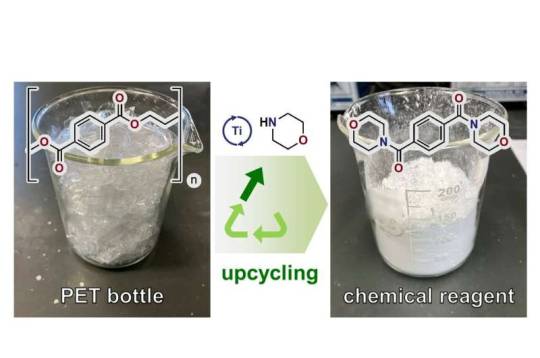

Scientists upcycle polyesters through new waste-free, scalable process

Researchers from Tokyo Metropolitan University have developed a new chemical process which upcycles polyesters, including PET in plastic bottles, to morpholine amide, a versatile and valuable building block for synthesizing a vast range of compounds. The reaction is high yield, waste-free, does not require harmful chemicals, and is easily scalable. The team have successfully broken the, often costly, closed-loop recycling loop of plastic waste, allowing upcycling to more valuable products.

Recycling plays an indispensable part of our fight against plastic waste. But at what cost? The recycling of polyesters, for example, including polyethylene terephthalate (PET) in plastic bottles, often requires power to get the required chemical reactions hot enough, or strongly alkaline conditions which generate chemical waste. At the end of it all, we get intermediate compounds which are used to make the same products they came from. Not only can this be wasteful, it can also be economically unviable.

This is where upcycling comes in. Scientists have been working to break this closed loop and create compounds from plastic waste which are more valuable and useful for society. An open-loop scheme like this is a vital part of practical strategies to help us transition to a greener society.

Read more.

#Materials Science#Science#Polyester#Recycling#Polymers#Polyethylene terephthalate#Tokyo Metropolitian University

74 notes

·

View notes

Text

Plastic degradation by marine bacteria

“Plastic waste pollution on Singapore beach.” - via Wikimedia Commons

#this is what i’m studying for my undergraduate capstone so it’s very much on the brain for me rn#microbiology#plastic remediation#bioremediation#wikipedia#wikipedia pictures#nature#plastic pollution#pollution#environmentalism#environmental science#wikimedia commons#bacteriology#bacteria#marine bacteria#marine pollution#ocean pollution#ocean plastic#science#polyethylene#polypropylene#polyethylene terephthalate#pe#pp#pet#biofilm

14 notes

·

View notes

Text

Exploring Revolutionary Impact of Chemical Recycling on PET

Embark on a journey to unveil the remarkable transformation underway in PET (Polyethylene Terephthalate) recycling through advanced chemical methods. For more information

1 note

·

View note

Text

PET Preforms Market size and forecast, 2021-2031: AMR

0 notes

Text

Polyethylene Terephthalate, High-Density Polyethylene

Connector housings are essential components that electrically isolate individual contacts from each another and enables mating of connectors for seamless functioning

1 note

·

View note

Text

Market demand for PET bottle blowing machines

The market demand for PET bottle-blowing machines is growing in line with the development of the packaging industry. At present, the total output of PET bottle-blowing machines in the world is more than 8,000 units/year, and it is estimated that the global output will exceed 10,000 units/year in 2018. The market demand for PET bottle-blowing machines is mainly from developed countries such as Europe and the United States, and the market demand in developing countries such as China and India is also growing rapidly.

How does it work?

PET, polyethylene terephthalate (PETE) is a lightweight, semi-rigid, or rigid plastic that provides improved impact resistance and helps protect food and liquids within.

What is its purpose?

There are a wide variety of food packaging products made of PET, including soft drinks, and sports, PET is a commonly used plastic that has a variety of applications. It's often used in food packaging because it is safe and durable. drinks, vitamin bottles, vegetable oil bottles, peanut butter containers, and single-serve water bottles.

Food-grade approval from the FDA?

Yes, it is.

Easily recyclable:

That's right. If you are unsure, contact your community recycling center

How it is safe and Where it is used?

PET is safe, as it is made of plastic, which is a non-toxic material. However, like any other material, it should be handled with care if it's going to be touched or ingested.

To get into the fastest growing business just like the food packaging industry Order your own Pet blowing machine. SEPPA Solutions is a leading PET bottle machine manufacturer and been in packaging equipment manufacturing industry for the past 5 decades. Call us now at or just log on to https://www.seppasolutions.com/pet-blowing-machine.html to book your own PET bottle blowing machine and become a successful entrepreneur.

1 note

·

View note

Text

World’s first ice cream made from plastic

Reuters | 28 September 2023

The world’s first food made from plastic waste - according to its developer - is vanilla ice cream.

Despite being locked in a freezer in London, she hopes it kickstarts a heated debate about the future of food and the plastic pollution crisis.

The ice cream is actually an art installation called ‘Guilty Flavours’ by artist and designer Eleanora Ortolani, 27, intended to challenge the way we think about plastic waste and what we are - and are not - prepared to eat.

"Guilty Flavours is what I believe is the first sample of ice cream made from plastic waste,” Ortolani told Reuters at Central Saint Martins, part of the University of the Arts London.

“It's coming from the same plastic as we can find in bottles, plastic bottles,” she said.

The process, developed by scientists in Edinburgh, harnesses the metabolic power of bacteria and enzymes to behave as eco-friendly factories to digest polyethylene terephthalate (PET) and turn it into vanillin, the molecule that gives vanilla its flavour.

“There are certain enzymes which do certain chemical reaction,” Dr Joanna Sadler, a biotechnologist at the University of Edinburgh, told Reuters.

“So if you plug those together, you can get through to lots of different chemical products," she said.

Plastic is made of a string of molecules bonded together into what are known as polymers.

Sadler broke those bonds with a hungry microbe, leaving her with molecules that were no longer plastic.

That former PET-soup was then easily processed by another bacteria into vanillin.

Sadler's research, published in the Journal Biochemist in December 2021, focuses on degrading and upcycling plastic and using it as feedstock for microbial growth.

She produced the specially engineered bugs for Ortolani's project but was at pains to point out that the student's ice cream is very much a research project.

It's not currently for human consumption.

"I've even had members of the public email me saying it's irresponsible to encourage people to eat plastic," Sadler said.

"It is really important that we take the safety side of it really, really seriously and we make it very clear that this has to go through exactly the same regulatory processes and food standard processes as any other food ingredient.

And only once it has been through all of those would it go anywhere near any kind of consumer product."

Ortolani, who is from Verona, Italy, said Guilty Flavours was inspired by her frustration with the failure of the recycling system to stop plastic polluting the environment.

It is locked away to highlight what she says is a looming global food crisis.

“We have the tools today to rethink the food system we're living in,” she said.

“This is ready now and today but nobody can really touch it or interact with it because it's not tested for safety yet."

Vanilla, sometimes called 'green gold', is the second most expensive spice in the world after saffron.

youtube

UK designer recycles plastic into vanilla ice cream

27 September 2023

Introducing the world's first food made from plastic waste... vanilla ice cream!

Named Guilty Flavours, the ice cream has been designed to provoke viewers into thinking about plastic waste.

The ice cream was developed by scientists in Edinburgh, who used bacteria and enzymes to digest PET plastic and turn it into vanillin -- the molecule that gives vanilla its flavour.

The ice cream is still in its research phase and currently not for human consumption.

#Guilty Flavours#vanillin#vanilla ice cream#ice cream#plastic waste#PET plastic#plastic pollution crisis#Youtube#Eleanora Ortolani#Central Saint Martins#University of the Arts London#polyethylene terephthalate (PET)#Dr Joanna Sadler#University of Edinburgh#plastic#polymers#Journal Biochemist#vanilla#green gold#biotechnology#recycle#upcycle

3 notes

·

View notes

Text

Shut up he's got a water bottle!!!

#haruto mizuya#masahiko kouzaki#ite! it's jellyfish love!#my art#it's polyethylene terephthalate :)#haruto mizunami

4 notes

·

View notes

Text

Polyethylene Terephthalate (PET): From Cracking Open the Basics to Shaping Our World

Polyethylene terephthalate, or PET for short, isn't your average plastic. This versatile material stretches its impressive properties across numerous industries, making it a hidden champion in our everyday lives.

This blog delves into the fascinating world of PET, exploring its diverse applications. We'll see how PET transforms from clear beverage bottles to the comfy clothes we wear and even the car parts that endure our daily commutes. So, buckle up and get ready to discover the surprising ways PET shapes our world!

Introduction

PET, a highly versatile plastic, touches many aspects of our lives. From clear beverage bottles to strong clothing fibers, PET's strength, lightness, and clarity make it ideal for packaging, textiles (including clothing, carpets, and upholstery), and even engineering applications like car parts. Beyond these industrial uses, PET shows up in strapping, food containers, medical packaging, and more, making it a truly everyday material.

Here are a few properties of PET (Polyethylene Terephthalate) that signifies its importance in the polymer world:

• Strength: PET can withstand great forces before breaking or deforming. This makes it suitable for applications requiring structural integrity.

• Heat Distortion Temperature (HDT): PET can handle higher temperatures before becoming soft and losing its shape compared to PBT. This allows it to be used in environments with higher operating temperatures.

• Stiffness: PET is more rigid and less flexible compared to PBT. This can be desirable for applications requiring dimensional stability.

• Very strong and lightweight & hence easy and efficient to transport: PET offers good strength while being lightweight, making it easier to handle and transport. This translates to lower transportation costs and easier assembly.

• Good gas (oxygen, carbon dioxide) and moisture barrier properties: PET can effectively block the passage of oxygen, carbon dioxide, and moisture vapor. This is important for applications where protecting contents from these elements is crucial, such as food packaging.

• Excellent electrical insulating properties: PET is a good electrical insulator, meaning it can resist the flow of electricity. This makes it suitable for electrical components and applications requiring insulation.

• Broad range of use temperature, from -60 to 130°C: PET can function well in a wide range of temperatures, from very cold (-60°C) to moderately hot (130°C). This versatility makes it applicable in various environments.

• Low gas permeability, particularly with carbon dioxide: PET has a low gas permeability, especially for carbon dioxide. This is beneficial for packaging applications where it's important to maintain freshness and prevent spoilage from CO2 buildup.

• Suitable for transparent applications, when quenching during processing: By rapidly cooling (quenching) PET during processing, it can be made transparent. This allows for clear packaging and other applications requiring visibility.

• It doesn’t break or fracture. It is practically shatter-resistant and hence, a suitable glass-replacement in some applications.

• PET is highly impact-resistant and less likely to shatter compared to glass. This makes it a safer alternative for applications where glass breakage could pose a risk.

• It is recyclable and transparent to microwave radiation: PET is recyclable, making it an environmentally friendly choice. Additionally, it allows microwaves to pass through for convenient reheating of food in PET containers.

• It is approved as safe for contact with foods and beverages by the FDA, Health Canada, EFSA & other health agencies. Food contact approved PET grades:

Specific grades of PET are rigorously tested and approved by various health agencies for safe contact with food and beverages. This ensures its suitability for food packaging and other applications involving food contact.

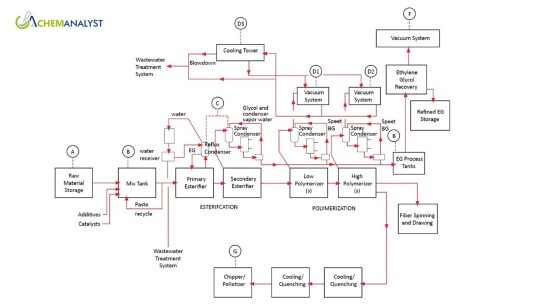

Manufacturing Process

The process involves a continuous PET/TPA system as shown in the following figure:

1. Initially, raw materials are delivered to the site and stored, where terephthalic acid, typically in powdered form, may be stored in silos, while ethylene glycol is kept in tanks. The terephthalic acid and ethylene glycol, both containing catalysts, are blended together in a tank to create a paste.

2. Within the mixing tank, ethylene glycol is directed into a manifold that disperses it via numerous small slots positioned around the periphery of the vent line. The terephthalic acid and ethylene glycol are then mixed using kneading elements operating in opposite directions. This process of forming a paste serves as a straightforward method of introducing these materials into the system, facilitating more precise control over the feed rates into the esterification vessels. A portion of the paste is cycled back to the mixing tank. This recycling of paste and the feed rates of TPA and ethylene glycol are managed to uphold an optimal paste density or the weight percentage of terephthalic acid.

3. The paste originating from the mixing tanks is transported, with the flow rate controlled by gear pumps, to a sequence of esterification vessels, also known as esterifiers or ester exchange reactors. It's possible to utilize two or more esterifiers. The duration of stay within each vessel is regulated by valves positioned in the transfer lines connecting them. These esterifiers function as sealed, pressurized reactors. Operating conditions regarding pressure and temperature within the primary esterifier typically range between 30 and 50 pounds per square inch gauge (psig) and 230 to 260 degrees Celsius (446 to 500 degrees Fahrenheit) respectively. The vapors, primarily comprising water (steam) and glycol, are discharged into a reflux column or distillation column. These vapors are then cooled via a heat exchanger. The recuperated glycol is reintroduced into the primary esterifier, while the water vapor undergoes condensation using cooling water at approximately 29 degrees Celsius (85 degrees Fahrenheit) within a shell-and-tube condenser before being directed to the wastewater treatment system. The monomer produced in the primary esterifier, along with the residual reactants, is pumped into the secondary esterifier.

4. The secondary esterifier operates at atmospheric pressure and a temperature range of 250 to 270 degrees Celsius (482 to 518 degrees Fahrenheit). Vapors from the secondary esterifier, primarily consisting of water vapor, are directed to a spray condenser, and the resulting condensate is sent to a central ethylene glycol recovery unit (12). The condensed water is cooled using cooling water in a shell-and-tube heat exchanger before being recycled. In some cases, the secondary esterifiers for staple PET lines feature a manhole or rotary valve for recycling chips and reworked yarn pellets, whereas these features are absent in the secondary esterifiers for industrial PET lines. Water vapor and monomer emissions occur from these manholes, with the monomer sublimating on nearby piping.

5. The monomer (BHET) produced in the secondary esterifier is subsequently pumped to the polymerization reactors. The number and operating conditions of these reactors vary depending on the type of PET being manufactured. Typically, there are at least two polymerization reaction vessels in series: an initial (low) polymerizer and a final (high) polymerizer. The former is sometimes referred to as a prepolymerizer or prepolycondensation reactor, while the latter is sometimes known as an end finisher. In the production of high-viscosity PET, a second end finisher may be utilized.

6. In the initial (low) polymerizer, esterification is completed, and polymerization occurs, facilitated by the removal of ethylene glycol. This reactor operates at pressures ranging from 20 to 40 mm Hg and temperatures between 270 to 290 degrees Celsius (518 to 554 degrees Fahrenheit) for staple PET and 10 to 20 mm Hg and 280 to 300 degrees Celsius (536 to 572 degrees Fahrenheit) for industrial filament PET, resulting in longer molecules with higher intrinsic viscosity and tenacity required for industrial fibers. Glycol released during polymerization, along with any excess or unreacted glycol, is directed into a contact spray condenser (scrubber) operating countercurrently to a spent ethylene glycol spray. Recovered glycol is pumped to a central glycol recovery unit, while vacuum on the reactors is maintained by a series of steam jets with barometric intercondensers.

7. In the production of high-viscosity PET, the polymer from the low polymerizer is transferred to a high polymerizer vessel, where the short polymer chains formed in the low polymerizer are elongated. Rotating wheels within these vessels facilitate polymer surface exposure for efficient removal of ethylene glycol. The high polymerizer operates under low absolute pressure (high vacuum), typically between 0.1 to 1.0 mm Hg, and at temperatures around 280 to 300 degrees Celsius (536 to 572 degrees Fahrenheit). Vapors evolved in the high polymerizer, including glycol, are directed through a glycol spray condenser. In cases of very "hard" vacuums (e.g., 0.25 mm Hg), the use of spray condensers can be challenging or impossible. Some facilities opt not to use spray condensers off the polymerizers, instead collecting recovered glycol in a receiver and pumping it to a central ethylene glycol recovery unit. Additionally, chilled water is utilized in the heat exchanger associated with the high polymerizer spray condenser.

8. At least one facility employs two high polymerizers (end finishers) for producing high-viscosity PET. The first end finisher typically operates at an intermediate vacuum level of about 2 mm Hg, with the polymer then entering a second end finisher, which may operate at a vacuum level as low as 0.25 mm Hg.

9. Vapors emanating from the spray condenser off the high polymerizers are also routed through a steam jet ejector system. In one instance, a five-jet system is employed. After the first three ejectors, there exists a barometric intercondenser, with another located between the fourth and fifth ejectors. The ejectors discharge into the cooling water hot well. The outflow from the vacuum system is directed either to a cooling tower, where the water is recycled through the vacuum system, or to a wastewater treatment plant in a once-through system.

10. At one plant, vacuum pumps were installed as an alternative to the last two ejectors, as part of an energy conservation initiative. These pumps operate at the discretion of the operator, running approximately 50 percent of the time. The vacuum system was designed to handle a maximum vapor load of about 10 kilograms per hour (kg/hr). Any loss or insufficiency of vacuum in the low or high polymerizers results in off-specification products. Each process line features a dual vacuum system. For each industrial filament (high-viscosity) process line, a standby five-stage ejector/vacuum pump system is maintained, while staple (low-viscosity) lines have a standby ejector system with only one vacuum pump per line. It's reported that steam ejectors recover faster from liquid carryover than vacuum pumps, but the spare system is utilized for the production of both high- and low-viscosity PET.

11. In many facilities, molten PET from the high polymerizer is pumped at high pressure directly through an extruder spinneret to produce polyester filaments. These filaments are then air-cooled and either cut into staple fibers or wound onto spools. Alternatively, the molten PET can be pumped out to form blocks as it cools and solidifies, which are subsequently cut into chips or pelletized. These chips or pellets are stored before being shipped to customers, where they are remelted for end-product fabrication.

12. Ethylene glycol recovery typically involves a system similar to that of the DMT process, with the primary difference being the absence of a methanol recovery step. However, at least one TPA facility implements a significantly distinct process for ethylene glycol recovery. In this setup, ethylene glycol emissions from the low and high polymerizers are directed straight to the vacuum system and then into the cooling tower. Ethylene glycol is then recovered from the water in the cooling tower, allowing for a higher concentration of ethylene glycol in the cooling tower.

Technologies used by Major Players

Technip Energies

• The Zimmer® PET process innovatively replaces the traditional SSP process. This process ensures high reliability, with plants operating continuously for up to seven years without shutdowns for maintenance. Heat recovery systems efficiently utilize thermal energy for polycondensation, while the internal 100% recycling of EG ensures minimal raw material usage and organic load in wastewater treatment. The resultant resin exhibits premium PET qualities, making it suitable for a wide array of applications.

• In PET production, essential raw materials such as Ethylene Glycol (EG) and Purified Terephthalic Acid (PTA), along with specific comonomers like Isopropyl Alcohol (IPA) and Diethylene Glycol (DEG), as well as a catalyst, are blended and continuously fed into the esterification section at predetermined molar ratios. Throughout esterification, water is removed, and PTA and EG react to yield esters and oligomers. The resulting product progresses to esterification stage 2, where esterification continues and polycondensation initiates.

• For textile applications, a Titanium Dioxide (TiO2) slurry may be introduced as a delustering agent. Vapors released during esterification are channeled to the rectification process, while water, along with EG, DEG, and oligomers, is directed to the wastewater treatment facility. Low molecular PET is continuously generated through ongoing polycondensation in the pre-polycondensation reactor. The final step occurs in the polycondensation disk ring reactor (DRR), where the product attains desired characteristics under high vacuum before undergoing filtration and subsequent processing into chips or spinning.

Applications of Polyethylene Terephthalate (PET)

1. Packaging

PET is a versatile plastic material with a wide range of packaging applications due to its valuable properties. Its excellent barrier properties against water and moisture make it ideal for water bottles and soft drink containers. High mechanical strength makes PET films perfect for tapes, while sheets can be thermoformed into trays and blisters. Chemical inertness combined with other properties allows PET to safely package food. Other applications include cosmetic jars, microwavable containers, and various transparent films.

2. Electronics & Electricals

Its electrical insulating properties and dimensional stability make it a valuable material in electronics. PET can effectively replace metal and thermoset parts in applications like electrical encapsulation, solenoids, smart meters, photovoltaic parts, and solar junction boxes. This makes PET a lighter and potentially more cost-effective alternative in these electrical applications.

3. Films & Sheets

PET film, also known as polyester film, is a super useful plastic made from PET (polyethylene terephthalate). It's not just for soda bottles! This versatile film finds uses in all sorts of areas, from keeping things clean and protected (antimicrobial films, surface protection, hard-coats) to making sure your labels stick well (labelling films) and even helping capture the sun's energy (photovoltaic back-sheets).

4. Textile

In the textile industry, PET becomes polyester, a strong and flexible fabric known for resisting wrinkles and shrinking. It's lightweight and perfect for activewear because it reduces wind resistance and tears. Beyond clothing, PET monofilament creates mesh fabrics used for screen printing, filters, agricultural support structures, and various industrial applications.

Market Outlook

The polyethylene terephthalate (PET) market is projected to experience steady growth throughout the forecast period, largely due to the numerous advantages it offers. PET polymer stands out as the most commonly utilized polymer worldwide, finding extensive applications as a textile fiber in clothing as well as in large-scale packaging and bottling. The increasing demand for packaged food is expected to significantly drive the growth of the polyethylene terephthalate market. A trend towards flexible packaging is poised to further enhance the global polyethylene terephthalate market. Additionally, its attributes including cost-effectiveness, high strength-to-weight ratio, shatterproof nature, and ease of recycling act as key drivers for market growth.

Polyethylene Terephthalate (PET) Major Global Players

Leading players in the Global Polyethylene Terephthalate (PET) market are China Petroleum & Chemical Corporation, China Resources (Holdings) Co., Ltd., Far Eastern New Century Corporation, Indorama Ventures Public Company Limited, JBF Industries Ltd, Reliance Industries Limited, SABIC, Sanfame Group, Zhejiang Hengyi Group Co., Ltd., and Others.

Conclusion:

PET plastic is incredibly versatile. It can be shaped into sheets or bottles, making it useful for many applications. The rise of online food delivery has boosted demand for lightweight, flexible packaging, which PET excels at. There's also growing interest in eco-friendly PET made from bio-based materials. Plus, PET is recyclable, unlike many other plastics. The global PET market is expected to boom in the coming years due to its ideal properties for food and beverage packaging. Its resistance to moisture, clarity, durability, and ability to handle temperature changes make it a top choice

0 notes

Photo

New PET-like plastic made directly from waste biomass

It is becoming increasingly obvious that moving away from fossil fuels and avoiding the accumulation of plastics in the environment are key to addressing the challenge of climate change. In that vein, there are considerable efforts to develop degradable or recyclable polymers made from non-edible plant material referred to as "lignocellulosic biomass."

Of course, producing competitive biomass-based plastics is not straightforward. There is a reason that conventional plastics are so widespread, as they combine low cost, heat stability, mechanical strength, processability, and compatibility—features that any alternative plastic replacements must match or surpass. And so far, the task has been challenging.

Until now, that is. Scientists led by Professor Jeremy Luterbacher at EPFL's School of Basic Sciences have successfully developed a biomass-derived plastic, similar to PET, that meets the criteria for replacing several current plastics while also being more environmentally friendly.

"We essentially just 'cook' wood or other non-edible plant material, such as agricultural wastes, in inexpensive chemicals to produce the plastic precursor in one step," says Luterbacher. "By keeping the sugar structure intact within the molecular structure of the plastic, the chemistry is much simpler than current alternatives."

Read more.

363 notes

·

View notes

Text

Polyethylene Terephthalate Foil Market - Forecast(2024 - 2030)

Overview

The Polyethylene terephthalate Foil market size is forecast to reach USD 18.5 billion by 2029, after growing at a CAGR of 4.42% during the forecast period 2024-2029. PET foil is highly versatile and can be used in a wide range of industries, such as construction, automotive, electrical, and packaging. Due to its adaptability, it is a material of choice for producers searching for affordable, strong, and lightweight solutions. As a result, the market for PET foil is growing.

Report Coverage

The report “Polyethylene Terephthalate Foil Market– Forecast (2024-2029)”, by IndustryARC, covers an in-depth analysis of the following segments of the Polyethylene Terephthalate Foil market.

By Type: Virgin, Recycled.

By Thickness: Up to 10 Microns, 10-20 Microns, Above 20 Microns.

By Material Type: Aluminum PET Foil, Copper PET Foil, Metalized PET Foil, and others.

By End Use Industry: Electrical & Electronics, Industrial Machinery, Automotive, Construction, and others.

By Geography: North America, South America, Europe, APAC, and RoW.

Request Sample

Key Takeaways

Due to its recyclable nature, PET foil supports sustainability and efforts to raise environmental awareness. PET foil's recyclability and lower environmental impact as compared to traditional materials have made it increasingly popular among consumers and industries looking for eco-friendly packaging options.

PET foil technology is constantly evolving, leading to new applications and market expansion through higher printability, increased heat resistance, and customizable formulas. Manufacturers spend money on R&D to create cutting-edge PET foil products that satisfy changing consumer and market demands.

The introduction of PET foil is driven by strict rules about environmental standards, product labeling, and food safety. PET foil satisfies regulatory criteria for interaction with food and beverages. Compliance with regulations enhances consumer trust and confidence in PET foil as a safe and reliable packaging material.

By Type- Segment Analysis

Virgin dominated the polyethylene terephthalate foil market in 2023.In terms of thickness, transparency, and barrier qualities, virgin PET material offers more customizability. Because of their versatility, PET foil products can be customized by manufacturers to meet the needs of certain applications, adding to their utility and performance. The utilization of virgin PET foil might improve consumer perception and brand image for items aimed at consumers. When compared to products packaged with recycled materials, those packaged in virgin PET foil are frequently thought to be of a superior caliber and quality.

By Thickness- Segment Analysis

10-20 Microns dominated the polyethylene terephthalate foil market in 2023. Foils that possess thicknesses of up to 10 microns find extensive usage in many packaging applications because of their exceptional printability, flexibility, and lightweight nature. They are frequently used for a variety of products, including food, drinks, personal care products, medications, and more, in flexible packaging formats such as pouches, sachets, labels, and wrapping sheets. For flexible electronics applications including printed circuit boards, flexible screens, and sensors, thinner PET foils are appropriate. Their thin, flexible nature makes it simple to integrate them into electronic equipment while yet offering the required insulation and protection.

Inquiry Before Buying

By Material Type- Segment Analysis

Aluminum PET Foil dominated the polyethylene terephthalate foil market in 2023. Aluminum PET foils are quite popular in the packaging sector because they are easy to use, lightweight, and offer excellent barrier qualities at a reasonable price. This has increased the demand for them in grocery stores, eateries, homes, and food delivery services. Global food and beverage corporations have declared their intention to grow to meet the increasing demand for prepackaged foods. For example, Nestle USA stated in June 2021 that it would be investing 100 million to expand its frozen food production in South Carolina. During the projection period, it is expected that these expenditures will stimulate packaging usage and ultimately aid in market expansion.

By End Use Industry- Segment Analysis

Packaging dominated the Polyethylene Terephthalate Foil market in 2023.Growth in the worldwide packaging industry is expected to support market expansion because the product is widely utilized in the packaging of a variety of goods, including pharmaceuticals, food, drinks, and cosmetics. Additionally, There are tremendous development prospects for the market due to the expanding demand for recycled PET from a variety of industries, including the packaging sector. As greenhouse gas emissions and pollution from plastic waste continue to rise, several of the top competitors in this sector are concentrating on developing innovative recyclable plastics. In addition, compared to other polymers, this polymer is easily recyclable, which helps the market expand. Polyethylene terephthalate is the most recycled plastic in the world, according to the PET Resin Association. Every year, more than 680 kilotons of used PET bottles and containers are recycled in the United States. Furthermore, the product's throwaway qualities have increased demand for single-use plastics like it.

By Geography- Segment Analysis

APAC dominated the polyethylene terephthalate foil market in 2023.APAC is rapidly industrializing and urbanizing, especially in countries like China, India, Japan, South Korea, and Southeast Asian states. The need for PET foil for packaging applications is driven by this development in the demand for packaged goods across several industries, including food and beverage, pharmaceuticals, electronics, and consumer goods. The APAC region's economic expansion has raised disposable incomes and altered consumer habits. The need for PET foil in packaging has expanded as a result of the rise in the consumption of packaged goods, which includes ready-to-eat foods, beverages, personal care products, and home items.

Schedule a Call

Drivers –Polyethylene Terephthalate Foil Market

· The Growing Adoption of Pet Foil in the Packaging Industry

PET foil is a great option for packaging applications because it is strong and lightweight at the same time. Its lightweight design lessens the impact on the environment and shipping costs, but its durability guarantees the protection of items during handling and transportation. To maintain the freshness and caliber of packed goods, PET foil provides superior barrier qualities against gases, moisture, and odors. Because of this, it's especially appropriate for packaging perishable items including food and drink, medications, and personal hygiene items. Due to its high degree of recyclable nature, PET foil supports packaging sector sustainability initiatives. Recyclable materials like PET foil are in high demand as customers and regulatory authorities value eco-friendly packaging solutions more and more.

For instance, according to IBEF India, India's packaging industry is expanding rapidly and has a lot of room to grow in the future. The industry is expected to grow at a compound annual growth rate (CAGR) of 26.7% from 2020 to 2025, from its 2019 valuation of $50.5 billion to $204.81 billion. The FMCG, food processing, pharmaceutical, e-commerce, manufacturing, and healthcare sectors are all experiencing significant growth in this field. The market for PET (Polyethylene Terephthalate) Foil is expanding as a result.

· Rise in Electrical & Electronics Industry.

PET foil is suited for usage in a variety of electrical and electronic applications due to its flexibility and ease of molding into different shapes and sizes. Because of its adaptability, it can be easily integrated and installed into intricate electrical assemblies. Because PET foil has a high dielectric strength, electrical breakdown can be avoided and the safe operation of electrical and electronic devices can be ensured. Because of its dielectric characteristics, it can be used in situations involving high voltage.

For instance, according to Invest India, Based on data from FY22, the domestic electronics production is divided into the following categories: mobile phones (43%), IT hardware (5%), consumer electronics (12%), strategic electronics (5%), industrial electronics (12%), wearables and wearables (0.3%), PCBA (0.7), auto electronics (8%), LED lighting (3%) and electronic components (11%). The total value of domestic electronics production is $101 billion in FY23.

For instance, as per the IBEF India, In 2020, the global electronics market was projected to be worth $2.9 trillion. The electronics manufacturing industry experienced exponential growth, rising from $37.1 billion in 2015–16 to $67.3 billion in 2020–21.The PET foil market is growing in the Electrical & Electronics industry due to a number of factors, including its insulating qualities, flexibility, heat resistance, dielectric strength, chemical resistance, lightweight design, cost-effectiveness, appropriateness for miniaturization, and environmental advantages.

Buy Now

Challenges – Polyethylene Terephthalate Foil Market

· Competition from Alternative Materials.

PET foil faces competition from substitute packaging materials like glass, paperboard, and aluminum foil. To show PET foil's superiority over these substitutes in terms of affordability, functionality, and sustainability, manufacturers must constantly innovate. A classic packaging material, aluminum foil is renowned for its superior ability to block out light, moisture, and gasses. It is extensively utilized in the pharmaceutical, food, and other industries. In some applications, aluminum foil performs better as a barrier than PET foil, especially where high barrier qualities or tolerance to high temperatures are required. PET foil can be recycled, yet worries about plastic waste and its effects on the environment still exist. If not properly handled, growing consumer awareness of single-use plastics and governmental pressure may have an impact on PET foil consumption.

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies players adopt in the Polyethylene Terephthalate Foil market. in 2023, The major players in the Polyethylene Terephthalate Foil market are Filiriko, Toray Industries, Inc, Akshar CoPack LLC, Finfoil, SunPRO, Shanghai Metal Corporation, UFlex, Constantia Flexibles Group GmbH, Terphane, Alfipa, and Others.

Developments:

Ø In July 2023, A recent initiative spearheaded by experts in Scotland seeks to turn plastic waste from industrial processes into drugs for neurological disorders, potentially revolutionizing the pharmaceutical sector. Impact Solutions scientists, University of Edinburgh biotechnology researchers, API Foil makers, a packaging company, and the Industrial Biotechnology Innovation Centre (IBioIC) are all involved in this cooperation. Together, they are investigating the viability of recycling PET, or polyethylene terephthalate, the plastic that is frequently used to produce food and drink packaging, to produce useful medications for the treatment of brain diseases.

#Polyethylene Terephthalate Foil Market#Polyethylene Terephthalate Foil Market Share#Polyethylene Terephthalate Foil Market Size#Polyethylene Terephthalate Foil Market Forecast#Polyethylene Terephthalate Foil Market Report#Polyethylene Terephthalate Foil Market Growth

0 notes

Text

Polyethylene Terephthalate Prices, Price Trend, Pricing, News, Analysis & Forecast

Polyethylene Terephthalate (PET) prices are a crucial indicator within the plastics industry, reflecting market dynamics influenced by various factors. PET, a widely used thermoplastic polymer, finds applications in packaging, textiles, and other consumer goods. Understanding the fluctuations in PET prices requires examining the intricate interplay of supply and demand dynamics, raw material costs, energy prices, and market sentiment.

In recent years, PET prices have been subject to volatility due to several factors. Fluctuations in crude oil prices, as PET is derived from petroleum feedstocks, directly impact its cost of production. Additionally, the availability and pricing of key raw materials such as purified terephthalic acid (PTA) and ethylene glycol (EG) influence PET prices significantly.

Market demand plays a pivotal role in determining PET prices. The packaging industry, particularly the beverage sector, accounts for a substantial portion of PET consumption. Changes in consumer preferences, shifts towards sustainable packaging solutions, and economic trends affect demand dynamics, thereby impacting PET prices.

Moreover, regulatory factors and environmental considerations exert pressure on PET prices. Stringent regulations regarding recycling and sustainability drive investments in PET recycling infrastructure, affecting both supply and demand dynamics. Additionally, consumer awareness and preferences for eco-friendly products influence market dynamics, leading to innovations in PET recycling technologies and bio-based alternatives.

Get Real Time Prices of Polyethylene Terephthalate (PET): https://www.chemanalyst.com/Pricing-data/polyethylene-terephthalate-72

Global economic conditions also influence PET prices. Economic downturns can lead to reduced consumer spending, affecting demand for PET-containing products, while economic growth typically stimulates demand. Geopolitical factors, trade policies, and currency fluctuations further contribute to market uncertainty, impacting PET prices on a global scale.

Technological advancements and innovation also play a role in shaping PET prices. Developments in manufacturing processes, such as improvements in efficiency or the adoption of new catalysts, can impact production costs and, consequently, PET prices. Furthermore, innovations in recycling technologies and alternative feedstocks contribute to market dynamics, influencing PET pricing trends.

The COVID-19 pandemic brought unprecedented challenges to the PET industry. Disruptions in supply chains, changes in consumer behavior, and economic uncertainty significantly impacted PET prices. While the pandemic initially led to a slump in demand, particularly in the beverage and packaging sectors, the subsequent recovery and adaptation to new market conditions have reshaped PET pricing dynamics.

Looking ahead, sustainability concerns are expected to play an increasingly significant role in shaping PET prices. With growing awareness of plastic pollution and the need for circular economy solutions, demand for recycled PET (rPET) is expected to rise, impacting both virgin PET prices and the overall market landscape. Investments in recycling infrastructure, advancements in recycling technologies, and regulatory measures aimed at promoting sustainability will continue to influence PET pricing dynamics in the coming years.

In conclusion, PET prices are influenced by a complex interplay of factors, including raw material costs, market demand, regulatory environment, economic conditions, technological advancements, and sustainability trends. Understanding these dynamics is crucial for industry stakeholders to navigate the PET market effectively and make informed decisions in a rapidly evolving landscape.

Get Real Time Prices of Polyethylene Terephthalate (PET): https://www.chemanalyst.com/Pricing-data/polyethylene-terephthalate-72

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Dive Into Polyethylene Terephthalate (PET) Industry Capacity and Capital Expenditure Forecasts. Get Details of Active and Planned Plants. Discover Now! 🔍

0 notes

Text

Xyz Market Size, Share, Trends, Global Demand, Growth and Opportunity Analysis

"Global PET Blow Moulder Market study by Data Bridge Market Research provides details about the market dynamics affecting the PET Blow Moulder market, Market scope, Market segmentation and overlays shadow upon the leading market players highlighting the favourable competitive landscape and trends prevailing over the years.

A number of estimations and calculations have been included in the first class PET Blow Moulder market report by assuming definite base year and the historic year. The report describes estimations of CAGR values, market drivers and market restraints about the PET Blow Moulder industry which is helpful for businesses in deciding upon numerous strategies. With this market report, businesses can effectively gain a holistic view of the market and then also benchmark all the companies in the PET Blow Moulder industry. To win the competition in the global market place, going for this global market research report is necessary. The credible PET Blow Moulder market report makes organization armed with information produced by sound research methods.

Access Full 350 Pages PDF Report @

Data Bridge Market Research analyses that the polyethylene terephthalate (PET) blow moulder market was valued at USD 121.98 million in 2021 and is expected to reach USD 185.79 million by 2029, registering a CAGR of 5.40 % during the forecast period of 2022 to 2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, patent analysis and technological advancements.

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: PET Blow Moulder Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

How the Report Aids Your Business Discretion?

This section of this Market report highlights some of the most relevant factors and growth enablers that collectively ensure a high-end growth spurt

The report unravels details on pronounced share assessments across both country-wise as well as region-based segments

A leading synopsis of market share analysis of dynamic players inclusive of high-end industry veterans

New player entry analysis and their scope of new business models

The report includes strategic recommendations for new business veterans as well as established players seeking novel growth avenues

A detailed consultation services based on historical as well as current timelines to ensure feasible forecast predictions

A thorough evaluation and detailed study of various segments as well as sub-segments across regional and country-specific developments

Details on market estimations, market size, dimensions

A review of market competitors, their high-end product and service portfolios, dynamic trends, as well as technological advances that portray high end growth in this Market

The Report Can Answer the Following Questions:

Who are the global key players of PET Blow Moulder industry? How are their operating situation (capacity, production, price, cost, gross and revenue)?

What are the types and applications of PET Blow Moulder? What is the market share of each type and application?

What are the upstream raw materials and manufacturing equipment of PET Blow Moulder? What is the manufacturing process of PET Blow Moulder?

Economic impact on PET Blow Moulder industry and development trend of PET Blow Moulder industry.

What are the key factors driving the global PET Blow Moulder industry?

What are the key market trends impacting the growth of the PET Blow Moulder market?

What are the PET Blow Moulder market challenges to market growth?

What are the PET Blow Moulder market opportunities and threats faced by the vendors in the global PET Blow Moulder market?

Some of the major players operating in the polyethylene terephthalate (PET) blow moulder market are:

ASB International Private Limited (India)

Aoki Technical Laboratory, Inc (Japan)

Milacron (U.S.)

R&B Plastics Machinery, LLC (U.S.)

Guangzhou Tech-Long Packing Machine Co Ltd (China)

Sacmi (Italy)

Amsler Equipment Inc (Canada)

NISSEI ASB MACHINE CO., LTD. (Japan)

SMF Maschinenfabrik GmbH (Germany)

Sidel (France)

Quinko Fujian Machinery Industrial Co., Ltd. (China)

Bekum America Corporation (U.S.)

KHS Gruppe (Germany)

Pet All Manufacturing Inc. (Canada)

Krones AG (Germany)

FlexBlow (Lithuania)

Meccanoplastica (Italy)

W. Amsler Equipment Inc. (Canada)

Browse Trending Reports:

Heat Transfer Film Market

Waste Paper Management Market

Collapsible Water Bottle Market

Composite Cans Market

Pet Blow Moulder Market

Polyvinyl Chloride Pvc Dunnage Trays Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]"

#Polyethylene Terephthalate Blow Moulder Market Size#Share#Trends#Global Demand#Growth and Opportunity Analysis#market research#market share#market trends#marketplace

0 notes

Text

Polyethylene Terephthalate Blow Moulder Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

Global PET Blow Moulder Market study by Data Bridge Market Research provides details about the market dynamics affecting the PET Blow Moulder market, Market scope, Market segmentation and overlays shadow upon the leading market players highlighting the favourable competitive landscape and trends prevailing over the years.

A number of estimations and calculations have been included in the first class PET Blow Moulder market report by assuming definite base year and the historic year. The report describes estimations of CAGR values, market drivers and market restraints about the PET Blow Moulder industry which is helpful for businesses in deciding upon numerous strategies. With this market report, businesses can effectively gain a holistic view of the market and then also benchmark all the companies in the PET Blow Moulder industry. To win the competition in the global market place, going for this global market research report is necessary. The credible PET Blow Moulder market report makes organization armed with information produced by sound research methods.

Access Full 350 Pages PDF Report @

Data Bridge Market Research analyses that the polyethylene terephthalate (PET) blow moulder market was valued at USD 121.98 million in 2021 and is expected to reach USD 185.79 million by 2029, registering a CAGR of 5.40 % during the forecast period of 2022 to 2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, patent analysis and technological advancements.

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: PET Blow Moulder Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

How the Report Aids Your Business Discretion?

This section of this Market report highlights some of the most relevant factors and growth enablers that collectively ensure a high-end growth spurt

The report unravels details on pronounced share assessments across both country-wise as well as region-based segments

A leading synopsis of market share analysis of dynamic players inclusive of high-end industry veterans

New player entry analysis and their scope of new business models

The report includes strategic recommendations for new business veterans as well as established players seeking novel growth avenues

A detailed consultation services based on historical as well as current timelines to ensure feasible forecast predictions

A thorough evaluation and detailed study of various segments as well as sub-segments across regional and country-specific developments

Details on market estimations, market size, dimensions

A review of market competitors, their high-end product and service portfolios, dynamic trends, as well as technological advances that portray high end growth in this Market

The Report Can Answer the Following Questions:

Who are the global key players of PET Blow Moulder industry? How are their operating situation (capacity, production, price, cost, gross and revenue)?

What are the types and applications of PET Blow Moulder? What is the market share of each type and application?

What are the upstream raw materials and manufacturing equipment of PET Blow Moulder? What is the manufacturing process of PET Blow Moulder?

Economic impact on PET Blow Moulder industry and development trend of PET Blow Moulder industry.

What are the key factors driving the global PET Blow Moulder industry?

What are the key market trends impacting the growth of the PET Blow Moulder market?

What are the PET Blow Moulder market challenges to market growth?

What are the PET Blow Moulder market opportunities and threats faced by the vendors in the global PET Blow Moulder market?

Some of the major players operating in the polyethylene terephthalate (PET) blow moulder market are:

ASB International Private Limited (India)

Aoki Technical Laboratory, Inc (Japan)

Milacron (U.S.)

R&B Plastics Machinery, LLC (U.S.)

Guangzhou Tech-Long Packing Machine Co Ltd (China)

Sacmi (Italy)

Amsler Equipment Inc (Canada)

NISSEI ASB MACHINE CO., LTD. (Japan)

SMF Maschinenfabrik GmbH (Germany)

Sidel (France)

Quinko Fujian Machinery Industrial Co., Ltd. (China)

Bekum America Corporation (U.S.)

KHS Gruppe (Germany)

Pet All Manufacturing Inc. (Canada)

Krones AG (Germany)

FlexBlow (Lithuania)

Meccanoplastica (Italy)

W. Amsler Equipment Inc. (Canada)

Browse Trending Reports:

Collapsible Water Bottle Market

Composite Cans Market

Pet Blow Moulder Market

Polyvinyl Chloride Pvc Dunnage Trays Market

Japan E Commerce Packaging Market

High Grade Bubble Wrap Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

#Polyethylene Terephthalate Blow Moulder Market Size#Share#Trends#Growth Opportunities and Competitive Outlook#market report#market analysis#market share#marketresearch#market size#markettrends#market trends#market research

0 notes

Text

Polyethylene Terephthalate Market Estimated to Witness Robust Growth Owing to Increasing Consumption in Packaging Industry

Polyethylene terephthalate (PET), also known as polyester, is a thermoplastic polymer resin of the polyester family that is clear, strong, and dimensionally stable. It is widely used in beverage, food, and other packaging, as well as in textile fiber manufacturing. PET is lightweight, transparent, odorless, tasteless, resistant to moisture, and economically recyclable. Bottled water and soft drinks constitute the largest PET packaging market. Apart from packaging, PET is also used in thermoforming applications for manufacturing automotive parts, medical devices, and white goods.

The global polyethylene terephthalate Market is estimated to be valued at US$ 53.53 Bn in 2023 and is expected to exhibit a CAGR of 8.6% over the forecast period from 2024 to 2031, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The increasing consumption of PET in the packaging industry is expected to drive the global polyethylene terephthalate market growth over the forecast period. PET is highly preferred in packaging applications owing to its transparency, lightweight, and durability properties. According to European PET Bottle Platform statistics, around 60% of PET produced globally is used for packaging water, carbonated soft drinks and other beverages. Additionally, expanding food and beverage industry is also fueling the demand for PET in food packaging applications. Furthermore, PET fibers are widely gaining popularity in the textile industry due to their moisture wicking and quick drying properties.

Another factor supporting the market growth is the superior recyclability of PET, which is boosting its adoption in sustainable packaging applications. Recycled PET (rPET) offers an eco-friendly alternative to virgin PET as it significantly lowers the carbon footprint of products. Leading brands are focusing on increasing the share of recycled content in PET bottles to move towards a circular economy. For instance, Coca-Cola aims to make its packaging 100% recyclable globally by 2025.

SWOT Analysis

Strength: Polyethylene terephthalate (PET) is durable, lightweight and versatile, making it suitable for various packaging applications. It provides excellent protection against moisture, gas and microorganisms. It can also be recycled and reused many times. PET is inexpensive to produce compared to glass and other materials.

Weakness: PET requires higher energy consumption during manufacturing and recycling processes compared to other materials. Additionally, discarded PET bottles take a very long time to degrade in landfills and pose environmental issues. Leaching of antimony from PET during recycling is also a concern.

Opportunity: Growing demand for sustainable and recyclable packaging solutions presents an opportunity for PET market players. Increasing health consciousness is driving the demand for bottled water and beverages, boosting the PET market. The high recycling rate of PET in developed countries can be replicated in other regions as well.

Threats: Stricter environmental regulations pertaining to packaging waste recycling may increase compliance costs for PET producers. Substitution threat exists from alternative materials that are more sustainable such as paper, glass and bioplastics. Volatility in crude oil prices affects the raw material costs for PET.

Key Takeaways

The global polyethylene terephthalate market size is expected to witness high growth over the forecast period of 2024 to 2031. The market size is projected to reach US$ 153.81 Bn by 2031, expanding at a CAGR of 8.6% during the forecast period.

Regional analysis:

The Asia Pacific region currently dominates the global PET market with the largest share, led by China, India and other developing countries. Rapid urbanization and rising disposable incomes in the region have been driving the demand for packaged food and beverages. North America and Europe are also major markets for PET owing to high recycling rates and stringent regulations favoring recyclable packaging.

Key players:

Key players operating in the polyethylene terephthalate market are Medtro, Petroquim, Indorama Ventures, Mossi&Ghisolfi Group, JBF Industries, OCTAL, Dhunseri Petrochem & Tea, Lotte Chemical, Far Eastern New Century Corporation, Zhejiang Hengyi Group, SABIC, Reliance Industries, EIPET, NEO GROUP, Selenis, and Donghua Polyethylene Terephthalate.Get more insights on this topic: https://www.newswirestats.com/polyethylene-terephthalate-pet-market-size-and-outlook/

#Polyethylene Terephthalate PET#Polyethylene Terephthalate PET Market#Polyethylene Terephthalate PET Market size#Polyethylene Terephthalate PET Market share#Coherent Market Insights

0 notes