#Plastics Processing Machinery Australia

Text

Plastics Processing Machinery in Australia: Expertise and Applications

In Australia's industrial landscape, plastics processing machinery stands as a beacon of innovation and production efficiency. These advanced machines, from extruders to injection molders, are the driving force behind the transformation of raw plastic materials into a diverse range of finished products. Their versatility and precision, showcased in sectors like packaging materials and automotive components, are instrumental in shaping our economy. This in-depth exploration unveils the expertise of plastics processing machinery and its applications within the Australian context, illuminating technological advancements, industry trends, and economic implications.

Understanding Plastics Processing Machinery Expertise:

1. Technical Proficiency and Innovation:

Plastics processing machinery manufacturers and operators demonstrate unparalleled technical proficiency and innovation in machine design, functionality, and performance. For instance, the integration of computer numerical control (CNC) systems has revolutionized the precision and speed of plastic processing operations. Similarly, the use of robotics and automation has significantly enhanced productivity and versatility in the industry.

2. Material Knowledge and Optimization:

Expertise in plastics processing machinery extends to a profound understanding of polymer materials, their properties, and processing characteristics. Machinery manufacturers and operators possess the knowledge and skills to optimize processing parameters, including temperature, pressure, and speed, to achieve desired material behavior and product quality.

3. Process Optimization and Efficiency:

The primary focus of Plastics Processing Machinery expertise is achieving optimal efficiency and productivity. One of the key strategies used in this pursuit is lean manufacturing, a systematic approach to identifying and eliminating waste through continuous improvement. This approach, along with other process optimization techniques such as Six Sigma and Total Productive Maintenance (TPM), helps manufacturers and operators streamline production workflows, minimize waste, and maximize throughput while maintaining stringent quality standards.

4. Customization and Adaptability:

Plastics processing machinery experts excel in adaptability and customization, a testament to their ability to meet diverse customer requirements and industry-specific applications. They offer tailored solutions, including modular machine configurations, specialized tooling, and software customization, to address unique processing challenges and enhance operational flexibility.

5. Quality Assurance and Compliance:

Ensuring product quality and regulatory compliance is paramount in plastics processing. Machinery experts adhere to stringent quality assurance protocols, including ISO standards and Good Manufacturing Practices (GMP). These standards, which are internationally recognized and regularly audited, ensure that the machinery and the products it produces meet the highest quality and safety standards. This commitment to product integrity, traceability, and safety is a cornerstone of the industry.

Plastics Processing Machinery in Australia: Applications and Impact:

1. Packaging Industry:

Plastic processing machinery is essential in the packaging business since it allows for the creation of a wide range of packaging materials, such as containers, boxes, films, and pouches. These materials are crucial packaging options for food, drinks, medicines, and consumer products, providing resilience, security, and convenience to end consumers.

2. Automotive Sector:

In the automotive sector, plastics processing machinery manufactures various interior and exterior components, including dashboards, bumpers, panels, and trim. Lightweight, high-performance plastics enable vehicle manufacturers to improve fuel efficiency, reduce emissions, and enhance safety while meeting stringent regulatory standards.

3. Construction and Building Materials:

Plastics processing machinery manufactures a variety of construction and building products, including pipes, profiles, insulation, and roofing materials. These materials provide durability, thermal efficiency, and design adaptability, promoting innovation and sustainability in the building sector.

4. Medical and Healthcare Products:

Plastic processing machinery enables the production of medical and healthcare products such as syringes, IV bags, surgical instruments, and diagnostic devices. These precision-engineered products meet stringent regulatory requirements for biocompatibility, sterility, and performance, contributing to advancements in healthcare delivery and patient outcomes.

5. Consumer Goods and Electronics:

Plastics processing machinery facilitates the manufacturing of consumer goods and electronics, including appliances, electronics casings, toys, and household products. These products benefit from engineered plastics' design flexibility, aesthetic appeal, and functional properties, enhancing user experience and product longevity.

Conclusion:

Plastics processing machinery expertise is a catalyst for innovation, efficiency, and competitiveness across diverse industries in Australia, shaping the nation's industrial landscape and economic growth. From technical proficiency and innovation to customized solutions and regulatory compliance, machinery experts are pivotal in advancing plastics processing technologies and applications. As Australia takes strides towards sustainability initiatives and circular economy principles, plastics processing machinery will continue to evolve, enabling the transition towards more resource-efficient, environmentally sustainable manufacturing practices. By leveraging the knowledge of plastics processing machines and encouraging collaboration among industry players, Australia can create new prospects for development, innovation, and wealth in the rapidly evolving global plastics market.

0 notes

Text

Non-Stick Coatings Market Trends & Global Future Forecasts

Non-Stick Coatings Market Overview

Maximize Market Research, a Non-Stick Coatings business research firm has published a report on the “Non-Stick Coatings Market”. Which provides Industry Analysis (Market Performance, Segments, Price Analysis, Outlook) and detailed Process Flow (Product Overview, Unit Operations, Raw Materials, and Quality Assurance).

Sample Request Link : https://www.maximizemarketresearch.com/request-sample/187696

Non-Stick Coatings Market Report Scope and Research Methodology

The Market Research Report (MMR) researches deep into vital growth determinants, exploring motivators and barriers. It furnishes extensive insights into competitive landscapes, major company offerings, and investment prospects. Embracing qualitative and quantitative analyses, it scrutinizes regional markets, providing indispensable insights for stakeholders. Employing historical data, technological advancements, governmental policies, and current Non-Stick Coatings market. Utilizing sources like annual reports, press releases, industry associations, governmental agencies, and customs data, it employs market engineering and data triangulation to forecast segments and sub-segments.

Non-Stick Coatings Market Regional Insights

The estimated growth in the Non-Stick Coatings market segment is driven by improved reliability and increasing demand. The Non-Stick Coatings market is largely segmented into North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa.

Non-Stick Coatings Market Segmentation

By Type

Fluropolymer

Ceramic

Silicone

Other Types

Based on Type, The PTFE segment held the largest Non-Stick Coatings Market share in 2023, owing to its extensive set of properties such as low friction, self-cleaning, and effective at a wide range of temperatures, long-term weather ability, non-flammability, chemical resistance, and high electrical & dielectric strength. The PTFE coatings are made with mainly four ingredients - fluorspar, hydrofluoric acid, chloroform, and water. Non-stick PTFE coatings have a very high melting point and auto-ignition temperature. Thus, it is used in a large range of components such as aluminum, brass, carbon steel, stainless steel, steel alloys, glass, ceramics, rubber, plastics, paper and magnesium.

By Application

Cookware

Food Processing

Fabrics and Carpets

Medical

Electronics

Industrial Machinery

Automotive

Other Applications

Global Non-Stick Coatings Market, by Region

North America (United States, Canada and Mexico)

Europe (UK, France, Germany, Italy, Spain, Sweden, Austria and Rest of Europe)

Asia Pacific (China, South Korea, Japan, India, Australia, Indonesia, Malaysia, Vietnam, Taiwan, Bangladesh, Pakistan and Rest of APAC)

Middle East and Africa (South Africa, GCC, Egypt, Nigeria and Rest of ME&A)

South America (Brazil, Argentina Rest of South America)

To Get More Information click Here: https://www.maximizemarketresearch.com/market-report/non-stick-coatings-market/187696/

Non-Stick Coatings Market Key Players

1. The Chemours Company - Wilmington, Delaware, USA

2. PPG Industries Inc. - Pittsburgh, Pennsylvania, USA

3. Daikin Industries, Ltd. - Osaka, Japan

4. Showa Denko K.K. - Tokyo, Japan

5. 3M - Maplewood, Minnesota, USA

6. Neeta Bellows - Mumbai, India

7. Umasons Steelfab Pvt. Ltd. - India

8. Neeta Enterprises - Mumbai, India

9. Thanavala Associates - Mumbai, India

10. Shree Kedar Trading Co. - Mumbai, India

11. Bhogale Coating & Paints Pvt. - India

12. The Cookware Company - Irvington

13. Jotun Group - Sandefjord, Norway

14. Whitmore Manufacturing Co. - Rockwall, Texas, USA

15. Oerlikon Balzers - Balzers, Liechtenstein

16. Solvay Group - Brussels, Belgium

17. Shaanxi Taporel Electrical Insulation Technology Co., Ltd. - Shaanxi, China

Sample Request Link : https://www.maximizemarketresearch.com/request-sample/187696

Key questions answered in the Non-Stick Coatings Market are:

• What is Non-Stick Coatings ?

• What was the Non-Stick Coatings market size in 2023?

• What is the growth rate of the Non-Stick Coatings Market?

• Which are the factors expected to drive the Non-Stick Coatings market growth?

• What are the different segments of the Non-Stick Coatings Market?

• What growth strategies are the players considering to increase their presence in Non-Stick Coatings ?

• What are the upcoming industry applications and trends for the Non-Stick Coatings Market?

• What are the recent industry trends that can be implemented to generate additional revenue streams for the Non-Stick Coatings Market?

• What segments are covered in the Non-Stick Coatings Market?

• Who are the leading companies and what are their portfolios in Non-Stick Coatings Market?

• What segments are covered in the Non-Stick Coatings Market?

• Who are the key players in the Non-Stick Coatings market?

Related Report Links:

India Gem & Jewellery Market : https://www.maximizemarketresearch.com/market-report/india-gem-jewellery-market/122565/

Anime Market : https://www.maximizemarketresearch.com/market-report/anime-market/124527

Key Offerings:

• Past Market Size and Competitive Landscape (2018 to 2022)

• Past Pricing and price curve by region (2018 to 2022)

• Market Size, Share, Size & Forecast by different segment | 2024−2030

• Market Dynamics – Growth Drivers, Restraints, Opportunities, and Key Trends by Region

• Market Segmentation – A detailed analysis by segment with their sub-segments and Region

• Competitive Landscape – Profiles of selected key players by region from a strategic perspective

Competitive landscape – Market Leaders, Market Followers, Regional player

Competitive benchmarking of key players by region

• PESTLE Analysis

• PORTER’s analysis

• Value chain and supply chain analysis

• Legal Aspects of Business by Region

• Lucrative business opportunities with SWOT analysis

• Recommendations

About Maximize Market Research:

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Banglore Highway, Narhe,

Pune, Maharashtra 411041, India

[email protected]

+91 96071 95908, +91 9607365656

0 notes

Text

global top 25 companies accounted for 53% of total Iron Ore market(qyresearch, 2021)

Iron ore is a relatively abundant metallic element (it composes about 5% of the Earth’s crust) and the main raw material used in steelmaking. Around 98% of global mined iron ore is used to make pig iron, which is an intermediate product of the steel-making process. The remaining 2% is used in several applications, such as production of cement, printing inks, plastics, cosmetics (eye shadow), artistic colors, fertilizer ingredients, and pigments. Currently, iron ore is mined in over 50 countries; however, the bulk of production comes from Australia, Brazil and China.

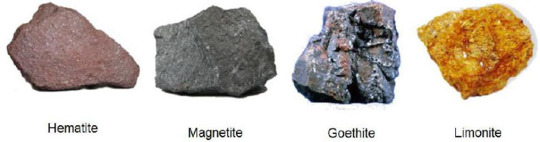

Several minerals contain iron, but the primary sources of iron ore: hematite (Fe2O3), magnetite (Fe3O4), goethite (Fe2O3H2O) and siderite (FeCO3). The first three are of major importance because of their occurrence in large economically minable deposits. Iron ore rocks are usually rich in iron oxides and vary in color: rusty red, dark grey, bright yellow and deep purple.

Most of the iron ore resources are located in sedimentary rocks known as banded iron formations (BIF). Deposits may cover thousands of square kilometers and be hundreds of feet deep.

Typically, a deposit must contain at least 15-25% of Fe to be considered economically recoverable. Usually, tradable iron ore grades ranges between 58% and 66% of Fe content; however, a market of lower grades (sub- 60% Fe) does exist.

According to the new market research report “Global Iron Ore Market Report 2023-2029”, published by QYResearch, the global Iron Ore market size is projected to reach USD 208.24 billion by 2029, at a CAGR of -2.5% during the forecast period.

Figure. Global Iron Ore Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Iron Ore Sales Market Report 2023-2029.

Figure. Global Iron Ore Top 25 Players Ranking and Market Share(Based on data of 2021, Continually updated)

Based on or includes research from QYResearch: 2021 data information of Global Iron Ore Sales Market Report 2023-2029.

The global key manufacturers of Iron Ore include Hainan Mining, Hainan Mining, Huaxia Jianlong, Dazhong Mining, Severstal, HBIS Resources, SSGPO, EVRAZ, LKAB, MRL, etc. In 2021, the global top five players had a share approximately 53.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Taiwan Industrial Valve Market: Forthcoming Trends and Share Analysis by 2030

The Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

The manufacturing and infrastructure sectors of Taiwan rely heavily on the industrial valve market. Industrial valves are crucial components that regulate the flow of liquids, gases, and other materials in a variety of industrial processes, such as water treatment, oil and gas production, petrochemical, and more.

Industrial valve demand is rising steadily as a result of Taiwan's robust economic expansion and thriving manufacturing sector. Local producers of valves contribute significantly to satisfying this demand by offering a vast array of valves for diverse industrial uses. Furthermore, Taiwan's strategic location and role in global trade made it a desirable hub for valve exports, which fueled the market's expansion even more.

There is fierce competition in the market for market share between local and foreign producers. Taiwan's industrial valve market is anticipated to increase and contribute to the nation's overall industrial development as global industries modernize and adapt to meet the changing needs of different industries.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Taiwan Industrial Valve Market include:

Yih Cherng Hydraulic Machinery Co. Ltd. (Taiwan), Yih Tek Automation Co. Ltd. (Taiwan), Forbix Semicon Co. Ltd. (Taiwan), Everfit Technology Co. Ltd. (Taiwan), A-T Controls Inc. (US), Chuan Chuan Metal Valves Co. Ltd. (Taiwan), Advan Flow Solution Co. Ltd. (Taiwan), Heaser Valve Corp. (Taiwan), Jeng Yuan Rech Co. Ltd. (Taiwan), Han Tai Valve Enterprise Co. Ltd. (Taiwan), Shako Co. Ltd. (Taiwan), Dezurik Taiwan Co. Ltd. (US), San Fung Automation Co. Ltd. (Taiwan), Stantec Engineering Co. Ltd. (Taiwan), Dura Flow Corporation (Taiwan), Ebro Valves (Taiwan) Ltd. (Taiwan/Germany), Jade Lung Industrial Co. Ltd. (Taiwan), Kao Lu Industry Co. Ltd. (Taiwan), RAYS Flow Control Equipment Co. Ltd. (Taiwan), Yung Ming Machine Industrial Co. Ltd. (Taiwan) and other major players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Taiwan Industrial Valve Market Report, Visit:

Segmentation of Taiwan Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Taiwan Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Taiwan Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Taiwan Industrial Valve#Taiwan Industrial Valve Market#Taiwan Industrial Valve Market Size#Taiwan Industrial Valve Market Share#Taiwan Industrial Valve Market Growth#Taiwan Industrial Valve Market Trend#Taiwan Industrial Valve Market segment#Taiwan Industrial Valve Market Opportunity#Taiwan Industrial Valve Market Analysis 2023

0 notes

Text

Innovating the Future: Plastic Tube Manufacturers in Australia

Australia's industrial landscape is witnessing a remarkable transformation, led by innovative plastic tube manufacturers. These industry leaders are not just meeting the growing demands across various sectors but are also redefining the standards of quality and sustainability in plastic production.

Plastic tube manufacturers in Australia are known for their commitment to versatility and excellence. They offer a wide array of products, catering to diverse needs ranging from intricate medical devices to robust industrial machinery. This versatility ensures that every sector finds the plastic tubing solutions it requires.

The demand for plastic tubing in Australia is on the rise, and manufacturers are responding with an impressive range of sizes, materials, and specifications. These tubes are essential in numerous applications, including fluid transport in healthcare settings and insulation in electrical systems. The adaptability of plastic tubing makes it a vital component in many industries.

Innovation drives these manufacturers. They continuously explore new materials and production techniques to enhance the quality and functionality of their products. This commitment to innovation ensures that Australian customers have access to some of the most advanced plastic products in the market.

Sustainability is a key focus for plastic tube manufacturers in Australia. Many are adopting eco-friendly practices, using recycled materials, and minimizing waste in their production processes. This approach not only caters to the environmentally conscious consumer but also aligns with global efforts to reduce the environmental impact of plastic production.

Customer service is another area where Australian plastic tube manufacturers excel. They are known for their collaborative approach, working closely with clients to provide tailored solutions and expert advice. This customer-centric approach ensures that clients receive precisely what they need, whether for specialized projects or regular supply needs.

In summary, Australia's plastic tube manufacturers are leading the way in the industry, offering a perfect blend of quality, innovation, and customer service. Their dedication to meeting diverse needs with high-quality, sustainable products positions them as key players in the global plastic industry.

Source

0 notes

Text

Waste Initiative: Revolutionising Recycling with Innovative Machinery

In the face of global waste management challenges, Waste Initiative stands at the forefront of efforts to create a more sustainable future. Our state-of-the-art equipment is reshaping the recycling landscape, streamlining processes for enhanced efficiency and affordability. In this article, we will delve deeper into our pioneering plastic shredding and cardboard compacting technologies, illustrating their significant impact on revolutionising Australia's waste management sector.

The Problem with Traditional Recycling:

Traditional recycling techniques are frequently expensive, ineffective, and slow. Due to this, it may be challenging for businesses and households to recycle efficiently, which could cause waste to accumulate and have a detrimental effect on the environment. At Waste Initiative, we want to reduce the amount of waste going to landfills while also making recycling more accessible and affordable for everyone.

Innovative Machinery: The Solution:

Our cardboard compactors and plastic shredders are made to make recycling quicker, cheaper, and easier than with conventional techniques. These machines are capable of processing a wide range of materials, from plastic bottles and containers to cardboard boxes and paper products.

Plastic Shredder:

The machine shreds the plastic into small pieces, making it easier to recycle and reducing the amount of space needed for storage. This not only saves time and money, but it also helps reduce the amount of waste that ends up in landfills.

Cardboard Compactors:

Our cardboard compactors are designed to compress cardboard and paper products, reducing the amount of space needed for storage. This not only saves space and money, but it also makes it easier to transport and recycle cardboard and paper products.

Benefits of Our Machinery:

Our innovative machinery offers a number of benefits for businesses and households looking to recycle more effectively.

These benefits includes are,

Increased efficiency: Our machinery is designed to process materials more quickly and easily than traditional methods, saving time and money.

Reduced storage space: Our compactors and shredders reduce the amount of space needed for storage, making it easier to recycle more materials.

Improved recycling rates: By making it easier to recycle more materials, our machinery can help increase recycling rates and reduce the amount of waste that ends up in landfills.

Baler Machine:

By compressing recyclable materials into small, manageable bales that are easier to transport and process, our baler machine is intended to assist businesses and households in recycling materials more effectively.

Conclusion:

At Waste Initiative, we're committed to making recycling more accessible and affordable for everyone. Our innovative machinery is revolutionising the way we recycle, making it easier, faster, and more cost-effective than ever before.

With our plastic shredders, cardboard compactors, and Baler machines, we're helping businesses and households recycle more effectively and reduce the amount of waste that ends up in landfills. Join us in our mission to transform the waste management industry in Australia and create a more sustainable future for generations to come. So why wait? Join us in our mission to transform the waste management industry and create a more sustainable future for generations to come. https://wasteinitiatives.com.au

0 notes

Text

APPEX: Australasia’s Processing and Packaging Expo

The hum of machinery, the vibrant clash of colors, and the buzz of excited conversation – these are the sounds that will engulf the Melbourne Convention & Exhibition Centre from March 12th to 15th, 2024. It's the stage for Australasia's Processing and Packaging Expo (APPEX), a colossal event that promises to rewrite the narrative of the plastics industry. Forget stale plastic fairs of the past; APPEX is an explosion of innovation, a melting pot of minds where the future of plastic processing and packaging takes shape.

Beyond Plastic Fair, A Processing Powerhouse:

While plastics often steal the spotlight, APPEX transcends the "plastic exhibition" label. It's a comprehensive showcase of the entire processing and packaging ecosystem, encompassing sectors like food processing, machinery, materials, and industry services. Think of it as a one-stop shop for anyone involved in bringing products from farm to shelf, from factory floor to consumer hand.

Unveiling the Next Big Thing:

But APPEX isn't just about showcasing the present; it's a crystal ball revealing the future. Hundreds of industry leaders will unveil their latest creations, from revolutionary packaging solutions that minimize environmental impact to automated processing lines that redefine efficiency. Imagine witnessing the birth of biodegradable plastics crafted from sustainable sources, or marveling at robotic arms dexterously picking and placing delicate products with unmatched precision.

Knowledge Bytes for Hungry Minds:

The brains behind the brawn take center stage in the seminar sessions. Experts from across the globe will dissect industry trends, delve into pressing challenges like sustainability, and ignite discussions on the ethical and environmental implications of our plastic footprint. Whether you're a seasoned veteran or a curious newcomer, APPEX offers a smorgasbord of knowledge to fill your plate and fuel your ideas.

Networking Hub: Where Ideas Spark and Collaborations Bloom:

APPEX isn't just about passive observation; it's a breeding ground for collaboration. Dedicated networking hubs create vibrant spaces for chance encounters and meaningful connections. Imagine bumping into the packaging guru who can solve your biggest production headache, or stumbling upon the engineer with the missing piece to your revolutionary product puzzle. In this hive of innovation, serendipity meets strategy, paving the way for game-changing partnerships.

A Feast for the Senses, A Fuel for the Soul:

APPEX isn't all work and no play. Live demonstrations bring cutting-edge technology to life, while the APPEX Show Restaurant tantalizes your taste buds with culinary delights. After a day of exploring the future of processing and packaging, unwind with industry colleagues and forge connections that go beyond the conference room.

A Call to Action, A Step Towards Progress:

APPEX isn't just an event; it's a call to action. It's a platform to reimagine the way we process and package products, a space to explore sustainable solutions, and a chance to shape a future where plastic doesn't come at the cost of our planet. Whether you're a manufacturer, a retailer, a consumer, or simply someone who cares about our environment, APPEX has something for you.

So, mark your calendars, pack your curiosity, and prepare to be amazed. At Australasia's Processing and Packaging Expo, the future of packaging is being molded, one groundbreaking innovation at a time.

Exhibition Date – 12 –13-14-15 January 2024

Exhibition Location – Victoria, Australia

Exhibition Address – Melbourne Convention and Exhibition Centre, Victoria, AustraliaTiming – 9:30 - 17:30

Entry Fees – Free Entry

Industry – Plastic

Who Can Visit - plastic Industry, Machinery Industry, Machinery Supply Industry and Equipment Manufacturers, Chemical and Raw Material Industry, Mould Industry, Cable Industry, Heating and Cooling, Air Conditioner Manufacturers, Electric Electronic Industry, Rubber Industry, Recycling Companies, Control Systems Manufacturers, Packaging Industry, Label – Barcode Products and Systems, Metal Industry, Home Appliances Industry, Glass Industry

Website –https://www.appex.com.au/

Organizer Name - Accurate Management,

#plastic exhibition#plastic fair#bioplastic exhibition#plastic trade fair#international plastic exhibition#PlastFocus plastic exhibition 2024

0 notes

Text

Bottled Water Processing System In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Bottled Water Processing System Market Research, 2032

The global bottled water processing system market size was valued at $39.4 billion in 2022, and is projected to reach $68.7 billion by 2032, growing at a CAGR of 5.6% from 2023 to 2032. Bottled water is a type of drinking water which is typically packed in a plastic or glass bottle. Bottled water processing systems are the machines and equipment used for the purpose of processing and packaging water. Bottled water processing systems typically include a wide range of water purification equipment such as filtrations units, UV treatment systems, and reverse osmosis equipment. Furthermore, bottled water processing systems also include packaging machineries such as blow molders, washers & fillers, capping machines, and labeling machines.

Bottled water processing systems are available in a wide range of water purification and packaging capacities and can be effectively modified as per the end user requirements. Thus, bottled water processing systems are suitable for use in large as well as medium and small-scale facilities bottled water processing facilities. Hence, the flexibility of bottled water processing systems positively influences the bottled water processing system market growth.

Asia-Pacific is primarily a developing region, with the exceptions such as South Korea, Japan, Australia, and few others, apart from them major countries such as China, India, Vietnam, Indonesia, Philippines and others are growing at a rapid pace. The high growth rate which significantly increases the disposable income per capita opens door for the growth of many industrial sectors including bottled water processing system market. In addition, people also buy bottled water during travel and public gathering in countries such India and China. This drives growth of the bottled water processing system market. For instance, in December 2022, Jeju Samdasoo, leading bottled mineral water brand of South Korea begun exports to India, shipping 45 tons of the water.

Competition analysis

Competitive analysis and profiles of the major players in the fmarket such as Merck KGaA, Creative OZ-Air (I) Pvt Ltd., E-Rotek Water Systems Co., Ltd., Shivsu Canadian Clear Water Technology Private Limited, Evergreen Technologies, Tetra Laval S.A., Accutek Packaging Equipment Companies, Inc., Lenntech B.V., Danaher Corporation (Pall Corporation), and Marlo Incorporated are provided in this bottled water processing system market forecast report. Major players have adopted product launch and acquisition as key developmental strategies to improve the product portfolio of the bottled water processing system market.

Full Report With TOC:-https://www.alliedmarketresearch.com/bottled-water-processing-system-market-A74856

0 notes

Text

What steps can you take to ensure optimum food safety: Let us explore!

Food safety is not something consumers have to worry about all the time: Thanks to the regulations put in place by governments. However, the story for food producers or packagers is different. Food manufacturing companies adhere to the most stringent food safety practices to ensure their product matches all safety standards and is safe for consumption. Using the right machinery for the job goes a long way in simplifying this critical process. With various industries around the world ramping up the use of professional-grade food testing machinery, early adopters will benefit the most.

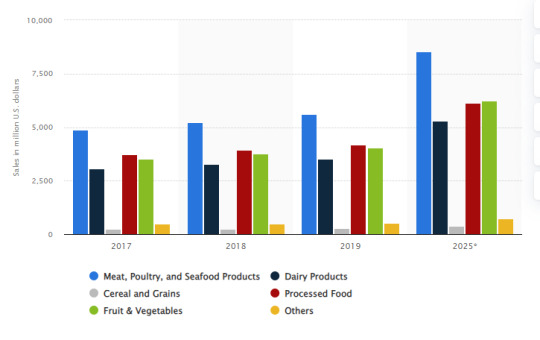

The global food safety testing market by category.

(Source: https://www.statista.com/statistics/1286148/global-food-safety-testing-market-by-food-type/)

Need for food safety standards:

Everyone agrees that we should have the right to obtain and consume nutritious and safe food. To ensure adequate safety standards, the adoption of testing machinery like X-ray scanners is becoming mainstream scenario. Especially in the meat, poultry and dairy segment, the demand of testing machinery is expected to skyrocket in the coming years according to Statista. The diseases and health risks of consuming expired or contaminated food can be severe and life-threatening. So it is a worldwide practice to maintain the utmost hygiene standards when producing food products. The packaged food industry is required to label the necessary information like manufacturing date and allergen information on the package so that the consumers can check for themselves whether the packaged product is safe to eat.

How to ensure optimum food safety?

The only way to make sure a food article is safe to eat is to get rid of contaminants. Depending upon the type of contamination, food may create different problems if consumed. Materials like low-quality plastic, broken tools, metal pieces or unwanted hazardous chemicals may cause physical mouth injury, obstruction in the digestive canal or poisoning. This is why it is wise to use high-quality packaging, labelling and inspection machines when building an assembly line for food products.

X-ray food inspection: The best in the market!

When your factory is producing hundreds or thousands of packaged goods per day, it is nearly impossible to check the contents of each package. The high output of a modern assembly line can easily overwhelm human eyes, so an automated solution is required. The X-ray for food inspection machines are belt-fed and can automatically scan through the produced goods without needing any physical human intervention. A supervisor may keep a watch on the scanned contents and take action if contaminants are detected in the final product.

What to look for in an X-ray food inspection machine?

The duties of an X-ray food inspector are straightforward. We can judge these machines on three factors: Speed, accuracy and reliability. In terms of speed look for a machine with 60 to 90 m / min of linear speed and a capacity of 25,000 grams. Dealing with food, pharmaceuticals or other similar goods requires the machine to be protected from food and pharmaceutical chemicals. An IP65 rating should be sufficient for protection against moisture, dust and other substances. Additionally, the best modern food inspection machines come enabled with a Windows operating system for a powerful yet convenient software framework.

In conclusion

X-ray inspection machines are not only part of the food industry but also an essential part of the cosmetics, pharmaceutical and chemical industries. Any manufacturer looking to provide reliable high-quality goods to its customers knows the value of inspecting final product output that reaches its customers. Paired with the best filling machines, this duo can skyrocket your production efficiency.Investing in a high-quality X-ray inspection machine is a no-brainer. You can find the best inspection machines online in Australia with a quick & easy Google search.

Source: https://packagingmachinesaustralia.blogspot.com/2023/07/what-steps-can-you-take-to-ensure.html

#skyrocket your production efficiency#X-ray for food inspection#food x ray inspection#x ray for food inspection#food x ray inspection equipment#packaging machines

0 notes

Text

Sustainable Solutions and Cutting-Edge Technology: Exploring Plastic Manufacturing in Melbourne.

Plastic manufacturing has been a crucial industry worldwide, but there is a growing emphasis on sustainability and the adoption of cutting-edge technology to mitigate environmental impacts. In Melbourne, a city known for its focus on innovation and eco-consciousness, plastic manufacturers are at the forefront of developing sustainable solutions and leveraging advanced technology to reshape the industry.

One of the primary areas of focus for plastic manufacturers in Melbourne is sustainable materials and processes. These manufacturers are investing in research and development to find alternative, eco-friendly materials to traditional plastics. They are exploring options such as bio-based plastics, recycled plastics, and biodegradable materials that have a reduced environmental footprint. By embracing sustainable materials, Melbourne's plastic manufacturers are taking significant steps towards minimizing waste and promoting a circular economy.

Furthermore, cutting-edge technology plays a vital role in revolutionizing plastic manufacturing processes. Melbourne-based manufacturers are leveraging automation, robotics, and artificial intelligence to streamline production and enhance efficiency. Advanced machinery and equipment enable precise control over manufacturing parameters, reducing material waste and energy consumption. This not only improves overall productivity but also reduces the environmental impact associated with plastic manufacturing.

In addition to sustainable materials and technology, plastic manufacturers in Melbourne are actively engaged in recycling and waste management initiatives. They collaborate with recycling facilities to collect and recycle plastic waste, promoting a closed-loop system. By incorporating recycled content into their manufacturing processes, these companies contribute to the reduction of plastic waste and the conservation of natural resources.

Melbourne's plastic manufacturers also prioritize eco-friendly packaging solutions. They design and produce packaging materials that are recyclable, reusable, and have minimal environmental impact. This commitment to sustainable packaging aligns with the growing consumer demand for environmentally friendly products and helps businesses meet their corporate sustainability goals.

In conclusion, plastic manufacturers in Melbourne are embracing sustainable solutions and cutting-edge technology to drive positive change in the industry. Their focus on eco-friendly materials, advanced manufacturing processes, recycling initiatives, and sustainable packaging demonstrates a commitment to reducing environmental impact. By leveraging innovation and sustainability, Melbourne's plastic manufacturers are paving the way for a more responsible and sustainable future for the industry.

0 notes

Text

#ISBM Mould Injection Machines#Plastics Processing Machinery Australia#Labelling or Decorating Machines

0 notes

Text

Choosing The Best Plastic Bottle Suppliers: A Comprehensive Guide

When it comes to packaging products, plastic bottles are widely used across various industries. Whether you’re in the food and beverage, pharmaceutical, or cosmetic industry, selecting the right plastic bottle supplier is essential for ensuring high-quality packaging solutions. In this comprehensive guide, we will delve into the process of choosing the best plastic bottle suppliers. From understanding your specific requirements to evaluating suppliers, this guide will help you make informed decisions and establish a successful partnership. Let’s explore the world of plastic bottle suppliers together.

Assessing Your Needs:

Before diving into the search for plastic bottle suppliers, it’s crucial to have a clear understanding of your specific requirements. Consider factors such as the type and size of bottles you need, the desired material, design specifications, and expected production volume. These details will help you narrow down your search and find suppliers that specialize in meeting your unique needs.

Researching Potential Suppliers:

To identify potential plastic bottle suppliers, conduct thorough research both online and offline. Explore industry directories, trade shows, and online platforms to compile a list of reputable suppliers. One such supplier to consider is Quality Blow Moulders, a renowned plastic bottle manufacturer in Australia. Their expertise and commitment to quality make them a reliable choice for businesses seeking top-notch packaging solutions.

Evaluating Supplier Capabilities:

Once you have a list of potential suppliers, it’s time to evaluate their capabilities. Consider the following factors during the evaluation process:

Experience and Reputation: Look for suppliers with a proven track record and positive customer reviews. A supplier with extensive experience in the industry is likely to have the expertise and resources to meet your requirements effectively.

Quality Standards: Ensure that the supplier follows strict quality control processes to deliver high-quality plastic bottles. Look for certifications such as ISO 9001 to ensure their commitment to quality.

Manufacturing Capabilities: Assess the supplier’s manufacturing capabilities, including their production capacity, machinery, and technology. A well-equipped supplier can handle your production volume efficiently and deliver on time.

Customization Options: If you require customized plastic bottles, inquire about the supplier’s ability to accommodate specific design specifications. Look for flexibility and willingness to work closely with you to meet your unique packaging needs.

Sustainability Initiatives: In today’s eco-conscious world, consider suppliers who prioritize sustainability. Look for suppliers that use recyclable materials and have implemented sustainable manufacturing practices.

Requesting Samples and Testing:

Before committing to a plastic bottle supplier, request samples of their products. This allows you to assess the quality, durability, and functionality of their bottles. Conduct thorough testing to ensure they meet your requirements and align with your brand image. Assess factors such as leak resistance, compatibility with your products, and overall aesthetics.

Considering Pricing and Logistics:

While price should not be the sole determining factor, it’s important to consider the supplier’s pricing structure and how it fits within your budget. Obtain detailed quotes from different suppliers, ensuring that all costs, including shipping and any additional fees, are clearly stated. Additionally, consider the supplier’s location and logistics capabilities to ensure the timely delivery of your plastic bottles.

Establishing Communication and Partnership:

Effective communication and a strong partnership are crucial for a successful relationship with your plastic bottle supplier. Ensure that the supplier is responsive, open to feedback, and willing to address any concerns or queries promptly. A good supplier will be a reliable collaborator, working with you to meet your evolving packaging needs.

Conclusion:

Choosing the best plastic bottle supplier is a crucial step in ensuring high-quality packaging solutions for your products. By assessing your specific needs, conducting thorough research, evaluating supplier capabilities, requesting samples, and considering pricing and logistics, you can make an informed decision and establish a fruitful partnership. If you’re seeking a reliable plastic bottle manufacturer Australia, look no further than Quality Blow Moulders. With their extensive experience, commitment to quality, and ability to meet customization requirements, they are well-equipped to fulfill your packaging needs. By following this comprehensive guide, you can confidently choose the best plastic bottle supplier and set the foundation for successful packaging solutions that align with your business objectives.

0 notes

Text

Weed Vaporizer Australia Review | My Next Vape

For individuals that want to reap the benefits of the full cannabinoid profile including therapeutic terpenes, vaporizing is a safer and healthier method. Vaporizers are also much easier to use than smoking weed.

In a Sydney suburban mall, Vape Shop owner Ali Ayoub sells bubblegum and pink unicorn flavours. He agrees e-cigarettes are disproportionately used by teens and kids but says they're not tobacco.

Portable Dry Herb Vaporizer Pens

Dry herb vaporizers are typically portable, discreet and easy to use. They use a heating element to heat and vaporize the dry herb in the chamber without burning it or producing smoke. The vapor is then inhaled through the mouthpiece. Depending on the device, there may be a temperature control system which can adjust the heat during the vaping process to get the best results. Some devices have LCD screens which display the battery level and the current temperature, allowing you to track your progress throughout a session.

Different manufacturers produce dry herb vaporizers in a range of shapes and sizes. They also use a variety of materials for the body and mouthpiece, with plastic being common on cheaper models and glass and aluminium preferred in the higher-end options. They may also offer accessories, such as grinders, packing tools, and water pipe attachments to improve your experience, but these are purely optional.

A good example of a quality dry herb vaporizer is the G Pen Dash from Grenco Science. This device features a quality build with an aluminum body and a smooth feel in the hand. It has a simple operation, with the main button being pressed five times to turn it on and off and three times to change between three heat settings. It has buzzy haptics and a nice weight, making it comfortable in the hand during long sessions.

Mighty Medic Vaporizer

A true powerhouse in the world of portable vaporizers, Mighty is a German designed and made unit built to last. While it doesn’t have the same sleek appearance as some other units, its industrial look is actually quite cool. It looks a little like a power tool, dressed in cooling fins and sporting a Black & Decker type color scheme. It is definitely not a discreet device but its sturdy construction, which allows it to be dropped without sustaining damage, makes up for that.

The Mighty uses a combination of convection and conduction heating to provide excellent quality vapor from the first draw. It also has another trick up its sleeve – it can be used to vaporize concentrates as well with the addition of a liquid drip pad. Its large herb chamber is also a great advantage, as it can handle a good amount of material with ease and without clogging.

Depending on the density of the vapor, inhalation may cause irritation of the respiratory tract and/or lungs. If this occurs, stop the use of Mighty Medic and consult your doctor. Inhalation of cannabis flowers contains cannabinoids (such as delta-9-tetrahydrocannabinol) that can have psychoactive effects – they affect perception and consciousness. Consequently, you must not drive or operate machinery after using Mighty Medic. You should also not use Mighty Medic if you are pregnant or breastfeeding, have respiratory or lung diseases or any other health condition.

DaVinci IQ2 Vaporizer

The DaVinci IQ2 is one of the most innovative and impressive pocket-vapes that you can get. It was designed to be the perfect combination of sleek design and futuristic technology. It is a high-quality, powerful vape that can be used for dry herb and extracts. It features an advanced ceramic vapor path that is very durable and produces some of the purest tasting vapor possible. It also has a replaceable 18650 battery which can last for an hour or more before it needs to be recharged.

The IQ2 is made from quality medical-grade materials including a glass-lined oven and zirconia ceramic airpath. The body is made from brushed aluminum that is sturdy and eye catching. The oven is 20% thicker than the original IQ to ensure that your herbs cook evenly without burning or overheating. The IQ2 has an easy-to-use heat adjustment dial and pre-set Smart Paths for optimal temperature control.

The IQ2 is an all-in-one device with an advanced app that gives you all of the tools you need to customize your experience. Its intelligent features make it easy to use and navigate, even if you’re new to vaping. It also has an integrated battery indicator that lets you know how much power your battery has left. The IQ2’s mouthpiece and flavor chamber are connected by a medical-grade silicone that is resistant to heat. This is a big plus for users that prefer to avoid any risk of hot vapor chemically reacting with the silicon in the air path.

Volcano Medic 2 Vaporizer

If you’re an at-home user that prefers pure and clean vapor, the Volcano is the vaporizer for you. It’s made with heat-resistant, flavorless and food-safe materials to ensure your vapor is untainted. It also meets ISO quality standards and UL and NRTL requirements, which means it’s one of the safest and most reliable vaporizers on the market. It may have a higher price tag than other vaporizers, but it’s built with the best and most durable materials, and its extremely accurate temperature control makes for a superior vaping experience.

Both the Volcano Medic 2 and the Mighty Medic are capable of reaching high temperatures, which helps them extract more flavours and potential therapeutic effects from your herb. Storz and Bickel’s patented technology allows the heating system to maintain the set vaporisation temperature without compromising on safety.

These desktop vaporizers can be used with medicinal cannabis formulations such as dried, milled and/or ground cannabis flowers and liquid cannabinoids dissolved in alcohol. The Volcano Medic 2 is a fully certified medical device, registered with the TGA and listed on New Zealand’s Web Assisted Notification of Devices (WAND) database.

0 notes

Text

Hemp - The Most Eco-Friendly Fabric For Furniture?

There has been a great deal of promotion recently concerning material building as well as the different products where it is made. "Synthetic" fabrics made from oil feed-stocks have actually been panned as not lasting. There has actually been progress in making these type of textiles from bio-based oil derivative basic material, however not much is being done commercially.

"Organic" cotton has obtained a lot of press too, but the integral issues in creating cotton remain. The lengthy warm growing period, the copious quantity of water needed for the plant, as well as the vulnerability to a selection of parasites as well as illness require a lot of treatment by the farmer, whether with herbicides as well as chemicals or equivalent amounts of organic choices.

Some other "quick renewal" fabric items are currently on the market such as bamboo, abaca, linen, and fabric made from various other lawns. Their rapid development indicates they soak up a lot of carbon in the atmosphere promptly, yet especially in the case of bamboo, the toxic chemicals needed to separate the fiber from the various other plant product before it can be woven, is problematic.

There is one rapidly expanding all-natural product that offers itself nicely for textile that is eco-friendly from a growing and also processing perspective. The product is mainly grown in Eastern Europe and also Asia where subsistence ranches make it a cash crop. I am speaking of hemp-a fiber that has actually been expanded by people considering that primitive times for its fiber, oil, medicinal high qualities, and as a base for soaps, creams, creams and shampoos.

Every year, an acre of land will generate as much fiber as 2-3 acres of cotton. The fiber is more powerful and also softer than cotton, lasts two times as lengthy in use, as well as will not mildew.

Historically most hemp fiber was used for rope (ropes) and the many weird names for aquatic ropes stem from the different certain fiber blends and also strengths for details on board ship makes use of.

Hemp Derived Thc grows in a much broader climate variety than cotton as well as is frost forgiving. In addition to the fiber for fabrics, hemp can be used for paper, cardboard, a plastic replacement as well as also as gas (believe bio-diesel).

It is interesting to keep in mind that in the United States most paper is made from tree fiber-which take years to grow to harvestable dimension. A hemp crop can be harvested in 120 days as well as calls for no hazardous chemicals to release the fiber from the pulp. (Any individual who has actually passed an operating paper mill will certainly connect to this!) Hemp fiber is launched mechanically by heavy steam and also machinery.

It is stressful that hemp has actually been unlawful to expand in the US considering that the 1930's, and made more stringent regarding a years earlier. Its relative, marijuana, has essentially equivalent fallen leave and stem structure, but Cannabis Hemp Thc Edibles(Indian hemp) does not have the THC material that makes marijuana such a social issue.

Most nations in the EU, plus Canada as well as Australia, permit industrial hemp to be expanded. In Eastern Europe and also Asia, hemp has actually always been a legitimate crop that replenishes the soil as well as does not require pricey herbicides and chemicals. Nevertheless, commercial hemp is lawful for import as well as sale in the United States, yet illegal to grow as a residential plant.

This state of affairs indicates that American consumers can gain from the green nature of the product, when utilized in their clothes or furnishings, as well as are sustaining mainly third world agricultural initiatives to be self-sufficient as well as enriching their standard of life.

0 notes

Text

What is CNC Machining?

CNC Machining is a manufacturing process that uses computer numerical control (CNC) machines to create products. These tools operate on a programming system that instructs them to remove material from a workpiece using various operations, such as drilling, milling and turning.

The process requires an understanding of CAD software and 2D and 3D design, as well as a solid knowledge of the machine and its tooling. It also involves a good understanding of the process of machining and how it relates to different materials.

A skilled cnc machinist understands the whole machining process, from designing parts and their corresponding CAD models to translating them into G-code, the machine's computer code, and then running it on the CNC machine itself to complete the job. This is a hands-on, creative career path that can be a great fit for people who enjoy seeing their work through the entire process.

How is the Process Done?

First, the cnc machine needs to be set up and prepared for operation. This includes affixing the workpiece directly to the machine or to machinery spindles and attaching the necessary tooling to the proper machine components.

After this, the cnc machine can run its program and complete the job with precision. This step is essential, as incorrect speed or position can cause damage to the machine and the part being produced.

Next, the cnc machinist runs a test run without the raw material in place to verify that the machine and its tools are ready for the production process. This step is important for quality assurance, as it ensures that the machine and the tooling are properly aligned with the CAD model of the part.

Once the cnc machinist is satisfied with the machining process, they can then begin producing the finished product. This can be done on a wide range of materials, including metals and plastics.

Common materials used to make parts include steel, aluminum and brass, among others. These materials are often used in medical equipment, such as masks and respirators, because they are durable and can resist high temperatures.

Other types of materials that are commonly used for machining include wood, plastics and composites. These can be cut using either a manual or an automated cnc machining system, but the latter is preferred in most cases.

Regardless of the material used, cnc machining services use subtractive fabrication methods, meaning that it is important to ensure that the right amount of material is removed from the final product. This is because it can damage a machine's axis and other parts if there is too much or too little material in the area being cut.

CNC machining can be used to produce many types of industrial and consumer products, including tools, machines, furniture and other items. It is especially popular in the medical industry, which depends on specialized, accurate and high-quality parts that meet patients' unique needs.

0 notes

Text

There is no need to be unduly hostile to EPS because EPS compactor helps to solve waste issues.

The usage and recycling of EPS has long been a contentious issue, not just in the US, where it has become a widespread norm. Aiming to make all packaging produced, used, or sold in Australia recyclable, reuse, or compostable by 2025 is the non-profit Australian Packaging Covenant Organization (APCO). It is quite clear from the report that individuals oppose the usage of EPS compactors. Since EPS is 100% recyclable while not degrading, it is actually not required at all.

There were expanded plastic foams comprised of polystyrene and polyethylene in around 60% of the product containers (colloquially known as Styrofoam). The National Plastics Plan calls for phasing out the use of expanded polystyrene (EPS), which APCO has designated as a substance of concern. Nevertheless, a schedule for accomplishing this goal has not yet been established. We can also understand the significance of EPS from this. It is preferable to use EPS properly and do scientific EPS recycling using an EPS crusher because it is still unclear whether this material can be fully banned.

Why is EPS claimed to be 100% recyclable? Crude oil serves as the primary starting ingredient for this substance, which is then expanded through the foaming process. After being processed by expert machinery, EPS trash can be converted into PS plastic particles and utilized as a raw material to combine with new ingredients to create new plastic products. Yet, one of the primary characteristics of EPS is its bulky size, and this characteristic has evolved into one of the primary causes for which EPS is rejected for recycling. This issue is satisfactorily resolved with EPS compactor.

Prior to recycling, waste is compressed into a compact block by an EPS compactor, drastically reducing the footprint and volume of EPS. Using a trailer to transport loose EPS was once considered a dumb idea. In fact, just a small amount of EPS can load a trailer, therefore moving EPS is expensive. No one returns to this type of loss-making enterprise. Using a 50:1 compression ratio, an EPS compactor may extrude the air within the material to create EPS blocs of consistent size and shape.

We don't need to fully outlaw the usage of EPS, a highly economical material, thanks to EPS compactor. Production processes can benefit greatly from the sensible usage of EPS. Simply remember that EPS may be recycled and take action by using an EPS compactor and recycling EPS.

0 notes