#Cement Bags Suppliers

Text

FIBC Bulk Bags Manufacturers in Australia

Get superior FIBC bulk bags produced in Australia. With strength and durability for storing and transporting a variety of commodities, our dependable bulk bags are made to satisfy your packing demands. We offer highly qualified FIBC solutions for a variety of applications, including construction and agriculture. Visit us: https://www.gpl.co.in/fibc_bulk_bags.html

#PP Woven Bags#Bulk Bag#FIBC#BOPP Bags#Bulk Bags#Woven Polypropylene Bags Suppliers#Jumbo Bags Manufacturer#Cement Bags Suppliers#FIBC Bulk Bags Manufacturers#BOPP Bags manufacturers#Box Bag manufacturer

0 notes

Text

0 notes

Text

Indian Cement Industry Challenges

The cement industry is an important sector of the Indian economy. India is the second-largest producer of cement in the world, after China. The segment contributes significantly to the economic development of the country by creating employment opportunities and generating revenue. The industry plays a vital role in the infrastructure development of the country, including the construction of highways, bridges, and buildings. In this article, we will discuss the cement industry in India, its history, growth, challenges, and future prospects.

History of the Cement Industry in India

The Indian cement industry dates back to 1914 when the first cement plant was set up in Chennai. Since then, the industry has grown significantly, and India is now the second-largest cement producer in the world. The industry has witnessed several milestones, including the establishment of the first dry process plant in 1956 and the commissioning of the first pre-cast concrete product plant in 1968.

Growth of the Indian Cement Industry

The cement industry in India has grown significantly in the past few decades. In the 1980s, the government opened up the industry for private players, which led to increased competition and growth. The industry saw a surge in demand in the 1990s due to the increase in infrastructure development and urbanization. The industry witnessed a compound annual growth rate (CAGR) of around 8% between 2012 and 2019. The cement industry’s production capacity is expected to reach 550 million tons by 2025, driven by the government’s infrastructure spending and the real estate sector’s growth.

Challenges faced Hitherto

The cement industry in India faces several challenges, including environmental concerns, land acquisition, and logistics issues.

The industry is a significant contributor to carbon emissions, and the government has implemented several measures to reduce its environmental impact.

The industry also faces challenges related to land acquisition, as the process can be time-consuming and expensive.

Logistics is another significant challenge for the industry, as transportation costs account for a significant portion of the overall cost of cement production.

Future prospects of the Cement Industries in India

Despite the challenges, the future of the industry in India looks bright. The government’s focus on infrastructure development and the real estate sector’s growth expects to drive demand for cement in the coming years. The industry is also adopting new technologies to reduce its environmental impact and improve efficiency. The use of alternative fuels and raw materials, such as biomass and waste, is expected to increase in the coming years, reducing the industry’s carbon footprint.

Conclusion

The cement industry is an important sector of the Indian economy, contributing significantly to the country’s development. The industry has grown significantly in the past few decades, and the future looks bright with the government’s focus on infrastructure development and the real estate sector’s growth. However, the industry faces several challenges, including environmental concerns, land acquisition, and logistics issues. The industry is adopting new technologies to address these challenges and reduce its environmental impact.

Note: Also Please Like Share, and Comment on Facebook Page

#Cement Order Online in Gurgaon#Cement Supplier in Gurgaon#Ultratech Super Cement Price Per Bag#Bangur Cement price Per Bag#Ambuja Cement in Gurgaon#Cement Supplier Gurgaon#ACC Cement Price in Gurgaon

0 notes

Text

WOODBINE Offers High-Quality Grounded Calcium Carbonate Powder, CaCO3

#IndustrialMinerals #GroundedCalciumCarbonate #WoodbineGCC #NewDelhi #Rajasthan #CalciumCarbonate

Attention industries! Looking for top-quality Grounded Calcium Carbonate Powder for your industry needs? Look no further! DHANSRI INFRAX PRIVATE LIMITED presents WOODBINE brand of GCC (Grounded Calcium Carbonate – CaCO3), your ultimate solution for various applications. Our extensive range of Grounded Calcium Carbonate Powder, with a formula of CaCO3, caters to diverse industries including cement, paint, glass, soap & detergent, ceramics, rubber, cosmetics, and more.

Available in micron sizes ranging from (2/5/8/10/15/20) and grades including (Super/2nd Super/Normal). WOODBINE GCC meets the stringent requirements of industrial manufacturers Like cement, paint, glass, soap & detergent, footwear, ceramics, paper & pulp, rubber, tyre, cosmetics, toothpaste, PVC wire & pipe, fertilizers, and putty manufacturers. Whether you're in any part of Entire India Tier 1, Tier 2, Tier 3 with in City Limit or with a manufacturing plant in Outer Area (Industrial Clusters), our Indian manufacturing facility based at Rajasthan, India, ensures high-quality alternatives to imported CaCO3. Search DHANSRI INFRAX Private Limited, Industries can rely on us for bulk purchases, with packaging options of 50 kg and 1000 kg HDPE woven laminated bags, ensuring convenient handling and transportation. With a brightness range of 92-98%, WOODBINE GCC guarantees superior performance in your products.

For B2B, B2C, and B2BD2C needs, DHANSRI INFRAX PRIVATE LIMITED stands as your trusted partner. Contact us now to elevate your industry standards with WOODBINE Grounded Calcium Carbonate Powder, a superior option for B2B, B2C, and B2BD2C buyers, suppliers, dealers, importers, exporters, and wholesalers.

2 notes

·

View notes

Text

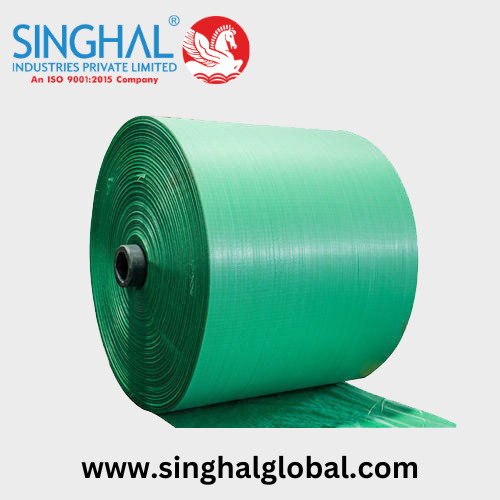

PP Woven Bag

We are BOPP laminated bags & PP Woven Bags manufacturer and Supplier in India & worldwide. We provide BOPP rice bags or rice sacks for packing rice, BOPP Grains Bags, BOPP Fruits Bags, PP Woven Sugar Bags, PP Woven Cement Bags.

For more information, contact us - +91- 9081802800

e-mail : [email protected]

1003, Pinnacle Business Park, Corporate Road, Prahladnagar, Ahmedabad, Gujarat - 380015 | INDIA

#ecommerce#commercial#ppwovenbag#manufactureandsupplier#ppwovenbagmanufacturer#boppbagmanufacturer#boppbagsupplier#polypropylenebag#ppbag#plasticbag#packagingbag#package

2 notes

·

View notes

Text

HDPE Sack Bag Manufacturer

Shree Plastic Industry is a highly trustworthy manufacturer, supplier, and exporter of high-quality HDPE sack bags. We specialise in high-strength, robust, and thinly fabricated HDPE woven sacks. Our products are in high demand in different industries as efficient packaging for flours, cements, rice, corn meal, etc. Our HDPE woven sacks are prepared from top-quality raw materials and fabricated according to the needs of our customers. Our HDPE sack bag gives wonderful protection and packaging at an affordable cost.

Visit here for more details - https://www.shreeplasticind.in/hdpe-sack-bag.htm

0 notes

Text

The Advantages of Using PP Woven Bags for Packaging

In the realm of packaging solutions, the prominence of PP woven bags has steadily ascended, driven by their robustness, versatility, and eco-friendly nature. These bags, crafted from polypropylene (PP) material, have become the go-to choice for various industries due to their myriad benefits. From agriculture to retail and beyond, the advantages of using PP woven bag manufacturers in Gujarat.

This article delves into the advantages of employing PP woven bags for packaging, addressing some frequently asked questions surrounding their utility and efficacy in diverse sectors.

What are PP Woven Bags?

PP woven bags, also known as polypropylene woven bags, are durable packaging solutions crafted from woven polypropylene material. They are renowned for their high tensile strength, resistance to tearing and puncturing, and excellent printability. These bags are commonly used for storing and transporting various products, including grains, seeds, fertilizers, chemicals, cement, animal feed, and more.

Why Choose PP Woven Bags for Packaging?

Strength and Durability:

One of the primary advantages of PP woven bag suppliers in India. The woven construction reinforces the bags, enabling them to withstand heavy loads without tearing or breaking. This robustness ensures the safe storage and transportation of goods, reducing the risk of damage during transit.

Moisture Resistance:

PP woven bags exhibit inherent moisture resistance, making them ideal for packaging products susceptible to moisture damage, such as grains, seeds, and chemicals. The moisture-resistant properties help maintain product integrity and extend shelf life, ensuring optimum quality upon arrival at the destination.

Cost-effectiveness:

PP woven bags offer a cost-effective packaging solution compared to alternatives like paper bags or jute sacks. Their durability translates to a longer lifespan, reducing the need for frequent replacements and lowering overall packaging costs. Additionally, the lightweight nature of PP woven bags contributes to reduced shipping expenses, further enhancing cost efficiency.

Customizability:

PP woven bags can be customized to meet specific branding and labeling requirements. Manufacturers can easily print company logos, product information, and handling instructions directly onto the bags, enhancing brand visibility and communication with consumers. This customization capability adds value to the packaging, elevating the overall product presentation.

Environmental Sustainability:

In an era where environmental consciousness is paramount, PP woven bags stand out as an eco-friendly packaging solution. Made from recyclable polypropylene material, these bags are reusable and recyclable, minimizing environmental impact and promoting sustainability. By opting for PP woven bags, businesses align with eco-friendly practices and contribute to reducing plastic waste.

conclusion:

the advantages of using PP woven bags for packaging are undeniable, encompassing strength, durability, cost-effectiveness, customizability, and environmental sustainability. Businesses can leverage these benefits by sourcing high-quality PP woven bags from reputable manufacturers and suppliers, including PP bag manufacturer exporters in Gujarat and across India. By making informed decisions and prioritizing quality packaging solutions, businesses can enhance product protection, brand image, and environmental responsibility in the ever-evolving market landscape.

FAQs

Where Can Businesses Source PP Woven Bags?

Businesses seeking reliable suppliers of PP woven bags can explore various options, including PP bag manufacturers and exporters in Gujarat, as well as PP woven bag suppliers across India. Gujarat, known for its thriving manufacturing sector, hosts numerous companies specializing in the production of PP woven bags. These manufacturers offer a wide range of bag sizes, designs, and customization options to cater to diverse packaging needs.

Why Choose PP Bag Manufacturer Exporters in Gujarat?

PP bag manufacturer exporters in Gujarat are renowned for their expertise in producing high-quality PP woven bags tailored to meet global standards. These manufacturers leverage advanced technologies and stringent quality control measures to ensure the superiority of their products. Additionally, Gujarat's strategic location and well-established infrastructure facilitate seamless export operations, making it a preferred destination for businesses seeking reliable packaging solutions.

How to Identify Reputable PP Woven Bag Manufacturers in Gujarat?

When selecting a PP woven bag manufacturer in Gujarat, businesses should consider several factors to ensure reliability and quality. These include:

0 notes

Text

Unlocking Excellence: Your Go-To Non-Trade Cement Suppliers!"

Looking for non-trade cement suppliers for your next project? You've come to the right place! In this article, we'll explore everything you need to know about non-trade cement and where to find reliable suppliers. Get ready to discover hassle-free solutions for all your cement needs!

What is Non-Trade Cement?

Before we dive into suppliers, let's quickly understand what non-trade cement is. Non-trade cement, also known as bagged cement, is a type of cement that comes in smaller, more manageable bags. It's perfect for DIY enthusiasts and small-scale projects around the house.

Why Choose Non-Trade Cement?

Non-trade cement offers several advantages over traditional trade cement. It's easier to handle, perfect for smaller projects, and more convenient for individual consumers. Plus, you can buy just the right amount you need without having to purchase in bulk.

Finding Reliable Suppliers:

Now, let's talk about finding the right non-trade cement supplier for your needs. Here are a few things to consider:

Quality: Look for suppliers that offer high-quality non-trade cement products. You want cement that's reliable and performs well for your projects.

Variety: Choose suppliers that offer a variety of packing sizes to suit different project requirements. Whether you need a small bag for a quick fix or a bulk bag for a major renovation, having options is key.

Convenience: Opt for suppliers that offer convenient ordering and delivery options. You want the process to be as smooth and hassle-free as possible.

Where to Buy Non-Trade Cement:

Ready to buy non-trade cement for your next project? Look no further than our website at https://nontrade-cementsupplier.com/. We're your one-stop shop for high-quality non-trade cement products in a variety of packing sizes. Plus, with easy ordering and delivery straight to your doorstep, getting the cement you need has never been easier. For inquiries or assistance, feel free to contact us at +91 85915 92236.

Conclusion:

Non-trade cement suppliers play a crucial role in ensuring the success of your DIY projects and small-scale constructions. By choosing the right supplier, you can access high-quality cement products and enjoy a seamless experience from start to finish. Visit our website today to purchase non-trade cement and take the first step towards completing your project with confidence!

1 note

·

View note

Text

Cement Bag Material: Why Polypropylene (PP) is the Preferred Choice

Introduction

Cement bags are essential in the construction industry, facilitating the safe transportation of cement. Among the materials used, Polypropylene (PP) plastic stands out for its exceptional advantages. Its strength and durability ensure the integrity of the cement during handling and transportation. Impermeable to moisture, PP plastic shields the cement from water damage, crucial in humid climates. Lightweight and weatherproof, it maintains quality in various conditions. Affordable and customizable, it offers cost-effective packaging solutions while being eco-friendly and recyclable, aligning with sustainability goals.

Cement Bag Material: Polypropylene (PP) Plastic

Availability and Reliability

Strength and Durability

Impermeability to Moisture

Tear Resistance and Chemical Inertness

Weatherproof and Lightweight

Affordability and Customizability

Eco-Friendliness and Recyclability

Where to buy these materials?

Looking for high-quality materials for cement bag manufacturing? Look no further than Formosa Synthetics Pvt. Ltd., As a trusted supplier in the industry, we specialize in providing premium Polypropylene filler masterbatch for cement bag production. Our flagship product is a superior blend of CaCO3 stone powder, PP base resin, and carefully selected additives, ensuring optimum strength, durability, and printability for cement bags. With our commitment to excellence and customer satisfaction, we have become the preferred choice for cement bag manufacturers seeking reliable materials for their production needs.

Whether you’re a cement bag manufacturer, Formosa Synthetics Pvt. Ltd. is your one-stop solution for top-notch PP filler masterbatch. Partner with us today and experience the difference in quality and service. Contact us now to request a quote or inquire about cement bag materials.

How are cement bags manufactured?

Cement bags play a vital role in the construction industry, providing a convenient and durable solution for storing and transporting cement. But have you ever wondered how cement bags are manufactured?

The manufacturing process of cement bags involves several intricate steps to ensure quality and durability. Let’s take a closer look:

PP Yarn Production

Woven PP Fabric Sheet

Coated PP Fabric Film

Printing on PP Bags

Finished Product Cutting and Packing

How can cement bags be recycled?

Recycling cement bags presents an opportunity to reduce waste and embrace sustainable practices. Here are several creative ways to recycle cement bags:

Transform into Shopping Bags

Craft Unique Tote Bags or Pouches

Donate to Art Communities

Utilize as Weed Barriers

Create Planters

Donate to Recycling Centers

What is the procedure for the customization of cement bags?

Customizing cement bags can be a creative and unique way to personalize them for various purposes. Here’s a general procedure for customizing cement bags:

Clean the Cement Bags

Design Planning

Gather Materials

Protect Your Workspace

Apply the Design

Allow Drying Time

Optional: Seal the Design

Evaluate and Touch-Up

Conclusion

cement bags crafted from Polypropylene (PP) plastic stand out as indispensable assets in the construction sector, offering a blend of durability, moisture resistance, and customization capabilities. Their intrinsic strengths ensure the safe and efficient transportation of cement while meeting stringent industry standards. Moreover, PP plastic’s eco-friendly nature and recyclability underscore its contribution to sustainable practices, aligning with environmental conservation efforts. Whether utilized by manufacturers for reliable packaging solutions or repurposed by individuals for creative endeavors, cement bags made from PP plastic exemplify innovation and versatility, driving forward the ethos of responsible manufacturing and consumption in the modern era.

Read More

#CementBags#ConstructionIndustry#Polypropylene#PPPlastic#ManufacturingProcess#Recycling#Sustainability#Customization#EcoFriendly#PackagingSolutions#MaterialSourcing#SupplyChain#EnvironmentalConservation#Innovation#Reuse#ReduceWaste#CreativeReuse#QualityControl#Durability#IndustryStandards

0 notes

Text

Reliable Jumbo Bags Manufacturer in France

Choose a dependable Jumbo Bags at Wholesale Price for your bulk material handling needs. We specialize in producing high-quality, durable, and customizable Jumbo Bags, suitable for a variety of industries such as agriculture, construction, chemicals, and food. Our bags are designed for safety, versatility, and cost-effectiveness, ensuring your products are securely stored and transported. Contact us to discover how our solutions can meet your specific requirements. Visit us: https://www.gpl.co.in/fibc_jumbo_big_bags.html

#pp woven bags manufacturer#cement bags manufacturers#Polypropylene (PP) Cover manufacturers#Polypropylene bags Manufacturer#FIBC Big Bag suppliers#Jumbo Bags#PP Woven Bags#PP Cover

0 notes

Text

1 note

·

View note

Text

Factors affecting Cement Prices

There are several factors that can contribute to an increase in the price of cement:Raw material costs:

The cost of raw materials such as limestone, clay, iron ore, and fuel, which are used to produce cement, can increase. This can cause the price of cement to rise. Get the Best Cement Price in Delhi, and Gurgaon

Energy costs:

Energy costs, such as the cost of fuel used in the production of cement, can increase. This can lead to an increase in the cost of production and, therefore, an increase in the price of cement.

Transportation costs:

The cost of transporting cement from the production site to the market can also increase. This can be due to rising fuel prices, the cost of maintaining transportation infrastructure, and other factors.

Currency fluctuations:

Changes in currency exchange rates can also affect the price of cement. If the local currency weakens against the currency in which cement is priced, the price of cement may increase.

Government regulations:

Government regulations and taxes can also impact the price of cement. For example, if the government imposes new environmental regulations on the cement industry, the cost of production may increase, leading to an increase in the price of cement.

Supply and demand:

Finally, supply and demand dynamics can also affect the price of cement. If there is strong demand for cement and limited supply, the price may increase. Conversely, if there is weak demand and an oversupply of cement, the price may decrease.

Production capacity:

If there is a shortage of production capacity in the cement industry, this can lead to an increase in the price of cement. On the other hand, if there is an excess of production capacity, the price of cement may decrease.

Natural disasters:

Natural disasters, such as earthquakes, hurricanes, and floods, can disrupt the production and transportation of cement. This can lead to a shortage of supply, which can cause the price of cement to increase.

Labor costs:

The cost of labor can also impact the price of cement. If there is an increase in the cost of wages, benefits, and other labor-related expenses, the cost of production may increase, leading to an increase in the price of cement.

Market competition:

The level of competition in the market can also affect the price of cement. If there are many players in the market, this can lead to greater competition, which can result in lower prices for cement. On the other hand, if there are fewer players in the market, the price of cement may increase.

Technological advancements:

Technological advancements in the cement industry can also impact the price of cement. If new technologies are introduced that increase the efficiency of production, the cost of production may decrease, which can lead to lower prices for cement.

Political stability:

Political stability in the countries where cement is produced and consumed can also impact the price of cement. If there is political instability in a region, it can disrupt the production and transportation of cement, leading to a shortage of supply and an increase in the price of cement.

Note: Also Please Like Share and Comment on Facebook Page

#Ultratech Super Cement Price Per Bag#Bangur Cement price Per Bag#Ambuja Cement in Gurgaon#Cement Supplier Gurgaon#Cement price in Delhi#Cement suppliers in gurgaon#Ambuja Cement Price in Delhi#Ultratech Cement Gurgaon

0 notes

Text

jsw cement price

JSW Cement proudly presents Power Pro, Concreel HD, the next-generation cement engineered for all your concrete construction needs.

Updated Price List: Find today's competitive rates per 50Kg bag for JSW Power Pro and Concreel HD cement.

Top Dealers & Suppliers: We connect you with reliable suppliers for 53-grade cement.

Free Delivery: Enjoy the convenience of free delivery within Dindigul (mention minimum order quantity if applicable).

Building Made Easy:

We offer a comprehensive solution for your cement needs. From finding the best price to ensuring smooth delivery, we've got you covered.

Expanding Our Reach:

While currently serving Southern tamilnadu, we're continuously expanding to deliver top-quality cement solutions to other cities.

0 notes

Text

PP Woven Fabric: The Sustainable and Versatile Workhorse of Textiles

Introduction:

In the vast landscape of textiles, one material stands out for its versatility, durability, and sustainability: PP (Polypropylene) woven fabric. Used across a myriad of industries, from agriculture to packaging, construction to geotextiles, PP woven fabric has become the workhorse of modern textiles. In this article, we delve into the characteristics, applications, and sustainability aspects of PP woven fabric, while also exploring the landscape of suppliers and manufacturers, particularly focusing on Ahmedabad, Gujarat, and India as a whole.

Understanding PP Woven Fabric:

PP woven fabric is a type of synthetic fabric made from polypropylene polymer. Its construction involves weaving polypropylene tapes or flat yarns together to create a strong and durable fabric. This weaving process imparts exceptional tensile strength and tear resistance to the fabric, making it suitable for a wide range of applications.

Key Characteristics:

Strength and Durability: PP woven fabric is renowned for its high strength-to-weight ratio, making it ideal for applications requiring robustness and resilience. It can withstand heavy loads, punctures, and abrasion, ensuring long-lasting performance.

Lightweight: Regardless of its solidarity, PP woven texture is lightweight, which makes it simple to deal with and transport. This trademark is especially favorable in applications like bundling and transportation.

Water Resistance: PP woven fabric exhibits inherent water resistance, making it suitable for outdoor applications where exposure to moisture is a concern. It can be further enhanced with laminations or coatings for increased impermeability.

UV Stability: UV stability is another notable feature of PP woven fabric, allowing it to withstand prolonged exposure to sunlight without significant degradation. This makes it suitable for outdoor applications such as agricultural covers and geotextiles.

Applications of PP Woven Fabric:

The versatility of PP woven fabric lends itself to a wide array of applications across various industries. Some of the key applications include:

Packaging: PP woven fabric is extensively used in packaging materials such as sacks, bags, and FIBCs (Flexible Intermediate Bulk Containers). Its strength and durability make it an ideal choice for transporting bulk goods such as grains, seeds, fertilizers, and cement.

Agriculture: In agriculture, PP woven fabric finds applications in crop protection, ground coverings, shade nets, and greenhouse films. Its UV stability and water resistance make it well-suited for protecting crops from adverse weather conditions and pests.

Construction: PP woven fabric is used in construction for purposes such as scaffolding nets, tarpaulins, and temporary enclosures. Its strength and durability make it an indispensable material for ensuring safety and protection on construction sites.

Geotextiles: In civil engineering and landscaping projects, PP woven fabric is employed as geotextiles for erosion control, soil stabilization, and drainage applications. Its permeability and strength contribute to the longevity and effectiveness of such infrastructure projects.

Sustainability Aspects:

In addition to its functional attributes, PP woven fabric also offers significant sustainability benefits:

Recyclability: Polypropylene is a recyclable thermoplastic polymer, which means that PP woven fabric can be recycled and reused in various applications, reducing the demand for virgin materials and minimizing waste.

Energy Efficiency: The manufacturing process of PP woven fabric consumes relatively less energy compared to other materials such as paper or traditional textiles, contributing to lower carbon emissions and environmental impact.

Longevity: The durability of PP woven fabric ensures a longer lifespan compared to alternative materials, reducing the frequency of replacements and the associated resource consumption.

Resource Efficiency: PP woven fabric is produced using minimal water and natural resources, making it a more sustainable choice compared to materials that require extensive water and land resources for cultivation or extraction.

Suppliers and Manufacturers:

Ahmedabad, Gujarat, and India as a whole boast a robust network of suppliers and manufacturers catering to the demand for PP woven fabric:

PP laminated woven fabric suppliers in Ahmedabad offer a diverse range of products tailored to specific applications, with options for customization and lamination to meet customer requirements.

PP woven fabric manufacturers in Gujarat leverage the state's industrial infrastructure and expertise in textile manufacturing to produce high-quality PP woven fabric at competitive prices.

PP woven fabric roll manufacturers in India cater to both domestic and international markets, supplying a wide range of industries with standard and customized fabric rolls to suit diverse applications.

Conclusion:

PP woven fabric emerges as a sustainable and versatile solution for a multitude of applications, owing to its inherent strength, durability, and eco-friendly attributes. As industries continue to prioritize sustainability and efficiency, the demand for PP woven fabric is expected to rise, further driving innovation and advancements in its production and applications. With a strong network of suppliers and manufacturers in Ahmedabad, Gujarat, and across India, the future of PP woven fabric looks promising as it continues to establish itself as the workhorse of modern textiles.

Frequently Asked Questions about PP Woven Fabric

Is PP woven fabric eco-friendly?

PP woven fabric's recyclability and durability contribute to its eco-friendly nature. However, the environmental impact depends on factors like production practices and end-of-life management.

Is PP woven fabric breathable?

In its natural state, PP woven fabric exhibits limited breathability. However, breathable variations are available for specific applications.

How strong is PP woven fabric?

PP woven fabric offers surprising strength and tear resistance, making it suitable for heavy-duty applications.

Can PP woven fabric be dyed?

While dyeing PP woven fabric directly is challenging, it can be produced in various colors during manufacturing.

What are the limitations of PP woven fabric?

PP woven fabric might not be the best choice for applications requiring high breathability or heat resistance.

#pp laminated woven fabric suppliers in Ahmedabad#pp woven fabric manufacturer in Gujarat#pp woven fabric roll manufacturers in india

0 notes

Text

Top PP Woven Bags Manufacturers in India: Providing Quality Packaging Solutions

At Singhal Industries, a leading manufacturer of flexible packaging solutions, we recognize the vital role PP woven bags play in diverse industries. While we don't directly manufacture these bags, we leverage our network within the Indian packaging sector to connect you with reliable suppliers. This guide empowers businesses to explore the top PP woven bags manufacturers in India, renowned for providing high-quality and cost-effective packaging solutions.

The Rise of PP Woven Bags and India's Prominence:

PP woven bags, constructed from polypropylene plastic, have become a ubiquitous packaging option across various sectors due to their numerous advantages:

Durability and Strength: PP woven bags are known for their ability to withstand significant weight loads, making them suitable for packaging heavy materials like grains, fertilizers, and chemicals.

Cost-Effectiveness: Compared to traditional packaging materials like jute or hessian sacks, PP woven bags offer a more economical solution.

Versatility: They come in a wide range of sizes, capacities, and configurations to accommodate diverse packaging needs.

Lightweight: PP woven bags are lightweight, reducing transportation costs and overall packaging weight.

Moisture Resistance: They offer a good degree of moisture resistance, protecting packaged goods from moisture damage.

Reusable: PP woven bags can be reused multiple times if handled properly, promoting sustainability and reducing waste.

Printability: They can be printed with logos, branding information, or handling instructions, enhancing brand identity and communication.

India has emerged as a leading manufacturer and exporter of PP woven bags, driven by several factors:

Thriving Manufacturing Base: India boasts a well-established plastics industry with expertise in polypropylene production and advanced weaving technologies.

Competitive Production Costs: The availability of raw materials and skilled labor contributes to India's competitive production costs for PP woven bags.

Stringent Quality Standards: Reputable Indian manufacturers adhere to strict quality control measures, ensuring consistent product quality and performance.

Innovation Focus: Indian manufacturers are continuously innovating, developing features like laminated PP woven bags for enhanced moisture resistance or UV-protected bags for superior durability under sunlight.

Applications of PP Woven Bags:

The versatility of PP woven bags makes them suitable for a wide range of applications across industries:

Agriculture: Packaging grains, seeds, fertilizers, and other agricultural products.

Chemicals: Storing and transporting chemicals, powders, and resins.

Construction: Packaging and transporting sand, cement, and other construction materials.

Food and Beverages: Packaging rice, flour, sugar, and other dry food items.

Pharmaceuticals: Transporting and storing pharmaceutical ingredients and bulk powders.

Retail: Packaging and transporting a variety of retail products.

Finding the Right PP Woven Bags Manufacturer:

Selecting the ideal PP Woven Bags suppliers in India is crucial for your business needs. Here are some key factors to consider:

Product Range: Ensure the manufacturer offers PP woven bags in the sizes, capacities, and configurations you require. This may include options with specific features like laminated lining, gussets for increased capacity, or drawstring closures for easy sealing.

Material Quality: Look for manufacturers using high-quality polypropylene resins for optimal strength and durability.

Printing Capabilities: If branding or informative printing is needed, choose a manufacturer with high-quality printing capabilities.

Certifications: Consider manufacturers with certifications like ISO 9001, signifying a commitment to quality management systems. Additionally, for specific applications, certifications like food-grade compliance might be necessary.

Minimum Order Quantities (MOQs): Understand the manufacturer's minimum order quantities to ensure they align with your production needs.

Competitive Pricing and Lead Times: Compare quotes and lead times from different manufacturers to find a solution that fits your budget and project timeline.

Singhal Industries: Your Partner in Finding Reliable PP Woven Bag Suppliers

While Singhal Industries doesn't manufacture PP woven bags directly, we can be your gateway to finding the perfect supplier in India. Here's how we can assist you:

Extensive Network: We leverage our network within the Indian packaging industry to connect you with top-tier PP Woven Bas Suppliers in Ahmedabad.

Understanding Your Needs: Our team can assist you in identifying the most suitable bag specifications based on your product type, weight requirements, and application.

Competitive Quotes: We can help you obtain competitive quotes from reliable manufacturers, ensuring you get the best value for your investment.

FAQS

What are PP woven bags, and what are their primary uses?

PP woven bags are durable and versatile packaging solutions made from polypropylene (PP) woven fabric. They are commonly used for packaging a wide range of products such as grains, seeds, fertilizers, animal feed, chemicals, and construction materials.

What types of PP woven bags are available from manufacturers in India?

Manufacturers in India offer various types of PP woven bags, including standard woven bags, laminated woven bags for moisture resistance, BOPP (Biaxially Oriented Polypropylene) laminated bags for enhanced printing, and block bottom bags for improved stability.

What are the key features of PP woven bags offered by manufacturers in India?

PP woven bags manufactured in India typically feature attributes such as high tensile strength, tear resistance, UV stability, breathable construction, and customizable printing options. They are designed to withstand rough handling and adverse storage conditions.

How do manufacturers in India ensure the quality of their PP woven bags?

Top manufacturers in India adhere to stringent quality control measures and utilize advanced manufacturing techniques to produce PP woven bags of consistent quality. They conduct rigorous testing for factors such as tensile strength, elongation, burst resistance, and dimensional stability.

What customization options are available when ordering PP woven bags from manufacturers in India?

Customers can customize PP woven bags according to their specific requirements, including size, capacity, color, printing design, handle type, and closure mechanism. Manufacturers offer flexibility in meeting diverse packaging needs across industries.

How can customers procure PP woven bags from manufacturers in India?

Customers can procure PP woven bags directly from manufacturers in India through various channels, including direct contact, online platforms, trade exhibitions, and authorized distributors. Manufacturers typically offer competitive pricing, timely delivery, and excellent customer service to meet client demands.

0 notes

Text

0 notes