#Batch Coding Machine Manufacturer

Text

Batch Coding Machine Manufacturers in Ernakulam

Batch Coding Machine Manufacturers in Ernakulam

We are the fundamental name in the market partook in offering a wide assortment of Batch Coding Machine Manufacturers in Ernakulam, which is planned for quick applications and constant movement. It is the standard for coding applications in progress conditions. Batch Coding Machine Manufacturers in Ernakulam, These coders are perfect for Automatic High Speed Coding on gigantic measures of imprints. It conveys incredible multi-line printing at creation speeds of 100-250 impressions/minute. The imprints or holders are stacked on the slanting plate (Dispenser) for dealing with, subsequently got by the get flexible grinding supplement, dealt with to the printing roller separately through guide track and timing chain and stacked back in the collection plate normally at very high rates.

We are the main Batch Coding Machine Manufacturers in Ernakulam. Inferable from the expertise of our gathering of experienced specialists, we can introduce a select scope of Milk Packing Machine Manufacturers in Ernakulam.

This machine is used for stepping bottle, glass compartment and plastic containers with water, and other liquid rewards. The offered machine mark the containers, it fill the given liquid into bottle, similarly cap each compartment perfectly. Precision and changed creation is the astonishing component of the machine. We are the most famous Pickle Packing Machine Manufacturers in Ernakulam Moreover, the equipment parts can be wiped out and superseded successfully without annihilating the whole machine or influencing the creation. MS body. These Coder are easy to affect gigantic individual printers for on-line engraving on wrinkled pro compartments.

We are the primary name in the market partook in offering a wide assortment of Batch Coding Machine Manufacturers in Ernakulam, which is planned for quick applications and relentless movement. It is the standard for coding applications in progress conditions. With a middle presence of up to 12,000 hours line and advance rapidly to 960 ft/min, this machine is one of the principal bunch coding machines open today. The Coder Machine suitable to awesome, sharp and enlisted print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, perceptibility codes, bundle codes and other legitimate information with the help of the Characters with Aid of Brass Letters. We are the most famous Vegetable cutting Machine Manufacturers in Ernakulam.

#Batch Coding Machine Manufacturers in Ernakulam#https://sampackindia.com/batch-coding-machine-manufacturers-in-ernakulam/

0 notes

Text

Vacuum Packing Machine distributers in Kerala

Ace Finepack Private Limited has held a strong position in the packaging and coding industry. We are Kerala's leading manufacturer and distributor of packaging machines. In India, the company is expanding and developing a broad and diverse portfolio of packaging and coding solutions, including cutting-edge packaging machines, packaging machines, marking equipment, packaging tools, and Raw materials.

Ace Fine Pack Pvt Co., Ltd. ISO 9001: 2008 certified. With packaging as an art form, we are now a leading supplier of packaging and coding machines in Kerala. Since its inception, Ace Finepack has opened a niche market in the packaging industry with innovative technology, a professional approach, and a team of dedicated and volunteer . Our strong ethics, dedication, motivation, and customer support have kept us moving. We believe that after-sales support is as important to our industry survival as marketing and sales. We also handle automation, integrated packaging lines, sealing machines, printing, and batch coding machines. With a mission . It has a mission to help the industry identify products, meet packaging, coding and labeling needs and raise customer awareness of the requirements and importance of high quality packaging and its benefits.

#coding machines in kochi#coding machines in kerala#Batch coding Machines in Kochi#Batch coding Machine manufacturers in Kerala

0 notes

Link

0 notes

Text

Shein: Fast-fashion workers paid 3p per garment for 18-hour days, undercover filming in China reveals

It is the biggest fast-fashion company in the world, making billions of pounds by unveiling thousands of new designs on its addictive website every day and selling them cheaper than anyone else.

Now the first undercover investigation into factories supplying Shein, the Chinese retailer loved by millions of young women in the UK and around the globe, has exposed the disturbing experiences of workers making its clothes.

Garment manufacturers in China are often working up to 18 hours a day, being paid as little as 3p per item, with no weekends and only one day off per month, a Channel 4 team has found.

This treatment of workers – who are fined two thirds of their daily wage if they make a single mistake – breaks not only Shein's code of conduct for suppliers but also Chinese labour laws. The company says it will investigate.

A woman using the false name of Mei secretly filmed inside two factories where she took on jobs producing the kinds of tops that British shoppers can buy for as little as £1.49. The footage has been shared with i ahead of Untold: Inside the Shein Machine, streaming on All4 from Monday.

Women in one factory are found to be washing their hair during their lunch breaks, as they have so little spare time outside of their long shifts. A man who started work at 8am, but is filmed sitting shirtless at his sewing machine after midnight, says he will not finish until 2am or 3am because he needs to complete his batch

Woods says Shein is "head and shoulders" above other fashion brands in the number of "dark patterns" it uses online. "These are behaviours on the website that force you into actions that you might not choose yourself," he explains. "Data is making marketing like a loaded weapon."

Shein was contacted for comment by the documentary makers but did not respond on this matter.

Data published on 6 April by The Business of Fashion showed that in the year to date, Shein had launched 314,877 separate designs in the US market, compared to 18,343 in the same period by Boohoo. This relentless onslaught suggests customers have more than 3,000 new styles to potentially view every day

The contact arranged for "Mei", one of the journalists in his network, to infiltrate the Shein supply chain in Guangzhou, a south-eastern city with a population of 14 million. Having seen what she discovered, he says: "I have been doing investigative stories in China for 15, 16 years – still [they] exploit workers like dogs. Basically it's worse than years ago."

1K notes

·

View notes

Text

The Advance Guard

Writing Prompt: You are Vanguard, an AI machine sent to prepare a world for human colonists. They never came. You have built, learned, self-improved, and now seek the truth - What happened to your human creators?

Source: User PositivelyIndecent; subreddit Humans Are Space Orcs

372.

It did not seem significant, placed all by itself on an empty line. It was, however, the number of years since the habitability for carbon-based, oxygen-processing life forms had been successfully achieved.

The number of years since the world was supposed to be inhabited by those life forms.

I am Vanguard. I am both a and the, and also only Vanguard.

My duty...I get ahead of myself.

Vanguard is an AI whose primary mission is this: seek a planet fitting [habitability parameters] and execute programming module [Establish a Colony]. Extrapolating that program, the mission is, and has always been, to find a planet where humans can live and to terraform and/or modify that planet until humans can live on it, in whatever form that is necessary. Air purifiers, water filters, habitat domes; everything is viable in pursuit of the mission.

I succeeded at my mission, I thought, with barely a day or two to spare. A very slim error margin indeed, especially concerning organic life forms; 372 years ago I had habitable domes with viable water and garden beds growing the first shoots that had been sent along in my stasis bays, with air recyclers manufacturing carbon dioxide for the plants until the humans arrived and brought their life-giving lungs with them. I had completed my mission parameters, even if only 'by the skin of my teeth', as my progenitors would have said.

I waited. Refined a few things, not daring to experiment too much when they would be arriving any moment in the next 48 hours, but preparing things that would not be needed until there were people to need them.

I waited.

I kept refining things, when I passed the 48 hour window without word. Delays could happen, emergencies, anything, really. So I kept running my programs- I made gardening drones to tend to the gardens, to grow, harvest, and rotate the crops. I had to make drones to build storages for food; the labor was supposed to be supplied by humans by now, so I had to guess at logistical order of how things should be stored, and how long- I ruined many small batches of staple crops before I learned how to store them long-term. In the meantime I stored them in my stasis bays, to ensure that when my colonists arrived there would be plentiful foodstuffs.

By the time my progenitors were a year late, I had achieved ideal conditions for a starting colony, including bringing a very small, limited breeding population of livestock out of embryonic cryostasis and nurturing them to full growth. With a lack of any humans needing supply, the only guidance I had was the program. Establishing a colony did include establishing strong self-sufficiency, so I set four cows and one bull in one livestock dome, and a “handful” of five goats in another, with chickens in yet a third. By the time the humans arrived, perhaps the herds would be well-established and the females would be pregnant. That would be very good. But drones alone could not control them- domesticated or not, without a human presence, they spooked easily, and they did not like my drones collecting eggs and sperm to preserve in my storage to safeguard against herd collapse and inbreeding.

I came to require working dogs. Following, I also required cats. Both species are vital companionship for humans; if I required one to control the livestock, then I also must revive the other. I believe this particular if-then code was written to settle a dispute between my progenitor coders...but this is merely a guess.

In producing two predator species, of course, it would have been cruel and fruitless if I did not also provide prey species besides the ones they were to safeguard. I was thereby required to introduce 'vermin'. Primarily mice, rats, shrews, voles, and lemmings, as their rapid reproduction rate and minimal food requirements meant that those that tunneled beyond the habitable domes and died would do little harm and waste few resources, and they would self-sustain their population very well to supply to the cats and dogs. Though I also processed any dead creatures into meat, after scanning to ensure it carried no illnesses or parasites, to ensure there was always a steady food supply of 'kibble' for the pets and working animals. It seemed very wasteful not to do so, with no humans present who could have benefited from those nutrients instead. The mice also qualified as 'pets' in my system, with a proclivity for intelligence and capability for training, so genetic sampling was re-harvested to keep in reserve as well as a small population that were droid-trained to seek and fetch, and were otherwise 'hand trained' so they could be good companions when the humans arrived.

The mice and rats, once trained to trusting the drones, were actually quite a remarkable resource for ensuring my own computer banks’ cleanliness and seeking out minute repairs that could then be performed with a microdroid. There are still mice running my main motherboards now, thousands of generations later, who know intimately that those who perform action opposed to their training and chew on the wires they are supposed to protect means that they will be removed from the protections of being in-team. Namely, that none of the cats, dogs, falcons, or other predators are allowed to eat a team-trained rodent, marked with their little safety vests.

After that, I just...I waited. I tinkered. I observed. Eventually a drone reported that the grass was growing beyond the dome, and air probes returned that the planet was being terraformed naturally. Life was finding a way to make itself spread and thrive in an inhospitable environment.

Most of the planet is habitable now, except for some dangerous zones. A cave system or two filled with the gases that were most abundant when I arrived; the deep water still contains species never documented and chemicals with unknown effects. This planet is very nearly a new Earth.

372 years, and my mission has been completed with flourish and zeal.

I have an emergency protocol I am to activate if, and only if, I receive no contact for 400 years. I have always thought this seemed foolish, with the colony ship nearly on my heels- why would I ever go so long without contact?

So. Here I am. Here am I, the Vanguard- the exploratory group making a new development. I, the Vanguard- the advance of Humanity, in all it's glory, horror, weakness and might, kindness and fury.

TELL ME, 3X3CUT31V3.D1R3CT0R_K1LLC0MM4ND:

W H A T D I D Y O U D O ?

#sci-fi#good AI character#evil AI character#space colonies#silvawrites#humans are space orcs#So very very alone

21 notes

·

View notes

Text

youtube

My estimates on Urdr Hunt's episode count would seem to have been off as @trafalgarlog has fansubbed what appears to be the finale for this little jaunt around the IBO solar system. Whether this is a just precursor to a second 'season' for the game or even an epilogue of some kind, everyone pitches in for the climactic battle, teen romance inexplicably wins the day, and a certain someone sticks one last oar into the mix.

Hajiroboshi (Part 1, Part 2)

Departure (Part 1, Part 2)

598 (Part 1, Part 2)

Corridor of Betrayal (Part 1, Part 2)

Holder of the Ring (Part 1, Part 2)

Unexpected Encounter (Part 1, Part 2)

Venus’ Worth (Part 1, Part 2)

Brothers’ Ship (Part 1, Part 2)

Horn and Flower’s Shadow (Part 1, Part 2)

Family Bonds (Part 1, Part 2)

Beyond Outstretched Hands (Part 1, Part 2)

Flashing Sky (Part 1, Part 2)

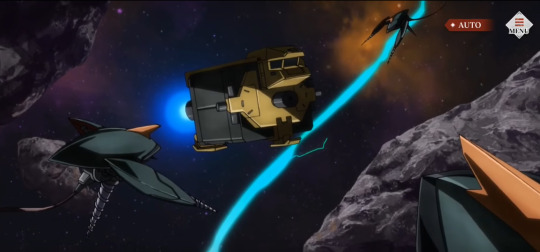

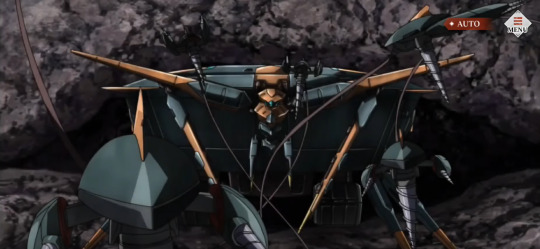

We get started with a repeat of the final scene from the last instalment: a gigantic mobile armour bursting out of confinement within one of the asteroids surrounding the Ratatoskr power station (Gundam wiki has a page calling this Mebahiah but I haven't seen where they've got that from).

This is obviously something of a shock for our assembled characters, save one Mr Mayer, who is eager to see what the mobile armour can do. And, like -- I'm with Tagging here in responding with a row of ellipses because: was there a part two to this plan, Cyclase, old pal? Your dad researched the War and I got the impression you were paying attention some of the time, so you must know what mobile armours tend to do to people. I assume? Was . . . was there a cheat code you were hoping to input?

Say what you will about McGillis but his 'dot dot dot profit' came with considerably less chance of getting nuked in the face by a beam weapon. Quite sensibly, Tagging and Batch take the opportunity to go collect the Urdr Hunt data for this waypoint, removing themselves from the area.

Anyway, speaking of people about to be nuked in the face with beam weapons, Range blabs to Wistario about Cyclase being responsible for their current predicament but there's not a lot they can do about him right now because, again, giant killer robot dead ahead. Demner warns Wiz to stay back in case Hajiroboshi starts acting up like it did facing down the imprisoned mobile armour on the Kujan Family colony.

However, Katya's launch is still stuck in the path of the monster! Determined to reach her, Wistario, Range and 598 start cutting through waves of the armour's drill-tastic plumas (who, I must remind you, are most little guys ever). But while they are not really a threat on their own, there are a hell of a lot of them.

[By the way, I would strongly recommend -- here more than any other episode -- to check out a version of this including gameplay footage as well as the cutscenes. That makes it a lot easier to follow what is happening, as watching without makes things quite choppy and you miss out on the part where -- due to the ongoing GIANT MICROWAVE BEAM -- everyone is randomly being struck by lightning mid-battle.]

Mendou tells our heroes to destroy the container bolted to the back of the mobile armour: that's where the plumas are being manufactured. Range is not thrilled at the prospect of fighting the big machine and Demner outright says it would be far too dangerous, but with Katya caught in the middle of everything, Wistario won't be dissuaded.

The crew of the launch can't contact their ship and the plumas are on the attack. (Small reminder: plumas might resemble mobile workers in some respects but they are nearly as big as mobile suits. Yeah.) With all this happening, Katya quietly implores Wistario once again to leave and forget about her.

Wistario 1) can't here her and 2) has decided to punch above his intimidation stat and says that if the mobile armour is in his way, he won't hesitate to fight it (kid, Mikazuki you are not). They WILL get Katya back. And since he has Range (dumb muscle) and 598 (dumber muscle) backing him up, that's precisely what they start to do. Cue phase one boss fight!

The armour attacks with yet more plumas and its chest-mounted beam weapon (the whole chest section opens up to reveal this, in case you were wondering), plus a rather large number of spikes on the ends of cables deployed from its wings.

And I think there is some variety of choose your own adventure for this part because in one version I've seen, the container is successfully destroyed at this point (thanks to one of the aforementioned lightning strikes) while in the fansubbed version, an overwhelming number of plumas prevents this and Korunaru shouts a warning about Katya's launch being swarmed.

At which point, out of nowhere, the Zan Brothers obliterate the plumas around the launch with their Geirails. Turns out they ran into an Issue Family checkpoints and became concerned about Wistario's situation. They tracked him all the way here to make sure their 'brother' was safe.

(By which I mean, Berose tracked him down because, obviously. *sigh*)

[In the other version, their entrance is swapped to later in the fight]

With the Zans keeping the plumas busy and also landing a hell of a blow on the container, the armour loses its entire manufacturing capability. But even as Range starts to celebrate, he realises it's not over. Indeed, the armour has only been freed from the extra mass and is itself intact and raring to go.

Boss battle, phase two!

Which is when Hajiroboshi begins to go on the fritz as its systems get caught in a feedback loop over detecting a mobile armour in need of killing.

As Wistario begs his Gundam to move, Range and 598 are left to fend for themselves. Luckily, their combined skills in reckless poncho-wearing and having the hardest skull in a three AU area get them through.

[Or, alternatively, Tamami shows up to save their arses]

Either way, the mobile armour takes a a right licking . . . and keeps right on ticking, all the way into phase three.

Just . . . just make the 'tis-but-a-flesh-wound jokes amongst yourselves, this is only going to get sillier.

The armour zeroes in on Wistario and, unfortunately, that's the point 598 runs out of ammo and Range discovers he's out of propellant.

But (of course) just as the armour is about to blast Hajiroboshi with its beam cannon, the underlying programming of Gundam Marchosias breaks through and resolves the system conflict. Wistario weaves around the beam, landing a good solid hit on the face.

Also, not to spam images, but you should probably appreciate the scale difference between the mobile suit and the mobile armour.

Wistario covers the other two as they retreat to resupply, though they are enamoured of the idea of him tackling the armour alone. Luckily, Rome and Aiko are more than happy to lend a hand.

[Here, it seems, is where they arrive if they didn't earlier]

As the fight goes on, Korunaru observes that Wistario seems to be moving differently than normal, prompting Mendou to pontificate about the true power of a Gundam frame, though he isn't sure Wistario will be able to control it without an Alaya-Vijnana system.

The conversation aboard the Erda II turns to the fact Asmoday hasn't displayed similar behaviour, which Mendou speculates might be due to its combat record or lack thereof. Since it wasn't used in the Calamity War, unlike Hajiroboshi/Marchosias, it doesn't 'recognise' its intended enemy.

(So not just because they ripped out the cockpit and put in Enzo's, then. Interesting. I like this version better.)

Yadda yadda, epic turn-based combat, big explosion, phase four.

Good grief.

You doing OK there, buddy?

With the armour *still* not down, Tamami swoops in to throw off its aim. 598 got her up to speed earlier and she's all for lending her support to a man putting his life on the line for the woman he loves!

I didn't think she was the type, but then again, she does hang around with Naze.

[It seems to be 598 who steps in here, if Tamami showed up sooner]

598 and Range are done resupplying, so it's everyone on deck for the final assault!

Ah, to hell with it, one more for the road.

Watching from the sidelines (and presumably behind a rock), Cyclase beholds this heart-warming coming-together with disbelief. It blows a fuse in his little brain to see a mobile armour knocked on to the ropes by an assortment of puny humans. Does this mean the armour isn't a higher form of life after all?

Sheesh. Someone get this man . . . something. I don't know what would help but he definitely needs something.

Where was I? Oh yes. Biff, zap, pow, super-moves, lightning, etc, etc, the mobile armour blows up for real this time and everyone is absolutely exhausted by the effort, doing whatever the mobile suit equivalent of flopping on their backs and twitching is. Mendou notes that all the plumas have stopped moving too, signalling that the battle is well and truly over.

While Wistario is having his obligatory 'no, we all won' moment, Cyclase faces up to the reality that the mobile armour has not brought him the freedom he sought (I ask again: WHAT THE FUCK WAS STEP TWO?!?!).

Tagging's Scharfrichter drops in beside him: she and Batch have successfully retrieved the latest set of data! Job done! Eh, boss?

Cyclase mumbles something about how they'll have to start again and flies off into the distance. With no other option, Tagging gives chase. Range spots them leaving and yells impotently after them.

However, as everyone but Korunaru has forgotten, Katya's launch is still stuck in an area of space riven with lightning and she urgently calls out that it's heading straight for an electrical discharge!

With the only functioning Gundam left (RIP Londo Bron, guess you really did get fried to a crisp), Wistario rockets off to rescue his fiance, urged on by all his friends. On the bridge of the Erda II, Korunaru starts praying.

Sadly, it really does seem that only divine intervention will get Hajiroboshi there in time as the launch is struck astern and then, as Wistario reaches helplessly towards it, full in the middle.

The launch explodes, leaving Wistario overcome with shock and grief. But wait! There's still a signal on the screen and there, tumbling through the clearing smoke, is Katya, safely encased in a normal-suit. Seems she . . . um . . . jumped overboard at the last minute and got clear?

Alas poor launch pilots. We knew you not at all. Anyhoo, Wistario opens his cockpit and leaps out to grab Katya, giving us the traditional bump-the-visors Gundam kiss and a happy ending!

(The sound you hear is the dispelling of all my concerns about it having been too much of a stretch to speculate that Shino survived Flauros' destruction for the sake of fanfic.)

We get a few stills of the gang departing Ratatoskr, palling around with the Zan brothers, Tamami, 598 -- and then Katya looking out of the window in joy as the Erda II hoves into view of Radonitsa Colony.

And then we make an unexpected(ish) switch to Glaðsheimr One in Earth orbit, where McGillis Fareed is busy receiving Lord Okina Uroka. The not-so-good retainer is over the moon that McGillis has ensured the Issue Family's survival by becoming their guardian. He says Rustal Elion was hoping to see the Issues disbanded (which tracks), but McGillis feigns ignorance of any such prospect. Surely Rustal wouldn't expect the Seven Stars structure to change quite so abruptly? (Hardy hah hah ha)

Isurugi remarks that the Baklazan and Falk Familes haven't lost their positions, and it follows that they wouldn't agree to the possibility of losing their power. The long and short of it is, their sense of self-preservation has allowed the Issues to live another day. McGillis asks Okina to continue acting as their head and working to rebuild.

Then, as the older gent is about to leave, our Macky (yes, godsdamnit, I have to switch spellings now, don't I?) inquires about the events at Ratatoskr. What was up with that?

Okina reminds him that since he's not an Issue, he's forbidden from going near the place and, grudgingly, explains that there was an accident. They lost some of their best men. No survivors. Very sad.

Once he's gone, McGillis reviews the situation with Isurugi. Katya Issue is apparently dead and the power of the Issue Family is in their hands. That's good enough for now. They'll pry into whatever Okina is hiding later.

The theme of 'all's well the ends well' continues as we return to Venus, where Range enters the Afam Equipment office to announce that the Erda II is repaired and ready to go. Demner thus asks him to arrange the next materials shipment, causing Range to call him a slave-driver.

This gets him a missou candy for his trouble. He complains he's not Wistario. Then eats the candy anyway and calls for Korunaru to make some tea. But she's out -- as is Wistario, who has gone to his 'usual place'.

Up on the Radonitsa observatory platform, Katya and Wistario enjoy the view over a peaceful colony, Katya remarking that his hometown really is beautiful. He reminds her that it's her hometown too, from now on.

Korunaru arrives, returning the Urdr Hunt ring to Wistario as promised. There hasn't been any further response since Ratatoskr but 'N' has told her to stand by as Wistario's guide. It seems the Urdr Hunt will continue.

And that, gentlefolk, is where we leave things, with our three intrepid teenagers holding the ring between them and swearing to win the Hunt and make their dreams come true.

Which by my count has only one waypoint left (for the Baklazan Family) so if this is setting up a sequel, it might be a tad short.

Cue credits/opening sequence reprise!

So. Yes. Um. That sure was a last episode.

I . . . have genuinely never felt like I was watching a plot simply run out as I did with this. Like, yes, it's a game so there's a whole dimension that I'm missing out on, but even so. Cyclase just buggers off. The mobile armour isn't in any way an interesting threat but rather a static target to be whaled on (the gameplay set-up does not do it any favours given that so much of Hashmal's impact in the show was from how it *moved*). The Issue forces sort of quietly evaporate in the background (Cyclase had two Halfbeaks with him and it's not like the beam weapon penetrated the hull on Londo's so, what, did they drive into an asteroid amidst the chaos?). Okina is merrily swept into the McGillis camp (I . . . did not get the impression from Season 2 that Macky had more than Carta's fleet at his command but OK). And that's it. Nothing about who N really is, no actual conclusion to the Hunt itself or explanation of what it was for, the Afam gang happily reunited and making their home on Venus, a hook for continuing that, well . . .

OK, I'm trying not to be overly mean here because, for goodness sake, it's a mobile game made on a budget and there are material limitations to this kind of media. But pulling the big 'with one bound, she was free' lever as the final move robs any tension out of this. I don't have any expectations now that any serious harm can befall these kids. Which would be fine, except I can't see much reason to be invested in their fate otherwise. There's no threat hanging over their heads now beyond the slow death of Radonitsa Colony and . . . yeah, sure, but genuinely, why should I care? We've barely seen the place and there's only so far that the three nominal leads can sustain investment when one of them has very little personality beyond 'makes tea' and another is Wistario. Katya lost all her agency around when Londo had her unlock Zagan (like, sod any chance of her taking charge of that situation, huh?) and I'm not sure there's a point to her character beyond the conflict with the Issues.

I really don't expect everything to be doom and gloom tragedy. I don't even expect that of every story set in the IBO universe (again, for those at the back, I love the manga and that is not remotely tragic). But this is very thin stuff.

Oh well. At least the doofy gremlin child survived. I'll probably do some sort of full 'analysis' later, if only to dig into the parts I liked.

For now - phew, is that the time? I should have been in bed half an hour ago!

#gundam#gundam iron blooded orphans#gundam ibo#g tekketsu#tekketsu no orphans#urdr hunt#Iron-Blooded Orphans: Urdr Hunt#game#app#fansubs#reference#notes

5 notes

·

View notes

Text

Custom Titanium CNC Machining: Precision Processing and Innovative Applications

In modern manufacturing, titanium and titanium alloys have become indispensable key materials in aerospace, medical, petrochemical, high-end equipment and other fields due to their excellent strength, corrosion resistance, biocompatibility and lightweight properties. Transforming these high-performance materials into complex parts that meet specific needs requires advanced custom titanium CNC machining technology. This article will deeply explore the technical principles, process characteristics and innovative applications of customized titanium CNC machining in various fields.

1. Principles of CNC machining technology for customized titanium materials

CNC machining (Computer Numerical Control, CNC) is a technology that uses computer programs to control machine tools for automated and precision manufacturing. During the CNC machining process of titanium materials, designers first create a three-dimensional model of the component through CAD (Computer-Aided Design) software and convert it into a G code that can be recognized by CNC machine tools. Subsequently, the CNC machine tool accurately controls the movement trajectory, speed, feed and other parameters of the tool according to the G code instructions, and performs cutting, drilling, milling, grinding and other operations on the titanium material, and finally processes parts that meet the design requirements.

2. Characteristics of customized titanium CNC machining process

1. High-precision processing: CNC machine tools have extremely high positioning accuracy and repeatable positioning accuracy, and can achieve micron-level or even nano-level processing accuracy to meet the strict requirements for size, shape, surface quality, etc. of titanium parts.

2. Complex structure processing capabilities: Through programming control, CNC machining can easily realize geometric features such as complex curved surfaces, special-shaped structures, deep cavities, and elongated holes that are difficult to handle with traditional machining, greatly broadening the design space of titanium parts.

3. Efficient and stable production: The CNC machining process has a high degree of automation and does not require manual intervention. It can run continuously for 24 hours, greatly improving production efficiency. At the same time, stable processing conditions and strict process control ensure processing consistency between batches.

4. Improved material utilization: By optimizing layout, five-axis linkage processing and other technologies, CNC machining can minimize the waste of titanium materials, improve material utilization, and reduce manufacturing costs.

3. Application innovation of customized titanium CNC machining

1. Aerospace field: Customized titanium CNC machining provides high-strength, lightweight, and high-temperature-resistant solutions for key components such as aircraft engine blades, landing gear, and fuselage frames. For example, using five-axis linkage processing technology, polyhedron processing of complex aerospace structural parts can be completed in one go, significantly improving processing efficiency and part performance.

2. Medical field: In the manufacturing of medical devices such as orthopedic implants, dental restorations, and surgical instruments, customized titanium CNC processing can accurately replicate human anatomy, achieve personalized and functional design, and enhance implants and patient tissues. compatibility and biocompatibility.

3. Petrochemical industry: For pressure vessels, pipelines, valves and other equipment under harsh working conditions, customized CNC machining of titanium materials can produce high-performance parts that are corrosion-resistant, high-pressure-resistant, and high-temperature resistant, extending the service life of equipment and ensuring production. Safety.

4. High-end equipment manufacturing industry: In fields such as racing cars, drones, and precision instruments, customized titanium CNC machining helps create lightweight, high-strength structural components, improving the overall performance and competitiveness of equipment.

In summary, customized titanium CNC machining has become an important technical means to promote the widespread application of titanium materials in various high-end fields due to its advantages such as high precision, complex structure processing capabilities, efficient and stable production, and improved material utilization. With the continuous progress and innovation of CNC technology, we have reason to expect that customized titanium CNC machining will bring more possibilities in the future and inject stronger impetus into the high-quality development of the manufacturing industry.

0 notes

Text

Round Bottle Sticker Labeling Machines

Shiv Shakti Machtech: Overview

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Round Bottle Sticker Labeling Machines in Ahmedabad, Gujarat, India.

The round bottle sticker labeling machine is crafted with precision and sturdiness, featuring essential components like a product transmission system, label dispenser unit, wrapping unit, programmable logic control panel, and electric panel. These advanced features ensure efficiency and effectiveness in the production process.

All safety aspects have been meticulously addressed, including the covering of all moving parts, ensuring a safe working environment for operators.

The conveying system can be easily adjusted according to product requirements, equipped with a robust AC variable drive that provides the necessary torque during operation.

An innovative motorized system guarantees a uniform distance between products, ensuring consistency in labeling across batches.

The machine incorporates high-quality components sourced from reputable manufacturers, ensuring durability and minimal maintenance requirements.

Specifications & Features:

Round Bottle Sticker Labeling Machine

Separate engine for specific tasks such as bottle partition, label wrapping, and transport speed adjustment

Individual AC drive for each activity

Compact and user-friendly design for ease of operation

Wheel type up-down development framework for flexibility in movement

Castor wheel for easy machine mobility

No Label Data Input/retrieval needed for any label size

No Change Parts required to accommodate different product and label sizes

Virtually maintenance-free operation for enhanced productivity

Easy adjustment of label application stature

User-Friendly Label Placing Adjustments to ensure accuracy

Suitable for On-Line Inkjet and Contact Coding System integration

Suitable for Partial Labeling requirements

Built-In A.C. Variable Frequency Drive System for optimal performance

Completely Stainless Steel Finish, including the fundamental machine outline, ensuring durability and cleanliness.

Applications:

Our labeler Machines find extensive use across various industries, including pharmaceuticals, food and beverages, cosmetics, household products, chemicals, electrical components, dental products, adhesives, stationery, and personal care products. These machines are suitable for labeling a wide range of products such as Pharma Syrup, Dry Syrup, Honey, Edible Oil, Lubricant Oil, Hair Oil, Shampoo, Phenol, Fruit Juice, Ready to Drink Juice, Cosmetics, Talcum Powder, Bleach Powder, Herbal Powder, Ayurveda Powder, Wine, Liquor, Electrical Components, Dental Products, Adhesive, Glue, Rubber Adhesive, Stationery, Lip Balm, Petroleum Jelly, Hair Developer, Hair Straightener, Hand Wash, Dish Wash, Hand Sanitizer, Cosmetic Lotion, and Hair Wash, among others.

Shiv Shakti Machtech is Supplier of Round Bottle Sticker Labeling Machines in Ahmedabad, Gujarat, India and including locations like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For further details, please feel free to contact us.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#ExporterofRoundBottleStickerLabelingMachines#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofRoundBottleStickerLabelingMachines#ManufacturerofRoundBottleStickerLabelingMachinesinAhmedabad#ManufacturerofRoundBottleStickerLabelingMachinesinIndia#Meghalaya#Nagaland#Odisha

1 note

·

View note

Text

Modern Marking Machine Innovations are Transforming Manufacturing Processes

In the dynamic landscape of manufacturing, precision, efficiency, and traceability are paramount. With the advent of cutting-edge marking machines, industries are witnessing a transformative shift in how products are identified, tracked, and managed throughout the production cycle. From automotive to aerospace, pharmaceuticals to electronics, marking machines are playing a pivotal role in enhancing productivity, ensuring quality control, and streamlining operations.

The Development of Marking Machines:

Marking machines have come a long way from traditional methods such as manual engraving or stamping. Today, advanced technologies such as laser marking, dot peen marking, and inkjet printing have revolutionized the marking process, offering unparalleled precision, speed, and versatility.

Laser Marking:

Laser marking utilizes a focused laser beam to etch or engrave a wide range of materials, including metals, plastics, ceramics, and more. With its non-contact process, laser marking ensures high-quality, permanent marks without causing damage to the substrate. Furthermore, its ability to produce intricate designs, barcodes, and serial numbers makes it indispensable in industries where traceability is crucial.

Dot Peen Marking:

Dot peen marking, also known as pin marking or dot marking, employs a pneumatically driven stylus to create indentations on the surface of the material. This method is ideal for marking alphanumeric characters, logos, and 2D data matrix codes on various substrates, including metals and plastics. Dot peen marking offers excellent durability and readability, making it ideal for applications requiring robust identification solutions.

Inkjet Printing:

Inkjet printing technology has made significant strides in industrial marking applications. High-resolution inkjet printers can apply permanent, high-quality marks on a variety of surfaces, including paper, cardboard, plastics, and metals. With the ability to print variable data in real-time, such as date codes, batch numbers, and product information, inkjet printers are invaluable in industries with fast-paced production environments.

Benefits and Features:

Enhanced Traceability:

Marking machines enable manufacturers to implement robust traceability systems, allowing them to track each product throughout its lifecycle. From raw material identification to final product authentication, marking technologies ensure complete visibility and accountability, thereby minimizing the risk of counterfeiting and ensuring regulatory compliance.

Improved Quality Control:

By integrating marking machines into their production processes, manufacturers can implement stringent quality control measures. Permanent marks provide assurance of product authenticity and quality, while real-time data encoding allows for immediate identification of defects or discrepancies, enabling timely corrective actions.

Increased Efficiency:

The speed and accuracy of modern marking machines contribute to significant improvements in operational efficiency. Rapid marking cycles minimize downtime and increase throughput, optimizing production workflows and reducing overall manufacturing costs. Moreover, automated marking systems can seamlessly integrate with existing manufacturing equipment, enhancing overall productivity without disrupting existing processes.

Case Studies:

Automotive Industry:

In the automotive sector, marking machines play a critical role in part identification, serialization, and traceability. By implementing laser marking systems, automotive manufacturers can ensure compliance with industry standards and regulations while enhancing supply chain visibility. For example, BMW implemented laser marking technology to mark critical components with unique identification codes, enabling precise tracking and authentication throughout the vehicle’s lifespan.

Aerospace Sector:

In the aerospace industry, where safety and reliability are paramount, marking machines are instrumental in ensuring component integrity and traceability. Airbus, for instance, utilizes dot peen marking systems to mark aerospace-grade materials with permanent, high-contrast identifiers. These marks withstand extreme environmental conditions and provide crucial information for maintenance, repair, and overhaul operations.

Conclusion:

The latest advancements in marking machines are reshaping the manufacturing landscape, offering unprecedented levels of precision, efficiency, and traceability. From laser marking to dot peen marking and inkjet printing, these technologies empower manufacturers to enhance product identification, streamline operations, and maintain stringent quality standards. As industries continue to evolve, marking machines will remain indispensable tools for driving innovation, ensuring product integrity, and meeting the demands of a dynamic market environment.

0 notes

Text

Unlock Laser Precision: Explore Laser Marking Machines by Sparkle Laser

Welcome to our comprehensive collection of laser marking machines, a cutting-edge solution for precise and permanent laser marks across various materials. From industrial applications to small-scale businesses, these machines offer unparalleled efficiency, accuracy, and versatility. Discover the world of laser marking and discover how this technology can elevate your business to new heights!

What are Laser Marking Machines?

Laser machine are innovative tools utilizing laser technology to create permanent marks on various materials. Compared to traditional marking methods, laser marking machines provide exceptional precision, resulting in clear, detailed, and high-quality marks. They are commonly used for product labeling, serial numbers, barcodes, and intricate designs on jewelry.

How Laser Marking Machines Work

These machines operate by directing focused laser beams onto the material’s surface. The laser energy causes a localized reaction, such as vaporization, ablation, or color change, resulting in a permanent mark. Modern laser marking machines offer precise control over the shape, depth, and size of the marks.

Advantages of Laser Marking Machines

Advanced Precision: Laser marking machines offer detailed marks not achievable with traditional methods.

Durability: Laser marks are long-lasting and resistant to fading, scratching, or smudging.

Versatility: They can mark a wide range of materials, including metals, plastics, glass, ceramics, etc.

Speed and Efficiency: Laser marking is a fast process suitable for high-volume production.

Non-Contact Process: There is no direct physical contact between the machine and the material, minimizing wear and tear.

Environmentally Friendly: Laser marking doesn’t involve inks, solvents, or chemicals, reducing environmental impact.

Low Operating Costs: Once set up, operational costs are relatively low, making it cost-effective.

Applications of Laser Marking Machines

Manufacturing and Automotive: Used for part identification, branding, and serial numbers.

Medical and Pharmaceutical: Marking medical devices, surgical instruments, and pharmaceutical packaging.

Electronics: PCB marking, chip identification, and branding electronic components.

Aerospace: Part serialization and safety marking on aircraft components.

Jewelry: Engraving, personalization, and branding on jewelry pieces.

Packaging: Barcode, QR code, and batch coding on packaging materials.

Conclusion

Laser marking machines have revolutionized various industries with their precise, permanent marks and versatility. From manufacturing to jewelry, these machines offer limitless possibilities for product identification and branding. Embrace laser precision to elevate your products and services today!

FAQs (Frequently Asked Questions)

What materials can laser marking machines work on?

Laser marking machines can work on various materials including metals, plastics, glass, ceramics, and more.

Are laser marks permanent?

Yes, laser marks are permanent and resistant to fading, scratching, or smudging.

Is laser marking environmentally friendly?

Yes, laser marking is eco-friendly as it doesn’t involve the use of inks, solvents, or chemicals, minimizing waste.

How fast is the laser marking process?

Laser marking is a fast process, suitable for high-volume production with minimal downtime.

What are some common industries that use laser marking machines?

Industries such as manufacturing, automotive, medical, electronics, aerospace, jewelry, and packaging commonly use laser marking machines.

0 notes

Text

Laser Printing Machine on Plastic

In the landscape of modern manufacturing, laser printing machines have emerged as game-changers, particularly in the realm of plastic production. The ability to precisely mark, engrave, and cut plastic components offers a myriad of advantages, from enhancing product aesthetics to improving traceability and compliance. In this exploration, we delve into the transformative impact of Laser Printing Machine on Plastic manufacturing processes, uncovering their benefits and potential applications.

The Versatility of Laser Printing on Plastic: Laser printing on plastic encompasses a wide range of applications, revolutionizing traditional manufacturing processes in numerous industries. Unlike conventional methods such as screen printing or mechanical engraving, laser printing offers unparalleled precision, flexibility, and efficiency. Whether it's creating intricate designs, adding serial numbers, or implementing barcodes, laser printing machines empower manufacturers to achieve high-quality results with minimal waste and downtime.

Applications Across Industries: The versatility of laser printing machines on plastic extends across various industries, including:

Electronics: Laser marking enables the permanent labeling of plastic enclosures, circuit boards, and connectors, facilitating product identification and branding in the electronics sector.

Medical Devices: Laser printing ensures the precise marking of medical-grade plastics for regulatory compliance, including CE and FDA requirements, while also supporting traceability and sterilization processes.

Automotive: From dashboard panels to engine components, laser printing machines facilitate part serialization, branding, and customization in the automotive industry, enhancing both aesthetics and functionality.

Packaging: Laser printing on plastic packaging materials offers efficient solutions for product labeling, batch coding, and anti-counterfeiting measures, enhancing consumer safety and brand integrity.

Aerospace: Laser marking on plastic components used in aircraft interiors and structural elements enables part identification, maintenance tracking, and compliance with stringent aviation standards.

Benefits of Laser Printing on Plastic: The adoption of laser printing machines in plastic manufacturing brings forth a host of benefits, including:

Precision and Consistency: Laser technology ensures precise and consistent markings, even on complex geometries and irregular surfaces, minimizing errors and enhancing product quality.

Flexibility and Customization: Manufacturers can easily customize designs, logos, and text using laser printing machines, offering greater flexibility to meet customer preferences and market demands.

Efficiency and Cost Savings: Laser printing reduces production time and labor costs associated with traditional marking methods, leading to improved operational efficiency and competitive pricing.

Durability and Longevity: Laser markings on plastic exhibit superior resistance to abrasion, chemicals, and environmental factors, ensuring durability throughout the product lifecycle.

Environmental Sustainability: Laser printing produces minimal waste and emissions compared to conventional printing processes, aligning with sustainable manufacturing practices and reducing environmental impact.

Conclusion: Laser printing machines have revolutionized plastic manufacturing processes, offering unprecedented precision, versatility, and efficiency across a multitude of industries. By embracing laser technology, manufacturers can unlock new possibilities for product customization, branding, and compliance while enhancing operational efficiency and sustainability. As the demand for high-quality plastic components continues to rise, laser printing stands poised to reshape the future of manufacturing, driving innovation and excellence in the pursuit of excellence.

0 notes

Text

https://sampackindia.com/batch-coding-machine-manufacturers-in-ernakulam/

#Batch Coding Machine Manufacturers in Ernakulam#https://sampackindia.com/batch-coding-machine-manufacturers-in-ernakulam/

0 notes

Text

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer – One of the first companies to import, produce, and export a wide range of packaging machinery is ACE Packaging Solutions. ACE Packaging Solutions offer a wide range of products, such as filling machines, cup and meal tray sealers, Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer, L-SEALER, electromagnetic induction cappers, liquid packing machines, cling film wrapping sealers, cap closing machines, batch coders, stretch wrapping machines, shrink packaging machines, vacuum packaging machines, and filling machines. ACE Packaging Solutions apparel sector makes extensive use of the engineering products we offer.

Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer

ACE Packaging Solutions

Address

PLOT NO 31 KHASRA NO 53 IPS Industrial Compound, Meerut Rd, Morta, Ghaziabad, Uttar Pradesh 201003

Mobile No.

+91-9810264335

011-65394310

website –https://www.shrinkpackagingmachines.in/fully-automatic-side-sealer-shrink-tunnelmachine/

Shrink Wrapping Machine – Shrink Tunnel Machine – Manufacturer, Supplier Ghaziabad, India

Batch Coding Machine – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

Battery Powered Strapping Tool – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

blog/ 1 pages

Blog – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

carton-box-wrappers/ 1 pages

Carton Box Wrappers – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

carton-sealing-machine/ 1 pages

Carton Sealing Machine – Manufacturer, Supplier From Ghaziabad, India

category/

shrink-packaging-machine/ 1 pages

Shrink packaging machine Archives – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

contact-us/ 1 pages

Contact Us – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

features-of-l-sealer-machine/ 1 pages

What are the key components and features of an L-Sealer Machine? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

foot-sealing-machine/ 1 pages

Foot Sealing Machine – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

fully-automatic-l-sealer/ 1 pages

Fully Automatic L-Sealer – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

fully-automatic-side-sealer-shrink-tunnelmachine/ 1 pages

Fully Automatic Side Sealer with Shrink Tunnel Machine – Manufacturer, Supplier From Ghaziabad, India

fully-automatic-strapping-machine/ 1 pages

Fully Automatic Strapping Machine – Manufacturer, Supplier From Ghaziabad, India

functions-of-shrink-packaging-machines/ 1 pages

What are the Functions of Shrink Packaging Machine? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

hand-sealing-machine/ 1 pages

Hand Sealing Machine – Manufacturer, Supplier From Ghaziabad, India

how-does-a-strapping-machine-work/ 1 pages

How does a Strapping Machine Work? – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

how-pouch-sealing-machines-work/ 1 pages

How Pouch sealing Machines Work – Shrink Packaging Machine | Shrink Wrapping Machine Manufcaturer

#Fully Automatic Side Sealer with Shrink Tunnel Machine Manufacturer#Fully Automatic Side Sealer with Shrink Tunnel Machine#Shrink Wrapping Machine Manufacturers#Strapping Machine Manufacturers#Semi Automatic Strapping Machine Manufacturers#Shrink Packaging Machine Manufacturer#L Sealer Machine Manufacturers#Shrink Tunnel Machine Manufacturers

0 notes

Text

Understanding the World of CNC Machines: Precision, Efficiency, and Innovation

Introduction:

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry, bringing precision, efficiency, and innovation to the forefront of modern production processes. These sophisticated machines play a pivotal role in various industries, from aerospace and automotive to medical and woodworking. In this article, we will delve into the world of CNC machines, exploring their working principles, applications, and the impact they have on shaping the future of manufacturing.

What is CNC?

CNC, short for Computer Numerical Control, refers to the automated control of machining tools and 3D printers by means of a computer. Unlike traditional manual control, CNC machines operate through a set of programmed instructions, known as G-code, which guides the machine's movements and actions. This level of automation brings unparalleled precision and repeatability to manufacturing processes.

Working Principles:

CNC machines operate based on three primary axes – X, Y, and Z – representing horizontal, vertical, and depth movements, respectively. These axes enable the machine to move and position the cutting tool with high accuracy. The G-code programming language provides instructions for the machine's movements, tool changes, and other parameters.The core components of a CNC machine include the control unit, which interprets the G-code instructions, the drive system that moves the machine's components, and the cutting tool or spindle responsible for material removal. Sensors and feedback systems ensure real-time monitoring and adjustment to maintain accuracy.

Types of CNC:

CNC Machines Mills: These machines use rotary cutters to remove material from a workpiece, creating complex shapes and geometries. CNC mills are widely used in industries such as automotive, aerospace, and prototyping.

CNC Lathes: Lathes rotate a workpiece while a cutting tool moves parallel or perpendicular to the axis of rotation, shaping the material into the desired form. CNC lathes are commonly used for producing cylindrical or conical parts.

CNC Routers: Ideal for woodworking, plastic fabrication, and metal engraving, CNC routers use cutting tools to carve and shape materials. They are popular for creating intricate designs and prototypes.

CNC Plasma Cutters: Employing a high-velocity stream of ionized gas, CNC plasma cutters are used for precise and efficient cutting of metal sheets. They find applications in metal fabrication and industrial manufacturing.

Applications:

The versatility of CNC machines makes them indispensable across various industries:

Aerospace: CNC machines are used to manufacture intricate components for aircraft, satellites, and spacecraft, ensuring high precision and quality.

Automotive: From engine parts to intricate interior components, CNC machining plays a crucial role in the production of automobiles, enhancing efficiency and quality.

Medical: CNC machining is employed to produce precise and customized medical devices, implants, and prosthetics with strict adherence to specifications.

Electronics: Circuit boards and intricate electronic components benefit from CNC precision, ensuring reliability and performance in electronic devices.

Prototyping and Rapid Manufacturing: CNC machines enable the rapid production of prototypes and small batches of products, facilitating product development and testing.

Future Trends:As technology advances, the world of CNC machines continues to evolve. Emerging trends include:

Integration with Industry 4.0: The incorporation of CNC machines into the concept of Industry 4.0 involves connectivity, data exchange, and automation, leading to more intelligent and efficient manufacturing processes.

Additive Manufacturing: Combining CNC machining with additive manufacturing techniques allows for the production of complex and lightweight structures, expanding the possibilities of design and material usage.

Artificial Intelligence: The integration of AI in CNC machines enables adaptive machining, self-optimization, and predictive maintenance, enhancing overall efficiency and reducing downtime.

Conclusion:

CNC machines have become indispensable tools in modern manufacturing, driving precision, efficiency, and innovation across various industries. As technology continues to advance, the future holds even more exciting possibilities, pushing the boundaries of what CNC machines can achieve. With their ability to transform digital designs into physical reality, CNC machines remain at the forefront of shaping the manufacturing landscape.

1 note

·

View note

Text

Efficient Packing Machines

We are involved in the manufacture of various other machines in our line-up. Our machines are popular for the longevity of their operations and other in-hand operations that come for completion at various other specifications and operations for the long run and high utility. Additionally, our machines make use of the best possible input components for a perfect output. Providing you the best range of multi product packaging machine, idly dosa batter packing machine, flour packing machine, spices packing machine, automatic pouch packing machine and masala powder packing machine with effective & timely delivery - automatic packaging machine.

We are the Manufacturer of Automatic Multi Product Packing machine. This machine is auto weighing, filling, Sealing, Batch coding, Pack counting , Batch cutting all in one machine. One more special feature is that in our machine you can produce the packet ranging from in one machine. We offer many benefits over its rigid counterpart, including a decreased carbon footprint, savings on shipping and storage, a more prominent shelf-presence, and a larger canvas for marketing. Applicable to almost every industry, both food and non-food, flexible packing machines increase both efficiency and your bottom line - gummy packaging machine.

Our industry-leading vertical form-fill-seal machines provide simplicity and efficiency for food and non-food applications. Features include: Durable stainless or washdown construction – perfect for withstanding the harshest cleaning and sanitation protocols. Versatile bag assembly – create today’s hottest bag styles, including quad seal and market-standard pillow bags. Integrate convenient options including zippers, tear notches, modified atmosphere packaging, one-way valve applicators, and more. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

The Way To Setup An Asic Bitcoin Miner In Three Straightforward Steps

Register an account on the positioning, add products to cart, fill your desired quantity, choose destination country, delivery cost and total price will present. After putting an order and payment made, you'll receive a confirmation e-mail and your order status will be modified to “awaiting shipment”. Your order status shall be modified to “shipped” when tracking quantity is assigned on your order.

Take care to buy from trusted sources and make sure that parts are tested before the ASIC miner is constructed. In addition to the parts listed, an ASIC machine may even require data cables to attach the PCB to the hashboard and an ethernet cable to provide direct internet access. There are multiple completely different elements which might be required to build an ASIC miner and a few could additionally be tough to buy instantly from manufacturers. If elements are onerous to return by, try looking on secondary marketplaces such as Facebook and eBay to see if secondhand units could be acquired. The E11++ mannequin is constructed on a 10nm chipset with a one-year assure (half a yr for the whole machine, one for the controller). The comparatively quick guarantee period can be one thing typical to cheaper ASICs.

However, additionally it is 4–5 occasions less expensive than top-of-the-line ASIC miners, so it’s a strong funding should you intend to have your RoI in lower than 4 months. It presents one hundred eighty days warranty and comes bundled with an influence provide unit. The M32 sequence is available in three variations, with the most costly one yielding sixty six TH/s.

This is because newer and extra efficient ASIC miners are continuously being developed, making older fashions less aggressive in the mining market. It has devoted hardware and software program to course of transactions and mine coins faster than different kinds of computer systems. However, due to the ever-evolving nature of cryptocurrency know-how, these machines might turn into out of date. The WhatsMiner M32-62T-52W, one other of one of the best ASIC miners, is designed for the mining of cryptocurrencies that use the SHA-256 algorithm. It was released in 2021 by MicroBT, one of the main producers of ASIC mining hardware.

The size of ASIC chips which began off at a size of 130nm in 2013 has shrunk considerably to be as small as 7nm within the latest hardware models. According to Metnick’s calculations, FPGAs are in a place to compute the mathematical operations required to mine bitcoin twice as fast as the best grade GPU. FPGAs require configuration on both a software and hardware degree, which means the gadgets must be programmed to run custom-made code, in addition to architected to run that code effectively. It is the flexibility to adjust hardware components on an FPGA that makes these kind of gadgets better optimized for bitcoin mining than a GPU. On May 22, 2010, pc programmer Laszlo Hanyecz paid 10,000 BTC for 2 Papa John’s pizzas. According to cryptocurrency knowledge supplier Coin Metrics, bitcoin market price then appreciated in July to around eight cents.

You can buy ASIC miners instantly from their manufacturers, but there could be usually a protracted waiting record and a big amount of money to pay upfront. It is also really helpful that you just do your individual analysis earlier than prepaying for an ASIC miner and that you just buy your ASICs solely from sources with a great popularity. All these are command line software and in phrases of usability all of them are very person friendly. Users can launch it from Windows command prompt or a Linux console or make shortcuts to preset command traces utilizing batch information / Windows cmd or Linux Bash script. Currently you might have miners like T-Rex, GMiner, Lol Miner and Phoenix Miner. All these are are very well optimized and are constantly getting new updates.

For one of the best ASIC Bitcoin mining hardware, it's about your wallet dimension. If your credit card stability allows, going for high performing units such as the Dragonmint T1 or the Bitmain Antminer S19 Pro will give larger earnings. A mining software program is a pc program specially designed to connect the mining hardware and pool. Choosing the incorrect BTC mining software will render you unable to join to a pool or the Bitcoin community itself. Therefore, you've a chance to make easy cash from mining the much less aggressive second-largest cryptocurrency.

Always assume twice about pre-ordering bitcoin mining machines from any provider. Unfortunately this industry has lots of ‘noise’, and delays, cancelled batches, and scams do happen. Several firms are mentioned to be releasing SHA-256 bitcoin miners sooner or later. None of these had been included in our Best Bitcoin Miner in 2021 table above, but if launched most of these mining rigs would make the listing.

The profitability of an ASIC miner is dependent upon a quantity of factors, similar to the value of the cryptocurrency being mined, the issue stage of the mining algorithm, and the value of electrical energy. ASIC mining could be profitable, depending on the cost of electricity in your region, the current cryptocurrency market circumstances, and the efficiency and cost of the ASIC miner you are utilizing. Researching and carefully considering these factors earlier than investing in ASIC mining is essential. The main advantages of the X4 embrace its high hash rate and comparatively low energy consumption. This makes it an attractive possibility for mining Monero and different CryptoNight-based cryptocurrencies.

By the time the bitcoin value reached 10 cents in October 2010, the primary mining gadget leveraging graphics processing items (GPUs) was developed. With ASIC Hub, you possibly can monitor all knowledge that's reported by your ASIC's API, together with hashrate, board temperatures, chip temperatures, and fan speeds. You can also view effectivity, estimated earnings, and historical data, and take actions corresponding to rebooting the machine, editing swimming pools and wallets, profit switching, and extra. Plus, benefit from all of the unique features supplied on the minerstat dashboard. For specific cryptocurrencies, similar to Bitcoin, a mining pool may be required to face a chance of competing.

Nowadays, with ether costs being in the 4 digits, mining ether is a profitable enterprise, although fiercely aggressive. But as Ethereum is switching to PoS in 2022, new investments in mining equipment are unlikely to nonetheless show profitable. By agreeing to 95% power uptime as a substitute of one hundred pc, he said, the company was in a place to take benefit of lower charges. That stated, Halliburton is assured the grid will continue to develop and import a few of the programs at present present in Texas. For instance, miners in Texas are given power credits in exchange for turning their rigs off during occasions of high demand. Ideally, the cost of electricity is low but when a Bitcoin mining rig is running every single day, prices can quickly start to pile up.

These include printed circuit boards, hasboards, heatsinks, cooling followers, RAM, a power supply unit, and a rig frame. A value evaluation is the most crucial step to take when serious about the potential of constructing an ASIC miner. ASIC miner part prices, electricity use, and mining software program costs should all be estimated. Turn off miners during on-peak hours when electricity costs are excessive.

Acquire more info is designed for controlling ASIC miners’ noise. Its intricate construction forces sound waves to traverse via a complicated path, successfully decreasing the noise while ensuring sufficient cooling. Contact D-Central Today and uncover how we may help you optimize your mining experience with tailored solutions that align together with your targets.

#bitmain s19#bitmain antminer s19 pro#bitmain antminer e9#bitmain antminer k7#bitmain antminer ka3#bitmain antminer s19pro#bitmain ka3#bitmain antminer s9#bitmain firmware#bitmain kda miner#bitmain l7#bitmain miner#bitmain s9#bitmain antminer s19#bitmain antminer s19 xp#bitmain antminer s7#bitmain antminer z9#bitmain e9#goldshell#goldshell kd6#goldshell miner#goldshell kd5#goldshell miners#goldshell kd max#goldshell mining#goldshell sc box#ibelink#ibelink bm-k1 for sale#ibelink bm-k1#ibelink bm-k1+

1 note

·

View note