Photo

Racing a very tight schedule -- we are immediately into production after the test fixture is blessed. Frames are 12’ tall.

0 notes

Photo

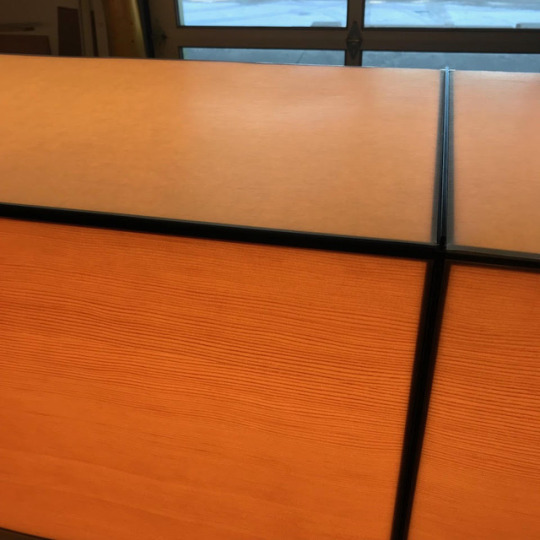

Wood veneer and our aramid composite are tested and evaluated. Aramid composite is chosen and a full size test fixture is tried in the space.

0 notes

Photo

Starting a new project for Olson Kundig. Large scale lanterns for a Seattle office tower lobby space. Beginning by welding a small steel test frame then a larger one and investigating illumination schemes.

0 notes

Photo

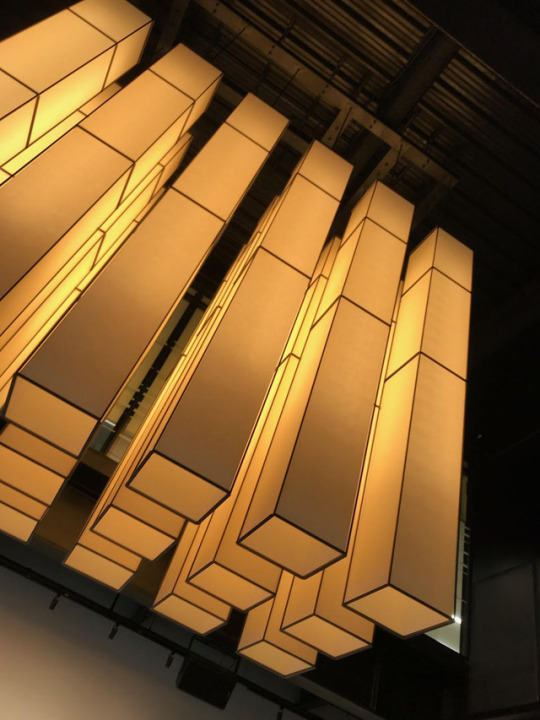

Cluster in the finished space.Delicate steel frames with blackened finish.Aramid composite shades. LED core illumination with proprietary Resolute diffusion.

Olson Kundig Architects.

https://www.olsonkundig.com/projects/9th-avenue-thomas/

Tom Kundig Design Principal. Kristen R. Murray Project Principal. Team: Scott Hallock, Jeff Ocampo, Sasha Leon.

0 notes

Photo

Cluster is hung and illuminated in the empty space. Sellen Construction and McKinstry (Mechanical/ Electrical) worked together to install these giants.

0 notes

Photo

Test hanging before crating

0 notes

Photo

Supporting structure

0 notes

Photo

Evolving details

0 notes

Photo

Working on support and balance.

0 notes

Photo

Production techniques getting dialed in.

The flattened flange helps control the piece.

These are the “small” size.

0 notes

Photo

Investigating various edge details.

0 notes

Photo

Spoon is primarily a product of the English Wheel

0 notes

Photo

Test fit of early sample.

0 notes

Photo

The “large” Spoon is, well, large!

0 notes

Photo

Undertaking a project with Olson Kundig Architects to develop, produce and deliver a batch of “Spoons” in a couple months.

First step is developing bucks and patterns in CAD and executing them on the router.

0 notes