Text

Identify The Main Advantage of Installing Steel Pipe or Tube

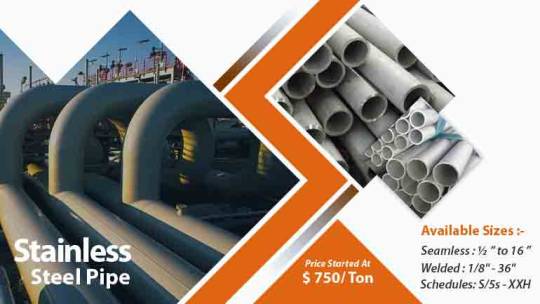

Do you intend to launch a building or industrial project in the near future? If such a project is on the horizon for your organisation, you must ensure that every element is properly planned. To make your project run effectively, you can contact with stainless steel heat exchanger tube manufacturers in India. Many infrastructure projects necessitate the planning of several aspects in order to be successful in the long run. Everything, from water connections to storage to energy, must be available. Due to the complexity of the project, an infrastructure plan would necessitate more resources and instalments than a typical residential construction project. Waterlines and pipes are common components of most infrastructure projects, so they should be among the first things you install. If the proper pipelines are not constructed in the property, you may face a lot of problems over time, which no one wants to go through. Steel pipeline installation is one of the most prevalent procedures in many projects around the world. If you have a project coming up, these are some of the primary benefits of installing good quality stainless steel pipes of stainless steel pipe suppliers in India or stainless steel tube suppliers in India.

The corrosion rate is extremely low.

Whenever it comes to metal & water, one of the most common issues is corrosion. When key components, such as a metal pipe, corrode, it can significantly impede the water's flow through the pipes and may even contaminate the water flowing within the pipes. The pipes may corrode & break down altogether over time, forcing you to pay for modern pipes all over again. However, steel water pipelines of Stainless Steel Square Pipe suppliers in India have a relatively low corrosion rate, implying that the pipelines will not corrode readily. This would prevent you from a lot of problems and even money.

There is usually a visually pleasing appearance.

Every aspect that you plan for an ambitious mission will be equally significant. When considering effectiveness and function of Stainless Steel Boiler Tube manufacturers in India, you should also consider appeal and appearance. Normal or typical pipes will not give off the attractive appearance that you desire for your site. The utilisation of steel pipelines will provide an aesthetically beautiful look that everyone will like! If look is essential to you, steel pipelines of best SS 304 pipe suppliers are the way to go!

Stainless steel pipelines are extremely durable.

Unexpected difficulties that arise from time to time may cause significant damage to an infrastructure project. The pipelines of SS 304L pipe suppliersyou install must be sturdy enough to withstand damage, which most pipelines are not. Steel pipelines of SS 316L pipe suppliers, on the other hand, are extremely strong! Steel pipelines are designed to withstand excessive damage since they are both robust and durable. Because these features are essential for any type of project, it is critical to complete it! You can even contact with galvanized pipe manufacturers in Indiafor best options.

0 notes

Text

Several upsides of investing in specialized steel manufacturing.

At some point, you'll need to make a choice about whether or not to install new gates, fencing, or other gear. You'll need to decide if you want to settle for the kind of off-the-shelf solutions available at any hardware or building supplies shop in your area, or whether you'd prefer to take the custom fabrication route. Here, we'll highlight some of the benefits of custom iron and metal work to help you make your decision.

In particular, the fact that the end product would be entirely one-of-a-kind is one of the main benefits of bespoke manufacturing. You and your fabricator may work together to come up with a plan that suits the aesthetic and character of your building. By incorporating unique features into your gates or fence, you can make a design that stands out from the crowd and is easily remembered by everyone who view it. Stainless steel pipe suppliers in India is in high demand all around the globe.

When it comes to perfection in form and function, nothing beats the beauty and expertise of artisan metalwork. The age-old technique of using a hammer and a forge results in elaborate designs that are both striking and immediately recognizable as the work of a talented craftsperson. Whether it's used to make a sign, an emblem, a fence, or any number of other gorgeous metal products, this level of care and attention to detail will be immediately apparent. Stainless steel tube suppliers in India has superior quality.

Personalization may be the most important facet of bespoke manufacturing. There's a great deal of satisfaction in realizing that a concept you had for a design or decoration may be realized in one of the many possible ways. Any space can be made into something really special and functional by adding a few personal touches. Many individuals like stainless steel heat exchanger tube manufacturers in India.

Modern metalwork combines time-honored methods like the hammer, anvil, and forge with cutting-edge tools like computer-aided design (CAD) software, water jet cutting, and even plasma cutting.SS 304L pipe suppliers have great deals. The resulting technological synergy lets you see your design before it goes to the workshop, enabling you to make any necessary changes to the computer-generated design before it goes to production. When you're happy with your choices, they may be transformed from a digital file into a unique, high-quality work of art. The StainlessSteel Square Pipe suppliers in India is excellent.

There are a number of benefits to opting for a custom-made product rather than buying something off the shelf. Bespoke metal fabrication is an integral part of creating a really unique and aesthetically pleasing space.Stainless Steel Boiler Tube manufacturers in India will always be a great help.

If you've found a reliable contract manufacturer that offers metal fabrication services, you should give them as much of your business as possible. It's best to stick with one contract manufacturer so that they can get to know your business and demands inside and out. You'll put yourself in a position to successfully negotiate for far lower costs if you do this.SS 304 pipe suppliers are available widely.

0 notes

Text

Do You Know Why Stainless Steel Fitting is A Better Option?

In a variety of applications, stainless steel is a cost-effective and long-lasting material provided by galvanized pipe manufacturers in India or stainless steel pipe fittings manufacturers in India. It's no surprise that most household fixtures, including pipe fittings, are made of this substance. There are numerous reasons why stainless steel is a popular material, and you should consider it for your pipe fittings for the same reasons.

It is incredibly durable - There is a reason why stainless steel is named stainless. It is stained resistant, making it an excellent choice for practically any given purpose. Fittings constructed of this material are not easily stained, which is something that cannot be said for other kinds of materials that may be utilized for the fittings. If you want to use this highly effective pipe fitting then you can contact with carbon steel pipe fittings manufacturers in India or Alloy Steel Pipe Fittings manufacturers in India.

It is rust proof - This property makes it ideal for domestic use, particularly in water systems in kitchens and bathrooms. Most homes have water system fittings made of stainless steel because they do not corrode when exposed to water and moisture. When you use fittings made of this material offered by carbon steel threaded fittings manufacturers in India, you won't have to worry about rust, which can harm your system and potentially alter the quality of water you use throughout house.

It is long-lasting - Just like any other item purchased for your house, you would like pipe fittings of SS Forged Fittings manufacturers in India that will last a long time, and stainless steel performs well in this regard. Pipe fittings can last and serve you for decades before they need to be replaced or repaired, especially when compared to carbon steel, which is less expensive but will needs constant replacements as well as repairs to serve you effectively.

It adapts well to heat - Some fittings on the market today do not adapt well to heat, but then you can trust your stainless steel fittings to adjust well even when exposed to heat. They are not easily harmed by high temperatures, allowing you to utilize the fittings in a variety of applications that have some heat requirements without fear of damage.

Stainless steel has a really nice finish, and while this may not be important in the context of pipe fittings, you will still reap the benefits of choosing stainless steel. To get the finest results from the fittings, it's a smart option to go to Alloy Steel Flanges manufacturers in India who can custom make them to your exact specifications.

It is strongly advised to make the finest option when it comes to hose fittings and other types of fittings in order to avoid repeated breakdowns and repairs or replacements. Stainless steel fittings will provide you with the excellent service you require regardless of your application type. To get the greatest for your needs, you simply need to discover a reputable stockiest or Carbon Steel Flanges manufacturers in India

0 notes

Text

Application and Significance of Steel Pipe

Today, stainless steel provided by stainless steel pipe suppliers in India is most likely one of the most widely utilized materials in the commercial and residential sectors. It is made by incorporating a little amount of chromium into a steel alloy. This type of steel is known as'stainless' because it is corrosion resistant. The inclusion of chromium to the steel alloy results in these corrosion-resistant characteristics.

It is also minimal maintenance and long lasting, in addition to being corrosion resistant. These characteristics make stainless steel pipes a popular choice in a variety of sectors. They available in a variety of configurations and sizes. They are suitable for use in high-temperature applications and those where corrosion is a key problem.

Type 316 stainless steel pipe from SS 316 pipe suppliersor SS 316L pipe suppliers is regarded as a high-quality tubing material that may be used in a wide range of applications, including those in the most demanding industries. Tubing composed of this material is used to convey a wide range of commodities, including oil, chemicals, hot water, Sulphur, gas, and others. In an ideal world.

There are various high-pressure applications that require the use of seamless tubing or piping. There are no welded connections or seams in a seamless pipe or pipe. These connections or seams can be weak points, particularly in high-pressure applications, where leaks as well as bursts can occur.

Here are some popular applications for stainless steel tubing:

Handrails, ladders, and railings are examples of architectural components that must look beautiful, be corrosion resistant, and last a long time. A stainless-steel pipe from stainless steel pipe suppliers in India is produced and fitted in such instances.

Automotive applications: Motorcycle handlebars and automotive piping systems must be corrosion resistant, vibration, dirt, rain, and other weather conditions. This is an excellent solution in such circumstances provided by Stainless Steel Square Pipe suppliers in India because it fits all of the criteria.

Catering processing equipment: A significant number of raw and processed goods must be carried through this network in a food manufacturing factory. The FDA has established various guidelines for the use of items that come into direct contact with food. When produced to a specified grade by Stainless Steel Boiler Pipe manufacturers in India, they are suitable to use with edibles.

Aside from that, there are several more applications such as the production of healthcare products, consumer devices, gym equipment, and so on.

The steel pipes through SS 304 pipe suppliers are designed using solid and round billet. These billets are then heated to a specific temperature and stretched till they adopt the shape of a hollow pipe or pipes. The advantage will illustrate why these pipes are beneficial to the industry.

The ability to tolerate extreme pressure

Seamless pipes of SS 304L pipe suppliers are excellent for pressure handling because, unlike welded pipes, they do not have welded seams, therefore the material turns into equally strong around the whole circle of the pipe.

0 notes

Text

You should know about the galvanized pipe.

Galvanized pipe fittings are coated with a coating of zinc, which increases their corrosion resistance and helps prevent mineral deposits from clogging the pipe. Galvanized pipe is mainly used to transport water to homes and businesses, but it can also be used as a scaffolding framework due to its rust resistance. You can look for the best galvanized pipe manufacturers in India.

Because of the material's ability to resist corrosion and salt, galvanized pipe fittings are employed in various outdoor and industrial applications. Except for underground lines, galvanized pipes and fittings can be utilized in most applications. They operate best with cold water lines, although they can also be used with hot. The main benefit of utilizing galvanized fittings is their higher corrosion resistance.

The Effects of Carbon Steel Piping on Your Production

Carbon steel produced by carbon steel pipe fittings manufacturers in India is frequently thought to be a less expensive alternative to stainless steel. However, because of its advantages and benefits, this material deserves to be the first choice, rather than a second-best alternative, in the selection of piping systems in some circumstances.

Get Alloy steel weld fittings and Alloy steel Elbow at the best prices.

Alloy steel produced by alloy pipe fittings manufacturers in India pipe fittings is available in a variety of grades. The alloy steels, which have minimum yield strength of 275 MPa and a minimum tensile strength of 485 MPa, are employed in pressure applications. As the material is so strong, it can also be utilized in hydraulic applications. The demand for carbon steel threaded fittings manufacturers in India has also increased.

Carbon, manganese, silicon, sulphur, phosphorus, chromium, and molybdenum are commonly found in the composition of Low Alloy steel fittings. ASME B16.9, B16.28, and more standards exist. As a result, the nominal bore sizes range from 12 inches to 48 inches.

What You Should Know About Forged Carbon Steel Fittings

The carbon steel produced carbon steel manufacturers in India

are heated to molten temperatures before being placed in dies and manufactured into Carbon Steel Forged Fittings. High-strength forged goods are extremely resistant to environmental conditions and long-lasting. These pipe fittings create a tight seal in your piping system, reducing the danger of leakage. Fittings made of forged steel have a 37 percent higher fatigue strength.

A105 Carbon Steel Forged Fittings are the way to go if you're searching for fittings that will provide you one-and-done results and years of worry-free service. You can accomplish similar results with more expensive titanium pipe fittings, but the cost-to-quality ratios don't add up. Titanium fittings are a terrific option, but they can be more expensive than Carbon Steel Forged Fittings, causing project costs to rise quickly.

Final thoughts

Female threads on the Alloy Steel Threaded Flanges connect to male threaded pipes. When welding and bolting are not practicable or necessary, threaded flanges are an excellent option. Oil and gas, offshore oil drilling, petrochemical, petroleum, power production, and various other industrial applications require Alloy Steel Plate Flanges. Alloy Steel Slip On Flanges is typically utilized with seamless pipes for improved connection location.

0 notes

Text

Know about stainless steel flanges

Flanges must be carefully selected as they can become a weak point in the system. You can know about Stainless Steel Flanges manufacturers in India. On the other hand, stainless steel flange fittings can endure the heat without deforming or warping.

What are Duplex flanges?

Compared to conventional austenitic 304 and 316 stainless, this austenitic-ferrite stainless version has a more robust stress corrosion cracking resistance but poorer toughness and impact strength. Choose among the top Duplex Flanges manufacturers in India. Heat treatment of high-pressure boiler pipes includes heating and chilling to increase toughness, hardness, and wear resistance.

Quenching is one of the processes in the heat treatment process. The metal tube is more durable and powerful than other forms of tubing. As a result, it has many uses in structural industries. Metal tubes have a high degree of rigidity and making it more useful for industrial purposes.

Why has the demand for Duplex Stainless Plate increased?

Alloy 2507 produced by Super Duplex Flanges manufacturers in India is a super duplex stainless steel with a chromium content of 25%, a molybdenum content of 4%, and a nickel content of 7%. The high amounts of chromium, molybdenum, and nitrogen give exceptional pitting, crevice, and overall corrosion resistance. The impact resistance is also relatively strong. Because of the danger of a loss in toughness, Alloy 2507 is not recommended for applications that require protracted exposures to temperatures above 570°F.

Alloy 2507 is a very strong super duplex stainless steel with a chromium content. The alloy 2507 steel has high thermal conductivity and a low coefficient of thermal expansion, making it resistant to chloride stress corrosion cracking. The high amounts of chromium, molybdenum, and nitrogen give exceptional pitting, crevice, and overall corrosion resistance.

What are Titanium Grade 2 Flanges?

Grade 2 Titanium blind flanges produced by Titanium Flanges manufacturers in India are available in different sizes ranging from 1/2″ (1.26 lbs) to 24″. Dimensional tolerances meet ASME B16.5, and flange bore diameters match ASME B36.9 wall pipe standards. Other bore diameters can be ordered on a custom basis.

Different surface finishes for gaskets can be ordered on a custom basis. Electrochemical etching is used to label titanium flanges according to ASME B16.5 permanently. Titanium flange weights are estimated using a density of—163 pounds per cubic inch. Titanium Industries has a large selection of Grade 2 Titanium. The Threaded Flange manufacturers In India also produce the best products.

Final thoughts

Carbon steel press-fit pipework is widely used in closed-circuit heating and compressed air systems. The primary source of oxidative corrosion, air or oxygen, is eliminated with a closed-circuit heating system. Carbon steel gives any material used to make a high tensile strength. It can be bent and stretched into any shape and retain its power.

Instead, it emphasizes how each piping material has advantages and disadvantages and how it is appropriate for some applications but not for others. Carbon Steel’s lower cost is perhaps the most critical factor in choosing it over one of the stainless steel grades.

0 notes

Text

Pipe made of stainless steel and metal tubes

Stainless steel pipe produced by stainless steel pipe suppliers in India is generally utilized in fluid or gas transport piping systems. You can choose among the best stainless steel tube suppliers in India.

Metal tubes, for starters, include metallic alloys and elements. The metal tube is more durable and powerful than other forms of tubing. As a result, it has many uses in structural industries. Metal tubes have a high degree of rigidity and making it more useful for industrial purposes. The impact resistance is also relatively strong.

The majority of tubes for smooth fluid flow have circular cross-sections. However, metal tubes come in various shapes, including rectangular, square, oval, and circular. Customized forms are also available from some manufacturers. However, they are more expensive than standard metal tubes. The most popular design is the circular tube, which provides even distribution throughout the tube.

Guide about stainless steel heat exchanger

Heat exchangers produced by stainless steel heat exchanger tube manufacturers in India are now available in various materials. The optimal material selection is critical for function and service life. As a result, it requires special attention right from the outset. In the building of heat exchangers, high demands are placed on the material. Large temperature fluctuations can cause heat stresses in the material, leading to cracks.

Mechanical factors within the devices, such as vibrations, steam hammers, and high pressure, pose a significant challenge to the material utilized. Corrosion and deposits, such as those caused by limestone or other wastes, are also problematic. If not considered, they will increase the heat exchanger's maintenance requirements.

Square Stainless Steel Tube manufacturers in India

The tubes' square cross-section gives excellent geometric strength. As a result, Stainless Steel Square Pipe suppliers in India produce the pipes used in applications requiring great strength. High-pressure and high-temperature services utilize pipes, such as heat exchangers. The 316 stainless steel square tubing is robust and resistant to corrosion.

Chromium, nickel, and molybdenum are all present in the 316 material. The tubes can also operate at temperatures as high as 870 degrees Celsius. The Stainless Steel Boiler Tube manufacturers in India can be used in various industries, including oil & gas, petroleum, petrochemicals, construction, and structural applications. Higher grades, such as SS317 Square Tubes, are available.

How are boilers made?

Boiler tubes are either carbon steel or alloy steel and are seamless. They are commonly found in steam boilers, power plants, fossil fuel plants, industrial processing plants, and electric power plants, among other places. It is essential to know about SS 304 pipe suppliers because they provide the best quality material.

Fine drawing, hot rolling, cold drawing, surface brightness, and heat expansion are all part of the original manufacturing process for medium-pressure and high-pressure boiler tubes. The following measures are conducted to make high-pressure pipes stronger and more resistant. Heat treatment of high-pressure boiler pipes includes heating and chilling to increase toughness, hardness, and wear resistance. Quenching is one of the processes in the heat treatment process.

1 note

·

View note