Text

With every step forward, guided by your support and good wishes, 2023-2024 has unfolded as a magnificent chapter in our lives.

We look forward to your continuous support and adding value to your Organisation.

#water treatment#water filter#water purification#etp plant manufacturers#wastewatertreatment#watertreatmentsolutions#etp#sewagetreatmentplant#industry#water softener#maharashtra#pune#Wastewaterindustry

1 note

·

View note

Text

MANDATORY SEWAGE TREATMENT: IS STP COMPULSORY IN PUNE?

IS STP COMPULSORY IN PUNE?

Maintaining a clean and sustainable environment depends on the sewage treatment process. The Sewage Treatment Plant (STP) is one of the most important procedures in sewage management. In order to make wastewater suitable for reuse or disposal, STPs are made to treat it and eliminate any impurities.

Pune and other developing cities face serious challenges with sewage control. In order to maintain environmental sustainability and public health, efficient sewage management techniques are essential given the growing urban population and mounting strain on the sewage infrastructure. The sewage treatment plant (STP) is one of the most important parts of the infrastructure for sewage management. But the issue remains: Is STP compulsory in Pune? We shall examine the response to this query and its ramifications for Pune’s sewage management in this blog.

Sewage Management in Pune

The garbage produced by homes, businesses, industries, and other establishments in Pune is frequently thrown into the rivers and other water sources untreated. This has resulted in serious environmental damage and a health risk to the public, spreading water-borne illnesses and endangering lives. Is STP compulsory in Pune? The Pune Municipal Corporation (PMC) has started an initiative to construct and maintain sewage treatment plants throughout the city in an effort to help address this problem. The initiative’s goal is to create long-lasting sewage treatment facilities to raise city residents’ standard of living in general.

STPs Law and Regulations in Pune

In order to tackle the problems pertaining to sewage management in the city, the Pune Municipal Corporation (PMC) has implemented legislation concerning STPs. The PMC has mandated that internal STPs be installed in all new residential and commercial buildings. Before receiving completion certificates for their projects, the builders and developers have to make sure that the STPs are operating properly. By requiring new buildings to have wastewater treatment equipment, this law lessens the strain on centralized treatment plants and stops untreated sewage from being released into the environment.

Pune’s STP laws are designed to encourage environmentally friendly methods of managing sewage. The PMC is strengthening the city’s overall sewage management infrastructure by requiring STPs for new developments. To satisfy increasing expectations, it is crucial to make sure that these laws are properly implemented and that the current infrastructure is updated.

Is STP compulsory in Pune?

Yes, STP is compulsory in Pune. All new residential and commercial buildings must have an internal STP, according to a mandate issued by the Pune Municipal Corporation (PMC). Before receiving completion certificates for their projects, builders and real estate developers need to make sure the STPs are operating properly. This legislation intends to lessen the load on centralized sewage treatment plants and promote sustainable sewage management practices in new construction, even if it does not apply to structures that already exist.

Challenges in sewage management:

Pune faces a number of difficulties in this area, making efficient sewage control techniques imperative. Even though there is already sewage infrastructure in place, the rapid population increase has put ongoing strain on it, which frequently results in blockages and spilling effluent. These densely populated areas produce a lot of wastewater, which is frequently dumped untreated into adjacent bodies of water, endangering human health and the environment. The problem is further made worse by growing urbanization, inappropriate land use, and poor maintenance.

Is STP compulsory in Pune? What are the penalties for non-compliance?

Pune residents who violate the STP laws risk facing harsh penalties. These sanctions might include monetary fines, permit suspension or revocation, and legal action taken against offenders. The seriousness of the infractions and the type of non-compliance determine how much of a penalty is imposed.

This will depend on the capacity of the STPs. As to the officials, STPs with a capacity of less than 300 kiloliters per day (KLD) will be fined Rs 2,500; those with a capacity between 300 and 500 KLD will be penalized up to Rs 4,000; and those with a capacity beyond 500 KLD will be fined Rs 5,000.

In conclusion,

Is STP compulsory in Pune? So, every new residential and commercial building in Pune is required to comply with STP, and non-compliance carries harsh fines. To update and strengthen the current sewage system and satisfy the city’s expanding needs, more substantial efforts are needed. A comprehensive strategy is needed to address the problems with sewage management, one that includes infrastructure investment, regulation enforcement, and public awareness-raising. Pune residents can benefit from cleaner and healthier surroundings thanks to efficient sewage control techniques. A step in the right direction towards accomplishing this goal is the Pune Municipal Corporation’s (PMC) initiative to require STPs in all new developments.

Overcoming these obstacles and eventually making Pune a sustainable and livable city will require maintaining the sewage infrastructure and firmly enforcing the laws. What do you think? Is STP compulsory in Pune? Comment below.

#water treatment#etp plant manufacturers#sewagetreatmentplant#watertreatmentsolutions#pune#india#stp manufavturers in maharashtra#wastewatertreatment

1 note

·

View note

Text

WHAT IS THE USE OF ETP SLUDGE?

WHAT IS THE USE OF ETP SLUDGE?

Definition of ETP

The eco-warrior who transforms the water that exits our homes and businesses into something Mother Nature would be proud of is the effluent treatment plant. See, water that has been used for many purposes—be it for an industrial operation or your daily shower—isn’t quite pure.

Before being released into rivers or other bodies of water, industrial wastewater is treated by an ETP, which is essentially a sophisticated system, to remove pollutants and poisons. Businesses that produce wastewater with various chemicals, suspended particles, and occasionally hazardous elements should pay particular attention to this.

I. UNDERSTANDING ETP SLUDGE

Definition of ETP Sludge

Let’s start with the basics. ETP stands for Effluent Treatment Plant, and the sludge it produces is essentially the byproduct of treating industrial wastewater. In simpler terms, when factories and industries clean up their water before releasing it back into the environment, what’s left behind is what we call ETP sludge.

Understanding ETP sludge composition and characteristics is crucial to developing effective plans for its treatment, disposal, or even potential resource recovery. Because of this, firms hoping to integrate environmentally responsible and ethical waste management practices alongside environmental compliance must grasp the complexities of ETP sludge.”

Composition of ETP Sludge

Solid components: The solid components come first. Imagine that little bits are floating about in the gummy mixture; picture the sediment collecting at the bottom of your grandmother’s homemade soup. These solids are a mixture of debris from the wastewater treatment process, fragments of organic materials, and chemicals. In essence, it is the cleaning procedure’s leftover material.

Liquid components: It’s not all sticky and viscous, unlike what you may believe. ETP sludge contains a liquid component as well. Water that was not entirely separated from the solids during the treatment procedure is carried out in this part. You have a two-layered sludge with coexisting liquid and solid components.

Chemical elements: There is a chemical fingerprint to ETP sludge; it is not just a random mixture. Phosphorus, nitrogen, and heavy metals are among the elements we are discussing. Before being concentrated in the sludge, these components were present in the industrial wastewater. Although many substances may be advantageous when used in moderation, high concentrations may pose a threat to the ecosystem.

Characteristics of ETP Sludge

Physical properties: texture, colour, and More

First up, let’s talk about the physical aspects of ETP sludge. Imagine a gooey, thick substance with a texture that’s a mix between pancake batter and creamy peanut butter. The colour can vary; it might be anything from earthy browns to murky greens, depending on what it’s been soaking up. Picture a cross between melted chocolate and swamp water—charming, right?

Now, let’s talk smell. Brace yourself; it’s not exactly a field of flowers. ETP sludge can have a distinct odour, kind of like a blend of earthiness and industrial vibes. Not exactly a candle scent, but it’s a part of what makes ETP sludge, well, ETP sludge.

Chemical properties: The Elemental Dance

Moving on to the chemical side of things, it’s like the sludge’s own little periodic table party. We’ve got elements like nitrogen, phosphorus, and various heavy metals joining the mix. It’s like the sludge is holding onto these elements after its spa day with industrial wastewater. While a pinch of these elements is natural, too much can be a bit like spicing up your soup—moderation is the key!

Biological Properties: Microscopic Life in Action

Now, let’s zoom in on the microscopic universe within ETP sludge. Yes, it’s got a whole ecosystem going on! Microorganisms, bacteria, and other tiny life forms are doing their thing in there. It’s like a bustling city of tiny creatures, breaking down the organic matter and playing a crucial role in the sludge’s transformation. Think of it as a microscopic cleanup crew with a bustling community.

II. USE OF ETP SLUDGE

Agricultural Applications

Soil conditioning: One of the amazing benefits of ETP waste is its ability to regenerate our soil. Consider it a spa day for the planet. The organic content and nutrients in the sludge help to improve soil structure and texture. It improves water retention and aeration, giving the soil a comfortable home for plant roots. ETP sludge, in a nutshell, functions as a natural conditioner, transforming tired, depleted soil into a healthy paradise for plants.

Nutrient content: Let us now discuss the nutritional benefits that come with ETP sludge. This sludge is a treasure trove of critical nutrients for plants, not just a random combination. Nitrogen, phosphorus, and potassium, the plant’s holy trinity, are abundant. These nutrients become readily available to plants when we apply ETP sludge to the soil, acting as a green multivitamin for our crops. It’s similar to providing them with a nutritional boost for optimal growth and development.

Impact on crop yield: The big kicker is the effect on agricultural yield. According to research, adding ETP sludge waste to agricultural operations can dramatically increase crop output. Improved soil structure and nutrient availability result in healthier, more vigorous crops. Farmers and the environment benefit from increased yields while reducing the demand for synthetic fertilisers.

Environmental Benefits

Reduction of waste: Ever wondered what happens to all the icky stuff filtered out during industrial wastewater treatment? Well, that’s where ETP sludge steps in as a waste warrior. Instead of letting those residues become a burden on landfills, industries are repurposing them into a valuable resource. By converting waste into something useful like ETP sludge, we’re not only cutting down on the amount of waste piling up but also finding a clever way to give it a second life.

Sustainable resource utilization: plants that treat wastewater are leading the way in adopting the circular economy. Imagine a society in which water is recycled and used again rather than merely being used and thrown away. These plants turn sewage into a valuable resource, almost like magical alchemists. They guarantee our communities have access to clean water constantly by collecting and treating wastewater.

Using Bioenergy’s Potential: Have you ever considered the potential that lurks in your sewage? Undoubtedly, wastewater treatment plants have! Many people are now using anaerobic digestion to harness the potential of bioenergy. Sewage contains organic debris that is broken down by microorganisms, yielding biogas as a byproduct. The plants that produced the biogas are thereafter able to use it as a sustainable energy source.

Rich in Nutrient Byproducts: Wastewater treatment plants generate more than just energy. Known as biosolids, the nutrient-rich wastewater treatment wastes are a boon to agriculture. These nutrient-rich materials can be applied as a natural fertilizer to improve soil quality and encourage strong plant development. Sustainable agriculture and wastewater treatment both benefit from this!

III. Where Does Sludge Generate in ETP?

Let’s get down to the specifics of wastewater treatment, starting with the ETP (Effluent Treatment Plants), where that infamous sludge originated. Get ready for a new perspective on the origins of this sleazy company!

Imagine this: Your home is abandoned when your regular trash disappears. But have you ever wondered about its final destination? Now for the unsung hero of waste management: the effluent treatment plant.

Now here’s the twist: ETP sludge doesn’t just appear; it results from the ETP’s constant fight against contaminants. Contaminants and solids are trapped in the wastewater as it passes through the treatment process, creating the infamous sludge. The main and secondary therapy phases are where the major action happens.

Grit and big particles, which are heavy hitters in the first treatment, bow down and form the first layer of sludge. But there’s still more! The microbial workforce feasts on organic contaminants in the secondary treatment, creating a second act of sludge in the process.

That’s right, sludge isn’t a cunning visitor; rather, it’s a consequence of ETP sludge’s enormous efforts to clean our wastewater.

Primary Treatment

We’re putting on our virtual diving gear today to examine the primary treatment and the initial stages of the cleansing procedure. Consider it the first part of the wastewater’s superhero transformation, leading up to more sophisticated treatments. So grab a seat, and let’s dive into the world of sedimentation and big solids removal!

1. Removal of large solids

The sewerage system of a major city is similar to a busy highway in that it carries a variety of undesirable passengers, such as plastic, leaves, and other heavy trash. Eliminating these unattractive passengers is the primary priority in the field of wastewater treatment.

Imagine an enormous screen positioned to capture the major participants. This is exactly what occurs in primary therapy when large solids are removed. As bouncers, screens, or barracks, make sure only the liquid passes through the entrance gate. It is comparable to a club bouncer, but for wastewater!

Why is this a critical step? In other words, clearing out these big solids not only keeps downstream machinery from becoming damaged but also makes the treatment process run more smoothly and effectively. It’s similar to organising your space before beginning a thorough cleaning; both are necessary for a flawless outcome.

2. Sedimentation

With the heavyweights now out of the way, let the minute details of sedimentation take centre stage. Imagine a peaceful pond; the still surface conceals the commotion below. Sedimentation functions similarly.

The water in the sedimentation tank slows down, allowing suspended particles—both inorganic and organic—to sink to the bottom. For wastewater, it’s similar to having a tranquil meditation session when it can release the contaminants it has been holding onto.

As gravity takes over and pulls these particles downward, magic happens. After that, the purified water gracefully rises to the top, prepared for the subsequent stage of treatment. This procedure not only gets rid of undesirable particles but also sets up the secondary treatment stage, which is where the real superheroes of microbiology come into play.

Secondary Treatment

1. Biological processes

A hive of microbes that never stop striving to decompose the organic materials in wastewater. The biological processes involved in secondary treatment are mostly driven by these microscopic heroes, who serve as nature’s cleanup team.

Wastewater carries a mixture of contaminants, including organic materials, into the secondary treatment stage. In this stage, we use the ability of bacteria and other microbes to eat these contaminants and change them into less dangerous materials. It resembles a fine dining experience for tiny organisms!

This organic process—often called “activated sludge”—creates a microbial dance in which the bacteria decompose the contaminants and generate more sludge as a result. Our wastewater choreographers maintain a careful balance by ensuring that everyone is moving in unison.

2. Aeration tanks

Let us now highlight the aeration tanks, which are the actual venue where the microbial dance takes place. These tanks resemble the wastewater treatment plant’s opulent ballrooms.

We add oxygen to the mixture in these tanks to provide an aerobic environment that promotes the growth of our microbial performers. Visualize the aeration tanks as active dance floors filled with swirling oxygen bubbles that invigorate our microbial dancers.

The microorganisms can break down contaminants more effectively because of the aerobic conditions in the tanks. It’s a rhythmic, dynamic process that guarantees our wastewater is thoroughly cleaned before it travels further.

The microbes grow as they break down organic waste, creating what is known as “activated sludge.” This sludge is a mixture of superhero microbes and the leftovers of the contaminants they have eaten. But don’t worry—our treatment plant gurus have a strategy for handling this waste.

Tertiary Treatment

1. Filtration

Consider your water flowing through a high-tech sieve, where every contaminant is collected and retained before reaching your glass. That is the filtration magic, the hidden hero of pure water. This procedure brings water purification to the next level during tertiary treatment.

Filtration is the process of removing residual particles, microorganisms, and toxins using various materials, such as sand, gravel, and activated carbon. It’s as if we’re giving our water a final spa treatment before it gets to our homes, to ensure it’s as pure as possible.

What’s the best part? Filtration is a natural procedure that closely resembles Mother Nature’s own washing methods. It is both environmentally friendly and extremely effective, providing us with water that not only quenches our thirst but also respects the environment.

2. Disinfection

Now that our water has been thoroughly cleaned by the filtration spa, it’s time for the second act: disinfection. This is when we say our final goodbyes to any leftover bacteria that may have survived earlier stages of treatment. We want our water to be as safe as it is refreshing, after all. Disinfection is often accomplished by the use of chlorine, ozone, or ultraviolet (UV) radiation—potent agents that eliminate any leftover nasties. Consider it the superhero phase of water treatment, in which invisible hazards are vanquished to ensure that the water is superhero-clean.

Sludge Dewatering

1. Centrifugation

Have you ever wondered how to transform wastewater sludge? Enter centrifugation or Sludge dewatering. Imagine a high-speed spin that separates water from sludge, with the dexterity of a superhero saving the day.

A centrifuge, in simple words, functions like a cosmic force field, employing centrifugal force to drive water out of the sludge. The result? Drier sludge is ready to say goodbye to surplus water. It’s like your sludge never knew it needed a spa day!

But why is centrifugation getting all the attention? It is, after all, lightning-fast, energy-efficient, and space-conscious. This strategy works brilliantly for industries looking to lower their water usage and carbon footprint. Say welcome to more environmentally friendly wastewater treatment!

2. Belt press

Let us now discuss the Belt Press, the unsung hero of sludge dewatering. Consider your sludge strolling along a conveyor belt, gently squeezed to yield its liquid treasure. This procedure is as lovely as it sounds!

Belt Press is like a sludge yoga class: slow, steady, and highly powerful. The sludge flows between two belts, becoming wedged and encouraging water to depart quickly. The result? Mother Nature gives you a standing ovation for reduced volume and improved solid content!

What distinguishes the belt press as a noteworthy option? It’s simple to use, low-maintenance, and ideal for managing large amounts of sludge. Belt Press has made a name for itself in the realm of sustainable wastewater treatment due to its effectiveness and simplicity.

IV. Challenges and Risks Associated with ETP Sludge

Volume Overload: ETPs treat thousands of gallons of water every day. The huge volume of sludge produced has the potential to overwhelm existing disposal facilities. Managing such a massive volume necessitates creative solutions and a solid infrastructure.

Chemical Conundrum: ETP sludge frequently contains a combination of chemicals employed in the treatment process. It is difficult to dispose of this chemically laden sludge without damaging the environment. It’s a conundrum that necessitates a delicate balance of effective treatment and environmental safety.

Regulatory Rigma: It is not easy to navigate the intricate web of environmental regulations. ETP sludge management must adhere to strict criteria, and any deviation can result in legal ramifications. Keeping up with ever-changing rules is critical for firms involved in this process.

Heavy Metal Contamination

To start with, let’s make some things plain. Not the newest Grammy-winning band—we’re talking about elements like lead, mercury, cadmium, and arsenic when we say heavy metals. Even if these metals lack the glitz of a rock star, they nevertheless know how to enter our ecosystems.

The Stealthy Intruders: Metals are quietly contaminating our land, water, and air—like a cunning ninja moving through the dark. Since heavy metal pollution lacks a loud sound system and flashy lights, it can easily go unnoticed, much like a rock performance.

The Sources: Let’s expose the guilty now. Agricultural runoff, poor waste disposal, industrial discharges, and even air deposition are some of the ways that heavy metals can find their way into our ecosystem. It’s as if these pollutants have a backstage pass that allows them to infiltrate our environment without our knowledge.

The Consequences:

What, then, is the major issue? Indeed, heavy metal pollution can have a disastrous effect on animals, ecosystems, and yes—you got it—humans. These quiet invaders can do more than just cause problems; they can cause havoc. They can hinder the growth of plants and cause serious health problems for both humans and animals.

Human Health Concerns: The effects of heavy metals are universal, affecting all people. Extended exposure to low concentrations of these pollutants can result in a variety of health complications, including reproductive difficulties and neurological impairments. It seems like a diabolical scheme taking place in our backyard.

The Battle Against Heavy Metal Pollution: Do not be alarmed, fellow Earth lovers! We are not without hope in this fight. Governments, businesses, and people are collaborating to address the issue of heavy metal pollution. An increasing number of measures are being taken to eject these undesirable guests from our ecosystem, ranging from strict environmental rules to cutting-edge clean-up technologies.

Pathogen Presence:

an invisible metropolis, yet one that is brimming with life. That is the microbial world found in ETP waste! Numerous microorganisms cohabit in this dense, nutrient-rich habitat, adding to the intricate dance of biological treatment.

Meet the Pathogens: Although the majority of the microorganisms living in the ETP sludge are helpful, there is a negative aspect to this tiny community: the existence of pathogens. These microscopic troublemakers include viruses, bacteria, and other microbes that can endanger the environment and human health.

Understanding the Risks: It’s important to remember that wastewater treatment facilities are built to reduce the hazards brought on by the presence of pathogens, so don’t freak out just yet. To protect our communities, we must nevertheless be aware of these possible risks and comprehend how they are controlled.

Managing Pathogens in ETP Sludge: To control pathogenic populations, wastewater treatment experts use a variety of techniques. Together, anaerobic digestion and thermal treatment lower the pathogen burden and increase the safety of the sludge for disposal or reuse in the future.

Impact on the Environment: Why is this important? Indeed, the environment and human health may be impacted by the microorganisms found in ETP waste. To maintain the general health of our ecosystems, it is imperative that hazardous bacteria not be allowed to escape into water bodies through improper treatment and management.

Gazing Forward: With the development of technology and our growing knowledge of microbial ecosystems, intriguing new opportunities for wastewater treatment lie ahead. The prevalence of pathogens in ETP sludge is continuously being reduced by experts and researchers to make the environment cleaner and healthier for everyone.

Conclusion:

Sludge from Effluent Treatment Plants (ETPs), which is the result of their hard work, is not merely the byproduct of cleaning. It’s an application-rich resource that supports sustainable environmental practices and ethical trash disposal. We looked at the uses of ETP sludge in agriculture, where it feeds crops with rich nutrients and conditions the soil. Unquestionably, the effect on crop yield demonstrates how important it is for ETP waste to reduce the need for synthetic fertilizers and increase agricultural productivity.

Another intriguing aspect was energy generation since biogas is produced using ETP sludge sewage as a raw material. Organic waste is converted into a useful source of energy through the microbial magic of anaerobic digestion, which is consistent with the concepts of sustainability and resource efficiency.

Environmental advantages like waste minimization and sustainable resource use highlight how crucial it is to see ETP sludge as a valuable resource rather than a burden in the fight for a cleaner Earth.

We also investigated the beginnings of sludge in the ETPs’ basic and secondary treatment phases. Sludge is not an enigmatic stranger; rather, it is a byproduct of the ETP sludge’s ceaseless attempts to clean wastewater, underscoring the interdependence of various treatment procedures.

On the other hand, some risks and difficulties are hidden, such as volume overload, complicated chemicals, and intricate regulations. Vigilant management measures are necessary to protect human health and the environment from heavy metal contamination and infections, If you want an ETP plant Quotation then contact us, and we will get in touch soon.

It’s evident, as we come to the end of our exploration of the world of ETP sludge, that comprehending and controlling this intricate byproduct are crucial first steps toward a sustainable and environmentally friendly future. A world free of pollution and disease is made possible by continuous research, technological breakthroughs, and a common commitment to environmental responsibility. To build a better, more sustainable tomorrow, let’s keep delving into the mysteries of wastewater treatment and ETP sludge.

0 notes

Text

MANDATORY SEWAGE TREATMENT: IS STP COMPULSORY IN PUNE?

IS STP COMPULSORY IN PUNE?

Maintaining a clean and sustainable environment depends on the sewage treatment process. The Sewage Treatment Plant (STP) is one of the most important procedures in sewage management. In order to make wastewater suitable for reuse or disposal, STPs are made to treat it and eliminate any impurities.

Pune and other developing cities face serious challenges with sewage control. In order to maintain environmental sustainability and public health, efficient sewage management techniques are essential given the growing urban population and mounting strain on the sewage infrastructure. The sewage treatment plant (STP) is one of the most important parts of the infrastructure for sewage management. But the issue remains: Is STP compulsory in Pune? We shall examine the response to this query and its ramifications for Pune’s sewage management in this blog.

In metropolitan areas like Pune, wastewater management has emerged as a crucial issue that cannot be disregarded. Maintaining the city’s cleanliness and hygienic conditions for residents depends on effective sewage management.

Sewage Management in Pune

The garbage produced by homes, businesses, industries, and other establishments in Pune is frequently thrown into the rivers and other water sources untreated. This has resulted in serious environmental damage and a health risk to the public, spreading water-borne illnesses and endangering lives. Is STP compulsory in Pune? The Pune Municipal Corporation (PMC) has started an initiative to construct and maintain sewage treatment plants throughout the city in an effort to help address this problem. The initiative’s goal is to create long-lasting sewage treatment facilities to raise city residents’ standard of living in general.

However, the adoption of these STPs has not happened quickly. STP is now required for anyone building a home or commercial property, according to recent government regulations. Before receiving their completion certificate, builders must guarantee that the building is operational and connected to the STP.

STPs Law and Regulations in Pune

In order to tackle the problems pertaining to sewage management in the city, the Pune Municipal Corporation (PMC) has implemented legislation concerning STPs. The PMC has mandated that internal STPs be installed in all new residential and commercial buildings. Before receiving completion certificates for their projects, the builders and developers have to make sure that the STPs are operating properly. By requiring new buildings to have wastewater treatment equipment, this law lessens the strain on centralized treatment plants and stops untreated sewage from being released into the environment.

Pune’s STP laws are designed to encourage environmentally friendly methods of managing sewage. The PMC is strengthening the city’s overall sewage management infrastructure by requiring STPs for new developments. To satisfy increasing expectations, it is crucial to make sure that these laws are properly implemented and that the current infrastructure is updated.

Is STP compulsory in Pune?

Yes, STP is compulsory in Pune. All new residential and commercial buildings must have an internal STP, according to a mandate issued by the Pune Municipal Corporation (PMC). Before receiving completion certificates for their projects, builders and real estate developers need to make sure the STPs are operating properly. This legislation intends to lessen the load on centralized sewage treatment plants and promote sustainable sewage management practices in new construction, even if it does not apply to structures that already exist.

Challenges in sewage management:

Pune faces a number of difficulties in this area, making efficient sewage control techniques imperative. Even though there is already sewage infrastructure in place, the rapid population increase has put ongoing strain on it, which frequently results in blockages and spilling effluent. These densely populated areas produce a lot of wastewater, which is frequently dumped untreated into adjacent bodies of water, endangering human health and the environment. The problem is further made worse by growing urbanization, inappropriate land use, and poor maintenance.

Is STP compulsory in Pune? What are the penalties for non-compliance?

Pune residents who violate the STP laws risk facing harsh penalties. These sanctions might include monetary fines, permit suspension or revocation, and legal action taken against offenders. The seriousness of the infractions and the type of non-compliance determine how much of a penalty is imposed.

This will depend on the capacity of the STPs. As to the officials, STPs with a capacity of less than 300 kiloliters per day (KLD) will be fined Rs 2,500; those with a capacity between 300 and 500 KLD will be penalized up to Rs 4,000; and those with a capacity beyond 500 KLD will be fined Rs 5,000.

In conclusion,

Is STP compulsory in Pune? So, every new residential and commercial building in Pune is required to comply with STP, and non-compliance carries harsh fines. To update and strengthen the current sewage system and satisfy the city’s expanding needs, more substantial efforts are needed. A comprehensive strategy is needed to address the problems with sewage management, one that includes infrastructure investment, regulation enforcement, and public awareness-raising. Pune residents can benefit from cleaner and healthier surroundings thanks to efficient sewage control techniques. A step in the right direction towards accomplishing this goal is the Pune Municipal Corporation’s (PMC) initiative to require STPs in all new developments.

Overcoming these obstacles and eventually making Pune a sustainable and livable city will require maintaining the sewage infrastructure and firmly enforcing the laws.

#wastewatertreatment#watertreatmentsolutions#water purification#sewagetreatmentplant#stp plant manufacturers#environment#stp manufacturer#stp suppliers

0 notes

Text

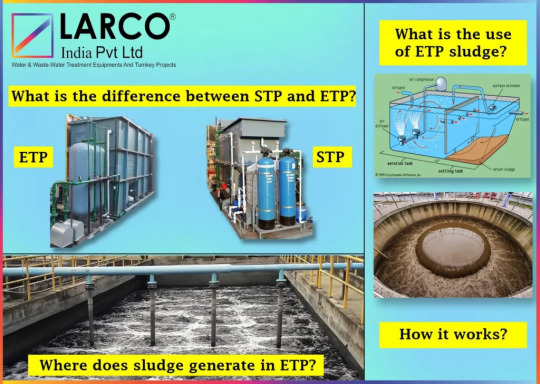

What is the difference between STP and ETP?

In this article, we’ll look What is the difference between STP and ETP?

Certainly! Let’s break down the differences between STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) in simpler terms.

To preserve the receiving waterways, two particular treatments, sewage treatment and effluent treatment are used to remove toxins from wastewater (sludge). Both of these treatments are made up of physical, chemical, and biological processes. The primary distinction between the two STP & ETP.

WHAT IS THE DIFFERENCE BETWEEN STP AND ETP?

Sewage Treatment Plant (STP):

What it does: STP handles the treatment of the waste water that is generated by residences, businesses, and other common locations (such as restrooms, sinks, etc.). Sewage is the term for this unsafe water.

Goal: The main duty of a STP is to treat this sewage so that it can be safely discharged into bodies of water like rivers and oceans or even utilized (for example, to water plants).

How it works: It works by separating solid waste from liquid waste, utilizing beneficial bacteria to break down trash, and adding chemicals to the water. STP Industries Inc. develops products to minimize the amount of toxic substances in sewage.

Effluent Treatment Plant (ETP):

What it does: Industrial wastewater, usually referred to as effluent, is the smelly water that is produced by factories and other industrial facilities.

Goal: An ETP, short for “environmental technology product,” is a chemical substance created to clean up industrial effluent so that it may be reused or released back into the environment in a manner that does not threaten the ecosystem.

How it works: The Etp wastewater solutions can be used to clean industrial wastewater. Sometimes these solutions might involve using chemicals, separating various materials, and occasionally using microbes to degrade dangerous materials.

To put it simply, STP cleans the environment by handling the regular, unclean water from households and businesses. ETP, on the other hand, controls the unsavoury water that emanates from industrial facilities, ensuring its safety before releasing or reusing it. With the aid of specialized techniques, each plant is created to manage a particular kind of contaminated water.

WHAT IS THE USE OF ETP SLUDGE?

https://larcoindia.in/wp-content/uploads/2023/10/diagram-package-plant-aeration-treatment-sewage-flows-1-1.png

What is the use of ETP sludge?

The uses of ETP sludge are many and varied:

https://larcoindia.in/wp-content/uploads/2023/10/wastewater-treatment-pool.jpg

Other use of ETP sludge:

the disposal of treated sewage sludge, which is combined with air and oxygen and applied to agricultural soil as a soil conditioner.

Sewage sludge is disposed of through burning, which involves burning it alongside other waste products like paper and plastic to create steam and energy for industrial uses or to create heat for home usage.

Typically, sewage sludge from sewage treatment plants is burned in a facility along with other waste products like paper and plastic. This burning process generates heat, which is then used to create steam that can be used both to heat domestic water in houses and for industrial applications.

The primary issue with using ETP sludge is that it includes a lot of ammonia (NH3), which is extremely harmful to people if consumed in large amounts over an extended period of time.

WHERE DOES SLUDGE GENERATE IN ETP?

So what you think, Where does sludge generate in ETP?

In an Effluent Treatment Plant (ETP), sludge is formed during the process of treating industrial wastewater. This sludge is essentially the solid waste that settles or is removed during the treatment of the wastewater. It contains the solid particles and pollutants that are separated from the water during the treatment process. The sludge includes things like particles of dirt, chemicals, and other materials that were in the wastewater.

To explain further, when the dirty industrial wastewater goes through the treatment steps, certain solid substances and pollutants settle down or are separated from the water. This separation forms a thick, muddy material, which we call sludge. Managing and disposing of this sludge properly is an important part of the overall wastewater treatment process to ensure that the environment is not negatively impacted.

#wastewatertreatment#watertreatmentsolutions#water purification#etp#sewagetreatmentplant#water treatment

0 notes

Text

BEST CONDENSATE POLISHING UNIT IN DISTILLERY

Larco India Pvt. Ltd., with its cutting-edge Condensate Polishing Unit in distillery, is revolutionizing the industry. Tailored for distillery operations, this unit stands as a pivotal solution to enhance efficiency and ensure the highest levels of purity in the water used within the distillation process.

Understanding the Need for a Distillery-Focused Condensate Polishing Unit

Distilleries must carefully balance various components and techniques to make quality spirits. Condensed water is formed during distillation when steam is produced and condensed. However, this condensate polishing unit frequently contains pollutants that might potentially harm the quality of the end product as well as the efficiency of the gear.

THE SIGNIFICANCE OF LARCO’S CONDENSATE POLISHING UNIT IN DISTILLERY OPERATIONS

Larco India Pvt. Ltd.’s Condensate Polishing Unit in distillery is extremely important in operations, providing a key solution to raise production standards and maintain purity throughout the distillation process.

1. Enhanced Purity and Quality Assurance

Larco’s Condensate Polishing Unit in distillery assures the purity of water used in distillery operations by successfully eliminating contaminants, resulting in a higher quality finished product.

2. Optimized Equipment Performance

The unit increases overall equipment efficiency, reduces equipment downtime, and increases the lifespan of essential distillation components by minimizing the accumulation of contaminants and scaling within the equipment.

3. Compliance with Regulatory Standards

The Condensate Polishing Unit in distillery assists distilleries in meeting strict regulatory standards by providing a dependable way to maintain water quality in accordance with industry and environmental laws.

4. Sustainable Water Management

By decreasing water waste and the need for chemical treatments, implementing eco-friendly procedures, and demonstrating the company’s commitment to environmental responsibility, Larco’s unit supports sustainability.

The Condensate Polishing Unit in distillery from Larco India Pvt. Ltd. is an important tool that not only ensures the supply of high-quality distilled products but also promotes sustainability and compliance with industry standards, positioning distilleries for success in a competitive market.

KEY BENEFITS OF LARCO’S CONDENSATE POLISHING UNIT IN DISTILLERY

Unmatched Product Quality: ensures that contaminants are successfully removed from the water, meeting and exceeding industry quality standards, and so enhances the quality of the distilled product.

Maximized Equipment Efficiency: It increases operating effectiveness and the lifespan of crucial components by preventing scaling and fouling in distillery equipment.

Environmental Stewardship: Eliminates the need for chemical treatments and water waste while adhering to sustainable practices, minimizing the environmental effect of distillery operations.

Features of Larco’s Condensate Polishing Unit in Distillery

Precision Filtration Technology: Utilizes advanced filtration mechanisms to eliminate particulates and impurities from the condensate water, ensuring optimal water quality for distillation.

Ion Exchange Resin Beds: Integrates specialized ion exchange resin beds to effectively remove dissolved ions, providing water of the highest purity.

Automated monitoring and regulation: This feature incorporates an automated system to accurately regulate the purifying process and monitor it in real-time, resulting in top performance with the least amount of user involvement.

Compact and Modular Design: Larco’s Condensate Polishing Unit is designed to be compact and modular, allowing for easy integration into the existing distillery infrastructure. This feature ensures flexibility in installation and space optimization within the distillery setting.

Quick Installation and Easy Maintenance: Larco’s Condensate Polishing Unit is designed for quick and hassle-free installation. Moreover, it facilitates easy maintenance, minimizing downtime and ensuring continuous, uninterrupted operation.

Conclusion: A Paradigm Shift in Distillery Water Treatment

The Condensate Polishing Unit from Larco India Pvt. Ltd. is revolutionizing distillery water treatment. It creates the conditions for a future in which distilled products achieve unmatched levels of perfection while sustaining sustainable practices by guaranteeing water purity and equipment effectiveness. Welcome to Larco’s Condensate Polishing Unit in distillery water treatment system of the future.

#water treatment#wastewatertreatment#watertreatmentsolutions#water purification#Condensate Polishing Unit#CPU

0 notes

Text

A COMPREHENSIVE GUIDE ON HOW TO CALCULATE STP CAPACITY

Sewage Treatment Plants (STPs) are essential for treating and preparing wastewater for discharge back into the environment in the context of wastewater management. Understanding how to calculate STP capacity is crucial for communities and industry alike to guarantee effective wastewater treatment and adherence to environmental rules. This article will go through how to calculate STP capacity in great depth. It is given to you by Larco India Pvt. Ltd., a recognized expert in sustainable environmental solutions.

STEP 1: DEFINING HOW TO CALCULATE STP CAPACITY

how to calculate STP capacity is the greatest amount of wastewater that a treatment plant can efficiently manage in a specific amount of time. It’s a key factor in the design and engineering of STPs to handle the wastewater produced by a particular facility or population.

STEP 2: GATHERING ESSENTIAL INFORMATION

Before beginning to determine STP capacity, one must collect important information, such as:

The average amount of wastewater produced each day is called the average daily flow (ADF).

Retention Time (RT): The intended amount of time for wastewater to be kept in the treatment plant for efficient processing. Peak Flow Factor (PFF): A factor accounting for peak flow periods or surges in wastewater.

STEP 3: CALCULATING PEAK FLOW

Peak Flow (PF) is the greatest anticipated flow of wastewater at any particular time and is determined by the following formula:

PF=ADF×PFF.

STEP 4: DETERMINING TOTAL DAILY FLOW

Average Daily Flow (ADF) and Peak Flow (PF) are added together to create the Total Daily Flow (TDF):

TDF=ADF+PF.

STEP 5: CALCULATING REQUIRED TANK VOLUME

Utilising the Total Daily Flow (TDF) and Retention Time (RT), calculate the necessary tank volume (V):

V=TDF×RT

STEP 6: ADJUSTMENTS FOR SLUDGE AND AERATION

Consider the STP’s sludge settling and aeration systems’ space requirements. To determine the ultimate tank volume necessary for efficient treatment, take these elements into account.

STEP 7: FINALIZING THE STP DESIGN

The computed tank volume and any other adjustments must be added to finish the Sewage Treatment Plant design. This provides a key service for a cleaner and greener environment and ensures that the STP can handle wastewater correctly.

ADVANTAGES OF STP CAPACITY CALCULATING

Efficient Resource Allocation:

One of the most important steps in developing a successful wastewater treatment system is calculating the capacity of the sewage treatment plant (STP). The volume of wastewater that a STP can process over a certain length of time is what determines its capacity. Here is a step-by-step explanation of how to calculate STP capacity:

Cost-Effectiveness:

Planning and design that are cost-effective benefit from accurately how to calculate STP capacity. Both the initial investment and ongoing operating costs can be reduced by avoiding unneeded costs associated with large structures or updating subpar systems.

Environmental Compliance:

Ensuring compliance with environmental rules and standards requires understanding and determining STP capacity. To prevent fines and penalties for exceeding permissible discharge levels, it’s critical to comply with regulatory regulations.

Optimized Treatment Process:

By estimating the appropriate flow rates and retention times, STP capacity estimates help to optimize the treatment process. This guarantees that the wastewater gets through the required treatment steps for efficient contaminant removal.

Improved Performance and Reliability:

The treatment plant functions within its design parameters with increased performance and dependability if the STP capacity is enough. Systems that are appropriately sized have a higher chance of regularly delivering on performance goals.

#water treatment#wastewatertreatment#watertreatmentsolutions#water purification#sewagetreatmentplant#STP#etp#stp plant manufacturers

0 notes

Text

“STP 101: UNDERSTANDING THE BEST STP WORKING PRINCIPLES”

Sewage Treatment Plants (STPs) are critical infrastructure in our attempts to properly manage wastewater and reduce its environmental impact. In this blog post, we will in-depth analysis into the STP Working Principles, deep into the intricate process that converts raw sewage into clean, safe water for disposal or reuse.

THE CRUCIAL STEPS IN STP WORKING PRINCIPLES:

1. Preliminary Treatment:

The sewage trip starts with preliminary treatment. Large debris, solids, and grit are removed from the wastewater at this stage. These undesirable components are thoroughly filtered out by bar screens and grit chambers, reducing damage to downstream equipment.

2. Primary Treatment:

When the preliminary treatment is finished, the effluent goes into primary settling tanks. The velocity of the water in these tanks is lowered, allowing heavy materials to settle at the bottom as sludge. Simultaneously, lighter things such as oils and grease rise to the surface, generating scum. This preliminary treatment prepares the groundwork for subsequent processing.

3. Secondary Treatment:

The secondary treatment stage involves the biological breakdown of organic materials in the wastewater. Microorganisms that are naturally present in sewage or that are added during this phase breakdown the organic components. This decomposition breaks down organic waste into simpler, more stable compounds, lowering the overall pollution burden in the water.

4. Tertiary Treatment:

Tertiary treatment is the final step in the process, and it focuses on polishing the water to satisfy specified quality standards. Nutrient removal, filtration, and disinfection (with chemicals, UV light, or ozone) are all employed. These processes improve the water quality even more, enabling reuse in a range of applications or release into bodies of water.

Environmental Impact and Sustainable Solutions:

In order to solve the challenges brought on by rising urbanisation and industry, it is essential to understand how STPs operate. By effectively processing sewage, we preserve our natural water resources, reduce pollution, and support a sustainable environment.

ADVANTAGES OF STP WORKING PRINCIPLES

Sewage Treatment Plants (STPs) operate in accordance with a set of precise guidelines that are advantageous to the environment and society at large. The purpose of this study is to examine and highlight the advantages of STP working principles in wastewater management.

1. Environmental Protection:

STP working principles positive effects on the environment are among its main advantages. By successfully treating sewage before release, STPs work to reduce water pollution. In addition to ensuring general ecological balance, this protects aquatic life and habitats from harmful pollutants.

2. Health and Sanitation:

By treating wastewater at the source, STPs stop the spread of diseases and sicknesses that are transmitted through water. Untreated sewage raises more health risks because it cannot be safely released into water sources or utilised for non-potable purposes like irrigation.

3. Resource Conservation:

Important resources like nitrogen and phosphorus are easier to recover from wastewater thanks to STPs. These nutrients can be used again as agricultural fertilisers, encouraging the use of sustainable farming methods and reducing the need for synthetic fertilisers.

4. Sustainable Water Management:

Putting STP working principles into practise offers a long-term strategy for managing water resources. We reduce the demand on freshwater sources and ensure their availability for crucial needs by cleaning and recycling wastewater for non-potable uses like watering plants or flushing toilets.

5. Compliance with Regulations:

STPs ensure that local, regional, and national water quality laws are followed. It is critical to meet these criteria in order to avoid penalties, protect public health, and demonstrate responsible wastewater management practises.

6. Reduction of Odor and Unpleasantness:

Proper sewage treatment considerably decreases the unpleasant odours and visual pollution associated with untreated sewage. This improves the quality of life in the surrounding areas, making them more habitable and appealing.

7. Economic Benefits:

STPs can gain financial advantages by using techniques like anaerobic digestion to recover energy from sewage. This method produces biogas, which can be used as a renewable energy source to offset operating expenses and lessen the overall carbon footprint.

8. Flexibility and Scalability:

STP working principles enable flexibility and scalability dependent on the population and wastewater generation in a particular area. To accommodate shifting requirements and expanding populations, systems can be successfully built and expanded.

#water treatment#watertreatmentsolutions#water purification#sewagetreatmentplant#STP#wastewatertreatment#water treatment plant

0 notes

Text

50,000 LITERS OF CHANGE: INSIDE A BEST 50 KLD SEWAGE TREATMENT PLANT

THE BASICS OF A 50 KLD SEWAGE TREATMENT PLANT

By removing contaminants from wastewater before it is released back into the environment, sewage treatment facilities (STPs) are essential to protecting our ecosystem. The daily treatment capacity of a 50 KLD sewage treatment plant is 50,000 kiloliters per day of wastewater. We’ll explore the foundational elements of a 50 KLD sewage treatment plant in this blog post.

Understanding the Need for Sewage Treatment

Wastewater production has increased as a result of population growth and urbanisation. This effluent can provide serious health and environmental problems if it is not properly treated. These issues are addressed by sewage treatment facilities, which clean the wastewater of toxins and make it suitable for reuse or discharge.

COMPONENTS OF A 50 KLD SEWAGE TREATMENT PLANT

1. Inlet Chamber:

The input chamber serves as the starting point for the sewage treatment plant process as it allows wastewater to enter the treatment facility. To protect the downstream machinery, heavy solids and debris are removed here.

2. Screening and Grit Removal:

The removal of big items, sand, and grit occurs in this stage using screens and grit chambers. In the next stages of therapy, these substances may harm pumps and other equipment.

3. Primary Treatment – Sedimentation:

After entering a sedimentation tank, the wastewater is allowed to settle, with heavier particles settling at the bottom to produce sludge. Lighter materials, such as grease and oil, float to the top where they can be skimmed off.

4. Secondary Treatment – Biological Process:

The biological treatment of the sewage often takes place in an activated sludge reactor or a sequencing batch reactor (SBR). Organic materials in wastewater is broken down by microorganisms into simpler, less dangerous compounds.

5. Tertiary Treatment – Filtration and Disinfection:

Further filtering is used to remove even smaller particles, and disinfection techniques like chlorination or UV radiation are used to get rid of any germs or bacteria that are still present.

6. Sludge Handling and Disposal:

The sludge produced during the treatment procedure needs to undergo additional treatment or be properly disposed of. Dewatering, digesting, or incineration may be used in this.

BENEFITS OF A 50 KLD SEWAGE TREATMENT PLANT

Water bodies and ecosystems in the natural world are protected from pollution through wastewater treatment.

Public health: Sewage that has been properly treated lowers the danger of waterborne illnesses, improving community health.

Reclaimed water: The demand on freshwater resources can be lessened by reusing treated wastewater for non-potable uses like irrigation.

Regulatory Compliance: Having a working STP guarantees adherence to environmental laws and regulations and helps prevents possible fines and penalties.

Conclusion

An essential piece of infrastructure for preserving a sustainable and healthy living environment is a 50 KLD sewage treatment plant. We can lessen pollution, conserve water, and improve the general health of our communities and the globe by treating wastewater effectively.

#water treatment#wastewatertreatment#water filter#sewage treatment plant#STP#watertreatmentsolutions

0 notes

Text

UNLOCKING THE MAGIC OF ETP WORKING

In today’s industrial setting, Effluent Treatment Plants (ETPs) are essential for guaranteeing sustainable wastewater management. With major advancements in ETP working, Larco India Pvt Ltd is at the forefront of this environmental battle. In this blog, we’ll dive deeply into the enthralling world of ETPs and see how Larco India Pvt Ltd is transforming how they operate.

THE INTRICATE DANCE OF ETP WORKING

Effluent Handling Like the unsung heroes of the industrial world, plants silently maintain the environment in the background. But exactly how do they operate? Let’s deconstruct it.

1. Inflow and Preliminary Treatment

The entry of industrial effluent kicks off the ETP’s working process. This water is frequently contaminated with a variety of substances, including chemicals, oils, and organic materials. Preliminary treatment, the initial stage of ETP working, involves the removal of big debris and particles using screening and grit chambers. Damage to equipment downstream is avoided as a result.

2. Primary Treatment

The wastewater enters the main treatment stage once it is clear of big particles. Here, the magic of ETP’s working is made clear. As suspended materials accumulate at the bottom of the treatment tanks and form sludge, gravity assumes control. The relatively cleaner water continues on for additional processing. Modern methods are used by Larco India Pvt Ltd to optimize this crucial ETP working phase.

3. Secondary Treatment: A Biological Ballet

The second stage of treatment is where ETP really starts to work. The ETPs produced by Larco India Pvt Ltd are made to resemble nature’s own cleansing mechanism. The wastewater contains microorganisms such as bacteria and fungi. The Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) of the water are drastically decreased as a result of the action of these small animals, who gorge themselves on organic contaminants. Like a microscopic cleansing ballet, it’s like that!

4. Tertiary Treatment: Polishing the Gem

The secondary stage of the ETP process is just the beginning for some sectors and strict environmental criteria. Tertiary treatment is included as a further effort by Larco India Pvt Ltd. A number of cutting-edge processes, including filtration, chemical coagulation, and disinfection, are used in this final step of the ETP process. It is at this point that the water transforms into a shining jewel that is fit for reuse or safe disposal.

5. Sludge Management: Closing the Loop

Sludge management is the final act in the overall scheme of the ETP Working. The solid residues that are separated during primary and subsequent treatment also require care. Larco India Pvt Ltd assures proper handling of sludge, frequently processing it further or disposing of it in an environmentally friendly way to finish the ETP working cycle.

Larco India Pvt Ltd: A Maestro in ETP Working

In the field of ETP operating, Larco India Pvt Ltd has established a distinct position for itself. Their focus on ensuring that the treated water meets or exceeds legal standards is demonstrated by the cutting-edge technologies they use, the meticulous monitoring of ETPs, and their commitment to environmental sustainability.

Larco India Pvt Ltd’s ETP working procedures shine as a beacon of hope in a world where ethical industrial practices are crucial. They are nourishing the world, one drop at a time, rather than just treating effluent. Let’s encourage and support businesses like Larco India Pvt Ltd as they lead the push in ETP to create a cleaner, greener future as we move forward.

ETP WORKING MAINTAINANCE

In order to maintain the plant’s efficiency and comply with environmental regulations, Larco India Pvt Ltd is here for you. Effluent Treatment Plant (ETP) maintenance is essential, Following are a few crucial ETP maintenance components:

Regular Inspections: Conduct routine checks to look for any signs of wear, corrosion, or damage on the ETP’s parts, including the screens, pumps, tanks, and pipes. Regular visual examinations can aid in early problem detection.

Cleaning: Maintain ideal flow rates by routinely cleaning screens, filters, and other machinery. The effectiveness of the ETP can be hampered by built-up trash and sludge.

Calibration and Testing: To guarantee correct readings of variables like pH, dissolved oxygen, and turbidity, calibrate sensors and monitoring devices. To gauge the effectiveness of the plant, test the quality of the influent and effluent waters often.

Chemical Handling: Be sure to handle and store coagulants and disinfectants—two examples of chemicals used in the ETP—properly. Maintain an inventory of chemicals and make sure that chemical dosing systems are working properly.

Sludge Management: Efficiently manage and remove any sludge that remains after the treatment procedure. Dewatering, additional treatment, or safe disposal may be necessary, depending on local laws and the type of sludge.

Equipment Maintenance: Pumps, mixers, blowers, and other mechanical parts should all be maintained and repaired as needed. Lubricate moving parts and replace worn-out ones to prevent breakdowns.

Industries can ensure that their wastewater treatment processes remain effective and environmentally responsible by concentrating on ETP Working maintenance and according to best practices. This will also extend the lifespan of the equipment.

0 notes

Text

LEADING THE WAY AS ETP PLANT MANUFACTURERS IN BANGALORE

In the bustling landscape of Bangalore, where innovation and sustainability converge, one name stands tall: Larco India Pvt Ltd. This article explores how Larco has become synonymous with excellence in the realm of ETP Plant manufacturers in Bangalore, reshaping the environmental footprint of industries in the city.

Setting the Stage for Sustainable Solutions

Amidst the dynamic business environment of Bangalore, Larco India Pvt Ltd has emerged as a pioneer in crafting ETP solutions that transcend conventional norms. Their commitment to addressing the critical issue of industrial wastewater treatment has redefined the city’s approach to environmental responsibility.

Innovating Beyond Expectations

At Larco India Pvt Ltd, innovation is not just a buzzword; it’s a way of life. Their ETP solutions incorporate cutting-edge technologies that optimize wastewater treatment processes. From advanced filtration mechanisms to real-time monitoring, Larco’s innovative mindset ensures that industries in Bangalore achieve higher levels of efficiency and environmental stewardship.

A Local Touch with Global Expertise

Larco, an ETP plant manufacturers in Bangalore, brings a global perspective to local challenges. Their team of experts combines international best practices with a deep understanding of the city’s industrial landscape. This synergy results in tailor-made ETP systems that are designed to tackle the unique wastewater treatment needs of Bangalore’s diverse industries.

Navigating Compliance with Confidence

Bangalore’s regulatory landscape is intricate, but Larco India Pvt. Ltd. navigates it with finesse. Their ETP solutions are meticulously crafted to meet and exceed local environmental regulations. Larco helps industries ensure they are complying with the law and contributing to the overall good of their communities.

Collaboration that Counts

Partnering with Larco India Pvt. Ltd. goes beyond a transaction; it’s a collaboration that has a lasting impact. By embracing Larco’s ETP solutions, industries in Bangalore unlock a multitude of benefits. These include enhanced operational efficiency, reduced environmental risks, and a bolstered reputation as environmentally conscious entities.

A Greener Tomorrow with Larco India Pvt Ltd

In a city known for its technological prowess, Larco India Pvt. Ltd. emerges as a beacon of environmental excellence. Their role as ETP plant manufacturers in Bangalore goes beyond manufacturing equipment; it’s about crafting a sustainable future for the city and its industries. Through innovation, expertise, and a commitment to compliance, Larco is redefining the possibilities of wastewater treatment, one ETP system at a time. As Bangalore evolves, Larco India Pvt. Ltd. paves the way for a greener, cleaner, and more sustainable tomorrow.

#wastewatertreatment#water treatment#etp#watertreatmentsolutions#effluent water treatment plant#etpplant#industry#water purification

0 notes

Text

ETP PLANT MANUFACTURERS LEADING ENVIRONMENTAL EXCELLENCE

ETP Plant Manufacturers (Effluent Treatment Plants) have a crucial role to play in a time when environmental sustainability is a top priority. Larco India Pvt. Ltd. stands out among these sector leaders as an example of innovation and dedication. An in-depth discussion of Larco India Pvt. Ltd.’s crucial contribution to the development of a cleaner, greener future is provided in this article.

THE ROLE OF ETP PLANT MANUFACTURERS: LARCO’S VISION FOR CLEANER ECOSYSTEMS

At Larco’s core, we devote ourselves to creating advanced ETP systems that effectively treat industrial wastewater. These systems act as environmental guardians, purifying effluents and safeguarding ecosystems from the harmful impact of pollutants. At Larco, we are more than just ETP plant manufacturers; We facilitate change and design a more ethical industrial environment.

Key Attributes of Leading ETP Plant Manufacturers

Innovation Beyond Boundaries: With their solutions for energy-efficient wastewater treatment, Larco India Pvt. Ltd. redefines innovation in the ETP sector. We are a privately held company that focuses on making unique products. Our goods arrive equipped with contemporary technology, such as sophisticated monitoring systems and energy-efficient treatment methods. This inventive mindset improves the effectiveness of wastewater treatment while also lowering the carbon impact of industrial processes.

Technical Expertise that Matters: Larco India Pvt. Ltd. is a top ETP plant manufacturers and has a staff of knowledgeable professionals. They can customize ETP solutions to meet particular needs because of their in-depth knowledge of various sectors. Larco’s experience guarantees that every system is specifically optimized, whether it be in the chemical or textile sectors.

Steadfast Compliance: Environmental laws are always changing, and Larco India Pvt. Ltd. stays up. They painstakingly create their solutions to comply with changing environmental criteria. This guarantees that companies working with Larco meet and even surpass regulatory requirements.

Benefits of Collaborating with ETP Plant Manufacturers

Comprehensive Solutions: Selecting Larco India Pvt. Ltd. entails selecting a comprehensive strategy. They carry out in-depth analyses, create customized ETP systems, supervise buildings, and offer continuous support. For organizations, this end-to-end service reduces complexity.

Financial Prudence: Long-term financial rewards result from working with Larco. The risk of regulatory fines is decreased by effective wastewater treatment, and over time, process optimization can result in significant cost savings.

Championing Environmental Reputation: Joining together with Larco India Pvt. Ltd. demonstrates a commitment to environmental stewardship on both sides. This partnership improves a company’s reputation by appealing to stakeholders and environmentally sensitive customers.

Conclusion

ETP Plant Manufacturers Larco India Pvt. Ltd. also act as stewards of the ecological balance. Thanks to their commitment to innovation, technical brilliance, and unwavering compliance, they distinguish out in a market where sustainable practices are strictly prohibited. Businesses that work with Larco pave the way for a better, sustainable future where commerce and nature live in harmony. We find a partner in advancement in Larco India Pvt. Ltd., not just a manufacturer.

#water treatment#wastewatertreatment#etp#water purification#watertreatmentsolutions#etp plant manufacturers

0 notes

Text

WHAT IS AN ETP PLANT? ITS USES, AND ITS ADVANTAGES.

In this blog post, we’ll learn What is an ETP plant? how it works, and its advantages. Larco India Pvt Ltd Pune handles ETP manufacturers and suppliers in Maharashtra.

Effluent water

The term for wastewater that needs purification before its release into the environment is “effluent water.” Effluent water contains organic and inorganic matter and harmful chemicals produced in tons of volume as a product of an industrial process.

WHAT IS AN ETP PLANT?

So, What is an ETP plant?

An ETP plant stands for Effluent Treatment Plant. ETP (Effluent Treatment Plant) is a process used to clean industrial wastewater so that it can be recycled or safely dumped into the environment.

Lime, sodium hydroxide, and sodium bicarbonate are the chemical agents that are most frequently used for pH adjustment in effluent treatment facilities.

Effluent Treatment Plant plays an important role in the treatment of industrial wastewater as well as domestic sewage. Organic matter, inorganic matter, heavy metals, oil & grease, suspended particles, and other impurities are all handled throughout the wastewater treatment process at an ETP plant. There are different kinds of wastewater treatment plants, including chemical, biological, combination chemical and biological, and thermal.

Most companies in various kinds of industries utilize effluent treatment plants (ETPs) to purify water and remove any toxic and non-toxic materials or chemicals from it so that it can be reused or released into the environment with less environmental harm.

The following sectors heavily utilize ETP plants:

> Chemicals:

Industrial effluents are waste materials from different industries, and different organic contaminants have been found in various water sources. The category they fall under include pesticides, fertilizers, hydrocarbons, phenols, plasticizers, biphenyls, detergents, oils, greases, etc.

ETPs filter pollutants from wastewater, minimizing its adverse impact on the environment and conserving natural resources. Protection of public health: Because the toxins in untreated wastewater can pollute drinking water sources, it can also be dangerous to release them into the environment.

> Pharmaceuticals:

Pharmaceutical companies and drug factories released waste that contains various chemicals, solvents, and other dangerous materials. Aerobic/anaerobic treatment, membrane filtering, and reverse osmosis are technologies that minimize Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), and Total Dissolved Soils (TDS) in pharmaceutical effluent.

> Textiles:

An essential biological component of textile wastewater treatment is the separation of potential microorganisms and the use of such organisms for removal. Microorganisms such as bacteria, fungi, and algae remove several types of dyes that are present in the textile effluent water.

> Automobile:

For washing, rinsing, and painting purposes, the automotive industry uses water. Metals, oils, grease, dyestuff, detergents, chromium, phosphates, paint, and other substances are some of the pollutants that researchers frequently detect in effluents.

Benefits of Effluent Treatment Plant

We are living in a region where pollution is a significant problem for the entire society. It can be any type, including Air, Water, and others.

The amount of water pollution grows by +100% as a result of our civilization and business expanding on a vast scale. Therefore, industries must produce garbage before releasing it into the environment. ETP Plants play an important role in this process.

Advantages:-

Produces reusable, clean water.

Prevents diseases

Provides for the best possible use of water

To avoid harsh penalties by adhering to the government-set standards for the emission or discharge of environmental pollutants from various industries.

To prevent pollution from affecting the environment and to support sustainable growth.

#water treatment#wastewatertreatment#industry#etp#water purification#watertreatmentsolutions#chemical treatment#biological treatment#pharma industry#textiles#automobile#effluent treatment#effluent water treatment plant

0 notes

Text

DID YOU KNOW, WHAT EQUIPMENT IS USED IN SEWAGE TREATMENT PLANTS (STP)?

A sewage Treatment Plant (STP) is a facility that treats wastewater from domestic, commercial, and industrial sources and converts it into an effluent that can be safely discharged into the environment. The STP requires several pieces of equipment to perform the various treatment processes involved.

Bar Screens:

The first step in a sewage treatment plant (STP) is to remove large objects such as rags, plastics, and other debris that can cause damage to downstream equipment. Before entering the treatment process, bar screens will remove big particles

Grit Chambers:

After the initial screening process, grit chambers will be used to remove small particles such as sand and gravel that can cause wear and tear on equipment. The grit chambers allow the heavier particles to settle at the bottom, which is then removed by a scraper mechanism.

Primary Clarifiers:

The wastewater then flows to the primary clarifiers where solids such as human waste, food scraps, and paper settle at the bottom of the tank. The primary clarifiers use the principle of gravity to separate the solids from the liquid.

Aeration Tanks:

The wastewater mixes with air in the aeration tanks, which gives the microorganisms that degrade organic matter and other pollutants oxygen to grow. The aeration tanks also help to keep the suspended solids in suspension.

Secondary Clarifiers:

The secondary clarifiers remove any remaining solids once the aeration tanks have finished treating the wastewater. The secondary clarifiers use the same gravity principle as primary clarifiers to settle the solids at the bottom of the tank.

Disinfection Units:

The final step in the Sewage Treatment Plant (STP) process is disinfection, which involves killing harmful microorganisms such as bacteria, viruses, and parasites. Disinfection units use chemicals such as chlorine or ultraviolet light to destroy these microorganisms.

Sludge Treatment:

During the wastewater treatment process, solids removed from the wastewater accumulate and form a sludge. This sludge requires further treatment, which can involve thickening, dewatering, and drying.

Conclusion

In conclusion, a Sewage Treatment Plant (STP) requires a combination of mechanical, chemical, and biological treatment processes, each of which relies on specific equipment. the equipment used in STP plays a critical role in ensuring that the wastewater will treated to the required standards and is safe for discharge into the environment.

#water treatment#wastewatertreatment#water filter#sewagetreatmentplant#watertreatmentsolutions#chemical treatment#biological treatment

0 notes

Text

HOW TO CHOOSE THE RIGHT WATER FILTER AND SOFTENER SYSTEM FOR YOUR HOME

For our health and well-being, we need access to clean, healthy water. But pollutants, chemicals, and minerals that might damage the water’s quality and flavor are frequently present in the water supply in many places. Purchasing a water filter and softener system for your home is a smart move if you want to satisfy these worries. But how can you pick the best option when there are so many on the market? With a focus on the products provided by Larco India Pvt Ltd in Pune, we will guide you through How to Choose the Right Water Filter and Softener System for Your Home in this blog post.

Assess Your Water Quality:

Before selecting a water filter and softener system, it’s important to evaluate the quality of your water supply. You can conduct a water test to determine the presence of impurities, contaminants, and the level of hardness. Larco India Pvt Ltd provides water testing services to help you understand the specific needs of your household.

Understand Different Types of Water Filters:

Different kinds of water filters are available, each aimed at removing a particular sort of impurity. Below is a list of some typical varieties:

Activated carbon: In these filters, activated carbon will be used to remove chlorine, organic compounds, and other typical contaminants. They successfully enhance flavor and smell.

Reverse osmosis (RO) systems use a membrane to filter out pollutants, minerals, and dissolved solids. They offer thorough cleaning but might also take out vital minerals.

UV filters: UV filters kill bacteria, viruses, and other microbes by exposing them to ultraviolet light. They are a fantastic option for water sources that are susceptible to microbial contamination.

Sediment Filters: Sediment filters clear the water of substantial particles, including sand, rust, and silt. They are frequently used in conjunction with other filtration systems as a pre-filter.

Consider water softener systems:

Installing a water softener system is essential if you live in an area with hard water. High quantities of minerals like calcium and magnesium in hard water can lead to the accumulation of limescale in plumbing and appliances. Water softening systems from Larco India Pvt Ltd Pune are dependable and may successfully lower the hardness of your water supply.

Establish your budget:

There is a large price range for water filter and softener systems. It’s crucial to decide on a budget and the characteristics you require. With no sacrifice to quality, Larco India Pvt. Ltd. offers solutions for any kind of budget.

Look for certifications and warranties: