Quote

http://www.innosilicone.com/faq.php

Inno Slica

0 notes

Text

China’s Commody Prices Exploring in Environmental Inspections

2017-08-12

China is adjusting the industrial structure, leading to a environmental friendly, rather than over consume the resource and at the cost of damaging the Environment.

The seven round of Environmental Inspections launched in Auguest, and this trend will be last till March 2018. The phenomenon of raw materials shortage and soaring will be absolutely deteriorating, as more and more factories will be forced and shut down to recitfy and productivity will be restricted.

#Inno Silica#silicone price#Liquid silicone price#silicone raw materials cost#silicone price increase

0 notes

Text

China launched the Seven round Environmental Inspections

2017-7-27

As China’s Environmental Inspections keep proceeding deeper and deeper, the seven round has been launched. This round could be estimated more harsher than previous rounds. All raw materials soars in immediate response.

Below is quoted from the official announce from Ministry of Environmental Protection The People’s Republic of China.

0 notes

Text

Technical Explanation of Liquid silicone rubber's Working time

When we talk about silicone rubber's working time, there is one important factor that always been mentioned: the working condition (working temperature.). People who used liquid silicone rubber before all know temperature has great impact on the silicone rubber's setting time, no matter for Tin-cured or Platinum-cured. Indeed, Platinum-cured silicone is even more sensitive to temperature.

Some users sometimes get confused that when silicone rubber come to their place from the suppliers’, they always have much different working time with the suppliers’, Even they exactly follow technical instruction.Surely, there are other factors that affect the working time and curing time, humidity for example, also has more or less impact, but here we focus on the temperature only.

To discuss how temperature affect the working time, we should presume the humidity is the same, and also, the supplier makes the correct instruction based on their lab test. Therefore, there two temperatures will be discussed, one is working temperature, one is liquid silicone’s temperature.

1. Working temperature. When Inno Silica test the working time, we normally set it under room temperature at around 25 degree. When silicone reach to client’s place and if their working temperature is different from 25 degree, the working time will be different. The higher temperature, the shorter working time. vice versa.

2. But under same working temperature, why the working time is still different from the instruction? There is one more important factor that always been neglected, which is liquid silicone’ temperature. The liquid silicone store under certain condition, it will get a certain temperature. For example, when the silicone is stored under room temperature 10℃, when it takes out and work under 25 ℃, with air conditioner, the liquid silicone rubber and catalyst’s temperature is actually much less than 25℃. When mix two parts together, the working time obtained will still much longer. Vice versa, when silicone rubber store under 30℃, for example, when it takes out to work under 25℃, the working time will be shorter than what supplier instructed.

By knowing these two factors, now we know how to avoid the impact from the temperature and how to get a suitable working time by yourself. Here are some advises and tips for Tin-Cured silicone rubber:

1.You could follow the intruction by the supplier first. If the working time and curing time are far more than you required, please try the second or third step.

2. After takes out the silicone from warehouse, judge the temperature of both silicone rubber and working temperature. If these temperatures are higher than what supplier instructed, please lower the mixing ration of catalyst a little bit. If your storage temperature and working temperature are lower than supplier’s instruction, better to increase the mixing ratio a little bit.

3. Before want to use the silicone rubber, you also could take out the silicone rubber from warehouse to leave it under the working temperature for around 10~24 hours till it closes to the working temperature. But this will take times.

4. If you still have problems after the three steps, please contact your supplier for further technical support.

#silicone rubber working time#How to prolong silicone rubber working time#how to shorten silicone rubber working time

0 notes

Text

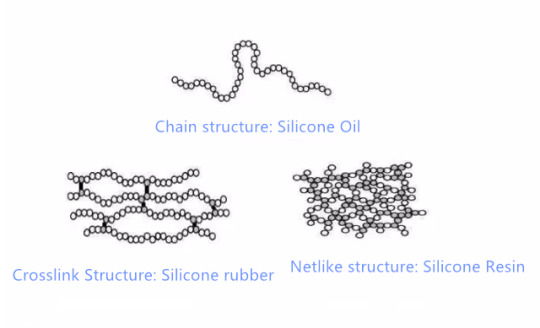

Polysiloxane decides what its ultimated product Forms

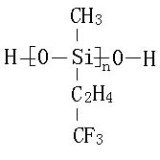

Polysiloxane ( (R2SiO)x ),

is a polymer with repeated Si-O as main chain, and each Si atom direct connect with organic group. In its chemical formulas, R represents organic group which could be methyl, phenyl etc.

In Polysiloxane, the ratio of R/Si decides what its ultimated product form is:

When R/Si <2, the ultimated product is Silicone Resin;

When R/Si ≈2, the ultimated product is Silicone rubber;

When R/Si >2 the ultimated low molecular weight, oil like product, namely silicone oil.

#silicone rubber#silicone resin#silicone oil#structure of silicone rubber#structure of silicone oil#structure of silicone resin

0 notes

Text

How Addition cure silicone rubber is made?

For many years, most of the Silicone Rubber manufacturers only focus on promoting their products, rather than explain how silicone rubber is made and what are its components.

Surely, there is patent and special ingredients concern, but the general processes and raw materials of the silicone rubber should be known by clients.

Here, Inno Silica (www.innosilicone.com, contact: [email protected] ) takes this opportunity to discuss how the addition cure silicone, namely RTV-2 food grade silicone is made.

Part One Vinyl Silicone Fluid

First, let’s start with Vinyl Silicone fluid. Vinyl Silicone Fluid is a kind of polysiloxane, which contains 2 or more than 2 -Si-CH=CH2. It is the main ingredients of silicone rubber. Through adding Vinyl Silicone Fluid, it could change silicone rubber’s crosslink density, and therefore enhance the tear and tensile strength as welll as hardness.

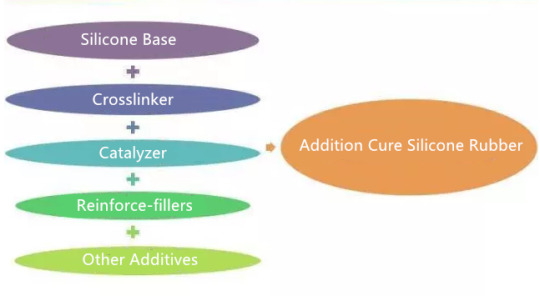

Part Two. Major Conponents of Addition Cure Silicone rubber

1. Silicone Base

Silicone base is mostly Polydimethylsiloxane which contains with 2 or more than 2 -Si-Ch=CH2. Normally, it is a type of linear Polysiloxane that brings each Vinyl at each end. (If brings only one Vinyl in one end, it calls Vinyl silicone oil )

2. Crosslinker

Crosslinker is a kind of Organic silicon oligomer which contains 3 or more than 3 -Si-H, also called methyl hydrogen silicone oil. It is one of basic components of Addition cure silicone rubber.

3. Catalyzer

There are mainly catalyzers that could initiate the Si-H reaction in Addition cure silicone rubber, but only Platinum catalyzer is the most efficient. By applying the Platinum catalyst, the addition cure silicone rubber could be vulcanized in room temperature. And by adding proper ratio of inhitor into the catalyzer, it could prolong the reaction speed and control the vulcanization.

4. Rainforce Fillers

Silicone rubber made by Vinyl Silicone Fluid and Hydrosilicone Fluid only does not have good mechanical properties, which means its tear and tensile strength, elongation etc are not good. In order to improve its mechanical properties, rainforce fillers should be added. These fillers normally are fume silica, precipitation silica, silicone powder...If want to get the clear silicone rubber, Methyl vinyl MQ silicone resin will be added to improve clear silicone’s mechanical properties.

5. Other additives

Other additives are added with the purposes of getting different colors, thermal conductiivity, flame resistance, electrical conductivity,thermostability, transparency, ect.

To get more information about silicone knowleage, technology and other supportive information, please pay attention to our website or follow our facebook, Tumblr...we will update some information, including the product information, new products, latest development...

Your consultant always at your service: Mr. Johns

Email: [email protected]

#How Addition cure silicone rubber is made?#How RTV-2 silicone rubber is made?#How to make liquid silicone rubber?#The main components of Liquid silicone rubber#What is liquid silicone rubber

0 notes

Text

New Product Arrival

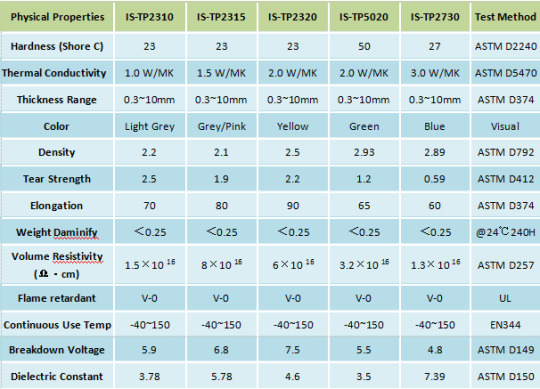

Thermally Conductive gap filler (Silicone pad)

INNO SILICA Thermally Conductive gap fillers are thermal conductive pads that use in interfaces of electronic devies to eliminate or reduce the heat. They are the compound of thermal conductive materials and silicones, and has great merits of thermal conductivity and exceptional Dielectric Strength. The pads are soft and flexible that could be easily applied in the electronic parts.

Key features:

★ Excellent thermal conductivity, dielectric strength and stability;

★ Sound and vibration absorbing;

★ Gap filling, anti-compression and deformation resistance;

★ Slightly self adhesion, application convenience;

★ Good alternative for thermal conductive silicone grease, tape and coat;

★ Consistent with RoHS ,UL Certificates;

Inno is silicone materials producer, more competitive in price with high quality

Applications:

Inno Silica® IS-TP Series are mainly used in Semiconductor, IC, CPU.MOS, Led Lighting, LCD TV, Telecom device, wireless Hub,NB, PC, power supply,Cooling Module, Thermal module, and all applications where a metal housing is used as heatsink.

For more information, please contact us

#thermally conductive pad#thermal silicone pad#thermally conductive gap filler#thermally conductive sheet#thermal pad

0 notes

Text

Shenzhen Inno Silica Co.,Ltd

Company Introduction:

Shenzhen Inno Silica Co., Ltd is an innovative company in silicone products. It devotes itself in researching and developing different series silicone rubber, bringing convenience to customers’ production and life with high tech, environment friendly silicone products. Our main products includes RTV-2 silicone rubber molding series, addition cured silicone rubber, silicone potting compound for electronic parts, silicone sealant, silicone oil and so on. With penetrating “innovation” in every detail in products and “honesty” in managing, Inno Silica has been a trustworthy partner to customers from worldwide. We not provide products only, but also full solution from your initial inquiry to every period we cooperate. Our team has been working for many years researching and listening to the consumers needs, your needs. Here, you will receive first rate support and service from us.

#Inno Silica#Inno Silicone#Shenzhen Inno Silica Co#Silicone rubber manufacturer#Liquid silicone rubber manufacturer#High Tech liquid silicone rubber manufacturer

0 notes

Text

Product catalog

Ⅰ. Mold Making System

#Silicone rubber for mold making#Polyurethane rubber for molding#addition cure silicone rubber for molding#condensation cure silicone rubber for mold making

0 notes

Text

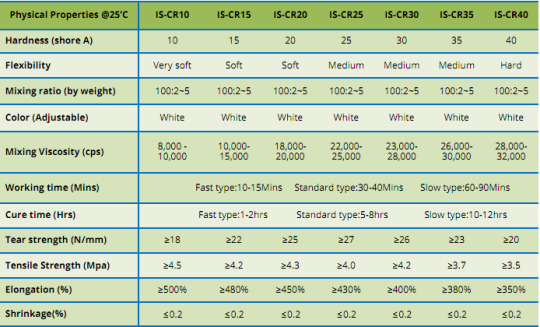

Condensation Cure mold making Silicone rubber

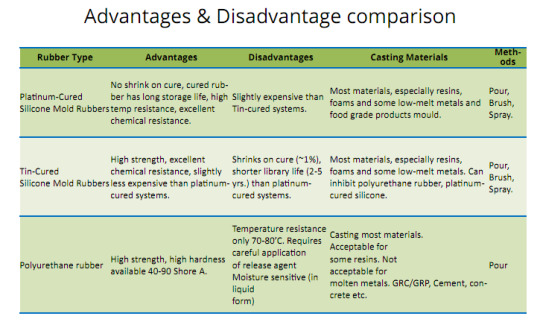

Condensation (Tin) Cure silicone overview (Pourable & Brush-able type)

CONDENSATION CURE SILICONE also called Tin-cure silicone rubber, which are two-part (Part A & Part B), curing room temperature . It is primarily used in the mold-making industry with POURING or BRUSHING onto models to make the molds.

They are available in a variety of hardness. Molds made from these rubbers offer high tear strength, good release properties, and high temperature resistance.

Inno Silica offers Pourable (IS-CR series) and Brush-able (IS-BR series) types for mold making.

Features

• High tear strength and tensile strength

• Good fluidity, operation friendly

• Excellent chemical and aging resistance

• Low shrinkage

• Long library life

Typical Uses & Casting Materials

• Resin casting (polyurethane, polyester, epoxy)

• Foam casting

• Wax casting

• Sculpture reproduction

• Soap and candle making

• Plaster casting

• Cold cast bronze art

• Low-melt metals

• Concrete, Cement, GRC casting

• Craft, toy casting

#RTV-2 silicone rubber#Condensation cure RTV-2 Silicone rubber#Mold making silicone rubber#RTV-2 mold making silicone rubber#liquid silicone rubber#liquid RTV-2 silicone rubber#silicone rubber for molding

0 notes

Text

ⅰ. Condensation cure silicone rubber for mold making

⑴. Condensation cure silicone rubber for molding: Pourable type

Key Features: Good fluidity; Easy Mixing; Less bubble; Penetrate fine details.

Package: 1kg/pail, 5kg/pail, 25kg/pail, 200kg/pail; 4% catalyst free, color adjustable.

•Thickener (TIN-THI) could be offered to thicken these silicone rubbers for brush-on molds.

#Moldmaking Silicone rubber#silicone rubber for casting molds#silicone rubber for molding#RTV-2 silicone rubber for molding#liquid silicone rubber for making molds#silicone rubber

0 notes

Text

ⅰ. Condensation cure silicone rubber for mold making

⑴. Condensation cure silicone rubber for molding: Brushable type

Key Features: Easy Brush-able/ spray-able; Applicable to vertical surface, mostly used in sculpture, architectural duplication.

Package: 1kg/pail, 5kg/pail, 25kg/pail, 200kg/pail; 4% catalyst free, color adjustable.

• Fiberglass could be layered among in the mold to enhance the tear and tensile strength.

#Brush-able silicone rubber for molding#molding silicone rubber with brush#brush-able silicone rubber#silicone rubber for molding#silicone rubber for brushing mold

0 notes

Text

Addition(Platinum cure silicone rubber)

Addition (Platinum) cure Silicone overview

(Translucent & Transparent type)

ADDITION CURE SILICONE also called Platinum-cured silicone rubbers that consist of two parts (Part A & Part B). After mixing, they cure at room temperature to flexible, high-strength rubbers. Addition cure silicones are more prefer to condensation cure silicone s, due to their food grade, none shrinkage and more resistant to higher temperature, aging, worse environment conditions.

Features

• Exhibit Non-shrinkage after curing, optimal for casting highly precise and dimensional stable parts

• No release agent required

��� High tear strength and tensile strength, long library life

• Excellent resistance to high temperature, chemicals and aging

• Food grade, skin touch safety

Typical Uses & Casting Materials

• Same uses with condensation cure silicones

Typical Uses in:

• Food product molding, including Candy/Chocolate/Cake molding

• Life casting

• Polyurethane, epoxy, polyester resins casting

• Dimensional stable parts Rapid Prototyping

CAUTION

During mold making, mixture should be avoided to contact with some material which may inhibit the curing system. These materials include:

1. Organotin and other metallorganic compound

2. sulphur, polysulfide, polysulfone and other sulfur-containing

3. Amine, polyester rubber and other ammoniac

4. phosphorig and other phosphorig-containing

0 notes

Text

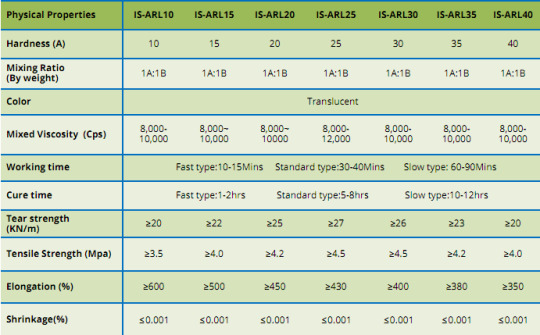

ⅱ. Addition cure mold making Silicone rubber

⑵. Translucent type Addition cure Mold making Silicone Rubber (IS-ARL Series)

Key Features: Non-Shrink on cure, Excellent fluidity, Easy mixing with 1:1/10:1, High temperature resistance up to 300’C, Color adjustable, both Pour-on and Brush-on mold available.

Package: 1kg/pail, 5kg/pail, 20kg/pail, 200kg/pail

Thickener (PLAT-THI) could also be offered to thicken these silicone rubber for brush-on molds.

#Platinum cure silicone rubber#platinum cure translucent silicone rubber#addition cure silicone rubber for mold making#addition cure silicone rubber for molding#translucent silicone rubber for molding#food grade silicone rubber for molding

0 notes

Text

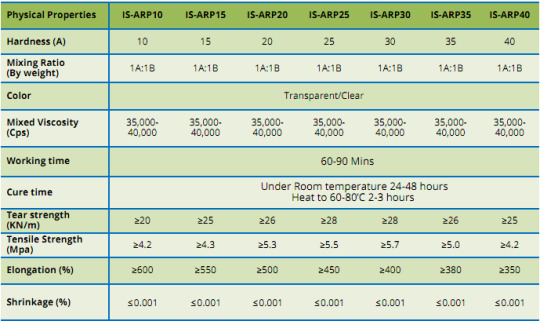

ⅱ. Addition cure moldmaking Silicone rubber

⑴. Transparent type Addition cure Moldmaking Silicone Rubber (IS-ARP Series)

Key Features:

High transparency, mainly used for fine accurate jewelry, dimensional stable parts prototyping, with inside details visibility required.

Package:

1kg/pail, 5kg/pail, 20kg/pail, 200kg/pail

#Platinum cure silicone rubber#addition cure silicone rubber#addition cure silicone rubber for mold making#transparent silicone rubber#transparent type silicone rubber for prototyping#non-shrinkage silicone rubber

0 notes

Text

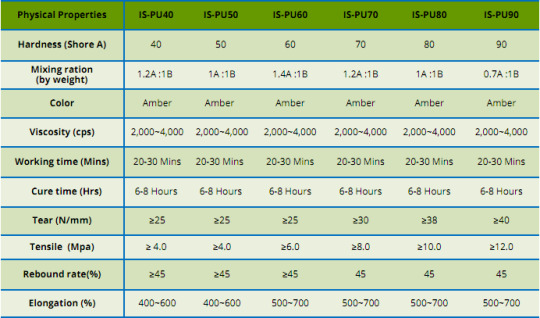

ⅲ. Mold making Polyurethane Rubber (IS-PU Series)

Polyurethane Mold Rubbers overview

Polyurethane rubber is also one of regular materials for mold making. Inno Silica’s Polyurethane liquid mold rubbers hardness range from 40-90A. They are two parts that cure at room temperature. Polyurethane mold rubbers offer high performance, superior flexible and durable to make molds for relatively simple to the most highly detailed, undercut and complex models.

Features

• High tear and tensile strength, easy-to-use

• cost-effective, wide range of hardness.

Typical Uses & Casting Materials

• Precast concrete casting

• Architectural GFRC

• Plaster casting

• Artificial stone casting

• Sculpture and décor reproduction

• Other hobby, craft, prop and display mold making and casting projects

Note: Polyurethane is not suitable for those molding applications where high temperature resistance and dimension stable are required.

#Polyurethane rubber for molding#Polyurethane rubber#Polyurethane rubber for concrete molding#Mold making Polyurethane rubber

0 notes

Text

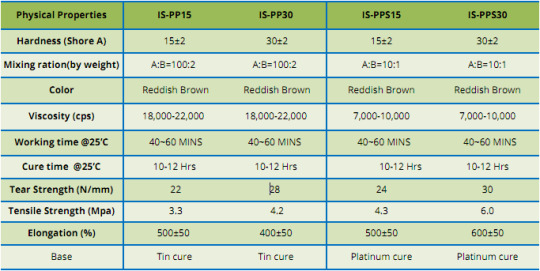

Ⅱ.Pad Printing Silicone rubber (IS-PP Series)

INNO SILICA offer both Tin and Platinum-Cured pad printing silicone. It has excellent tear, tensile strength and elongation properties for Pad Printing application. IS-PP (Tin type) and IS-PPS (Platinum type) pad printing silicone offer varied possibilities for adding silicone oil to adjust as customers require.

Features

• Excellent Tear and tensile strength, high durability in pressure

• Good property of transfer the oil from pad to product surface

• Available in different hardness for different requirements

• Good resiliency

• Exquisite, no impurity

Applications

Inno Silica® IS-PP and IS-PPS Series are optimal to use in printing pad.

#silicone rubber for pad printing#silicone rubber for making printing pads#pad printing silicone rubber#printing pads

0 notes