Text

Steel for Marine Use

https://www.huaro-shanghai.com/marine.html

General description of steel products application in Marine

Marine also is known as the shipbuilding industry, it's one of the biggest steel products cost in the whole steel products market. The marine business has grown the very fast need for Grade A type of hot rolled steel plate, hot rolled steel sheet and stainless steel for marine use.

These flat steel products are one of the most commonly used in the marine industry. It is produced by rolling machines with smooth surfaces and ranges of dimensions, varying in thickness. Grade A steel plates are used for hull structures and platforms in shipbuilding. Marine steel plate A class is ordinary tensile strength steel. Stainless steel in marine environment has good toughness and high strength, strong corrosion-resistance, machining, and welding properties.

Huaro's stainless steel for marine applications

We have a large quantity of marine grade steel with the properties required for a corrosive environment and have established relationships with some of the best steel mills in the world, which enable us to ensure material availability for large projects. Our inventory operations are supported by technical and supply chain management capabilities, including logistics setup to enable timely delivery.

We also provide a wide range of services, including:

Profiling

Blasting shot

Cutting, drilling and grooving

Straighten and bend

Painting/primer

Nondestructive testing

The trend of steel products application in Marine

The rapid rise of China's economy has promoted the development of international trade, which in turn has stimulated ship demand. After 2007, it is difficult for global ship orders to usher in new peaks, and it is likely that they will continue to linger during the low tide. For the steel industry, the downturn in the domestic shipbuilding industry means"shelving" for the release of "steel demand", and the procurement growth of steel plates, profiles and other types of steel products used for shipbuilding boards and high-strength shipbuilding boards will inevitably slow down. Demand in the shipbuilding market has changed, and steel companies must be prepared early.

0 notes

Text

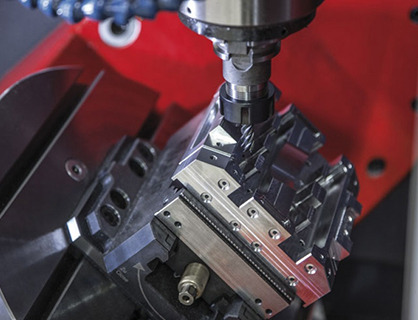

Application of Steel in Mechanical Engineering

https://www.huaro-shanghai.com/machinery.html

Application of steel in mechanical engineering

Tools and machinery cover a wide range of equipment from small workshop tools to machinery and rolling mills in large factories. Tools and machinery accounted for about 15 percent of global steel use in 2017.

In construction, steel provides almost all the equipment used on the construction site, such as cranes, drills, bulldozers, scaffolding, concrete mixers, etc.

In agriculture, even the basic hoes, shovels and forks or modern combine harvesters, irrigation systems and grain storage silos, steel must be used. High-quality steel products make agriculture easier and more efficient. Steel and mechanical equipment are essential from planting and sowing to watering, harvesting, storing and transporting crops.

Steel types for Machinery

Including the construction engineering transportation and infrastructure sector, the manufacturing of machinery is the key to these sectors' development. A big amount of hot rolled steel plate and cold rolled steel sheet and high-quality alloy steel will be used in the key part of various types of machinery. In China, about 22% of steel production belongs to all kinds of machinery needs.

0 notes

Text

Hot Rolled Steel

https://www.huaro-shanghai.com/hot-rolled-steel/

Hot rolled steel is steel that has been roll-pressed at very high temperatures—over 1,700˚F, which is above the re-crystallization temperature for most steels. This makes the steel easier to form, and resulting in products that are easier to work with. As one of the professional hot rolled steel manufacturers, HUARO offers high-quality hot rolled steel for sale, come and buy hot rolled steel at HUARO.

Types of Hot Rolled Steel Sections:

Hot Rolled Steel Coil

Hot Rolled Steel Coil

The production of hot rolled steel coil is the first procedure for the steel slab. After the first mill and finish mill, the thickness will reduce and finally get hot rolled coil.

Hot Rolled Steel Plate

Hot Rolled Steel Plate

Hot rolled steel plate, also known as HRP,can be used in different fields including general manufacturing, structural members, high-rise buildings, bridges, storage tanks and mixers.

Hot Rolled Steel Sheet

Hot Rolled Steel Sheet

The characteristic of hot rolled steel sheet is akin to hot rolled steel coil. Advantages of our hot rolled steel sheet is that the surface finish of the product is not an issue.

Hot Rolled Strip

Hot Rolled Strip

The hot rolled strip is made from plain carbon steel, low alloy steel, stainless steel and silicon steel. It can be applied into raw materials of cold rolled strip, welded pipe, cold-formed and welded steel or for making various components.

Pickled Coils

Pickled Coils

High quality and value-added pickled coils are available! Good surface quality, high dimensional accuracy, fine appearance. The main application includes utomotive industry, the compressor industry, ect.

How to Process Hot Rolled Steel

The continuous casting slab first enters the heating furnace, then passes through the blooming mill for repeated rolling, then enters the finishing mill. In the hot rolling production line, the slab is heated and softened, sent to the rolling mill by the roller table, and finally rolled to the size required by the user. Hot rolling is processed at high temperature. Let the steel recrystallize when the temperature is above 1000 ℃. Make it better. However, hot rolling does not change the structural properties of metals.

Identified Hot Rolled Steel by the Following Characteristics:

A scaled metal surface—remnants of extreme temperatures cooling

Bars and plates have slightly rounded edges and corners (due to shrinkage and lower machining accuracy)

Slightly twisted, cooling may result in a slightly trapezoidal form rather than a completely square Angle

The Advantages of Hot Rolled Steel

Hot rolled steel (HRC) usually requires less processing than cold rolled steel products, which makes it cheaper. In general, the mechanical properties of hot rolled steel are better than that of cold rolled steel. After heat treatment, the tensile strength, yield strength, plasticity and toughness of steel will be improved. In addition, it is important that heat treatment can eliminate residual stress.

For the hot rolled steel products, it can eliminate some defects in casting metal, improve the compactness and mechanical properties of the metal. As a result, the heating plasticity is improved, and the deformation resistance is reduced. Therefore, the deformation amount can be increased and the productivity can be improved during rolling

0 notes

Text

Application of Steel in Energy

https://www.huaro-shanghai.com/energy.html

General description of steel product application in Energy

Energy is vital to development. The international energy agency's global world energy outlook 2016 predicts that global energy demand will grow by 30 percent by 2040, with most of this coming from developing countries. Still, they predict that 500 million people will be without access to electricity by then.

Whether it's based on fossil fuels, nuclear technology or renewable sources like wind, solar or geothermal, steel energy will be vital to providing the world with energy. Regardless of the source, steel plays a vital role in producing and distributing energy and improving energy efficiency.

Steel is used to produce and distribute electricity, include the transformer's electromagnetic steel core, Generator and motor, and Distribution tower and steel cable.

Steel is used for energy transportation and distribution: Ships, trucks, and trains.

Huaro's Hot rolled Steel in Energy application

The most widely used in the Energy sector for hot rolled steel products will be the oil pipeline and natural gas transport pipeline. In recent years, in order to meet the demand, the scale of China's oil and gas pipeline network has been continuously expanded, and the construction and management level of pipelines has been greatly improved. According to the "medium and long-term oil and gas pipeline network planning", by 2020, the national long-distance oil and gas pipeline network will reach 169,000 km; by 2025, the pipeline network will reach 240,000 km, and the country will usher in a new period of pipeline development.

Steel products' trend in Energy application

The scale of the oil and gas pipeline network will continue to expand, and the distribution of the pipeline network will also become reasonable, especially the natural gas pipeline will be the priority of construction. Therefore, the hot rolled steel products, include hot rolled steel sheet, hot rolled steel coil, hot rolled steel plate will be constantly needed in the feature.

0 notes

Text

Application of Steel in Construction

https://www.huaro-shanghai.com/construction.html

Importance of steel in construction

Construction is one of the most important steel-using industries, accounting for more than 50% of world steel production. Buildings - from houses to car-parks to schools and skyscrapers - rely on steel for their strength. Types of steel products are also used on roofs and as cladding for exterior walls.

The steel used in buildings mainly includes bar steel, angle steel, strip steel, etc. With high strength steel grade, widely uses in all types of steel products, commonly in flat, square, round or hexagonal shapes. Steel provides equipment such as cranes, drills, bulldozers, scaffolding and reusable and portable shelters used on construction sites.

Huaro's steel used in construction

The possibilities for using steel in buildings and infrastructure are limitless. The most common application of steel in construction is listed below.

Structural sections: these provide a strong, stiff frame for the building and make up 25% of the steel used in buildings.

Reinforcing bars: these add tensile strength and stiffness to concrete and make up 44% of the steel used in buildings. Steel is used because it binds well to concrete, has a similar thermal expansion coefficient and is strong and relatively cost-effective. Reinforced concrete is also used to provide deep foundations and basements and is currently the world’s primary building material.

Sheet products: 31% is in sheet products such as roofing, purlins, internal walls, ceilings, cladding, and insulating panels for exterior walls.

Non-structural steel: steel is also found in many non-structural applications in buildings, such as heating and cooling equipment and interior ducting.

Internal fixtures and fittings such as rails, shelving, and stairs are also made of steel.

Steel application in construction

More and more new material has applied in the Building Construction sector and infrastructure filed. The construction steel materials will become the composite steel with multiple functions and features to protect from the complex environment condition. Steel products will remain as an important material in the construction business.

0 notes

Text

Cold Rolled Steel

https://www.huaro-shanghai.com/cold-rolled-steel/

Cold rolled steel is the steel produced by cold rolling. Cold rolling is to further thin the steel plate to the target thickness at room temperature. Compared with hot rolled steel plate, cold-rolled steel plate is more accurate in thickness, smooth and beautiful in the surface, and has various superior mechanical properties, especially in processing performance.

Because the original cold rolled coil is brittle and hard, it is not suitable for processing, so usually, the cold rolled steel plate is required to be annealed, pickled and leveled before being handed over to the customer. The maximum thickness of cold rolling is less than 0.1-8.0mm, for example, the thickness of cold rolling steel plate in most factories is less than 4.5mm; the minimum thickness and width are determined according to the equipment capacity and market demand of each factory. As one of the professional cold rolled steel suppliers, HUARO offers high-quality cold rolled steel for sale, come and buy cold rolled steel at HUARO.

Types of Cold Rolled Steel Sections:

Cold Rolled Coil

Cold Rolled Coil

Cold rolled steel coil is made of hot rolled steel coil. The main difference of the hot and cold rolled steel coil is the thickness, surface treatment and the rolling temperature.

Cold Rolled Steel Sheet

Cold Rolled Steel Sheet

The cold rolled sheet are manufactured from the hot rolled sheet. The hot rolled sheet are cleaned chemically and processed further in cold reduction mills.

Cold Rolled Steel Strip

Cold Rolled Steel Strip

Cold rolled steel strip is commonly used in many applications in many industrial fields. We offer high quality and value-added cold rolled steel strip.

Galvanized Steel Coils

Galvanized Steel Coils

Advantages of HUARO galvanized steel coils includes total protection, less maintenance, lowest long term cost, ect. Galvanized steel coil with good raw materials can meet different needs.

Galvanized Steel Sheet

Galvanized Steel Sheet

High-graded galvanized plain sheet are available in sizes and prices, meeting your project requirement. Zinc Coating: Zinc Coating; Thickness: Thickness; Width: 600-1250 mm; Length: custom.

Tinplate Coil

Tinplate Coil

Tinplate coil can be widely used in the canning, can ends, larger containers and a range of closed parts packaging industry. Different grades with great corrosion resistance.

Tinplate Sheet

Tinplate Sheet

Two sides coated with commercially pure tin cold rolled low carbon sheet or steel strip. Corrosion resistance, non-toxic, tasteless, high strength and good ductility.

Prepainted Galvanized Steel Coil

Prepainted Galvanized Steel Coil

Advantages of HUARO prepainted galvanized steel coil includes affordable maintenance, promote durability, ect. Colors can be customized according to RAL color CARDS or customer samples.

What are the benefits of cold rolled steel?

1. The size of cold rolled coil products is accurate and the thickness is uniform.The thickness difference of coil is generally not more than 0.01-0.03mm or smaller, which can fully meet the requirements of high precision tolerance;

2. Cold rolled steel can obtain extremely thin strip which can not be produced by hot rolling (the thinnest can be less than 0.001mm);

3. The surface quality of the cold rolled products is superior.There is no such defects as pockmarks and oxide scale that often appear in the hot rolled coils. According to the requirements of the users, the coils with different surface roughness (gloss surface or rough surface, etc.) can be produced to facilitate the processing of the next process;

4. Good mechanical and technological properties (such as high strength, low yield limit, good deep drawing property, etc.) of rolling distance;

5. Realize high-speed rolling and full continuous rolling with high productivity.

0 notes

Text

Application of Steel in Automotive Industry

https://www.huaro-shanghai.com/automotive.html

Types of steel used in automotive industry

Hot rolled steel products and cold rolled steel products have been the most important material in the automobile industry for the past decades. While meeting increasingly stringent automotive engineering requirements, gm steel products are also cost-effective in terms of cost, longer service life and variability in strength levels. The steel product is also very suitable for correction rework.

According to the international organization of automobile manufacturers, 95.6 million vehicles were produced in 2018.

Each car uses an average of 900 kilograms of hot and cold rolled steel. The use of steel products in the vehicle is as follows:

• 34% for body structure, panels, doors and trunk covers to prevent high intensity and energy absorption during a collision

• the 23% powertrain consists of cast iron for the engine block and machined carbon steel for the wear resistant gears.

• 12% in suspension ,use high strength rolled steel strip.

• the rest is located in the wheels, tires, fuel tanks, steering and braking systems.

HUARO is your best automotive steel suppliers

The automobile manufacturing industry mainly uses the cold rolled coil for the automobile structure production. Cold rolled steel plates with a thickness of 0.5 to 1.5mm are mainly used for vehicle bodies. Soft non-alloy materials were preferred earlier because of their high formability and design freedom. Cold rolled steel coil is the core material of the automobile industry. Mainly used for the shell and structure of vehicles. Huaro's high quality cold and hot rolled coil steel can be adapted to various types of steel specifications, such as jis 3112-90 DIN 17102-83. In addition to deep drawing and drawing molding, the suitability of welding, joining and painting is also an important criterion for processing. Higher strength steel products can also meet these requirements.

Automotive steel products trend

With the advancement in technologies of production newer alloys of aluminium and magnesium are also being used more. Plastics and composite with their lightweight and recyclable properties are also liked by the automotive companies.

0 notes

Text

Common Uses of Steel

https://www.huaro-shanghai.com/application/

Automotive

AUTOMOTIVE

The automobile manufacturing mainly uses cold rolled coils for vehicle structure production. It’s a core material for the automotive industry. Mainly used for the vehicle shell and structure.

Construction

CONSTRUCTION

The construction steel mainly includes bars steel angle steel strip steel etc. With high strength steel grade, widely uses in all types of finished steel products.

Marine

MARINE

Steel plate products are one of the most commonly used in the marine industry. It is produced by rolls with smooth surfaces and ranges of dimensions, varying in thickness.

Energy

ENERGY

General description of steel product application in energy. Energy is vital to development.

Household Appliances

HOUSEHOLD APPLIANCES

Cold rolled coil is the main material of the household electronic shell and inner structure. Such as refrigerator, wash machine, air conditioner, oven, and office appliances.

Machinery

MACHINERY

Tools and machinery cover a wide range of equipment from small workshop tools to large factory-based robotic machinery and rolling mills. Low-carbon steel can be easily machined.

0 notes

Text

Hot Rolled Steel Plate

Main feature of hot rolled product

Hot steel coils production is a rolling procedure that relates rolling steel at a high temperature (usually above 1700°F) and over the recrystallization temperature of steel. When the steel heating temperature is higher than the recrystallization temperature, it can be formed and shaped easily, and the steel can be made to larger sizes. Hot rolled steel is usually cheaper than cold rolled steel because of the fact that it is usually manufactured without any delays and then does not require reheating of the steel (as with cold rolling). As steel cools, it contracts slightly compared to cold rolling, so there is less control over the size and shape of the finished product. Hot Rolled Steel Plate is a piece of flattened hot rolled steel that is thicker than 1/4 inch (0.250mm). It has many applications in the manufacturing, industrial and construction industries where it is used structurally (not aesthetically). It is measured by its thickness in inches.

HRP production procedure

The hot rolled steel plate as known as HRP. This main produce semi-finished material is steel slab with certain thickness and width. The slabs are heated in a natural gas fired furnace before processing it through a hot rolling mill. This process reduces the thickness of the standard figures.

Specific Uses and Applications of Hot Rolled Steel Plate

Typical uses of hot rolled Steel Plate involve general fabrication, structural members, high-rise buildings, bridges, storage tanks, and mixers

Our Steel Plate is ideal for the following applications:

General structural articles

Sports stadiums

Buildings and skyscrapers

Bridges and other foundations

Reinforcing requirements

Various heavy machinery, earthmovers and bulldozers

https://www.huaro-shanghai.com/products/hot-rolled-steel-plate.html

0 notes

Text

Hot Rolled Steel Coil

Description of Hot Rolled Steel Coil

Hot rolling is a mill process that involves rolling the steel at a high temperature (typically at a temperature over 1700° F), which is above the steel’s recrystallization temperature. When steel is above the recrystallization temperature, it can be shaped and formed easily, and the steel can be made in much larger sizes.

As we all know, the steel slab is made from the continuous casting machine after the steel pellets melted in the EAF furnace and the removal of the impurities. The production of hot rolled steel coil is the first procedure for the steel slab. After the first mill and finish mill, the thickness will reduce and finally get hot rolled coil.

HRC main feature and production procedure

Hot steel coils production is a rolling process that involves rolling steel at high temperatures (usually above 1700°F) above the recrystallization temperature of steel. When the steel is higher than the recrystallization temperature, it can be formed and shaped easily, and the steel can be made to larger sizes. Hot rolled steel is usually cheaper than cold rolled steel because of the fact that it is usually manufactured without any delays and then does not require reheating of the steel (as with cold rolling). As steel cools, it contracts slightly compared to cold rolling, so there is less control over the size and shape of the finished product.

The Advantage of Hot Rolled Steel Coil

The hot rolled coil as known as HRC. The slabs are heated in a natural gas fired furnace before processing it through a hot rolling mill. This process reduces the thickness. Once it is cooled, the plate is cut into desired length and the coil is further processed through the cold rolling mills. Huaro Steel offers a range of Hot Rolled Coils with diverse specifications. All our products meet international standards. They fulfil a wide range of market needs like deep drawing, bending, laser cutting, welding and forming. We offer the Hot Rolled Coils in the form of coils and cut to long sheets.

Application of Hot Rolled Steel Coil

Commercial steel like steel commercial tubes, general fabrications, steel sheets, and corrugated steel.

Structural steel for the electrical industry.

For sour and non-sour applications in oil and gas pipelines as well as water pipelines.

Gas cylinders and presser vessel tanks.

Carton steel can be used for atmosphere corrosion applications like open steel containers.

The Chequered form of Hot Rolled Coils can be used for Anti-slip applications like floors.

https://www.huaro-shanghai.com/products/hot-rolled-steel-coil.html

0 notes

Text

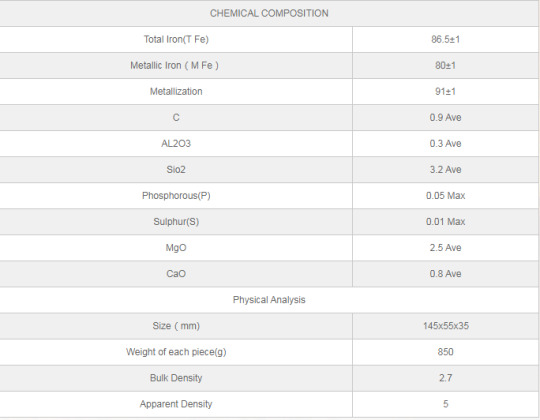

Hot Briquetted Iron (HBI Iron)

Definition of HBI

Hot Briquetted Iron (HBI) is a premium form of Direct Reduced Iron (DRI).As a supplement for pig iron and scrap in electric furnace steel mills. It is a compacted form of direct reduced iron (DRI), which facilitates its handling, storage, and use.Direct Reduced Iron (DRI) has been compacted at a temperature greater than 650° C at time of compaction and has a density greater than 5,000 kilograms per cubic metre (5,000 kg/m3).

Typical Specifications of HBI

The advantage of Hot Briquetted Iron (HBI)

HBI is a much safer form of DRI than DRI pellets. It is far more resistant to overheating if it becomes wet. HBI was developed as a product in order to overcome the problems associated with shipping and handling of DRI - due to the process of compaction it is very much less porous and therefore very much less reactive than DRI and does not suffer from the risk of self-heating associated with DRI.

The principal market for HBI is electric arc furnace (EAF) steel-making, but HBI also finds application as a trim coolant in basic oxygen furnace (BOF) steel-making and as blast furnace feedstock.

https://www.huaro-shanghai.com/products/hot-briquetted-iron-hbi-iron.html

0 notes

Text

Galvanized Steel Sheet

Description of Galvanized Steel Sheet

Hot dipped galvanized steel sheet is a carbon steel sheet coated with zinc on both sides through continuous hot dip process. When the heated steel strip is in contact with the molten zinc, the coating is firmly adhered to the steel by the iron-zinc alloy adhesive layer formed by the diffusion process. One of the disadvantages of galvanizing is that if the zinc coating is scraped off the steel, the steel will lose its protection and may fail.

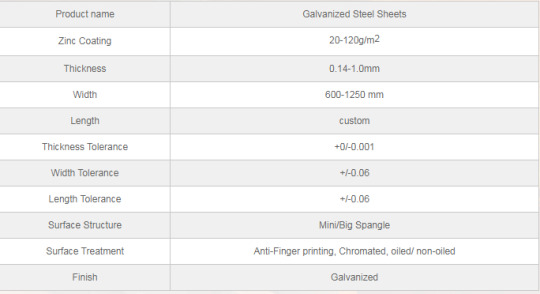

Specification of Galvanized Steel Sheets

Surface Finish of Galvanized Steel Sheet

Galvanized steel coils production process:

1. Uncoiler

2. Welder

3. Entry Looper

4. Pre-treatment

5. Annealing Furnace

6. Zinc Pot

7. Cooling Tower

8. Water Quench Tank

9. Skin Pass

10. Tension Leveler

11. Passivation Coater

12. Exit Looper

13. Recoiler

Quality Control of Galvanized Steel Sheet

Use bending machine, pencil hardness tester, gloss meter, meteorological tools, row lattice unit, micrometer tools, thickness gauge to control the quality of galvanized steel coil.

https://www.huaro-shanghai.com/products/galvanized-steel-sheet.html

0 notes

Text

Galvanized Steel Coils

Description of Galvanized Steel Coils

Hot-dip galvanized steel coils are produced by passing the acid-washed and calendered full hard plate through the zinc tank, thereby galvanizing the film on the surface. Galvanized steel coil with good raw materials and 7 times the cold rolling machine, can meet the general purpose of drawing cutting and clamping processing. Zinc has excellent corrosion resistance, coating and processability due to its properties.

Production procedure of Galvanized Steel Coils

Hot dip galvanization is the process of coating steel or iron with a protective zinc coating to prevent rust. This treatment is the highest zinc coating standard according to ISO and EN JIS ASTM applications. The following are the core functions and detailed steps in production. All products will be provided with factory technical data analysis sheet and quality assurance.

Eexcellent corrosion resistance, paintability and processability due to zinc's self-sacrificing properties.

can be used to select and produce the required amount of zinc-zinc, in particular to thicken the zinc-layer (maximum 120g/m2).

classified as zero sparkles or super smooth according to whether the sheet has been polished or not.

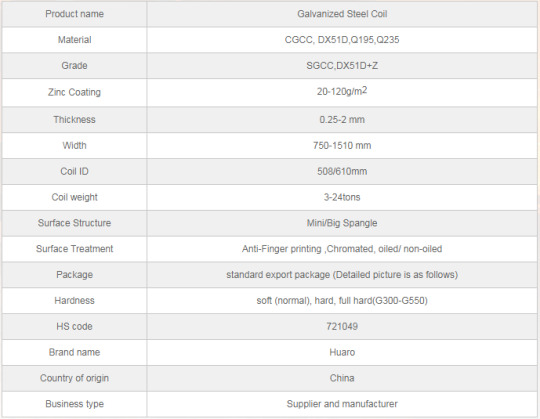

Specification of Galvanized Steel Coils

Advantages of Galvanized Steel Coils

Total Protection – With hot dip galvanizing for preventing rusting and corrosion.

Less Maintenance – ensures never shrink or crack, bonded to the steel it protects. It also offers superior resistance to abrasion and water.

Lowest First Cost – Hot dip galvanizing is lower in first cost than protective coatings for steel.

Lowest Long Term Cost – invariably more cost effective in the long term because it lasts longer and needs less maintenance.

Reliability – Coating life and performance are reliable and predictable.

Long Life – With hot dip galvanizing, the Complete galvanized on all the surfaces, Zinc Coating will be uniform and adherent at all places.

Complete Protection – Zinc coating from hot dip galvanizing process is reasonably smooth and free, provide for the complete protection of the underlying cold rolled steel.

https://www.huaro-shanghai.com/products/galvanized-steel-coils.html

0 notes

Text

Direct Reduced Iron (DRI Steel)

Description of Direct Reduced Iron (DRI Steel)

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suitable for direct reduction.

Direct reduction refers to solid-state processes that reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron derives its name from these processes, one example being heating iron ore in a furnace at a high temperature of 800 to 1,200 °C in the presence of the reducing gas syngas, a mixture of hydrogen and carbon monoxide.DRI is produced through the removal (reduction) of oxygen from iron ore in its solid state. This technology encompasses various processes based on different feedstocks, reactors, and reducing agents. DRI processes can reduce CO2 emissions by using natural gas instead of coal due to the replacement of carbon reductant by hydrogen from the methane.

Basic characteristics of Direct reduced iron (DRI)

1. Stable chemical composition can effectively dilute the residuals and metal elements in steel thus improve the steel quality.

2. Low content of harmful elements, such as P and s and it can shorten refining time.

3. Reduce the loading times, power cut operation and heat loss. Fast melting speed and low power consumption can improve efficiency and reduce cost.

4. During the melting period, with a stable electricity supply, high power supply is allowed.

5. Low cost and high economic benefit.

Direct Reduced Iron Process

Indirect reduction plant, the oxide pellets produces in the pelletizing plant enters the reduction plant from the top into the furnace after it has had its chemical and physical properties checked, and loses its oxygen to the reducing gas which flows upwards from the bottom of the module.H2 and CO and H2O is the initial mixture of the reducing gas with the radio of 1.5 to 1.7. This mixture absorbs the oxygen content of the pellets and changes into CO2 and H2O and gets out of the furnace from the top.

https://www.huaro-shanghai.com/products/direct-reduced-iron-dri-steel.html

0 notes

Text

Copper Cathode

Description of Copper Cathode

Copper is one of the basic chemical elements. In its nearly pure state, copper is a reddish-orange metal known for its high thermal and electrical conductivity. It is commonly used to produce a wide variety of products, including electrical wire, cooking pots and pans, pipes and tubes, automobile radiators, and many others. Copper is also used as a pigment and preservative for paper, paint, textiles, and wood. It is combined with zinc to produce brass and with tin to produce bronze.

The content of copper in the crust is about 0.01%, and in some copper deposits it can reach 3% - 5%. Copper in nature mainly exists in the form of compounds, namely copper minerals, which are mainly distributed in North America, Latin America and Central Africa. In terms of national distribution, the world's copper resources are mainly concentrated in Chile, the United States, Zambia, the Commonwealth of Independent States and Peru.

The Definition of Copper Cathodes

The thick plate made of crude copper (including 99%) is used as anode, the thin plate made of pure copper is used as cathode, and the mixture of sulfuric acid and copper sulfate is used as electrolyte. After being electrified, copper dissolves into copper ions (Cu) from the anode and moves to the cathode, where electrons are obtained and pure copper is precipitated. Impurities such as iron and zinc, which are more active than copper, will dissolve into ions (Zn and Fe) with copper. Because these ions are not easy to precipitate compared with copper ions, they can be avoided to precipitate on the cathode as long as the potential difference is adjusted properly. Impurities such as gold and silver, which are less active than copper, are deposited at the bottom of the cell The copper plate produced in this way, called "Copper Cathodes", is of high quality and can be used to make electrical products.

Application of Copper Cathodes

Copper cathode is an non-ferrous metal which is closely related to human beings.Its widely used in electric, light industry, machinery manufacturing, construction, national defense industry and other fields.

Copper cathode is widely used in electronic industry, accounting for more than half of the total consumption. It is used for winding various cables, wires, motors, transformers, switches, printed circuit boards and other machinery and field.

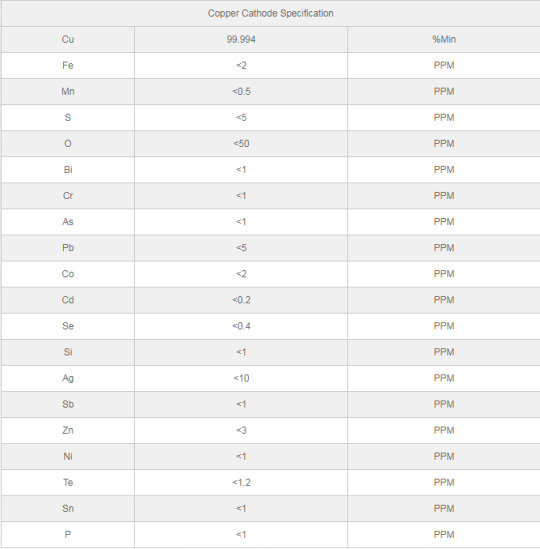

Chemical composition for HUARO Copper Cathode

https://www.huaro-shanghai.com/products/copper-cathode.html

0 notes

Text

Cold Rolled Steel Strip

Description of Cold Rolled Steel Strip

Strip steel has more stringent thickness tolerances than cold-rolled steel. Before rolling, hot rolled strip steel is pickled to remove surface impurities and ensure a clean, even finish. The strip does not shrink or creep at ambient temperature. It is a uniform lightweight steel that is easy to manufacture, transport and install. Although there are many tempering options, determining the right tempering for your project depends on your formability requirements.

Main feature and production procedure of Cold Rolled Steel Strip

The rolling of the cold-rolled strip begins with the removal of the hot-rolled strip from the storage area, where the coil is usually set up and retrieved according to the rolling schedule by a fully automatic crane. The coil is first descaled in a continuous pickling line. The cleaned and oiled coil is fed to a cold mill, which is usually a four - to six-stand tandem mill with an opening reel at the entrance and a coiler at the exit. For example, when rolling from 2mm to 0.3mm, the first stand's cold roll rate is typically 35% and the final stand's cold roll rate is 15%. Due to the fact that strip temperatures can be as high as 200°C (390°F), proper cooling of strip and roll is essential. Heavy duty lubricants are also used to minimize friction in the roll gap.

Applications of Cold Rolled Steel Strip

Cold rolled steel strip is usually shortened to steel strip or cold rolled strip. It is a metal product and is commonly used in many applications in many industrial fields. Cold-rolled strip steel is a popular metal product in the automobile industry, which is pressed into body panels and other auto parts. You will find strip steel for refrigerators, washing machines and dryers. The unique properties of strip steel also make it a popular building materials.

https://www.huaro-shanghai.com/products/cold-rolled-steel-strip.html

0 notes

Text

Cold Rolled Steel Sheet

Description of Cold Rolled Steel Sheet

The cold rolled sheet are manufactured from the hot rolled sheet. The hot rolled sheet are cleaned chemically and processed further in cold reduction mills, where the material is cooled (at room temperature) followed by annealing and/or tempers rolling. This process will produce steel with closer dimensional tolerances and a wider range of surface finishes. Cold rolling increases strength, enhances the surface finish and offers uniform thickness. To prevent the cold rolled coils from rust, they are usually coated with thin layer of oil. Further coating of Zinc-Aluminium alloy or galvanization on the metal can be processed. Huaro Steel offers cold rolled coils in a range of international standard grades.

Production Procedure of Cold rolled steel sheet

The cold rolled sheet as known as CRS. The CRS is made of hot rolled steel products. The cold rolling process helps to obtain the Cold Rolled Steel Sheet from the cooling (in the cold rolling mill) of hot rolled pickled products (made from finest steel), that are reduced to much finer thickness with increased strength via strain hardening (up to almost 20%). The resulting Cold Rolled Steel Sheets are smaller as compared to the sheets formed by the hot rolling process, and they are less ductile. They possess improved surface finish and tighter tolerances.

Applications of Cold Rolled Steel Sheet

Tube making

Shelving

Automotive parts

Containers and drums

White goods and furniture

Flooring systems

Precision tubes

Packaging Industry

Steel grade available of Cold Rolled Steel Sheet

ASTM (USA) : A 1008: DS type A & B, DDS, EDDS, EDDS+

DIN (GERMANY) : DIN 17100: ST 37.3, ST 44.2, ST 44.3, ST 52.3

EN (EUROPE) : EN 10268: HSLA 340, HSLA 420,EN 10130: DC 01, 03, 04, 05/06

JIS (JAPAN) : G 3141: SPCD, SPCE, SPEN, SPRC 340/ 390,SPFC 340/ 390/ 440

https://www.huaro-shanghai.com/products/cold-rolled-steel-sheet.html

0 notes