Text

Learn More About Vibro Sifter

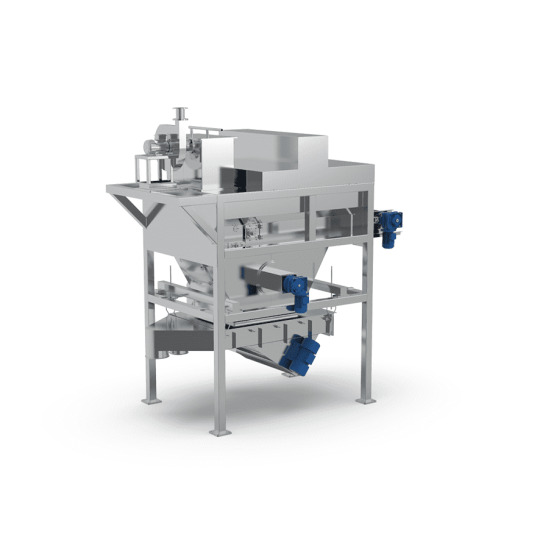

Separating, grading, and scalping materials can be time-consuming and labor-intensive with traditional methods. This is where a vibro sifter comes in, offering automation for these tasks. Specifically designed for various industries such as chemical, pharmaceutical, and food processing, this equipment uses an automated vibrational sifting system. It efficiently sorts, grades, and scales ingredients or materials, relying on an advanced vibrational mechanism for the process.

Why vibro sifters are essential in pharmaceuticals and food industries

Vibro sifters are indispensable tools in the production of pharmaceutical and food products. Operating on the principle of gyratory motion, these sifters place the mixture in the center of a screen. The mixture then travels down a spiral path to the periphery while being sifted. This action separates the screened material into finer particles. A significant advantage of using a vibro sifter is that it maintains the quality and integrity of the ingredients by sieving them with minimal abrasion. Moreover, this equipment is versatile enough for both moist and dry granulation applications.

Versatile applications of a vibro sifter

Apart from sifting, vibro sifters are also valuable for several other functions:

Scalping: Vibro sifters efficiently remove unwanted foreign objects and lumps, producing a finer end product.

Grading, scoring, or screening: This machine makes it easier to differentiate ingredients or materials based on their sizes.

Proof sifting: In pharmaceutical applications, proof sifting serves as a quality assurance step, ensuring drug consistency.

Features of a high-quality vibro sifter

Some vibro sifters stand out for their advanced technology, longevity, easy maintenance, and reliable features. Characteristics of a top-notch vibro sifter include:

Single and double-deck configurations

cGMP-compliant and hygienic design

Central and side discharge screen options

Oversized outlets for larger, rejected particles

Vacuum screening capabilities

Centralized discharge screen, either supported or suspended

Various anti-binding devices such as ultrasonic, electromagnetic, mechanical, or rotary blades

Explosion-resistant builds conforming to ATEX standards

Automation options to integrate with downstream and upstream processes

Tailoring to your manufacturing needs

Renowned manufacturers offer vibro sifters in various capacities, ensuring that companies can select the equipment best suited to their specific needs. Customizable features such as mesh size and overall capacity make these sifters even more versatile.

In need of a vibro sifter? Consider the innovative solutions from Cybernetik, a leader in automation and material processing. Contact us at Cybernetik.com for a personalized quote.

About the author:

Cybernetik is a leading global automation solutions provider based in India. With over 25 years of experience, the company offers innovative automation solutions for various industries, including food, pharmaceuticals, chemicals, automotive, and more. Their services include process design, equipment supply, integration, and after-sales support. They specialize in delivering customized solutions to meet clients' specific requirements, resulting in higher efficiency, improved product quality, and reduced costs. Cybernetik's expertise in advanced technologies such as robotics, artificial intelligence, and machine vision enables them to provide cutting-edge automation solutions to clients worldwide.

0 notes

Text

Trending Now: Automation and Robotics in 2023

In today's hypercompetitive market, leaders face the challenge of maximising results with finite investment resources. Balancing economic unpredictability, workforce concerns, and the rapidly evolving landscape of automation and AI has complicated their decision-making processes. Could robotic automation be the solution? Let’s look at the current landscape of robotics and automation for answers.

Changing definitions

Since the inauguration of the first industrial robot in 1961, robots have been primarily recognised as devices for material handling or tool manipulation. But today's definition of robotics has broadened to include physical and business process automation. Autonomous mobile robots (AMRs) have joined the family of four, five, and six-axis machines prevalent in factories worldwide. These AMRs navigate warehouses and distribution centres, transporting materials and kits between storage, kitting, and packing areas.

Robotics and automation are presently at the forefront of Industry 4.0. Intelligent sensors, communication technologies, analytics tools, machine learning, and artificial intelligence are facilitating data-driven decision-making. Simultaneously, the European Union is promoting the concept of Industry 5.0—a vision of interconnected smart manufacturing that prioritises humans over machinery.

Progress in artificial intelligence and machine learning

AI and ML have an expanding roster of applications in robotics and automation. They aid in optimising route planning, decision support, safety enhancement, material yield optimisation, and factory efficiency enhancement.

Developments in smart manufacturing

Research group Forrester suggests manufacturers adopt an "Automation Triangle," blending the abilities of hardware and software automation with the adaptability, creativity, and resilience of human workers.

In this model, hardware automation handles repetitive tasks while software automation undertakes repetitive data processing and analytical functions. This strategy liberates human workers to oversee automation and address issues such as sustainability.

This approach provides numerous benefits for human workers. By being relieved from unpredictable manufacturing tasks, they experience reduced stress and uncertainty while having more opportunities to use their creative skills and exert greater autonomy over their work. For employers, this translates to a more motivated and engaged workforce.

The way forward

While robotics and automation technology are drivers of growth, manufacturers must be prepared to adapt to a rapidly evolving environment.

If you need a partner to deliver stunning, ergonomic, and fully integrated robotics and automation solutions from inception to implementation, consider Cybernetik. Beyond robotic automation, Cybernetik also delivers process automation, designed to enhance the beauty of engineering from an aesthetic, productivity, safety, ergonomics, and efficiency standpoint. Schedule a consultation to start.

About the author:

Cybernetik is a leading global automation solution provider based in India. With over 25 years of experience, the company offers innovative automation solutions for various industries, including food, pharmaceuticals, chemicals, automotive, and more. Their services include process design, equipment supply, integration, and after-sales support. They specialise in delivering customised solutions to meet clients' specific requirements, resulting in higher efficiency, improved product quality, and reduced costs. Cybernetik's expertise in advanced technologies such as robotics, artificial intelligence, and machine vision enables them to provide cutting-edge automation solutions to clients worldwide.

0 notes

Text

Why Is Robotics and Automation Considered a Revolution in 2022?

Technology has become a vital part of our lives in the modern age, and each year it seems as if something new is being discovered or perfected. It could be anything from the latest smartphones to decentralised digital currencies. Robotics and automation are the two main technologies revolutionising the manufacturing industry.

The importance of robotic automation - How it can change the manufacturing industry

Industrial robotics and automation involve using computers and control systems to control and manage industrial processes and machinery. These technologies are used everywhere, from food processing facilities to chemical and extraction plants.

But why are they considered revolutionary? Overall, robotic automation is valuable for businesses because they offer the following benefits:

· Improved productivity

Robots and computers can work 24 hours a day, seven days a week, with little to no downtime. All it takes is some code, and you can program your equipment to perform precise and repetitive tasks.

As a result, these technologies help boost your overall productivity and efficiency, allowing human workers to focus on higher-value tasks that require expertise and can’t be automated.

· Enhanced workplace safety

Tasks that require repetitive movements, such as lifting heavy weights or handling sharp objects, can lead to costly, irreversible injuries. Dealing with the medical and legal aspects of such injuries usually costs hours and hours of time. Not to mention, some workplaces constantly expose human labourers to hazardous materials, such as chemicals, fire, and lasers.

Investing in robotics and automation is investing in the health and well-being of your employees. This is because, unlike humans, machines are made to withstand large amounts of stress or handle toxic chemicals without breaking.

· Increased savings

Fewer injuries and better productivity lead to more cost savings. Consider an automatic bagging machine, for example. This machine can perform automatic bagging at a rate of 6,000 kilograms per hour, allowing your organisation to produce more products in less time.

In fact, according to experts, industrial robots can reduce total manufacturing costs by up to 60%. Moreover, these technologies are becoming more affordable as more innovations are made.

Robotics and automation processes can also help reduce material waste thanks to their precision.

The future of your manufacturing organisation begins with robotic automation. If you’re looking for a solution that is tailored to your needs and industry, consider working with an experienced and knowledgeable industrial automation company.

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years of experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes

Text

Advantages of Automation in the Food Industry

Many industries are already using automated technology to help their daily business operations. However, the food industry appears far behind as some businesses still prefer traditional and manual processes for reasons of hygiene and safety. However, the latest automation technologies are now available to discerning food businesses that are considering digital transformation to usher traceability into their supply chain, reduce labour costs, and ensure the safety of their workers and customers.

Do you own a food business?

There are many ways robotics and automation can benefit your business, especially when you need more reliable and secure ways to improve operations, save money, and stay competitive. Turning to specialised hardware, software, and technologies can help you overcome the challenges.

Automation can assist with quality control, scalability, and efficiency – all with a view to help achieve better results with minimal human labour. Automated systems from robotics automation companies in Pune can overcome the human errors and inconsistencies that cause issues for your food business. Here are more advantages you can expect from the latest automation technologies:

Improve traceability

Combining automation with analytics can enhance the traceability of food and raw materials from the field to order fulfilment. The process simplifies tracking ingredients and production without or with minimal manual input, so you can increase transparency throughout your production, supply, and delivery chains.

Standardize quality control

Food businesses involve many stages involving movement and transport, but robotics and automation ensure everything is working in harmony. Distribution, supply, and production processes have several different touchpoints that require sufficient quality control. A serious mishap, like contaminated food, could negatively impact the business and its reputation. High-quality automation systems and food processing equipment make it easier to identify issues at earlier stages to prevent costly problems later.

Increased efficiency

Well-developed and correctly deployed automation systems can help the food business perform better. They help save time and reduce operational costs by improving food and product quality, and limiting waste.

Better workplace safety

The latest automation technologies may not completely replace skilled workers and safety training but can enhance workplace safety. Robotics automation companies in Pune offer solutions for performing, controlling, and monitoring risky tasks to limit the worker’s exposure to potential injury and health hazards.

Investing in the latest robotics and automation solutions could protect brands in the food industry. Consider working with a solutions provider that can combine components and provide integrated solutions backed by reliable after-sales support to get the most from automation in your business.

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years of experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes

Text

News Feed of Cybernetik Technologies

Cybernetik Technologies is a leading Indian industrial automation & robotics manufacturing company. They offer innovative designs, and easy to install customized automation solutions for all types of industries. For more details visit their website today!

https://www.cybernetik.com/feed/

0 notes

Text

What Is the Use of Sifters in the Pharma Industry?

Are you looking for a compact and efficient solution when dealing with pharmaceutical-grade materials? Sifter machines for pharmaceuticals are widely used in the industry, both for educational and industrial purposes. But what exactly do these systems do?

The importance of sifter machines for pharmaceuticals

First, to understand the significance of sifters in pharma, it’s important to learn about how these structures work. The Vibro sifter is a vibrational sifting system that is designed for the following applications:

· Sifting

· Scalping

· Proof sifting

· Screening or grading

Vibro sifters can have one or two decks, depending on your needs. A single deck is designed for scalping or sifting materials, while multiple decks allow for classification according to particle size.

The machine has four essential components. Here is a quick overview of how each works:

· High-quality springs

The springs in a Vibro sifter machine are designed to allow its upper section to vibrate freely. Moreover, it acts as a damper, preventing the transmission of vibration to the floor and minimizing power consumption.

· Vibratory electric motor

This is the main motor that causes a sifter’s multiplane vibratory motion.

· Screen structures

These structures are where the sieves are fitted for separating materials according to their size and shape. The screens are held in tension; however, you can adjust their motion depending on the type of material and your performance requirements.

· Casing and hopper lid

The casing is a stainless steel structure that confines your product into the desired shape. Meanwhile, the hopper lid protects the material from the environment, keeping it away from dust and other contaminants.

Put all of these components together, and you’ll have a process that works like this:

· The material is fed through the hopper and covered securely.

· The machine is powered on, and the vibrating motor starts, causing a vibratory motion due to an unbalanced weight assembly.

· The screen will begin to vibrate, allowing the material to travel across sieves depending on their particle size.

· The material exits the machine through the discharge system.

If you are looking for a sifter for active pharmaceutical ingredients (APIs), consider quality as your number one priority. First-class sifter machines for pharmaceuticals boast the advanced capabilities, such as vacuum screening, explosion and flame resistance, anti-binding devices, and several automation options for upstream and downstream processes.

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes

Text

Types, Advantages, and Managing Tips for Storage Silos

A wide range of industries need storage silos for the safekeeping of materials – raw, semi processed, and completely processed. But different silos have different applications, catering to a specific material or two. So how do you know which is best for you? Here are all the basics you need to know about storage silos.

Types of silos and their advantages:

· Tower silos

Tower silos are the most common type of silo, known for their cylindrical structures. They are typically around 10 to 90 meters in height, made of wood staves, concrete, and steel panels.

These silos are best for packing substances due to their size and weight. In addition, they require less area for construction because they are longer vertically rather than horizontally.

· Bunker silos

As their name suggests, bunker silos are trenches built with concrete walls. They are traditionally seen on the farm, filled and packed with tractors and loaders. However, these silos must be covered with plastic tarps to prevent air from escaping.

The greatest advantage of bunker silos is their capacity. They can hold tons of material without sacrificing unloading rates, which is ideal for large-scale operations. Moreover, they are relatively inexpensive to maintain.

· Silo bags

Silo bags are long plastic tubes that range from 2.4 to 3.6 m in diameter. They are made to be packed and sealed on both ends after filling, offering a flexible storage system for feeds and grain.

These silos are some of the more affordable options on the market, requiring a lower capital investment than tower or bunker silos. Additionally, they are excellent for inventory management and help lower storage losses.

How to manage your storage silos?

Silos are designed for the storage of different materials, such as barley, sugar, tobacco, beans, and chemicals, among other things. You may need additional equipment and accessories to manage these substances, depending on their properties—pressure relief valves, air vents, and high/low-level sensors are just a few examples. Moreover, you must consider your loading options, which can be through a vacuum device, screw conveyor, or manual loading.

Are you looking for a storage silo solution tailored to your needs? Make sure to work with a trusted industrial automation company offering top-of-the-line storage systems for a wide range of applications!

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years of experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes

Text

The Workings of Cell Phone Controlled Pick and Place Robots

Nearly 70% of workers agree that automation can help improve efficiency and reduce the time spent on repetitive work. Pick and place robots are an excellent example of automation technology, helping the food processing and packaging industries increase productivity and meet growing demands.

How do pick and place robots work?

As their name suggests, these robots perform simple tasks such as lifting and moving objects from one location to another. They are built with the following parts:

· Sensors

Sensors are the “eyes” of the robot. They are necessary to identify the type of object on a surface and its position.

· Controllers

Controllers are the “brain,” synchronizing and controlling the movement of the robot’s different parts. They can come in the form of a mobile phone application or a computer software program.

· Robot arm tool

The robot arm is in charge of translating the controls into movement. Its design is similar to a human arm, with links, joints, and cylindrical parts.

· End effector

The accessory at the end of a robotic arm is called the end effector. It is designed to perform specific tasks, such as gripping and lifting objects.

· Actuator

The actuator creates motion in the robotic arm and end effectors. They can be made with various motors, including servo motors, stepper motors, or hydraulic cylinders.

The advantages of using cell phone-controlled pick and place robots:

· Improved productivity

Overall, pick and place robots are meant to streamline your factory operations. They can lift small to large objects much more effortlessly than a human worker, significantly increasing productivity.

Moreover, robots can work 24 hours a day, seven days a week. This reduces the number of interruptions in your assembly line due to breaks. As a result, you can produce more products in less time.

· Better consistency

Human error is responsible for 70% to 100% of incidents in an organization. A robotic arm can drastically reduce this issue, improving your operations' consistency.

Cell phone-controlled pick and place robots can also help increase safety in the workplace and offer a significant return on investment. Moreover, they have numerous applications, from food packaging to capacitor assembly.

To guarantee consistent operation and improved productivity, work with a leading industrial automation solutions provider offering advanced technologies and systems.

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years of experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes

Text

Why use automation for chocolate manufacturing?

Chocolate is undoubtedly one of the favorite sweets and desserts loved by people of all ages across the globe. There are numerous brands in the industry that manufacture chocolate. The chocolate manufacturing process needs to follow various steps; thus, advanced machinery is necessary. Automation emerged as a necessity to simplify the process of chocolate manufacturing without compromising on quality.

Benefits of using automation in chocolate manufacturing:

The chocolate manufacturing process needs to undergo several stages. These processes are-

Roasting cocoa beans and sterilizing them to eliminate bacteria.

Delinking the outer shell of the cocoa beans.

Grinding and separation.

Blending is the step wherein the manufacturers add coca butter to press the cake.

Conching, tempering, molding, etc.

Wrapping is the final sub process which is necessary to protect the chocolates from contamination.

The above chocolate processing methods are best executed using advanced technologies. As a result, automation systems are used in the chocolate making industry. Manufacturers use different automated chocolate-making machines to harness the following advantages.

The prime reason to use an automated machine for chocolate preparation is to simplify the operation. These machines can take on a huge workload and manufacture chocolates without consuming much time. And while minimizing the production time, automation ensures compliance with food safety and industrial safety norms as well as with quality guidelines.

Automated machines help enhance the efficiency of chocolate manufacturing. Automated machines properly mix all ingredients and lower the wastage rate.

Using advanced chocolate machinery seems to be the best way to improve production accuracy. In addition, this automated machinery will maintain consistency while producing chocolates.

Chocolate wrapping is one of the essential methods to keep the chocolate free from contamination. Advanced machinery helps in different ways of wrapping chocolates. Machinery used in wrapping chocolates is tampering machines, chocolate pumps, nut feeders, feeder mixers, auto chocolate depositors, granule mixers & juicers, etc.

Automation for chocolate manufacturing helps in enhancing the production output. This machinery aids in producing more chocolates in less time.

Above, we have mentioned why to consider using automation for chocolate manufacturing. Automation is now a must to ensure quality production in large volumes.

0 notes

Text

Why Is the Robotic Sector Growing in Pune?

Robotics has extensive applications, present and potential, in industries worldwide due to its high efficiency and precision. In fact, automation is indispensable in some sectors. This is because robots perform with more speed and accuracy, thereby protecting humans from encountering hazardous working conditions.

In the recent past, robotics companies in Pune have chosen to increasingly use robotic automation. As a result, more and more industries shift to automated technologies to increase productivity and quality production.

Which Industries Use Robotics Extensively?

Following is a list of industries that need robotics for their production operations. Due to the vast spectrum of application of robots, robotics companies in Pune have increased the utilization of robots.

· Food and Beverage – Robots create minimal chances of contamination in this industry.

· Packaging – Robots can consistently perform repetitive operations such as handling, palletizing, picking, etc. without fatigue or loss of concentration.

· Automobile – Welding, painting, assembly and other operations on automotive parts is possible without human technicians.

What Is the Need for Robotics in Various Sectors?

Robotics has become almost mandatory in most sectors. Many robotics companies in Pune are therefore deploying more and more robots to eventually meet the industrial demands. However, the key reasons why industries require robotics go much beyond replacing human employees.

· Maintaining Safety – Robots can perform tasks under extremes of heat and temperature. Also, they can easily deal with hazardous substances that could be highly dangerous for humans.

· Consistent Performance – Robots do not need rest or breaks between their working schedules. In contrast, humans must rest to increase or even maintain their efficacy levels. Thus, robots can work round the clock with the same precision, automatically enhancing productivity.

· High Accuracy –Robotics companies in Pune are also growing due to the high precision of automated robots. The entire system is computerized and, once programmed correctly, causes minimum or even zero errors during operations.

· Utilization of Floor Space – One of the foremost reasons for utilizing robotics in various sectors is to leverage the workstation’s floor space. Robots have flexible space requirements. Also, they can work atop conveyor belts, increasing the utilization of available space.

Closing Thoughts

Industries require robotics to increase their production and efficiency. In today’s times, robotics companies in Pune are growing at an impressive rate because industries are demanding more and more robotic automation. to the inherent advantages of robotic automation enables them to keep pace with the competitive market.

0 notes

Text

All About The Best Spice Grinding Machine in India

In the growing world of cooking and culinary arts, the demand for one piece of equipment always remains high. Spice grinding machine has changed the definition of how you would grind your spices for personal or commercial use. Not so long ago, it took a lot of labour to grind spices. But thanks to the spice grinding machine, the whole process has become easy and time-saving.

You can buy spice grinding machines for commercial use and grind fresh herbs and spices for your café or restaurant. You can also buy a small spice grinding machine for domestic use and utilize it to the fullest.

Not all spice grinding machines are created equal. Hence, you must understand how to pick the best one before shopping. Here is everything about the best spice grinding machine in India:

1. When you shop for a spice grinding machine in India, make sure that its power rating is more than sufficient to grind the quantity of spices you want to process in one batch. There are several power sources for this machine: electricity, disposable battery, rechargeable battery, etc.

We suggest you make a list of your requirement and analyse them thoroughly before choosing the power source. Rechargeable battery is a good option if your home or café suffers from frequent power cuts.

2. Many people face the common issue of controlling the speed of the spice grinding machine. To avoid this, always look for a machine that comes with adjustable speed settings. A standard spice grinding machine will provide three settings to work on – coarse, medium, and fine.

3. It is good to tinker with the innovations and technology when choosing a spice grinding machine. Always look at the extra features that a device offers you. For example, some grinding machines include detachable pods where you can replace one part with another one. This is a good option for multiple spice grinding. In addition, always look for the safety features of the grinding machine and operate it according to provided instructions.

We hope the above-listed considerations help you when choosing a spice grinding machine for your kitchen. So shop for the best one now. Happy grinding.

0 notes

Text

Features to Look for in a Spice Grinding Machine When Buying

If you belong to the world of cooking and culinary arts, you must own food processing equipment. Yes, we are talking of a spice grinding machine, the only way to get the most out of the fresh herbs and spices. Moreover, spice grinders are affordable, which means you can get one regardless of your skill or budget. However, it would help if you remember that not all spice grinders are equal. Therefore, you need to consider the following features while purchasing your spice grinder:

Essential features of a spice grinding machine you must consider

Wattage

The first thing that you need to check is the wattage. If you need to grind tougher ingredients faster, a higher wattage mixer grinder is the best choice. Spice grinders having a power range between 500 W and 750 W are ideal for an Indian kitchen.

Speed

It would help if you also decided on the RPM of a mixer grinder. It indicates the speed at which the blades rotate every minute. If you are looking for a domestic mixer grinder, choose one between 18000 and 23000 RPM. A juicer mixer grinder requires a low RPM for efficient performance. Opt for a spice grinding machine having a speed control knob or switch so that you can change the settings according to the requirements.

Blades

Blades form the primary part of the machine, as they grind your herbs and spices. Therefore, you need to verify the quality. Opt for blades made from stainless steel, preferably of the 304 grade. Always check the steel grade, as it tells you whether the steel is corrosion resistant. Moreover, high-quality steel blades retain their sharpness for longer.

Warranty

Ensure that you check the warranty period offered by the company. If the brand offers you a good warranty, then it is a quality product. Opt for a brand that gives you a warranty between 2 and 5 years. Some companies also offer an additional warranty on their motor, which indicates that your appliance will last longer without any hassle.

Jars

Opt for a spice grinding machine that comes with two-three jars of varying capacities. The more the number of jars, the better is the product. Opt for a product with a durable body and break-resistant lid. It helps in withstanding the daily wear and tear in the kitchen.

0 notes

Text

Cybernetik is Conducting a Webinar on Robotic Solutions for the Food Industry

Oct-21: Cybernetik Technologies Pvt. Ltd. is an Indian industrial automation company that provides industrial automation to manufacturing companies in food, pharma, chemical and automobile industries.

Cybernetik is going to conduct a webinar on robotic solutions for food industry with a Singapore-based company named Enabling.Win on 29th Oct 2021. This webinar will be hosted by the Business Head, Srivatsa Mahesh at 12:30 pm- 1:30 pm IST in India.

Srivatsa Mahesh is the business head at Cybernetik who is looking after business and technology development for robotic applications for the food, automobile and manufacturing industries. With over 12 years of experience, he is passionate about technical design, automation, AI & digitisation.

The webinar session will last for an hour and will cover the following topics:

Types of robots

Applications in food industry

Design considerations

Advantages and limitations of robotic systems

During this live session, you can interact with the speakers, panelists, and other audience members and get your questions addressed right away.

Register now at https://www.airmeet.com/e/3df878b0-263c-11ec-9d2a-b1b4170f5b7b.

Cybernetik’s robotic solutions deliver the two primary benefits of automation viz. quality and speed. Designed to comply with various international standards, our pick and place robots, palletizers, case packers, and stretch wrappers sizably improve throughput, efficiency, and safety of food packaging operations.

About the Author:

Cybernetik Technologies Pvt. Ltd is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customised automation solutions for food, pharmaceutical, chemical, and manufacturing industries across the world.

Address - Gat No. 365, Urawade, Mutha Road, Opposite Indo-German Technology Park

City – Pune

State – Maharashtra

Country – India

Zip code/ PIN code – 412108

Phone Number – 020 6790 9600

Toll Free Number, if any – n/a

Fax Number, if any – n/a

Company Email ID – [email protected]

Website: https://cybernetik.com/

1 note

·

View note