Text

Mastering CNC Machining: Precision in Motion

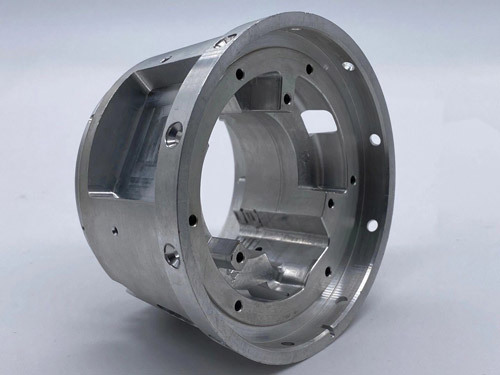

Delve into the world of CNC machining with "Mastering CNC Machining: Precision in Motion." Explore the mastery, precision, and artistry required to create flawless components using advanced machinery, expert programming, and meticulous craftsmanship. Experience the power of CNC machining and witness how every movement is carefully orchestrated to achieve unparalleled precision. Discover the transformative capabilities of CNC machining in industries ranging from aerospace to consumer electronics. Join us on a journey where precision meets motion, and witness the expertise behind the art of CNC machining.

Learn More:

https://www.worthyhardware.com/cnc-machining/

#CNC machining#CNC Machining Parts#cnc machining services#cnc aluminum machining#cnc parts#cnc service#china cnc service#cnc machining china

0 notes

Text

The ultimate guide to CNC machining acrylic parts

Acrylic is a standard transparent plastic used in CNC machining. As opposed to polycarbonate and glass, acrylic materials have many advantages, making them a popular choice for various applications.

Acrylic production methods include acrylic CNC machining, a precise and versatile process that allows for the creation of complex and detailed parts and designs. Acrylic components, such as acrylic sheets and acrylic machining, have widespread use in various industries.

What is Acrylic?

Acrylic, also known as PPMA or Plexiglas, is a type of plastic material commonly used in various applications due to its transparency, strength, and versatility. It is often used as a replacement for glass and is known for its ability to withstand shock and other types of damage.

Acrylic is a great material for CNC machining, as it can be easily shaped and molded into various forms. It can be machined using a CNC system to achieve precise cuts and smooth finishes, making it a good starting point for those working with plastic materials. In addition to being used in CNC machining, acrylic can be joined together using double-sided tape or other methods, such as solvent bonding or welding.

Despite its strength and durability, acrylic is a relatively soft material and can be easily scratched or marred if not handled properly. It is important to handle acrylic carefully and use appropriate techniques, such as clamping the material tight and using a linen towel to wipe away any excess debris to ensure that it is machined properly.

Learn More: https://www.worthyhardware.com/news/machining/cnc-machining-acrylic-parts/

0 notes

Text

Everything you need to know about Steel CNC Machining

Steel comes in various shapes and sizes, including flat stock for CNC machinings, such as sheets and plates, round stock such as bars and beams, and curved stock such as pipes.

Considering its mechanical properties, the wide range of uses, and businesses that employ steel, the material would come in various forms. This article will explore the various types of machining steel, their characteristics, and the best practices for CNC machining.

What is Steel CNC machining?

Steel CNC Machining uses steel to create various products from this metal needed in manufacturing to be high-performance, long-lasting, and efficient. Among its most desired qualities are steel’s strength and hardness.

The steel is well suited for building and transportation because it can withstand large, sustained loads for an extended period. Ssteel alloys are the ideal option for parts operating in harsh environments since they are corrosion-resistant.

1 note

·

View note

Text

Will CNC Precision Machining Be Affected By Artificial Intelligence?

Introducing CNC machining

CNC machining is a digital process that facilitates the production of high-accuracy parts from solid blocks of hard materials or substances. The machining processes are complex, but with the help of the CNC system, everything becomes easy. Some operations include cutting operations geared towards developing the parts, tool changes, and more.

The CNC machining technology comprises tools such as lathes, mills, blades, and grinders. A particular computer plays the essential role of controlling the mentioned parts to create the end products.

Learn More : https://www.worthyhardware.com/news/machining/will-cnc-precision-machining-be-affected-by-artificial-intelligence/

0 notes

Text

The Essential Guide To CNC Milling Machines

What does a CNC milling machine operate and what is it used for? What differences do CNC milling machines and CNC lathes have? When would you need a CNC machine tool like that?

CNC milling machines are a standard in industries all over the world. They are focused on milling machining, which is the process of gradually removing material from a workpiece using rotating tools.These machines use a variety of cutting tools along one or more axes to mechanically remove material from a workpiece.

Numerous industrial sectors, including those in the aerospace, shipping, automotive, oil drilling, pumping, and refining, as well as the medical, FMC manufacturing, and precision engineering fields, frequently use CNC milling machines.

The most sophisticated CNC milling machines, also known as CNC Machining Centers, can operate along many axes. To increase the effectiveness and precision of machining operations, they may be equipped with automatic tool changers, cutting-edge machine coolant systems, pallet changers, and cutting-edge software.

0 notes

Text

CNC machining motorcycle parts

Custom CNC parts are gaining popularity because of their high durability and accuracy. You can choose CNC machining to upgrade and recycle your motorcycle parts and get precise parts with high accuracy and fast production.

You can produce custom motorcycle wheels, engine parts, cylinder heads, camshafts, and motorcycle lights using various CNC machining materials such as aluminum, zinc, stainless steel, etc.

The custom parts are produced with CNC turning and milling processes with an ending surface finish through anodizing, powder coating, electroplating, or polishing for an aesthetic appearance.

Learn More: https://www.worthyhardware.com/news/cnc-machining-motorcycle-parts/

0 notes

Text

7 Types of CNC Steel Cutting and Its challenges

A steel/metal cutting machine is, as the name suggests, a machine or tool that is used to cut steel/metal. Depending on how it is driven, the steel cutting machine is either manual, semi-automatic, or automatic.

Many tools for cutting steel/metal, like band saws and chop saws, are cheap, versatile, and easy to use. They are better for metal-cutting shops that don't make a lot of money. And sometimes, the manual tools for cutting steel don't cut well and make a lot of mistakes.

This guide is produced by Worthy Hardware to inform you about the 7 different types of CNC steel cutting machines and their challenges.

What is CNC Steel /Metal Cutting?

Laser, flame, plasma, and water-jet cutting are the most common types of computer numerically controlled steel cutting. Using the CNC nesting software's optimized cutting program, they can cut in a way that is automatic, quick, and of high quality.

CNC steel cutting is a modern, high-tech way of making things. The CNC machine for cutting steel was made by putting together cutting machinery and advanced computer numerical control technology.

Learn More: https://www.worthyhardware.com/news/7-types-of-cnc-steel-cutting-and-its-challenges/

0 notes

Text

Benefits of CNC machining of brass

Brass is a part made of a combination of copper and zinc. Named because of its yellow color. Brass with a copper content of 56% to 68% has a melting point of 934 to 967 degrees. Brass has good mechanical properties and wear resistance. Because of its special points of interest, it has become a key part of the component manufacturing industry. In most cases, it is more used for precision copper parts such as automotive parts, medical parts, and electrical parts. Brass CNC manufacturing has many advantages compared with other metal CNC manufacturing. Brass CNC parts are processed using specific methods. Let's take a look at some of the benefits of using brass to cnc machine parts:

1.Durability

Brass can be utilized for a long time. In spite of the fact that it could be a delicate metal, machined brass has the quality and sturdiness that can final for a long time. They are not inclined to splitting or misshaping and stay unaltered in heavier mechanical applications.

2.Ductility

Typically a metal that's exceptionally simple to handle. Delicate metals can be effortlessly cut and have tall ductility. This implies it can be bowed, beaten and made into any shape. This is often a colossal advantage of sourcing precision CNC parts, and we are seeking out for exceptionally exact details. Brass can be made concurring to needs and necessities.

3.Erosion resistance

It has solid resistance to numerous destructive variables (such as dampness and certain chemicals). This makes it have the potential to be utilized in a wide run of businesses.

4.Tall temperature resistance

In zones where we handle tall temperatures, brass is the perfect choice. Being a CNC portion too implies that brass can offer assistance us dodge overheating. It'll not liquefy, extend or distort when the machine performs its work.

5.Versatility

Its composition can too be changed agreeing to operate. Since brass is an combination, its composition and interaction decide its execution. By changing the composition, able to infer a wide extend of brass CNC parts. In reality, brass parts as of now have a assortment of plans and capacities.

0 notes

Text

CNC stainless steel machining from WORTHY HARDWARE CO.,LTD

Stainless steel could be a exceptionally prevalent combination since of its amazing physical properties and superior erosion resistance. But to urge the foremost advantage from stainless steel parts, it is exceptionally imperative to select a company that gives proficient stainless steel CNC machining services. Stainless steel requires carefully kept up instruments and machining to obtain precision parts. At WORTHY HARDWARE CO.,LTD, our experienced staff and state-of-the-art machines empower us to supply exact comes about on time each time.

Classification and use of stainless steel

1.304 stainless steel. It is one of the foremost broadly utilized austenitic stainless steels. It is reasonable for the make of deep-drawing shaping parts and corrosive channels, holders, auxiliary parts, different instrument bodies, etc. It can moreover fabricate non-magnetic, low-temperature hardware and portion.

2.304H stainless steel. The inner department of 304 stainless steel features a carbon mass division of 0.04%-0.10%, and its tall temperature execution is superior than that of 304 stainless steel

3.304L stainless steel. The ultra-low carbon austenitic stainless steel created to illuminate the genuine intergranular erosion propensity of 304 stainless steel due to the precipitation of Cr23C6 beneath certain conditions, its sensitized state of intergranular erosion resistance is altogether way better than that of 304 stainless steel. But for the somewhat lower quality, other properties are the same as 321 stainless steel. It is primarily utilized for corrosion-resistant hardware and parts that cannot be solid-solution treated after welding, and can be utilized to make different instrument bodies.

4.316 stainless steel. Molybdenum is included to the 10Cr18Ni12 steel to form the steel have great resistance to decreasing media and setting erosion. In seawater and other different media, the erosion resistance is superior than 304 stainless steel, basically utilized for setting erosion safe materials.

5.316L stainless steel. Ultra-low carbon steel has great resistance to intergranular erosion within the sensitized state, and is reasonable for the fabricate of welded parts and gear with thick cross-section measurements, such as corrosion-resistant materials in petrochemical gear.

The reasons why stainless steel materials affect the accuracy of machined parts:

The solidifying inclination of stainless steel materials is genuine. In expansion, the processing is hindered cutting, and the affect and vibration are as well expansive, which makes the processing cutter simple to wear and chipping. When utilizing small-diameter conclusion plants, it is simple to break; in expansion, once the processing handle The toughness of the apparatus diminishes, and the harshness and size of the machining surface of the stainless steel precision parts cannot meet the comparing prerequisites.

We have 20 years of CNC processing experience, focus on quality first, customer service, beautiful price of CNC machining services,Our product tolerance is small, the price is cheap,which are used in a variety of sectors, including industrial equipment,automotive , etc.

Worthy Hardware is a CNC manufacturing and sheet metal fabrication company,including CNC machining services,CNC milling services, CNC turning services, laser cutting services and stamping services.Call us +86-76989919645 or email us [email protected] for more discounts for your projects.

0 notes

Text

About stainless steel machining services

Dongguan Worthy Hardware Co.,ltd gives exactness cnc machining services for a assortment of plastics and metal combinations (counting stainless steel). We have decades of encounter in preparing high-quality and ultra-precision stainless steel mechanical parts and items utilizing different grades of stainless steel.

Utilizing total inner tooling capabilities and progressed preparing gear, we will plan and fabricate stainless steel handling parts and gear.

I、The benefits of stainless steel machining:

1. Virtually upkeep free and no defensive coating or uncommon surface treatment is required, which implies lower upkeep and repair costs

2. Tall temperature resistance, counting oxidation and scaling in forceful situations and hoisted temperatures

3. Corrosion resistant to moisture, various atmospheric conditions, and many chemicals and acids

4. Combination of strength and erosion and warm resistance offers extraordinary coldness for a long and trouble free benefit life.

5. Offers fabrication flexibility and excellent machinability, malleability, and weldability

II、Stainless Steel CNC Machining Services

Stainless steel is one of the challenging materials to work with. When machining a stainless steel portion, it is exceptionally critical to guarantee that there's no device chatter or rubbing caused due to vibration. Our progressed CNC machines offer assistance us guarantee high-quality surface flawlessness. Our clients approach us for the taking after CNC machining services:

1.CNC milling and Turning Services: We utilize live tooling and 3 & 4 apparatus pivot to supply a comprehensive extend of CNC milling and turning services.

2.Precision CNC Machining Services: we have contributed in a state-of-the-art CNC machining hardware, which empowers us to require up complex projects requiring precision CNC machining administrations

Some types of stainless steel

Characteristics: As one of the most widely used steel grades, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Good hot workability for stamping, bending, etc., no heat treatment hardening phenomenon (non-magnetic, use temperature -196℃~800℃).This steel is additionally effectively weldable and can be effortlessly welded utilizing different resistance and combination welding processes.

Features: Mo should be added, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, and it can be used under harsh conditions. Excellent work hardening (non-magnetic)

Uses: Mainly used for equipment, chemistry, dyes and paper making in sea water. Oxalic acid, fertilizer and other production equipment; food industry, coastal area facilities, ropes, CD rods, bolts, nuts.

This is one of the foremost prevalent austenitic assortment of stainless steel, which is well-known for its erosion resistance, and ductility. The steel encompasses a inclination to work solidify, in any case, it can be effortlessly overcome by moderate speeds.

CNC machining is the center of our company. At Worthy Hardware, we are glad of our capacity to contract fabricating and CNC preparing any item from concept to completion, and provide 100% high-quality finished products on time each time. We fulfill this commitment to our clients through a strict commitment to lean manufacturing and 5S planning.

Worthy Hardware is a CNC manufacturing and sheet metal fabrication company,including CNC machining services,CNC milling services, CNC turning services, laser cutting services and stamping services.Call us +86-76989919645 or email us [email protected] for more discounts for your projects.

0 notes

Text

How to choose a good CNC machining supplier?

When you are purchasing cnc machining parts, in many cases we will not know how to choose the right supplier. We must consider not only the price, but also the quality, delivery, service and other factors. I hope that our article will give you some help.

(1) Choose high reliability: it means that when the machine tool performs its function under the specified conditions, it runs stably for a long time without failure, that is, the mean time between failures is long; even if it fails, it can be restored in a short time and put into use

(2) Choose machine tools with reasonable structure, well-manufactured, and mass-produced machines. Generally, the more users, the higher the reliability of the CNC system.

However, the quality of a CNC part reflects not only the strength of a manufacturer, but also his handling of some details. For CNC machining parts, if the manufacturer does not handle it well, the processed product is unqualified. What should the manufacturer pay attention to in order to avoid processing failures and reduce costs during processing?

I. Burrs on the surface of the workpiece

This point is easily overlooked by many businesses. For a part, CNC lathe processing parts are completed by equipment, then there will be problems during injection molding, and this burr is also generated at this time, if it is not polished in time If trimmed, this part can only be scrapped, otherwise it will affect other links during use.

II. Accuracy of parts

For CNC lathe machining parts, its accuracy is very strict. Only the required accuracy can be used. The accuracy criterion is mainly based on the part's ability to control the size and the resulting tolerance. Within the allowable fluctuation range, if the tolerance is exceeded, the part is unqualified and cannot be put into future production and sales.

III. Analysis of test results

Parts need to undergo performance testing before leaving the factory. If the performance is qualified, they will be shipped. If they are not qualified, some of the reasons should be analyzed, so as to avoid mass scrapping. Manufacturers in the processing industry basically deal with it in this way. They will make a certain quality control chart based on the performance of many companies to analyze the reasons.

1. Attention should be paid to the CNC machining:

(1) For the current economic CNC lathes in my country, ordinary three-phase asynchronous motors are used to achieve stepless speed change through frequency converters. If there is no mechanical deceleration, the spindle output torque is often insufficient at low speeds. If the cutting load is too large, It is easy to get stuffy, but some machine tools have gears to solve this problem well;

(2) As far as possible, the tool can complete the processing of a part or a work shift. In the finishing of large parts, special attention should be paid to avoid changing the tool in the middle to ensure that the tool can be processed in one time;

(3) When using CNC turning to turn the thread, use a higher speed as much as possible to achieve high-quality and efficient production;

(4) Use G96 as much as possible;

(5) The basic concept of high-speed machining is to make the feed exceed the heat conduction speed, so that the cutting heat is discharged with the iron filings to isolate the cutting heat from the workpiece, and to ensure that the workpiece does not heat up or does not heat up. Therefore, high-speed processing is selected very high The cutting speed is matched with the high feed and the smaller back-grab is selected at the same time.

2. Vibration and tool breakage often occur during grooving. The fundamental reason for all of these is the increased cutting force and insufficient tool rigidity. The shorter the tool extension length, the smaller the clearance angle, and the larger the area of the blade, the better the rigidity. The cutting force can be increased with the greater the cutting force, but the greater the width of the groove tool, the cutting force it can bear will increase correspondingly, but its cutting force will also increase. On the contrary, the smaller the groove tool, the smaller the force it can bear. Its cutting force is also small.

3. Reasons for vibration during car trough:

(1) The extension length of the tool is too long, resulting in lower rigidity;

(2) The feed rate is too slow, which will cause the unit cutting force to increase and cause a large vibration. The formula is: P=F/back-cutting amount*f P is the unit cutting force, F is the cutting force, and the speed is too fast Also vibrate the knife;

(3) The machine tool is not rigid enough, which means that the tool can withstand the cutting force, but the machine tool cannot withstand it. To put it bluntly, the machine tool does not move. Generally, the new machine does not have this kind of problem. The machine with this kind of problem is either old. Either the machine killer is often encountered.

0 notes

Text

10 Tips for Better Surface Finish For Your CNC Machining Parts

There are several things we need to keep in mind in order to get a perfect CNC machining part. Some of these major pointers come before we begin manufacturing them, like correct dimensions and tolerances, shape, quality of the raw materials used etc. But there is something that needs to be worked on after the machining part is produced.

Surface Finish: A process that helps define and refine the overall texture (lay, roughness, and waviness) of the machining part. We just cannot ignore the importance of an impeccable surface finish.

How to ensure the steps we are adopting will get a better surface finish?

We understand your dilemma. Hence, we have created a checklist of major surface finish that will help you make your CNC machining parts better.

1. Increase Your Speed

This really applies most when using carbide tools. When you increase the surface feet per minute speed (SFM), you will ensure that the material is in contact with the tool tip for a shorter amount of time and will also reduce edge buildup on the tool, which causes poor surface finishes.

2. Reduce Your Feed Rate

Reducing the feed rate helps to improve surface finish. This will also help to reduce flank wear and prolong the insert’s longevity. In addition, doubling the nose radius will help to improve surface finish. For roughing applications, it’s best to use a tool capable of a high feed rate to remove material quickly. For finishing, it’s best to have a lower feed rate and shallower cut.

3. Increase the Top Rake Angle

Positive rake angles will lead to a finer surface finish, requiring lower cutting forces. Using a 45° cutter will act downward, possibly making the part flex. As a result, this will cause the back half of the cutter to recut the machined part and create a poor surface finish. Using a 90° cutter will create cutting forces parallel to the part and will not flex it. This will produce a smoother surface finish.

4. Use a Chip Breaker

A poor surface finish can also be caused by improper chip breaking, downtime to remove chips and higher temperatures at the tool’s cutting edge. A chip breaker can produce smaller chips that are cleared from the cutting area quickly. And because there is no longer a need to clear chips by hand, safety is improved.

If the chip breaker can break the chips into adequate lengths, then vibration will be minimized; the chips will not wrap around the workpiece and tools will not be damaged. Chip breakers also reduce cutting resistance, which can avoid chipping or breaking the cutting edge. A lower cutting resistance can decrease heat and delay tool wear.

5. Use a Large Nose Radius

The idea is to use a larger nose radius and decrease the feed rate to get a smoother, finer surface finish. This is because the nose radius and depth of cut affects the shape and direction of chips. Therefore, it’s best to use the largest radius possible to achieve the best surface finish and avoid creating chatter (machine vibration). But, on the other hand, a larger nose radius will increase demands on the tool, causing vibration and poor chip breaking, whereas a smaller nose radius produces thinner chips that are easier to clear away from the workpiece, but this will also limit the feed rate.

6. Use an Insert with a Wiper

To ensure a good surface finish, use a special wiper insert that has a modified nose radius with larger corners to wipe the surface smooth. This will allow you to cut at a faster feed rate.

7. Use the Right Technique

Creating a chip that is thick-to-thin is what you want. Your technique plays a vital role in getting smooth surface finishes. Choose a cutter that is smaller than the nose radius so you can program it for a smooth transition from line-to-line.

When you run your final cuts, don’t just limit yourself to checking your workpiece; you should also read your chips. The characteristics of your chips will indicate what machining set up or tooling adjustments are necessary.

8. Use Different Tools for Roughing and Finishing

Some may say that the same inserts can be used for both roughing and finishing. But it’s best to use separate inserts, one for roughing and one for finishing. For roughing, you can use a course-pitch cutter with a large nose radius, and a large rake angle with a rapid feed rate. For finishing, you can use a fine-pitch finishing tool with the proper lead angle and a wiper flat, which will give you a better surface finish.

9. Clear the Chips

There is a debate whether to use coolant in milling applications. But it all depends on the type of work you’re doing, such as deep cavity milling, the type of material and which insert you are using. Using coolant, in some cases, should be avoided. It may cause thermal cracking and shorten tool life and could affect the surface finish negatively. But with aluminum, low-carbon steel or nickel-based alloys, using coolant will prevent the tool from sticking to the workpiece.

10. Check Your Toolholding and Workholding

It’s a good idea to check the condition of your toolholder. An old, worn-out toolholder may cause the insert to move. This will cause chatter and will negatively affect the surface finish of your part. You also want a rigid workholding that is stable, especially with a higher metal removal rate.

All these tips are from our 20 years of experience in the cnc machining parts and cnc machining services field. It helped us, it might help you too. So, go ahead and adopt these practices so you get a perfect surface finish.

0 notes

Text

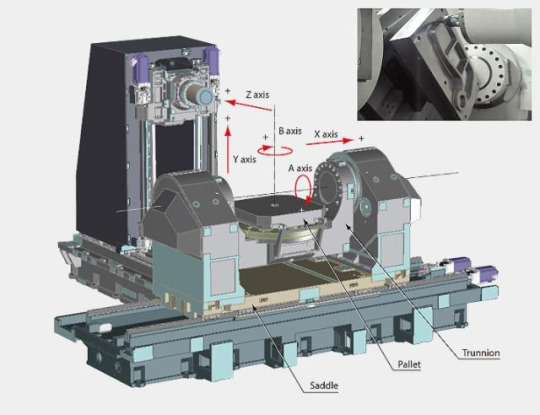

What is 5 axis CNC machining?

5-axis machining involves using a CNC to move a part or cutting tool along five different axes simultaneously. This enables the machining of very complex parts, which is why 5-axis is especially popular for aerospace applications. Usually five-axis linkage refers to the linear interpolation movement of any 5 coordinates among x, y, z, A, B, and C.

Compared with three-axis CNC machining, from the perspective of technology and programming, five-axis CNC machining for complex curved surfaces has the following advantages:

(1) Improve processing quality and efficiency

(2) Expand the process range

(3) Meet the new direction of composite development

Type of 5-axis CNC machining

(1) Double swing head form (+A ,+C)

(2) Swing head type (+B, +C tool)

(3) Double turntable form (NC table)

(4) Overhanging worktable (+B ,+CNC work table)

(5) One pendulum and one rotation form (+A, NC workbench)

0 notes

Text

Top CNC Machining Services in USA

Metal Tech Inc.

They are a multinational company that specializes in close tolerance, precision metal stamping and machining services. Their service sector includes automotive, consumer products, electronics, government/defense, HVAC, lighting, marine, medical,and metal buildings.

They are a custom manufacturer of medium to high volume precision metal stamping which always provide excellent customer service.

Website: https://www.metaltechcompany.com/index.html

F.M. Machine Co.

F.M. Machine Co. provide a full range of precision machining, prototype, special machine building, fabricating, complete assemblies, machine wiring and electrical panel building to their. customers

Premium cnc machine and works will be working closely with clients in providing the perfect cnc system and fulfill the client’s demand with ease.

Website: http://www.fmmachine.com/index.html

Worthy Hardware Co., Ltd

Worthy Hardware specializes in machined components and assemblies. They offer precision stamping service and laser cutting service with metal and plastic material.

This company is a cnc machining parts and sheet metal fabrication

vendor for 100+material with free samples in global shipping. They welcome their customers and those interested in developing long, stable and mutually beneficial relationship to meet and discuss customer's needs.

Website: https://www.worthyhardware.com/

0 notes

Text

Benefits of CNC Machining

CNC Machining, otherwise known as Computer Numerical Control machining, is a cost-effective way to increase efficiency in the workplace. CNC machining is an assembling technique that utilizes pre-modified PC programming to control machining devices. This innovation can be utilized to play out a scope of complex cycles, including granulating, steering, processing, punching, turning and lathing.

Benefits of CNC Machining

1. Worker Safety

The CNC machine administrator is protected from any sharp parts behind a defensive development. The administrator can perceive what is happening in the machine apparatus by means of the glass. The administrator doesn't really have to go near the shaft or plant. The administrator doesn't need to draw close to the cooling liquids. A few liquids are risky to human skin, contingent upon the material.

2. Reduced Error in Set-Up

Traditional machine tools depend on the capability of the administrator in utilizing estimating instruments. Some great specialists are fit for setting up leaves behind a ton of exactness, however they are not very many. This is the reason CNC frameworks utilize a unique facilitate estimating test, which is introduced into the shaft. The test contacts the fixed part to set its position. The facilitate framework zero focuses are confirmed so the arrangement blunders are diminished.

3. Reduced Test Runs

Traditional machining has a couple of test parts. The administrator should get to know the innovation and might miss a few things while doing the initial segment. CNC frameworks have approaches to try not to do trials. They use representation frameworks that permit the administrator to perceive what will occur after the device passes are done.

4. Increased production speed and increased efficiency

Computers are used to control the machines, the process is automated therefore increasing speed and quality of manufacturing. Considering machines do not tire or need breaks it makes it more efficient than manual machining.

5. Economy of Labor

Traditional machine tools required the administrator to give close consideration and move each piece of the instrument. Thus, every laborer could just work one machine device. With the CNC, this changed, and most pieces just require about 30 minutes to measure during every arrangement. The CNC machine apparatus cuts without assistance, and the administrator doesn't need to do anything. The device consequently moves, with the administrator simply checking for mistakes in the arrangement or program. The present circumstance implies the administrator has leisure time in the middle, time that can be utilized to work more instruments. With one administrator with a few machine apparatuses, you can save money on the expenses of employing more individuals to work the machines.

6. Higher Machine Tool Flexibility

The traditional method was that a milling machine made planes and groves; a lathe makes tapers and cylinders, while a drilling machine drills holes. CNC machining combines the above in a single device, as opposed to the traditional machines where you needed separate machines. Since you can program the trajectory of the tools, you can easily replicate whichever movement you choose on any machine tool.

Conclusion

CNC machining came along to ease the burden of having to do everything manually. The CNC assures you of worker safety, reduces the need to employ more operators as the CNC allows multitasking and myriad other advantages.

#cnc service#cnc machining#cnc milling#cnc turning#precision machining#cnc machine shop#cnc machined parts

0 notes

Text

What are the benefits of Metal Stamping?

Precision metal stamping is an industrial process that uses machinery fitted with dies to transform flat sheet metal in either blank or coil form into different custom shapes. Besides stamping, these metal presses can also perform a wide range of processes such as punching, tooling, notching, bending, embossing, flanging, coining, and much more.

Metal stamping offers a wide range of benefits that make it a useful process for the mass production of many designs. Some of the primary benefits include:

1) Cost Effective

While initial tooling may come with elevated upfront costs, the overall cost of metal stamping can be significantly reduced for larger production runs. Since the dies can be reused for each process, larger orders gain significant economies of scale.

2) Quick Setup

The lead times for metal stamping are relatively short, which means production can begin quickly.

3) Precision

The dies and tooling used in metal stamping offer extremely precise cuts and shapes. In addition, metal stamping is a cold forming operation, which means no additional heat is applied to the metal during the stamping process. This avoids warping and improves the accuracy of the final part.

4) Consistent quality and accuracy

Precision metal stamping enables the production of very precise parts to the high degree of accuracy required in many industries today

0 notes

Text

How CNC Parts are improving the manufacturing industry?

Article from: https://www.worthyhardware.com/how-cnc-parts-are-improving-the-manufacturing-industry/

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Short for “computer numerical control,” the CNC process runs in contrast to — and thereby supersedes — the limitations of manual control, where live operators are needed to prompt and guide the commands of machining tools via levers, buttons and wheels. To the onlooker, a CNC system might resemble a regular set of computer components, but the software programs and consoles employed in CNC machining distinguish it from all other forms of computation.

Why CNC Parts Machining is becoming Popular Globally?

For any manufacturing plant, opting for CNC Machining instead of traditional machining has become an obvious choice due to its numerous advantages. CNC parts have better tolerances overall and their repeatability is off the charts. This is due to the fact that the performance of a human operator may get affected due to several external factors and the operator’s precision would drop with time, however, CNC can operate with the same precision throughout the day and can also prepare more parts in the same timeframe. With a CNC machining, rapid prototyping gets extremely easier and your plant can be operated without a break. Similarly, with CNC parts, the acceptable tolerances of machined products have reduced a lot because modern machines can provide tolerances up to the factor of 10-3. For high-intensity applications in sectors like aerospace and defence, this is quite important.

Major Applications of CNC Parts

(1)Automotive

The automotive industry regularly uses CNC machining for both prototyping and production. Extruded metal can be machined into cylinder blocks, gear boxes, valves, axels, and various other components, while plastic can be machined into components like dashboard panels and gas gauges.CNC is also useful for creating one-off custom automotive parts and even replacement parts since turnaround times are fast and there is no minimum required part quantity.

(2) Consumer electronics

CNC machining is widely used for the prototyping and production of consumer electronics such as laptops and smartphones. The chassis of an Apple Macbook, for example, is CNC machined from extruded aluminum and then anodized.In the electronics industry, machining is used to create PCBs, housings, jigs, fixtures and other components.

(3) Defense

The military sector frequently turns to CNC machining for the prototyping and production of rugged and reliable parts that will withstand wear and tear with minimal upkeep.Many of these parts overlap with other industries such as aerospace and electronics, though the ability of CNC machines to provide on-demand replacement parts and upgraded components is particularly useful in an industry that demands constant innovation and security.

(4) Medical

Since CNC machining can be used on various medically safe materials, and since the process is suited to one-off custom parts, it has many applications in the medical industry. The tight tolerances afforded by CNC machining are essential to the high performance of machined medical components.CNC machinable medical parts include surgical instruments, electronic enclosures, orthotics, and implants.

(5) Oil & gas

Another industry in which tight tolerances are required for safety-critical applications, the oil and gas sector uses CNC machining for precise, reliable parts such as pistons, cylinders, rods, pins, and valves.These parts are often used in pipelines or refineries and may be required in smaller quantities to fit specific quantities. The oil and gas industry often requires corrosion-resistant machinable metals like Aluminum 5052.

Whether you need cnc parts in any shape or material, Worthy Hardware can help you out. Our team of experts have both the technical knowledge and the facilities to deliver even the most complex parts in the shortest time possible, making it possible for you to launch your product in the market sooner.

0 notes