Link

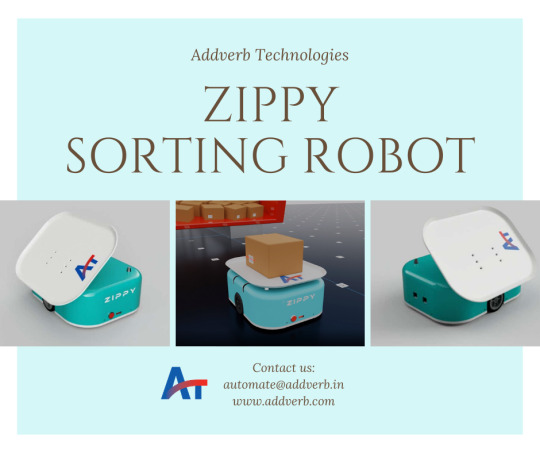

Zippy, an ultra-fast moving sorting robot to perform 100% accurate SKU level sorting task up to 20,000 sorts/hour. Zippy reads the bar code of the load and relays the information to the fleet management system with a perfect vision system to perform SKU level intelligent sorting at very high speeds. Ideal for industries like 3PL, E-commerce, Airport, Fashion, Grocery Retail, Pharmaceuticals. Visit here to know more about Zippy: https://addverb.com/product/zippy-sorting-robot/

0 notes

Link

Do you know?

Industrial robots or mobile robots were gifted to us by the third industrial revolution and basically they are capable of undertaking pre-defined tasks such as moving certain objects for short destinations, or welding on the production line, repeatedly and rapidly; rendering them quite significant for factories.

Take a stop here to know more about How the revolution of mobile robots has paved the way for a new digital world?

0 notes

Photo

Zippy - Sorting Robot for Intelligent Sortation from Addverb

Zippy, an ultra-fast moving sorting robot to perform 100% accurate SKU level sorting task up to 20,000 sorts/hour. Zippy reads the bar code of the load and relays the information to the fleet management system with a perfect vision system to perform SKU level intelligent sorting at very high speeds. Ideal for industries like 3PL, E-commerce, Airport, Fashion, Grocery Retail, Pharmaceuticals. Visit here to know more about Zippy: https://addverb.com/product/zippy-sorting-robot/

0 notes

Photo

Robotic sortation solution to ensure efficient sorting process by Addverb

Sorting may not be a difficult task but it can become tedious if your SKU amounts in thousands in a day. A fast moving sorting robot facilitates fast reading bar code and intelligent sortation solution. Here Addverb making your job easier by introducing Zippy, sorting robot which facilitates fast bar code reading & the intelligent sortation. For more detail, visit: https://www.addverb.in/AGV-For-Warehouses-Factories-Mobile-Robotics-Solution.html

0 notes

Text

Pallet Shuttle – A need for a warehouse to achieve your business targets

Pallet shuttle technology is relatively new but is gaining popularity. It is used to store and retrieve full pallets in the drive-in style rack. It can significantly increase pallet storage density and almost eliminate pallet picking and replenishment labor. Automatic or Semi-Automatic compact system that uses an electric motorized shuttle to load and unload the pallets inside shelves quickly and accurately. An operator, using a controller (tablet) gives commands to perform the operation, both storage & retrieval of pallets. Shuttle receives the commands, identifies the pallet location with the help of the vision system & sensors & performs the carrying operation. It can sync with WMS and work in an automatic fashion too. It considerably reducing operating times and enabling items to be grouped by channels rather than complete lanes. It is an ideal solution for companies with a high volume of pallets per item and intensive loading and unloading activity. Shuttles can operate in FIFO and LIFO mode (controlled by the operator).

Pallet shuttle can drastically improve warehouse functioning either in a semi-automatic mode through forklift or in advanced applications like mother-child shuttle/complete AS/RS system. Addverb is one of the largest players of Pallet Shuttle in India. Addverb has developed and deployed more than 60 pallet shuttle sin last one year. If you have any requirements in automation to achieve your business targets, do write to us at our email id [email protected].

youtube

#warehouseautomation#palletshuttleinindia#palletshuttle#automated storage and retrieval system#warehouse storage solution

0 notes

Link

With Industry 4.0 and IoT, such storage technology is more important than ever especially in retail, e-commerce, and multi-channel. To know more about automation in the storage space, reach out to Addverb that have a magnificent experience in multi-level shuttle system for your high-density storage and high throughput requirements. www.addverb.in

0 notes

Text

Sorting robot to short your all business problem

In recent years, the overall scale of the express industry has expanded rapidly with swift growth of the e-commerce industry, and the annual business volume has exceeded 30 billion. This increase requires higher sorting efficiency of express and amount to minimum one lac deliveries per day for an average logistics or e-commerce warehouse. This huge demand requires a unique solution and sorting robot is one such gem. Now, Let’s delve deeper into its functioning.

How does it work?

These sorting robots are fastmoving robots that perform SKU level sorting operation by reading the bar codes printed on the operational area. They perform route wise sorting operations by reading the bar codes around the area where they operate. The process is completely automated, ensures safety, efficiency, and accuracy. The operators place the parcel on the automated sorting robot, it carries the parcel through the portal frame and reads the order information. It automatically weighs the parcel as well and displays all the necessary information on the operator interface system. Fleet management system manages this army of robots in coordination with one another and manages all the control and scheduling. Each robot is deployed on the most optimized path for delivery based on the algorithm used.

If you are looking for the robotic sortation solution for your warehouse Keep in touch with Addverb. Visit: https://www.addverb.in/AGV-For-Warehouses-Factories-Mobile-Robotics-Solution.html or drop your queries at [email protected]

0 notes

Photo

Robotic Automation has become the norm of the day. With robotics automation, robots are used to automate manual operations. These robots are designed to carry out the task to improve efficiencies. This robotic solution can be considered as one of the major developments that have helped ease and streamlined various major changes in robotic processes in different industrial applications. It also undergone a vital change in terms of motion control hardware and software and is fast becoming the pivot of robotics. The motion control hardware and software are used to find objects and guide the robotic arm to pick these objects and release them. To know more about robotic automation and best Robotics Companies In India.

#RoboticsCompaniesInDelhi#warehouseautomationsolution#addverb#Industrial Automation Companies in India

0 notes

Video

youtube

Life@Addverb

From engineering to product management, from sales to marketing. Take a peek into the Life of Addverbians. Stay connected to know more about us.

visit: https://www.addverb.in/

Drop your queries at [email protected] Subscribe to Life at Addverb for more videos: https://bit.ly/2mkKyDH

Follow us on Facebook: https://www.facebook.com/AddverbTech/

LinkedIn: https://www.linkedin.com/company/addv...

Instagram: https://www.instagram.com/addverbtech...

Twitter: https://twitter.com/_Addverb

0 notes

Link

Automated material handling, an intuitive way to reduce or even eliminate the need for humans in movement, storage and control of material for manufacturing and intra-logistic warehouse operations. Know more about automation solution to improve the productivity of your warehouse. Visit: www.addverb.in or drop your queries at [email protected]

0 notes

Link

The dawn of Industrial IoT solutions in the field of logistics and warehouse is increasingly becoming part of the smart automation system. Addverb a fast-growing company in Intralogistics Automation Solutions that focusing on Industrial IoT solutions to provide improved operational efficiency & productivity through supply chain visibility and green practices. Visit here to know more: www.addverb.in or drop your queries at [email protected]

#industrial iot solutions#warehouse automation solutions#automated storage and retrieval system#automated warehouse storage#Industrial Automation Companies in India

0 notes

Text

Automated Storage and retrieval system for automated material handling

An automated storage/retrieval system (AS/RS) can be defined as a storage system under which a defined degree of automation is to be implemented to ensure precision accuracy and speed in performing storage and retrieval operations. ASRS is most commonly used to handle a wide variety of SKUs in manufacturing industries. Automated storage and retrieval are the most advanced material handling system that can promptly and accurately handle, store and retrieve products from designated storage locations in fully automated warehouses. ASRS system consists of dense racking structure, Warehouse Execution/Management System and an SRM (Storage & Retrieval Machine) crane for material handling. It is widely used in production environments, distribution centers, and warehouses. Addverb Technologies, a leading player in industrial automation that offering best-in-class automation storage solutions to the customer based on their requirement.

#warehouse automation solutions#automated storage and retrieval system#Industrial Automation Companies in India#automated warehouse storage

0 notes

Photo

A new innovative idea for picking solutions that automate the picking process to maximize the throughput and accuracy of the Person-To-Goods Order Picking System. Pick to Light is best suited for high-speed picking, zone picking, and batch picking operations. It consists of digital display which shows the quantity to be picked and LED lights to guide the picker. Once the picking process is done, picker acknowledged and update by pressing that LED light. Addverb’s Rapido - Pick-to-Light and Put-to-Light solution is efficient Paperless product Picking and Order fulfillment automation solution which enhances productivity and picking rate in order picking operations. Visit www.addverb.in to know more about Rapido.

0 notes

Photo

Has Sorting Robot sorted the Sortation problem for businesses today?

Have you ever imagined a warehouse in the form of a video game consisting of an army of speed cars rushing their way off on the raging roads? You probably won't have, but robotic automation has turned this imagination into reality. In recent years, Sorting Robot has emerged as one of the finest solutions so far in the automation and distribution space.

The sorting robot system has gained high acceptance in the logistics industry, transformed from a labor-intensive industry to batch intelligence. Parcel sortation is demanding on e-commerce marketplace where sorting happens to sort the parcel, those sorting robot can sort the 5,000 parcels every hour as against 450 parcels sorted by a human in the same duration.

Today automation is seeping into many industries and, sorting is one of the major tasks at hand. Addverb can help you in sorting your problem for your warehouse with the most appropriate sortation solution for your needs to improve profitability and efficiency and overall productivity. For more query, you can write to us at [email protected]

0 notes

Link

Addverb's revolutionary idea "Quadron" - India’s first carton shuttle robot to optimize the movement of goods in hashtag#warehouse and factories to ensures the human movements are more productive, safe and ergonomic, these are few words well defined by Techstory.in. Let's Give it a read!! https://lnkd.in/fuRBPyx hashtag#Quadron hashtag#addverb hashtag#warehouseautomationindia hashtag#industryautomation hashtag#futureready hashtag#industry4_0

0 notes

Video

Kinepick - Industrial Robotic Solutions | Addverb

Our Vision based Bin Picking robots completely eliminate the human requirement for the monotonous and strenuous task of the production line. By its Enhanced Vision System, the robot randomly picks items of any shape and size in any orientation, transfers them and places them precisely in the predetermined position with help of Magnets, pneumatic grippers, Servo Grippers. This modified version of the bin picking technology is more flexible, dynamic and accurate, as it can identify the object in real-time through sensing colors and depth in a Point Cloud. Visit us for more details at www.addverb.in or drop your queries at [email protected]

0 notes

Text

Introducing Dynamo | Mobile Robot - Addverb Technology

Hi, I am Dynamo. I am a mobile robot who carries load and travel without an onboard operator. My movement is guided by software and sensor-based guidance. I am equipped to make dynamic movements across the warehouse and suitable for complex production flow environments. To know more about me visit here: https://www.addverb.in/AGV-For-Warehouses-Factories-Mobile-Robotics-Solution.html

0 notes