#industrial iot solutions

Text

Telecom, Media & Communication Create a compelling communication experience for your customer

The Telecom, Media and Communication industry seems to be more promising as new-age technologies, new ecosystems and advanced use cases are coming to the fore. We see 5G finally moving from hype to reality with leading telcos rolling out the first commercial 5G networks. Now, 2020 is expected to see a further boost to the fifth generation of networks with companies across industries set to benefit from the higher speeds, lower latency and better connectivity on offer. We at The DataTech Labs Inc help the Telcos to accelerate the race to develop value while continuing to reduce costs in connectivity and differentiate with ultra fast networks. We help you meet an increasing competitive pressure on core business while finding blue ocean growth strategies to sustain in the market. Working in collaboration with us, you will be well positioned to offer improved capabilities and create new business opportunities.

0 notes

Text

IoT Network Protocols (e.g., MQTT, CoAP)

Harness robust IoT network protocols, including MQTT and CoAP, for seamless connectivity!

#IoT software development services#embedded software development services#IoT device selection#IoT strategy consultation#IoT data visualization tools#edge computing for IoT#IoT network protocols (e.g.#MQTT#CoAP)#IoT user experience design#AI in IoT solutions#IoT and blockchain integration#IoT app design services#IoT app development#IoT device integration#IoT data analytics services#IoT security solutions#custom IoT application development#enterprise IoT services#industrial IoT solutions#IoT firmware development#IoT cloud integration#IoT connectivity solutions#mobile app development#software development#TechAhead Corp#TechAheadCorp#techaheadcorp.com

0 notes

Text

How Industrial IoT Solutions are Transforming Manufacturing and Production Processes

The manufacturing and production industries have long been characterized by large, complex machines and manual labor. However, with the advent of the Industrial Internet of Things (IIoT), these industries are being transformed by the integration of advanced sensors, connectivity, and data analytics.

In this blog post, we will explore how industrial IoT solutions are revolutionizing manufacturing and production processes.

Real-time Monitoring and Predictive Maintenance

One of the key benefits of industrial IoT solutions is real-time monitoring and predictive maintenance. By integrating sensors and data analytics, businesses can monitor their machines and equipment in real-time and identify potential issues before they occur.

For example, sensors can detect changes in temperature, vibration, and other factors that can indicate potential machine failure. This allows businesses to proactively address issues before they lead to unplanned downtime, reducing costs and improving overall efficiency.

Moreover, IoT solutions can help with predictive maintenance, which involves using data analytics to predict when maintenance will be required. This helps businesses to schedule maintenance at optimal times, minimizing the impact on production and reducing the need for costly emergency repairs.

Improved Inventory Management

IoT solutions can also help businesses to manage their inventory more efficiently. By integrating sensors with inventory management systems, businesses can monitor inventory levels in real-time and automatically order new supplies when inventory reaches a certain threshold.

This helps to prevent stockouts and overstocking, reducing waste and minimizing costs. Moreover, businesses can use data analytics to identify trends and optimize their inventory management processes, thereby improving overall efficiency and reducing the risk of errors.

Enhanced Quality Control

Quality control is a crucial aspect of manufacturing and production processes. However, traditional quality control methods are often manual and time-consuming, which can lead to errors and delays.

Industrial IoT solutions can help to improve quality control by providing real-time data on product quality. For example, sensors can be used to detect defects in products as they are being manufactured, allowing businesses to identify and address issues in real-time.

Moreover, IoT solutions can provide data analytics that help businesses to identify trends and patterns in product quality, allowing them to make improvements to their processes and products over time.

Optimized Supply Chain Management

Supply chain management is another area where industrial IoT solutions can provide significant benefits. By integrating sensors with supply chain management systems, businesses can monitor the location, condition, and status of their goods in real-time.

This helps businesses to optimize their supply chain processes, reducing delays and improving overall efficiency. For example, businesses can use data analytics to identify bottlenecks and optimize their logistics processes, reducing transportation costs and improving delivery times.

Improved Worker Safety

Worker safety is a top priority for manufacturing and production businesses. However, traditional safety measures are often reactive.

Industrial IoT solutions can help to improve worker safety by providing real-time data on working conditions. For example, sensors can detect changes in temperature, humidity, and other environmental factors that can affect worker safety.

Moreover, businesses can use data analytics to identify trends and patterns in worker safety, allowing them to make improvements to their processes and safety measures over time.

Efficient Energy Management

Energy consumption is a significant cost for manufacturing and production businesses. Industrial IoT solutions can help to optimize energy usage by providing real-time data on energy consumption.

For example, sensors can be used to monitor energy consumption in different areas of the factory or production facility, allowing businesses to identify areas where energy usage can be reduced.

Moreover, businesses can use data analytics to identify trends and patterns in energy consumption, allowing them to make improvements to their processes and equipment over time.

Conclusion

Industrial IoT solutions are revolutionizing manufacturing and production processes, providing businesses with real-time data and analytics that enable them to improve efficiency, reduce costs, and enhance overall performance.

0 notes

Text

0 notes

Text

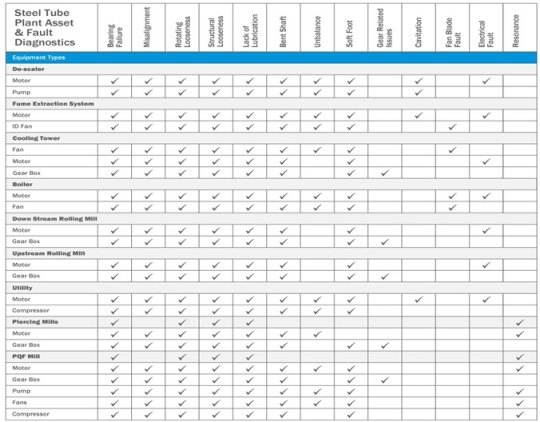

Prognostic Solutions in Steel Plant and Tube Mill Industry

The global steel market reached a value of US$ 874.6 Billion in 2021. Looking forward, IMARC Group expects the market to reach a value of US$ 1,052.25 Billion by 2027, exhibiting a growth rate (CAGR) of 3.02% during 2022-2027. Significant growth in the automotive industry across the globe and Increasing oil & gas production owing to the transportation industry’s demand is creating a positive outlook for the market. But with growth comes a lot of challenges in the steel manufacturing process. Companies in the industry face major challenges with rapid digitalisation and unlocking potential in data, shifts in consumer demands, and the attraction of top talents.

To address these challenges and improve profitability, the largest integrated producer of engineering steels and specialized seamless tubes in the Asia Pacific region has the foresight to expand its market in the coming years. In recent years, the leadership team has placed a greater emphasis on better asset utilization and process optimization.

Steel Plant & Tube Mill Challenges:

Failure of AssetsComplex procedures and important resources are used to produce steel tubes. Production and product quality are both impacted by the unforeseen failure of assets. It is not practical to inspect equipment frequently due to the harsh steel mill environment and the risks that inspection of rotating equipment poses to operator safety.

Mills in poor condition

A poorly maintained mill costs valuable time and scrap during setup and operation. The mill must be dependable so that the operator is not chasing mechanical problems during normal operation and setup. A good maintenance program, as well as rebuilds or upgrades when necessary, is essential.

Tube mill misalignment, poor mill condition, and inaccurate setup account for 95% of all problems in tube production. Most mills should be aligned at least once a year.

Low investment in technologyOne of the major problems which these industries face is the lack of incorporation of advanced technologies in Research and Development work in production. The same is the case for other sectors of the industry and has been the case for decades. One of the outcomes has been the relative unattractiveness of the sector vis-a-vis others among young engineers. With little research being done by the government or the private sector, Industries lack effective implementation of Industry 4.0 and technologies that can reduce risks and helps to cut overall production cost.

Process monitoringSteel mills’ inspection and monitoring process usually follow specific procedures, requiring that workers operate in a typical analog way. Since it is a critical environment, stopping production to execute corrective actions is unfeasible, and the current method for monitoring these problems is not able to predict failures in the same way as intelligent predictive models do, thus demonstrating an inevitable gap to errors.

Lack of Talent and TrainingEven though the operators are skilled and trained to operate in tube mills, there are still some challenges and issues that they need to face every day. Tube mill owners should arrange training sessions on how to troubleshoot the problem and figure out what was causing the problem. If these problems are not addressed properly, aluminum fabrication, steel fabrication, or stainless-steel fabrication processes won’t have precise tubes and pipes to work with.

MaintenanceBesides the difficulty in performing the inspection itself because of the hostile environment of steel industries, the maintenance of the encountered problems is also difficult.

The corrosion of equipment and structures is also a common problem in these industries and the maintenance of these components is very complicated because of the hostile environment, as mentioned before. Besides, the diversity of complex processes in this industry also makes it difficult to understand the extracted data in the operation, and the improper management of this information in diffuse systems compromises the maintenance of the structures.

Because of this lack of precise management tools, failure prediction in the operation is not usually achievable, leading to unplanned shutdowns and the extensive use of corrective maintenance methods.

Our Solution:

With the advent of Industry 4.0, predictive maintenance has gained huge popularity in maintaining machine health. Predictive maintenance is aimed at reducing costly and unplanned downtimes and offers organizations to plan maintenance schedules in advance for increased efficiency. According to McKinsey, predictive maintenance typically reduces machine downtime by 30% to 50% and increases machine life by 20% to 40%.

CIMCON Digital’s VIBit is an intelligent, powerful, and compact sensor that monitors the conditions of machines or equipment and predicts their failures in advance using the latest AI/ML Technologies to avoid unplanned downtime saving time and money for the owners.

We set up VIBit, a platform for detecting and diagnosing machine anomalies so that we could track the real-time performance of crucial machinery and processes throughout the year. VIBit Tri-axial vibration, Temp, and audio sensors installed on rotary equipment transmit machine health data over Plant’s Wi-Fi. AI/ML algorithms on the edge platform provide early machine anomaly detection along with diagnostics and recommendations for corrective and preventive action.

It can be used in Steel Tube Plant Asset and Fault Diagnostics to identify faults like bearing failure, misalignment, and electrical faults in types of equipment like De-scalar: motor/pump, Fume extraction system: motor/pump, etc.

Benefits of setting up a VIBit:

Real-time monitoring of critical equipment’s health on a single dashboard.

Prioritize and plan maintenance action before catastrophic failure.

Reduce the risk of operator safety with remote monitoring.

Reduce planned downtime and eliminate unplanned downtime.

Reduce process and quality-related issues.

Increase equipment efficiency and reduce carbon emissions.

In conclusion, the steel and metal industries are undergoing significant changes and it is important for manufacturers to adopt technologies that can assist in reducing manual labour, leveraging data, and improving asset health. By embracing the latest technological advances, steel and metal manufacturers can use predictive analytics to anticipate failures and proactively take action to reduce unplanned downtime and improve plant efficiency.

#Steel Industry#Metal Industry#Steel Manufacturing#Predictive Maintenance#IoT#Digital Transformation#Smart Manufacturing#IoT sensors#Industrial IoT solutions#Unplanned Downtime in Manufacturing#net zero sustainability#Factory 4.0

0 notes

Photo

Augmented Reality (AR) and the Internet of Things (IoT) are promising technologies that can unlock the full potential of manufacturing. Here’s how the AR and IoT combination transforms the manufacturing domain. >> https://www.rejigdigital.com/blog/benefits-of-ar-iot-in-manufacturing/

0 notes

Text

Trinetra T-Sense has a vision to provide innovative solutions integrating intelligent IoT elements. The hardware design and cutting edge software are leveraged to deliver high quality industry specific solutions that create value for partners and clients present across the world.

#iot solution and services#IoT Connected Platform Solutions#iot device management platforms#iot solution provider#industrial iot platforms#iot device management#iot application platform#new iot devices#embedded iot solutions#iot service platform#industrial iot solutions

1 note

·

View note

Link

Low-code no-code approach has assisted companies to maintain competitiveness by adapting to changing business needs effectively. Considering the current business scenario, upcoming trends, and advancing technology, we can assume that low-code platforms will play a vital role in accelerating digital transformation.

Solution Analysts provides enterprise application solutions based on Out systems Low-code No-code platform. We follow all the standards of enterprise app development to come up with customized and user-friendly applications. Visit our website or simply mail us at [email protected].

0 notes

Link

#industrial iot platform#industrial iot devices#industrial iot solutions#product design deveopment#product engineering services#product engineering solutions#IOT Consulting Services#Iot and AI solutions company#IoT Services#iot solutions#IoT Devices#teksun inc#teksuninc

1 note

·

View note

Text

In this blog post, we’ll discuss what you should consider when deciding between mobile and Wi-Fi networks for your hotel’s IoT connectivity. Read More....

#IoT Connectivity#Connectivity#Pbx System in Texas#VoIP#PBX System#VoIP Advantages#Hotel Phone System#Modern Telephone#Business Phones#hospitality industry#hospitality communication#communication solutions#VoIPCall

4 notes

·

View notes

Text

IoT Solutions for Industrial Manufacturing: The Case of Nanoprecise

Nanoprecise Sci Corp is revolutionizing the industrial manufacturing landscape through its cutting-edge IoT solutions. By integrating advanced sensors and AI-driven analytics, Nanoprecise offers a comprehensive suite of products that enable real-time monitoring and predictive maintenance of machinery. This technology significantly enhances operational efficiency, reduces downtime, and lowers maintenance costs.

Nanoprecise's IoT solutions stand out due to their ability to provide granular insights into machine performance and health. The system collects data on parameters such as vibration, acoustics, temperature, and humidity, which are then analyzed to predict potential failures before they occur. This predictive maintenance capability is crucial for manufacturers looking to avoid costly unplanned outages and extend the lifespan of their equipment.

Moreover, the implementation of Nanoprecise’s IoT solutions facilitates a shift towards smart manufacturing. By leveraging big data and machine learning, manufacturers can optimize production processes, improve quality control, and achieve greater flexibility in operations. The seamless integration of these technologies into existing manufacturing systems ensures minimal disruption while delivering maximum value.

In essence, Nanoprecise is not only enhancing the efficiency and reliability of industrial operations but also paving the way for a more connected and intelligent manufacturing ecosystem. Their innovative approach underscores the transformative potential of IoT in industrial settings, making them a key player in the ongoing digital transformation of the manufacturing industry.

0 notes

Text

IoT Services for Blockchain Initiatives- Mobiloitte

Empower your IoT initiatives with Mobiloitte's robust blockchain services. Our solutions integrate IoT devices with blockchain technology, ensuring secure data transmission, tamper-proof records, and streamlined processes. Leverage the potential of blockchain to enhance trust, transparency, and efficiency in your IoT projects. Explore mobiloitte for transformative IoT solutions today.

#iot solutions for manufacturing#telecom iot platform#agriculture iot solutions#iot in gaming#iot in biotechnology#iot automation solutions#iot solutions for education#iot solutions for hotels#iot in hospitality industry#smart home iot solutions#iot solutions for transportation#blockchain iot app development company#blockchain iot software development company

0 notes

Text

IoT Device Selection

IoT App Development Company: Everything You Need To Know

Get a balance between quality, cost, and time with superior IoT Services for dealing with your business challenges in the best possible manner. We serve global clients with boastful services on a varied scale, with end-to-end network vs. device integration services with the most innovative solutions. Optimize your IoT strategy with meticulous IoT device selection tailored to your goals.

Benefits of IoT Development

The Internet of Things (IoT) is the technology that allows businesses to integrate their service via secondary devices. With IoT, you can build user-friendly apps compatible with various devices, operating systems, and screen resolutions. You can also integrate your smart apps with third-party apps using secure APIs and collect vital user data and behavior on the mobile application to personalize the experience even further.

How to choose a reliable partner for IoT Development?

While analyzing an IoT vendor partner, you should prioritize secure organizations that behold strong web security and development. You must also adopt Full-stack organizations and companies that can establish an ‘all-in-one’ solution that manages a single project’s hardware, mobile interface, and web interface. Opting for a vendor offering these development capabilities and improvements is a much safer bet.

Why TechAhead for IoT App Development?

With over 13+ years of experience delivering cutting-edge digital transformation and mobility solutions, TechAhead has been a major digital partner for globally established companies like Disney, Audi, and American Express. Clutch has ranked us among the top IT IoT development services companies and the top multicultural companies with a strong-willed presence across Los Angeles and Noida.

Who is the top IoT development company?

TechAhead, of course! We have been accelerating business agility and stimulating digital transformation since 2009. Our company was recognized last year as the top IT service provider by Leaders Matrix, an industry-recognized, unbiased ranking entity.

We disrupt the traditional outsourcing model of other IoT companies. We ensure long-term and sustainable success for our customers and the mobile and digital ecosystem. Our relationships with our customers go beyond transactional. Our software development services give entrepreneurial ideas life. We infuse existing mobile and digital platforms with innovation and creativity.

What are the top IoT Apps developed by TechAhead?

We are a world-class digital transformation and mobility solution company and have delivered over 2,000+ project developments on Android, iOS, and cross-platform compatible apps for global brands. We recently announced the launch of “The Healthy Mummy” fitness app, which was recently ranked the world’s #1 Mum’s fitness app, attracting over 2M+ users and adding to many of our success stories.

What about Data security and integrity of IoT Apps?

All TechaAhead development practices are highly efficient and secure thanks to meticulous adherence to security practices and data governance at every step. Our development process considers the devices connected, cloud computing requirements, IoT platforms, and security while developing IoT mobile applications. We ensure that our IoT apps follow all the guidelines and protocols for the highest security.

How to get IoT app maintenance help and post-launch support?

Our role remains strong after the go-live. TechAhead takes full responsibility for the smooth functioning of IoT solutions in your company. With platform support services, maintenance, and the support of process management, our team will monitor your app’s success, it’s adaptability and remove any bugs/errors as per our client’s business needs and user reviews.

In conclusion, the world of IoT app development is a realm of boundless possibilities. Through TechAhead's expertise and commitment, businesses can harness the power of IoT to create user-friendly apps, ensure data security, and drive innovation. TechAhead's track record of success, recognition, and dedication to post-launch support make it a reliable partner in the journey of IoT app development. With a focus on disruptive innovation and holistic relationships, TechAhead is poised to continue shaping the landscape of IoT solutions, delivering transformative results for businesses worldwide!

#IoT software development services#embedded software development services#IoT device selection#IoT strategy consultation#IoT data visualization tools#edge computing for IoT#IoT network protocols (e.g.#MQTT#CoAP)#IoT user experience design#AI in IoT solutions#IoT and blockchain integration#IoT app design services#IoT app development#IoT device integration#IoT data analytics services#IoT security solutions#custom IoT application development#enterprise IoT services#industrial IoT solutions#IoT firmware development#IoT cloud integration#IoT connectivity solutions#mobile app development#software development#TechAhead Corp#TechAheadCorp#techaheadcorp.com

0 notes

Text

MELSS provides robotic solutions after careful study of your requirements and brings you a diverse range of solutions from the leading brands - Doosan and OnRobot . The range is also augmented by a set of tools and accessories.

The Lift100 from OnRobot is one such tool.

It increases the reach of a robot, enabling more cycles even in remote locations. Not only does the Lift100 offer the seventh axis to traditional six-axis robots, but it is also future-proof for palletising and other manufacturing applications. Its capability to handle high payloads with minimum deflection ensures precise positioning even at high speeds. Robustly built, it is reliable over a long period. Pallet stations for pallet positioning, along with #palletising software make it a complete package.

For more: https://zurl.co/qYEK

#Robotics hashtag#EndOfArmTool hashtag#Lift100#melss#industrial automation and robotics#automated test equipment manufacturers#industrial iot solutions india

0 notes

Text

#IoT Sensors Market#Smart IoT Sensors#IIot Sensors#Wireless IoT Sensors#IoT Enabled-Sensors#IoT Sensor Solutions#IoT Sensors and Devices#Industrial IoT Sensors

0 notes

Text

youtube

VIBit - State of the Art Intelligent Vibration-Based Predictive & Prescriptive Maintenance Solution

CIMCON Digital’s VIBit is an intelligent, powerful, and compact sensor that monitors the conditions of machines or equipment and predicts their failures in advance using the latest AI/ML Technologies to avoid unplanned downtime saving time and money for the owners.

Machine Anomaly Detection and Diagnostics Solution:

Our Cloud-based Health Management platform is a powerful tool for reducing maintenance spending and increasing Mean Time Between Repairs (MTBR) by proactively identifying detrimental system conditions prior to catastrophic machine failure by using an Artificial Intelligence/Machine Learning (AI/ML) model to provide FFT graph analysis, asset health monitoring, real-time data, and historial data. It provides a dashboard that helps you understand the overall equipment efficiency of assets in the form of waveforms. This further reduces unplanned downtime, increases equipment availability, and significantly reduces inventory costs.

Benefits:

Decrease Downtime

Eliminates Human Error

Reduced Service Costs

Improved safety

#Steel Industry#Metal Industry#Steel Manufacturing#Predictive Maintenance#IoT#Digital Transformation#Smart Manufacturing#IoT sensors#Industrial IoT solutions#Unplanned Downtime in Manufacturing#net zero sustainability#Factory 4.0#Youtube

1 note

·

View note