Text

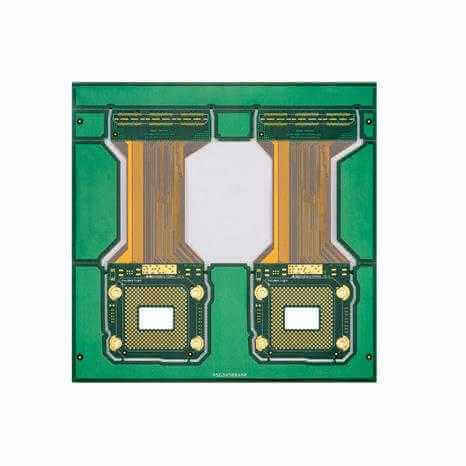

A Guiding Steps For Flexible PCB assembly.

On the surface, the standard flexible PCB assembly seems straightforward to make. However, the construction of these boards involves various additional procedures. The primary step for the rigid-flex board is typically the flex layer, which is either double-sided or single-sided Layer. Rigid-flex PCB fabrication may begin using the foil, laminated before or after the flex. This PI film is unclad…

View On WordPress

0 notes

Text

Ultimate guide to know about RO4350B PCB manufacturer

Laminations are typically used to create high-frequency flexible pcb manufacturers which are utilized for defense and aerospace applications such as radars, electronic warfare equipment, satellite communications, among others and so on. The high-performance PCB materials allow circuits to work with reliability using mm-wave or frequencies in the microwave range that extend beyond 10 GHz.

RO4350B PCB Material Properties

RO4350B PCB manufacturer is a reinforced glass polymer-based fluoropolymer composite circuit board that is designed to meet the most stringent standards for microwave and mm-wave circuit specifications. Dielectric constant (Dk) is 3.48 for 10 GHz

Tangent with lower loss 0.037 0.0037 at 10 GHz

A glass-reinforced woven ceramics and hydrocarbon infused with the PTFE composite

Good thermal conductivity of 0.69 W/m/K

Design Considerations

Rigid flex pcb manufacturer Is the layout of a RO4350B motherboard intended for use by the military, should be able to take into consideration the following factors:

Controlled Impedance

Set the impedance of the trace and ensure that they match to the RF IC connections

RF Shielding

Make sure you have adequate shielding enclosures to control emissions

Minimal Passives

Limit passive components in such a way that you can reduce the loss of higher frequency.

RF Transitions

Carefully design components/connectors interfaces

Thermal Management

Make use of thermal vias along with the backing of a metal sheet to disperse the heat

Reliability Testing

Subject prototypes subject to thermal cycling, vibration and tests for shock

PCB Fabrication Process

RO4350B PCB manufacturer using specialized equipment to comply with standards of the military:

Material - Select RO4350B laminates from Rogers or other similar sources

The layer Count is an ad hoc measurement. Stackups can contain anywhere between four and 32 layers dependent on the degree of difficulty

Dielectrics-Combination of RO4350 prepregs with bondplies

Trace width-RF trace from the 3 millimeter mark all the way to the line, with spacing of 3 millimeters

Component Selection

The active and passive components on the PCB need to comply with the specifications for RF applications:

RF Transistors

Gallium arsenide (GaAs) Power transistors designed for radio frequency that work at frequencies higher than 10 GHz.

Power Amplifiers

GaAs, or GaN power amplifiers that are available from companies like Qorvo, Microchip, etc.

RF Connectors

High frequency SMP the SMPM connector and SSMP connectors are designed to work in frequencies in the microwave spectrum.

Passive Components

For assembly, the RO4350B PCB, it is necessary to have a exact SMT assembly as well as inspection and testing.

Solder Paste Printing

Apply solder paste for tiny RF components. Make sure you are distributing precise volumes.

Component Placement

Select and position the machine that can handle tiny chip pieces.

Reflow Soldering

Use the recommended thermal profile from the manufacturer of the solder paste. If you can, use nitrogen.

Read more related:

0 notes

Text

A Guide To Choose flex PCB assembly

These are the major steps in making flex PCBs assembly. The whole process of choosing the substrate materials, through-hole and mounting on surface along with connecting are included here. Besides there is a step concerned with quality assurance as well. Understanding industry-standard requirements; using the most modern inspection techniques and instruments we can produce a product that meets…

View On WordPress

0 notes

Text

XPCB: A Synthesis of Innovation and Precision in Flexible PCB Assembly Services

In a world that demands both rapid advancement and unwavering precision in electronic manufacturing, XPCB emerges as a preeminent solution, offering a decade of expertise in the creation and assembly of printed circuit boards (PCBs). Strategically located in China’s bustling technological hub, XPCB has built a formidable reputation for its steadfast commitment to excellence and quality. Their…

View On WordPress

0 notes

Text

Revolutionizing Circuit Board Design: A Deep Dive into XPCB's Services

In the dynamic world of printed circuit board (PCB) design and manufacturing, XPCB emerges as a luminary, particularly distinguished in the domain of flexible PCBs. The company's decade-long journey is punctuated by relentless innovation, unwavering dedication to quality, and an overarching commitment to client satisfaction. With a vast array of services, ranging from flex PCB prototyping to comprehensive manufacturing solutions, XPCB has solidified its reputation as a flexible PCB manufacturer and supplier par excellence.

Mastery in Flex PCB Prototyping and Assembly

The cornerstone of XPCB's service repertoire is its exceptional flex PCB prototyping. This critical step in the product development lifecycle is approached with a meticulous attention to detail, ensuring that each prototype is a testament to the company's commitment to quality. The journey from a prototype to a fully-assembled product is seamless, thanks to XPCB's proficiency in flex PCB assembly. Here, advanced Surface Mount Technology (SMT) and Through-Hole Technology (THT) are leveraged to perfection, ensuring that each assembly meets the stringent standards set by the company and expected by the clients.

XPCB's expertise in flex PCB assembly is complemented by a profound understanding of the nuanced challenges associated with flexible circuitry. The team's extensive experience serves as a bedrock, enabling them to navigate the complexities of various assembly requirements with ease and precision. This, coupled with a steadfast commitment to innovation, ensures that XPCB remains at the forefront of flex PCB prototyping and assembly, continually pushing the boundaries of what is possible and delivering products that stand as paragons of quality and reliability.

XPCB: Your Premier Flexible PCB Manufacturer and Supplier

As a leading flexible PCB manufacturer, XPCB is synonymous with excellence. The company's manufacturing capabilities are expansive, encompassing a wide range of flexible PCB solutions. Here, state-of-the-art machinery is operated by a cadre of highly-skilled professionals, ensuring that every product that leaves the facility does so with the stamp of quality that XPCB is known for. As a flexible PCB supplier, the company takes pride in its ability to provide clients with not just products, but solutions that are tailor-made to meet their specific needs and challenges.

The journey with XPCB, however, extends beyond manufacturing and supply. The company’s value-added services ensure that clients are supported at every stage of the product development and manufacturing process. From preliminary design reviews to comprehensive manufacturing support, XPCB stands as a beacon of support, ensuring that every client's journey from concept to creation is smooth, efficient, and ultimately successful. In doing so, XPCB not only solidifies its position as a premier flexible PCB manufacturer and supplier but also as a trusted partner in innovation and excellence.

0 notes

Text

Demand of Flexible Pcb Manufacturer

The increasing need for compact and high-efficiency electronics has prompted a transition to flexible PCBs. Unlike their rigid counterparts, flexible PCBs offer adaptability, allowing them to conform to various shapes while maintaining their functionality. Consequently, industries ranging from aerospace to medical devices are actively in search of proficient manufacturers of flexible PCBs who can meet these demands.

0 notes

Text

Best Rigid-Flex PCB Fabrication

The fusion of flex PCB assembly and rigid-flex PCB fabrication techniques hints at a promising horizon for electronic design. Engineers and designers are equipped with tools that provide unparalleled versatility. This opens the door to envisioning electronics that not only excel in efficiency but also embrace a more innovative design philosophy. Consider a world where foldable tablets and phones become the standard, illustrating just one of the exciting possibilities.

0 notes

Text

Rigid Flex Pcb Manufacturer in California

This manufacturer of Rigid-Flex PCBs prioritizes minimal space utilization, offering an ideal solution for intricate electronic setups. Their durability sets a benchmark, while their design streamlines assembly, making them the preferred choice across various sectors, ranging from automotive to consumer electronics.

0 notes

Text

The Future of Circuit Boards: Rigid Flex PCB

In the realm of electronics, the unsung heroes are often the circuit boards that bring our favorite devices to life. Among the varied choices, the seamless convergence of flexibility and rigidity in one circuit board stands out. Enter the world of Rigid Flex PCB.

Innovations from a Leading Rigid Flex PCB Manufacturer

One cannot delve into the world of Rigid Flex PCBs without acknowledging the…

View On WordPress

0 notes

Text

RO4350B Printed Circuit Board Manufacturing

RO4350B PCB manufacturing involves precise design, fabrication, and assembly techniques to meet specific requirements, such as impedance control and signal integrity. These PCBs are widely used in applications like RF/microwave communication systems, radar systems, satellite communications, and high-speed digital circuits, where reliable and consistent performance is critical.

0 notes

Text

When You Selecting Flexible PCB Prototype

When searching for a flex PCB manufacturer, prioritize those with a proven track record and extensive experience in prototyping. Their expertise in designing and manufacturing rigid-flex PCBs and Flexible PCB Prototypes will assure high-quality results that perfectly align with your specific prototyping requirements. Trusting an experienced manufacturer will provide you with the confidence and assurance that your projects are in capable hands.

0 notes

Text

Chossing The Best Flex PCB Manufacturing

When in need of a substantial quantity of Flex PCB Manufacturing, it's essential to explore the possibility of volume discounts. Numerous manufacturers provide cost advantages for large orders, resulting in noteworthy cost savings for your overall expenses. By considering volume discounts, you can optimize your budget and obtain a more cost-effective solution for your Flex PCB requirements.

0 notes

Text

Future Of Flexible PCB Manufacturer

As 5G technology takes center stage and IoT devices continue to proliferate, the demand for high-speed applications is surging. To cater to this growing need, Flexible PCB Manufacturers are embracing cutting-edge materials and manufacturing techniques. These advancements are vital to meet the stringent requirements of high-speed signal transmission. Rigorous signal integrity analysis and precise impedance control techniques are now employed to ensure peak performance in these challenging applications.

0 notes

Text

Future Of Quick Turn Rigid Flex PCB Manufacturing: 4 Key Trends Shaping The Industry

The field of rigid flex PCB manufacturing is constantly evolving, driven by advancements in technology and the demand for more compact and flexible electronic devices. As we look to the future, several key trends are shaping the industry and revolutionizing the way these specialized PCBs are designed and produced.

1. Miniaturization:

The demand for smaller, lighter, and more portable…

View On WordPress

0 notes

Text

Rogers PCB manufacturer - X-Pcb

Radio Frequency PCB technology that has been growing quickly in recent years. It is widely used in various fields like satellite communication systems, military equipment, broadband access, and optical data networks. RF PCB operates within a frequency range of 500 MHz to 2 GHz. Once the design work is completed, the two important steps in the Rogers PCB manufacturing process are prototyping and volume production.

0 notes

Text

Best Quick Turn Flex Circuits

In the fast-paced world of electronics, quick turn flex circuits have become essential for rapid prototyping and product development. XPCB specializes in the production of quick turn flex circuits that enable you to bring your ideas to life in record time.

0 notes

Text

Revolutionizing Electronics with XPCB's Flex PCB Assembly

Through rigorous quality control measures, XPCB guarantees that every flex PCB assembly meets the highest industry standards and specifications. This attention to detail ensures that the final product is reliable, efficient, and performs optimally, reducing the risk of product failure and minimizing costly repairs or recalls.

Visit :

0 notes