Text

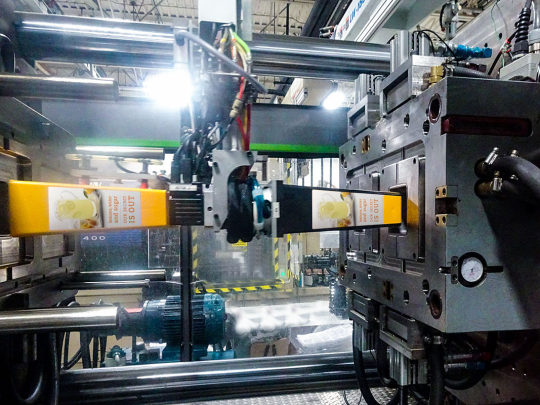

How To Buy The Right Used Nissei Injection Molding Machines

Selecting the right used Nissei injection molding machines for your business needs can be a challenging task if you don’t know what to look for. You want to make sure that the machine you are choosing can serve your business needs well. The following are some of the things you should pay attention to when making your selection.

Before you go ahead to buy a used Nissei injection molding machines, you should find out whether it supports full injection. You should calculate the shot weight requirement according to your product’s weight and mold’s cavities. The formula is shot weight = product weight x cavities. You need to make sure that the injection machine’s shot weight is a bit bigger compared to your requirement.

You should need to make sure that the injection molding machine that you are choosing is well shot. You should adjust and select the right screw with L/D ratio and injection pressure. This is mostly depends on the type of raw material your product is. You should check for injection pressure of different materials in order to know which one is right for the materials you will be working with in your business.

Last but not least, you should check if the used Nissei injection molding machines you are considering have fast injection speed. In order to produce a quality product, the right injection speed is needed. This depends on the exact product, its material and mold design. You should check it out with the mold manufacturer first and make sure that the plastic injection molding machines can meet its requirement.

While finding the right used injection molding machine for your needs can take a bit of time and research, it will be worth it in the end.

For more tips on how to buy the right used nissei injection molding machines, visit us at https://www.premierplasticsnj.com/

0 notes

Text

How Used Plastic Injection Molding Machines Work

You are probably considering investing in used plastic injection molding machines if you want to venture into the business of producing plastic products and you do not have the finances to purchase a new machine. If you get a good used machine, it can serve you just as good as a brand new one.

Used plastic injection molding machine is a specialized machine that is used in the injection molding technology line. This machine adapts well to various products and has a high production capacity. So, it is widely used in the production of plastic products.

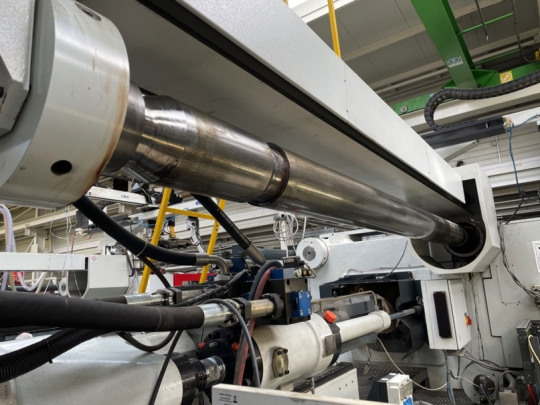

Before you go ahead to buy a used plastic injection molding machine to use in your business, it would be good to understand the structure of a plastic injection machine. This machine comprises of two components that are responsible for different jobs. The mold clamping part and the plastic injection part are very crucial.

Additionally, the mold clamp section divides into a fixed mold clamp part and a movable mold clamp part. Particularly, the fixed mold clamp holds the fixed mold part and the mold positions accurately thanks to the positioning ring on the mold and the positioning hole on the machine.

The movable mold clamp is used to clamp the movable mold half. This part is crucial and has the effect of parallel translation in the opening and closing direction of the mold. It performs the closing and opening of the mold in the plastic injection molding machine.

The movable mold of the machine also arranges to help impact the battery ejection plate to push the product out. Additionally, the plastic injection part is the part that is used to convert the material from solid to liquid by temperature. It pushes the molten plastic into the mold by pushing pressure through the screw and nozzle system.

For more information on how used plastic injection molding machines work, visit our website at premierplasticsnj.com

0 notes

Text

How To Buy The Right Used Nissei Injection Molding Machines

Are you looking for the right used Nissei injection molding machines to use in the production of plastic products in your business? When buying any second-hand machine, you need to do it carefully because there are some that can break down after serving you for only a short period of time. The following are some of the things you can do in order to make the process of choosing the right injection molder easier.

If you want to choose a used injection molding machine that will serve you well for many years to come, you will need to know the difference between a used and a refurbished unit. A refurbished unit is fixed, cleaned, and readied for long life, so it is the better option if you are looking for something long lasting. On the other hand, used equipment is more of a gamble because you may never know the real reason why it being sold. Maybe the seller is disposing the machine off because they have noted a number of problems with it.

Another thing you should do when looking for the right used injection machines to purchase is research. Keep in mind that a used machine is priced lower compared to a brand new unit because it tends to have some problems, such as loose parts or faulty components. When you know the parts that need to be replaced, you will have an idea about how to easily find a spare part and how much would it cost you.

You also need to decide where to buy the used Nissei injection molding machines. You can either go to manufacturer’s representatives (like those who take used machines for trade-ins) or purchase and sell vendors which that you can easily find on the web.

For more tips on how to buy the right used Nissei injection molding machines, visit our website at https://www.premierplasticsnj.com/

0 notes

Text

How To Buy Used Injection Molding Machines

If you have decided to start manufacturing plastic, one of the important things you should do is look for a good plastic injection molding machine to buy. It can be costly to invest in a new injection molding machine, so it is a good idea to acquire used injection molding machines if you are operating on a tight budget. The biggest benefit of a second-hand injection molding machine is good quality offers for a significantly lower price than the price of a new one.

When you start looking for the right used injection molding machines to buy, there are various factors you should take into consideration. First of all, you will need to decide what type of injection molding machine you need. Even though custom shapes are good shopping, there is a possibility that it will be quite expensive. To know the type of molding machine you want to buy, it is important to determine the design as well as shape of the final product.

If you want to make a unique shaped plastic part, it will be a good idea to choose a custom injection molding machine. In other respects, conventional injection molding machines work perfectly. The amount of money that you have to pay for each individual form is quite high because it is developed specifically for you.

Another factor to consider before buying a second-hand used injection molding machine is how much money you can spend on it. The answer to this question is not static. It will depend on various factors such as the age of the molding machine, the material of the manufacturer, the purchaser and so on. It is important to know how much you use for forming machines to be able to budget accordingly.

For more tips on how to buy used injection molding machines, visit our website at https://www.premierplasticsnj.com/

0 notes

Text

Purchasing Used Plastic Injection Molding Machines

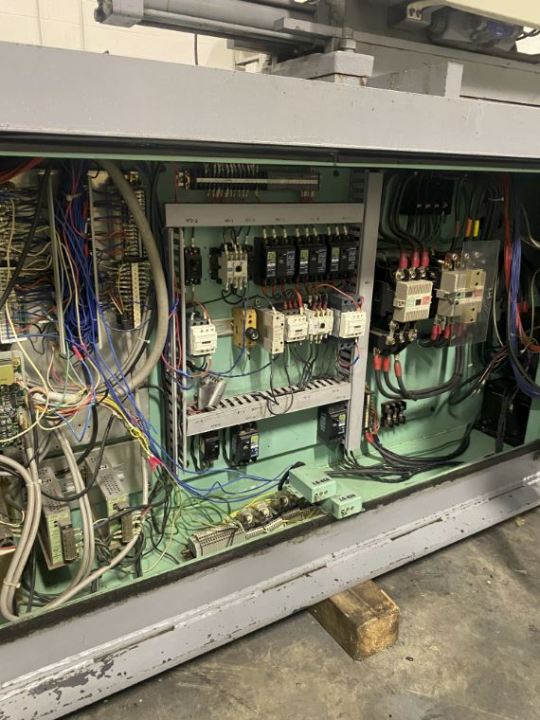

If you are looking for a used plastic injection molding machine, it may be best to start by examining your current equipment. You may be able to find a similar machine at a lower price, if you look around. There are a few factors to consider when purchasing a used machine, including whether you need a robotic interface or specific hydraulic and air functions. Then, you can start comparing prices of different machines, which can help you decide which machine will suit your needs best.

The most common plastic injection system mechanism is the reciprocating screw. In rare cases, two-stage screws are used. The plastic is fed into the mould through a screw, which rotates to melt it. The screw also acts as a ram to inject molten plastic into the mold. The screw is fitted with a non-return valve, which prevents back flow of melt along its threads. The screw itself can be made of a variety of materials, including ABS and PC, and can also be customized for a variety of applications.

The maximum clamping pressure on a plastic injection molding machine is 68 tons, and this figure does not include the clamping force. Clamping pressure is essential to the quality of the finished part, as too much or too little pressure will lead to poor results. Additionally, if the clamping pressure is too high, flashing will result. In addition, pressure has a direct impact on the viscosity of plastic, affecting the viscosity. MFI is a metric that indicates how easily a plastic compound flows under pressure. This factor is also considered when purchasing a used plastic injection molding machine.

For more information on purchasing used plastic injection molding machines, visit our website at https://premierplasticsnj.com/

0 notes

Text

How To Buy The Right Used Plastic Machinery

Selecting the right used plastic machinery to use in your business is easier said than done. Since you are about to purchase a machine that has ever been used before, you need to be very careful in your choice to avoid regrets. The right machine can help keep costs low and make you more competitive. This will allow you to sell more parts, earn more money and establish a reputation as a quality manufacturer.

As you search for the right used plastic injection molding machine to buy, there are various mistakes you will need to avoid. One of them is purchasing a used injection molding machine that does not work. The key to purchasing a reliable used machine is to find one that has been fully inspected and tested before it is delivered to your business so that you will not suffer loss of production due to multiple breakdowns.

Another mistake you should not make when looking for the right used plastic machinery to buy is selecting large screw diameters. Large screw diameters can lead to quality problems because of material degradation. When small shot sizes are used with large screw diameters, the plastic material is forced to spend more time being heated by the barrel heaters compared to large shot sizes. Material degradation is more likely to happen if the shot size is smaller than the injection unit’s maximum shot capacity especially for heat sensitive materials.

Large screw diameters also generate large shearing forces during screw rotation, which can also degrade the material and is likely to lead to reject parts. So make sure that you check the screw diameters of the machines that you are interested in before you go ahead to pay for them.

For more tips on how to buy the right used plastic machinery, visit our website at https://premierplasticsnj.com/

0 notes

Text

How To Choose The Right Used Nissei Injection Molding Machines

Buying used nissei injection molding machines may be a good alternative to buying new machines if you really want to get into the business of manufacturing plastic products but you are on a tight budget. Since you expect a lot from this machine, you need to choose one that will perform optimally. Some used machines may let you down after using them for a short while, so you need to be careful about which one you buy.

There are various important factors you should take into consideration during your search for the right used injection molding machine. One of them is the manufacturing company. Even though there are several excellent plastic injection molding companies, even among those, you will find stark differences in quality and pricing. So, it is good to start by identifying a trusted and reliable plastic injection molding machine company.

To be on the safe side, you should focus on manufacturing companies that specialize in supplying customers with this type of equipment. It would also be good if the company offers a broad range of products. This is especially important if you make a variety of products.

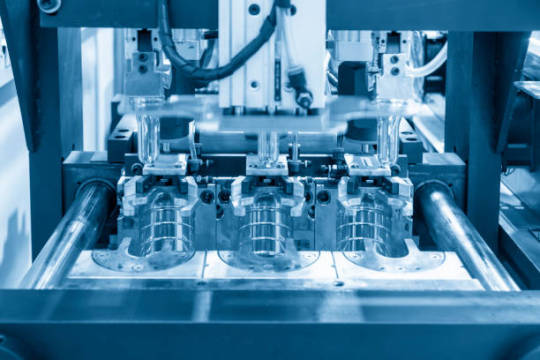

Another factor you need to consider when looking for the right used nissei plastic injection molding machines to buy is the size of the platen. As the table per se that holds the mold cavity, you want to make sure you have the appropriate size for your specific needs. The platen is what the clamped mold secures to as part of the injection molding process.

Last but not least, make sure that you check shot size. Remember that if you need guidance at any time, the plastic injection molding machine company you do business with will help. As for the size of the shot, it refers to the maximum amount of plastic that the machine can inject going into the mold cavity. The best option is a machine that can produce between 30 and 40 percent greater shot sizes compared to what the part requires.

For more tips on how to choose the right used nissei injection molding machines, visit our website at https://www.premierplasticsnj.com

0 notes

Text

How To Buy A Used Plastic Machinery

If you are looking to purchase used plastic machinery to use in the production of plastic products in your business, you need to know how to separate the best from the rest. This being a secondhand purchase you are about to make, you need to ensure you make the right choice in order to avoid regrets later on. If you choose the wrong machine, it may stop working shortly after using it, which will be a huge waste of your money.

There are a number of factors you should take into consideration as you look for the right used injection molding machine to buy. One of them is the size of the platen. The platen is simply the tool that holds the mold cavity. Spaced apart, the mold is inserted and clamped securely to the platens. Once the two platens come together and are held under the pressure of tonnage, the plastic is heated, injected under pressure, and then allowed to cool through a molding cooling cycle. The plastic takes on its hardened, final shape here while continuing to be kept in place with many tons of pressure to retain the desired shape.

Another factor you need to consider when looking for the right used plastic machinery to buy is tie bar spacing. The holes in the platen allow pins to pass through it, ejecting molds. Tie bar spacing refers to the space between the horizontal tie-bars on an injection molding machine. Basically, this measurement, along with the platen max spacing, is what determines the maximum size of molds that can be placed in the molding machine. So make sure that you check that before you go ahead to buy the injection molder you are interested in.

For more tips on how to buy a used plastic machinery, visit our website at https://premierplasticsnj.com/

0 notes

Text

How To Choose The Right Used Plastic Injection Molding Machines

Are you looking for reliable used plastic injection molding machines to use in the production of plastic products in your business? If you have been in the machine industry for quite some time, you know that plastic injection molding is just as relevant and important as any other machining process. There are many things to take into consideration when buying plastic injection molding equipment, like shot size, tie bar spacing, ejector stroke, platen size, and tonnage.

Shot size is the maximum amount of plastic that the injection molding machinery is can inject into the molding cavity during one molding cycle. The amount is rated in ounces of “general purpose polystyrene” (GPPS) for U.S. machines, and cm3 for European and Asian machines. When searching for a machine to use in your business, it is a good idea to look for one that is capable of producing 30 to 40% greater shot sizes than what your parts require.

Clamp tonnage or clamping pressure of an used injection molding machine could be considered the same concept as when you are examining press brakes. With press brakes, tonnage capabilities are measured by the number of tons of down force the machine can direct towards a work piece. However, with plastic injection molding machines, tonnage is measured by the number of tons with which the machine is capable of pressing together the platens, which hold the mold cavity and form the plastic that is injected into said cavity to produce the desired part.

The platen is the table or tool that holds the mold cavity. Spaced apart, the mold is inserted and then clamped securely to the platens. After the two platens come together and are held under the pressure of tonnage, the plastic is heated, injected under pressure, and then it cools through a molding cooling cycle.

Here, the plastic takes on its hardened, final shape while continuing to be kept in place with many tons of pressure to retain the desired shape.

For more tips on how to choose the right used plastic injection molding machines, visit our website at https://premierplasticsnj.com/

0 notes

Text

Used Plastic Injection Molding Machines

For more tips on how to choose the right used plastic injection molding machines, visit our website at https://premierplasticsnj.com/

0 notes

Text

Used Nissei Injection Molding Machines

For more tips on how to choose the right used nissei injection molding machines, visit our website at www.premierplasticsnj.com

0 notes

Text

Used Injection Molding Machine

For more tips on how to choose a good used injection molding machine, visit our website at https://www.premierplasticsnj.com/

0 notes

Text

Used Plastic Machinery

For more tips on how to buy the right used plastic machinery to use in your business, visit our website at https://premierplasticsnj.com/

0 notes

Text

Used Injection Molding Machines

For more tips on how to buy the right used injection molding machines, visit our website at https://www.premierplasticsnj.com/

0 notes

Text

How To Buy The Right Used Injection Molding Machines

Buying used injection molding machines to speed up the production of plastic products in your business can be much easier if you know the right steps to take. If you manage to get a good used injection molder, you will be up for good quality offers at a lower price compared to a brand new machine. The following are some tips to help you make the right choice.

One of the important things you should do when looking for a good used injection molding machine to buy is consider the size of the injection unit that can be used by the injection molding machine you use. Most manufacturers usually have two injection units to choose from. To select the right one for your production needs, you need to calculate the shot size as a percentage of the machine's injection power.

Another thing you should do when looking for the right used injection molding machine to buy is check the warranty and make sure that proper inspections are performed prior to purchase. This check should determine the parts that are working properly and which parts need to be repaired or replaced.

If the used injection molding machine is running, make sure that you check before shipping. If this is not possible, you should ask the seller for a video that shows is playing, with a short activity on the monitor screen, the end of the injection with the fast running of the rest of the surrounding machine. Watching the machine in person or via video should be a prerequisite for purchase. Since you will be spending a significant amount of money to acquire the machine, you need to be sure that you are making the right choice.

For more info on how to buy the right used injection molding machines, visit our website at https://premierplasticsnj.com

0 notes

Text

How To Choose The Right Used Plastic Machinery

If you are looking to get into the business of manufacturing plastic products and you are not able to buy a new injection molding machine, you can start off with a used plastic machinery. Not all used injection molding machines are bad. If you take your time to search for a good one, it can work just as good as a brand new injection molding machine.

So, where is the best place to search for used plastic machinery to use in your business? One of the first places you should look for used plastic injection molding machines is in trade journals and magazines. Most of them contain advertisements from various manufacturers. When you start going through these ads, you can locate a manufacturer that is advertising on a regular basis and they will have their own ad for you to peruse over. That way, you can be able to find out about any new or used machines that they may have and what they have to offer you.

You can also look for the right used injection molding machine to buy on the World Wide Web. There are a large number of different websites out there that have information about injection molding equipment. It is important that when you are searching for a used injection molding machine, you should take the time to browse through as many different sites as possible. You should not make the final decision without knowing all of the information that you can possibly get your hands on.

There are a number of other places that you can look for used plastic machinery as well. For instance, you may be able to locate used injection molding machines at factory liquidation sales and auctions. In some cases, you can even be able to find pieces for sale and repair old machines. The most important thing is that you need to put in the time necessary so as to ensure you are finding the best deals possible.

For more tips on how to choose the right used plastic machinery, visit our website at https://premierplasticsnj.com/

0 notes

Text

How To Choose The Right Used Nissei Injection Molding Machines

Buying used nissei injection molding machines may be a good alternative if you would like to venture into the business of manufacturing plastic products but your budget does not allows you to but a new machine. Provided you get a used plastic machinery that is still in good working condition, it can work as good as a new one and generate enough profit for your company.

To make your selection of the right used injection molder easier, there are various factors you should take into consideration. One of them is the shot size. Remember that if you ever need guidance at any time, the plastic injection molding machine company you are buying the machine from can help. The shot size refers to the maximum amount of plastic that the molding machine can inject going into the mold cavity. To be on the safe side, you should look for a machine that produces between 30 and 40 percent greater shot sizes than what the part requires.

You also need to check the tonnage of the injection molding machine you want to buy. This is the clamping pressure that the equipment delivers. The number of tons the molding machine is capable of producing when pressing the platens together is how experts measure tonnage.

Another factor you should consider as you look for the right used nissei injection molding machines is the ejector stroke. This is the action of the machine as it ejects the completed workpiece from the platens. Once the plastic heats, moves into the mold, shapes the product, and then cools, the ejector stroke is what releases the finished product. This process makes use of ejector pins, which help with the pushing action.

For more tips on how to choose the right used nissei injection molding machines, visit our website at www.premierplasticsnj.com

0 notes