Link

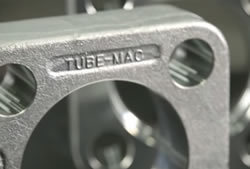

A weldless pipe fitting system is a replacement technology for welded pipe fitting, which are mainly used in pressure piping system for oil, gas, and more applications. There are so many types of pipe fitting used in industries. It also allows flexibility to change the pipe direction and is also available in various types. To know more visit: https://tube-mac.com/en/

0 notes

Link

Tube-Mac® Piping Technologies Ltd. is known as a reliable non-welded piping system supplier that utilizes technologically advanced non-welded 37° flare and retains ring flanges and PYPLOK® connectors as a more cost-effective alternative to welded piping systems. The company was founded in 1977 as a piping system repair and installation business. The firm has since grown into a progressive worldwide company with Tube-Mac® offices in Canada, USA, Spain, Austria, and Brazil, distributors and agents throughout North America, Europe, Scandinavia, Asia, and the Middle East.

0 notes

Text

What Essential Things You Should Consider to Select Mechanically Attached Fittings?

Summary:

Traditional pipe-joining approaches for shipbuilding are time taking and can stance momentous security apprehensions with the use of a torch or blaze for welding and brazing pipe associates. Along with security apprehensions, these approaches present effectiveness, employment, and regulatory contests. These challenges and apprehensions can be resolved with the connection of mechanically attached fittings (MAFs), rather than pipe furnishings that need welding or brazing. In this article, we will discuss some tips that you should consider for choosing mechanically attached fixtures.

Body:

MAFs, or mechanically attached fittings, are pipe-joining approaches that use alternative approaches to keep pipes composed with the same presentation as-welded or brazed fixtures. They come in dissimilar variabilities depending on fastening and sealing approaches, i.e., press, bite, and slip-on.

These categories of innovative fixtures are multipurpose and can offer reliable connections without the necessity for fire watches or hot work authorizations. They endorse considerable labor reduction with constant first-time superiority and abridged testing/contracting of systems. It is ideal to find one of the best non-welding piping solution providers for buying mechanically attached fittings, weldless fittings, flare flange, and many others at the best possible price. Below, I’m going to share some important things that you should consider for choosing mechanically attached fixtures.

· Innovations In MAFs

One of the recent inventions in MAF expertise is the overview of hybrid fixtures, which combine structures from the bite, press, and grip-type furnishings. These fixtures contain a sleeve, grip ring, sieve ring, and sealing component. The grasp ring with bidirectional teeth grips the outside surface of the tube and locks the fitting to the pipe. The continuous firmness crops a positive, non-detachable powered joint.

· Types Of Mechanical Joints

There are three categories of connections for power-driven joints that are recognized for steel containers: pipe unions, compression couplings, and slip-on joints.

· Qualifying A MAF

MAFs are qualified grounded on temperature and pressure competencies. They are also categorized according to different thresholds as Class I (high temperature and pressure competence), Class II (mid-temperature and pressure competence), and Class III (low temperature and heaviness capability). These are well-defined by the operative necessities of the systems in which they are used.

MAF prerequisite is based on preventive testing that authenticates system presentation, longevity, and security. When choosing what kind of MAF to comprise in the requirement procedure, it is imperative to deliberate endorsements, presentation, ease of use, constancy, tooling, situation, and fitting price.

· Safety And Quality Benefits of Selecting MAFs

MAFs are innocuous, effective, and eradicate the requirement for hot work, fumes, and gases. They also do not need bulky apparatus to take down, reposition and arrangement. Installing MAFs decreases lifting and affecting heavy substances, which lessens the load on the labor force as well as decreases welding-related accidents and injuries. The installer is moveable and can move deck to deck connecting furnishings using a hand-held battery tool, as well as a distinct spark-free device for dangerous/confined places.

Accelerating pipe connections by using MAFs lets other trades like painting, lagging, and electrical work in a similar area, so proceeding with the whole project schedule and not just the piercing. MAFs are a decent resolution for plummeting a ship’s early build cost for the new structure, as well as dropping the overall price of ownership when applied for retrofits, transformation, and permanent maintenances while underway.

· The Future of MAFs

In the approaching years, advanced technology, like hybrid MAFs, will ultimately rewrite the business rules. By compounding the best expertise and qualities from the bite-, press- and grip-type fittings, the dependable and strong influences made by hybrid furnishings have the potential to make new morals for building and overhauling ships.

Conclusion:

All types of MAFs are not equal. So, it is important to select consistent, safe, and easy-to-install mechanically attached fittings that will advance shipbuilding expertise into the twenty-first century.

About the Author:

The author is associated with a piping system repair and installation business, capable of providing field technical services to train local contractors or shipyard personnel on the proper use of pipe fabricating equipment and installation of non-welded piping systems. The company is also known as one of the best split flange suppliers that provide a wide range of products including non-welded 37° flare, retain ring flange, weldless fittings, mechanically attached fittings, supplemental products, and many others at affordable process.

0 notes

Link

Tube-Mac® Piping Technologies Ltd. is founded in 1977, a leading worldwide business in piping system repairing and installations. We operate in multiple locations which includes Canada, Spain, USA, Austria, and Brazill.

0 notes

Link

Tube-Mac® Piping Technologies Ltd. is a top global supplier of non-welded piping systems and components. The company was founded in 1977 as a piping system repair and installation business

0 notes

Text

Why Non-Welded Piping Systems are Perfect for High Pressure Applications

Pipeline systems are used to transport liquids, gases, and slurries by conveying the product through a pipe. There are many benefits of non-welded piping that make them perfect for high-pressure applications such as oil & gas refineries and offshore. The piping system is more economical than the conventional ones because there is no need to purchase expensive welding equipment or hire skilled workers with extensive training in this field.

Let’s check why non-welded Hydraulic Piping Systems are perfect for high-pressure applications.

1. There’s Less Downtime

If a problem occurs with hydraulic pipes, it can be fixed with relatively less downtime. Parts such as fittings and valves are easily accessible on-site for companies rather than waiting for the engineering department to make repairs. There will also be fewer after-hours service calls due to this factor alone.

3. They're Easier to Clean and Inspect

Non-welded hydraulic piping systems also have the advantage of being easier to clean and inspect. Since they are not welded, there's no need for expensive cleaning equipment or technicians with special skills to conduct these tasks. This can save a company money on maintenance costs since it is cheaper than welding expenses such as purchasing the required equipment, hiring experienced operators, etc.

4. Less Risk of Leaks and Breaks

There is less risk of leaks or breaks in non-welded piping sets. Since it's not welded, there are no weak points along the juncture where two pieces meet together. For example, if a leak does occur due to faulty welding on a standard pipe set, it can often lead to complete failure of the component due to connection at various angles. This causes uneven pressure distribution within the system resulting in bends under high pressures. The small cracks caused due to this ultimately result in breakage after prolonged usage.

5. They're Environmentally Friendly and Safe

Non-welded piping systems are also environmentally friendly. Since there's no need for welding, this eliminates the hazards associated with it, such as dangers of fire or explosion due to gas leaks from pipelines. In addition, these pipes do not use toxic chemicals in their manufacturing process because they only require a few pieces that can be easily assembled without additional materials. This reduces costs even further since there is no longer a requirement for hazardous substance disposal, saving both time and money by eliminating these expenses.

6. They're Durable

Non welded piping systems are also more durable than their welding counterparts. Since there is no need for additional materials, they can be produced faster and don't require additional time to finish the process, saving both money and resources. Also, non-welded hydraulic piping systems are very resilient due to the simple design that allows them to endure even under harsh conditions without breaking or leaking fluids.

0 notes

Link

Non-welded piping solutions are ideally suited for the offshore, industrial and marine markets that offer many benefits to design project engineers and specifiers. So, as you look for advantages of hydraulic pipe fittings, you should look at what benefits non-wielded piping will provide you. Here we have discussed four benefits of non-welding piping solutions in oil and gas applications.

https://tube-mac.com/en/products/supplemental-products

0 notes

Link

Tube mac is the best manufacturer of oil flushing, pressure testing services. We deliver a wide range of oil flushing services, pressure testing units, and piping systems equipped with a vast amount of resources to deliver superior results for your unique needs. Contact us for more details or visit our site!

https://tube-mac.com/en/services/oil-flushing-pressure-testing

0 notes

Photo

The Most Successful Piping Technologies Ltd Company In Region

Tube-Mac is the top leading Global Supplier of Non-Welded Piping Systems. We provide services to worldwide industry non-welded piping systems, components, mechanically attached fitting, and installation. Tube-Mac Piping Technologies Ltd. is known as a reliable non-welded piping system supplier that utilizes technologically advanced non-welded 37° flare and retains ring flanges and PYPLOK connectors as a more cost-effective alternative to welded piping systems. To know more visit here.

https://www.prfree.org/@tubemac/tube-mac-piping-technologies-ltd-a-global-supplier-of-non-welded-piping-systems-retain-flanges-and-many-others-jekrer554mxr

0 notes

Photo

The Ultimate Guide for Types and Applications of Hydraulic Pipe Fittings.

Tube-Mac is a heavy-duty supplier of Hydraulic Pipe Fittings. Tube-Mac supplies and uses only the finest hydraulic hoses and couplings which meet and exceed SAE standards. They are used for connecting the hydraulic pump to several components including hydraulic cylinders, pipes, tubes, or different kinds of hydraulic hoses in hydraulic systems. They also have some types of Hydraulic Pipe Fittings like Petroleum-Based Fluids, Water-Based Fluids, Synthetic-Based Fluids. Get more details.

https://theomnibuzz.com/what-are-the-types-and-applications-of-hydraulic-pipe-fittings/

0 notes

Photo

Get the best Hydraulic Pipe Flanges by Tube-Mac Piping Technologies

Hydraulic piping provides transportation for fluid from one component to another. It provides an inherent versatility to designers at times. Tube-Mac Piping Technologies provides best services like Hydraulic piping . It is a very important part of the system to enable components to be positioned inside the most efficient places.

https://www.sharepresentation.com/alcottsmith1077/hydraulic-pipe-flanges-supplier-tubemac-piping

0 notes

Photo

Find the best Weldless Piping Technologies in Industry.

Best weldless piping technologies company . get benefits of services like non-welded piping systems, components, mechanically attached fitting and installation to worldwide Industry. we also have weldless, threadless piping .

https://www.edocr.com/v/j4nladnm/tubemac/benefits-of-using-weldless-pipe-fitting-in-industr

0 notes

Photo

Had to share this @WeHeartIt

Get top skilled Tube-Mac Piping Technologies on Funadvice.

Best Tube-Mac Piping Technologies company. we are providing services like non-welded piping systems, components, mechanically attached fitting, and installation to the worldwide Industry. we have weldless, threadless piping.

https://www.funadvice.com/tubemac

1 note

·

View note

Photo

Had to share this @WeHeartIt

Get top skilled Tube-Mac Piping Technologies on Funadvice.

Best Tube-Mac Piping Technologies company. we are providing services like non-welded piping systems, components, mechanically attached fitting, and installation to the worldwide Industry. we have weldless, threadless piping.

https://www.funadvice.com/tubemac

1 note

·

View note

Text

4 Important Factors to Consider Before Proceeding with Oil Flushing

An equipment and machine in an industrial setting works as good as it is taken care of. With continuous usage, a machine’s internal components require maintenance and service, amongst which oil flushing is one of the most important procedures.

While oil flushing may seem an easy task to carry on with, but there are several factors that need to be taken in considered to get the best results and improve the life and performance of the engine. Below, we have listed 4 important factors to take note of before proceeding with oil flushing services:

1. Flushing Procedure

The procedure and steps are of paramount important for oil flushing. Remember, the objective of flushing is to remove the old oil efficient and timely and achieve clean equipment components and pipe without spending much. This is the basis that must be factored upon deciding how the flushing needs to take place to ensure maximum result with minimum effort.

2. Oil Velocity

For a successful flush, the oil velocity should be high, usually two times, than the normal system velocity, as it results in increased turbulent that removals oil from any gathering area. Also make sure that components which are sensitive for high-velocity flush must be flushed by other methods.

3. Fluid

The fluid is the most important part for any oil flushing procedure. Make sure to pick a fluid that is compatible with the procedure. It must not react with the oil which is to be removed as this can result in deposition of particulates formed because of reaction.

4. After Flushing Process

After you are done with the flushing, there can be some form of flushing fluid left in the system. This should be removed using displacement oil, which should be compatible like mentioned in the above point and must also have same viscosity as the operating charge.

Make sure that the fluid and oil should be heated to particular, industrial equipment recommended temperature which helps in absorbing and dissolving contaminants.

Taking full care of your system with right maintenance procedure is important. Also, make sure to utilize advanced components and industrial procedures like weldless fittings services and so that can enhance your system’s efficiency and performance, whereby removing maintenance and repairing costs.

0 notes

Text

5-Step Guide to Find the Right Supplier for Your Industrial Fittings

If your business revolves around piping systems and components, then industrial fittings are a must, an essential commodity for your plant. And therefore, it becomes all the more important to source only the finest quality of industrial fittings, specific to your requirements.

Finding a reputable and reliable supplier for your industrial fittings is not that easy a task. If you want to boost the production done by your industry, then acquire the weldless fittings of superior quality from a reputable retailer. So, given below are the few things that one should consider while searching for the best supplier of weldless fittings:

1. Inventory: A supplier should have a comprehensive inventory of the products, equipped with state-of-the-art mechanically attached fittings, and more such products, suitable to meet the different and varied requirements of the industry. The inventory should be organized and extensive so that you will get the materials and services on time. If the retailer’s inventory is flourished with project coordinators and field technicians, then you can be rest assured that you will get a reliable and quick supply, coupled with genuine and complete assistance.

2. Supply Process: From services to products, a supplier that can provide everything in all the corners of the world is a more reliable one that a local-only supplier. With a global supply process, the provider ensures that they understand the requirements of the industries’ top names across the globe and offer products and services in accordance to that.

3. International Standard Products: Before buying anything from the supplier, you need to make sure that the products pass the international standards. It means that the quality of the products does not differ from place to another along with the integrity.

4. Latest Systems: The supplier must be up-to-date with the industrial growth and incorporate high-end technological process to provide latest, innovative and cutting edge solutions, like weldless piping systems for the related industry.

5. Add-On-Value: Make sure that your retailer is able to provide the project managers and service technicians that have experience and ability to manage the project from start to finish. The concerned supplier should be capable of providing the field technical services along with proper installation of systems, training to local contractors across the globe.

So, now the things that you need to consider before buying products related to industrial fittings. Some of the companies also provide repair services for the piping systems. So, finding weldless fittings and other such systems will no longer be a daunting task if you follow the above given aspects.

0 notes

Text

What Are The Different Types Of Pipe Fabrication Tools

Pipe fabrication can be considered an integral and important part of any pipe system installation. Without piping fabrication, there cannot be any proper pipe installation, whatever be the industry it is.

It is one before the installation process, and being so vital, requires different types of tools to carry out. The better the tools, the better are the results considering pipe and tube fabrication. These specialized tools are used to carry out bending of round tube, square tubing and many more such processes, utilizing proper dies for tube size. There are different pipe fabrication tools, which are used for different functions and purposes, like:

1. Bender

This is the most commonly utilized pipe and tube fabrication tool, and includes both automatic and manual benders. Used for professionally bending pipes, any of these techniques can be used to get the desired results, depending on the purpose, budget and the type of product.

2. Rolling Machines

These are similar to benders in functionality, and are used to give a wider arc to the bent tube. Utilized for different industrial functions, these are used to make engineered radius circles.

3. Notchers

These tools are used to give right and exact cuts to the pipes and tubes when notching and joining them together. Professionally speaking, the notchers should ne able to provide high end fit-up and accuracy.

4. Vises

A vise is a metal device that is used to hold an object firmly, while fabrication process is being done with that object. These are usually attached to a workbench.

These are different types of pipe fabrication tools, that are most common and used across the industries for almost all types of fabrication jobs. Fabricating a pipe and tube to the most suitable, effective and the right shape and size is essential for every industrial unit, and therefore only the right tools need to be utilized.

Depending on your requirement, budget, and preciseness of the job, you must choose quality and efficient fabrication tools. Every industrial process needs an efficient and maximized utilization of tools and services, like for fabrication, or for oil flushing services, to get desirable results.

0 notes